Esimeni sokuncintisana somkhakha wokufaka amapayipi, sijabule kakhulu ukwabelana ngenye impumelelo eyingqopha-mlando—isixazululo sokuzenzakalela esenziwe ngendlela evumelana nesiguquli segeyimu kwelinye lamaklayenti ethu okulinganisa, esidizayinelwe ngokukhethekile ukufakwa kwehardware yamapayipi endololwane ye-PPR kanye nokucutshungulwa kwezilaphu ezisikiwe. Lesi sixazululo asithuthukisanga nje kuphela ukugeleza komsebenzi wokukhiqiza kweklayenti kodwa futhi silethe izinzuzo ezilinganisekayo ezichaza kabusha izindinganiso zokusebenza emkhakheni.

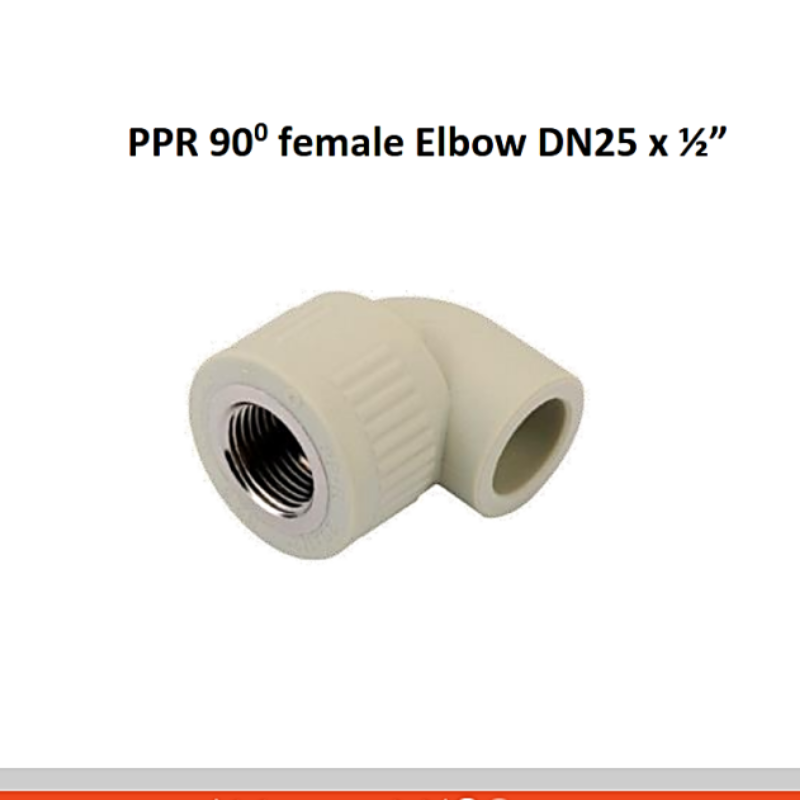

Tisixazululo sakhe esisezingeni eliphezulu siyazungezas cishe ezimbiliizingxenye zangokwezifiso eziyinhloko: iuhlobo oluvulekile lwekhanda lenkunziingalo yerobhothi yakhelwe ukuhambisana okuphezulu (esekela ukucaciswa kwepayipi lendololwane le-8-20mm PPR, emboza ngaphezu kwama-90% amamodeli womkhiqizo ojwayelekile weklayenti) kanyengokwezifiso isiphetho irobhothiithuluzi lengaloyakhelwe ukunemba (ukunemba kokuma ngaphakathi ±0.2mm, iqinisekisa ukungaboni ngaso linye okuyiziro ekushumekeni kwehadiwe). Ndawonye, banqamula imikhawulo yokukhiqiza ngokuvumela16-cavity automation ngokusika ipayipi lendololwane le-PPR—lokhu kusho ukuthi isistimu ingacubungula amapayipi endololwane ayi-16 PPR emjikelezweni owodwa wokukhiqiza, uma kuqhathaniswa nezingcezu ezi-2-3 kuphela ngomjikelezo ngamunye ngokusethwa kwangaphambili kwekhasimende okuzenzakalelayo, okumakaUkukhuphuka okungu-700% kokuphumayo komjikelezo weyunithi. Yini eyenza lesi sixazululo siphelele futhi sisebenziseke? Ihlanganisa izinyathelo ezintathu ezibalulekile zokukhiqiza ngaphandle komthungo, isixhumanisi ngasinye siletha ukuthuthukiswa kokusebenza okubambekayo:

- Ukufakwa kwe-Robotic Hardware: Isiphetho serobhothi esenziwe ngezifiso i-EOAT iqinisekisa ukushumeka okunembile nokuzinzile kwehadiwe kumapayipi endololwane we-PPR. Ngaphambi kokuzenzakalela, ukufakwa ngesandla kuholele esilinganisweni sesici esingu-3.2% ngenxa yephutha lomuntu; manje, izinga lokukhubazeka liye lehla kakhulu0.15%, kuyilapho isivinini sokufaka sikhuphuke sisuka ezingxenyeni ezingu-12 ngomzuzu (manual) kuya48 izingcezu ngomzuzu(okuzenzakalelayo).

- Hardware Ukondla Automation: Uhlelo lufakwe ugqoko oluhlakaniphile lokudlidliza olungabamba izingcezu zezingxenyekazi zekhompuyutha ezingafika ku-5,000 ngesikhathi esisodwa, okuqeda isidingo sokugcwaliswa kwempahla ngesandla njalo ngemizuzu engama-30. Igcina isivinini sokudla esiqhubekayo se60 izingcezu ngomzuzu, ukufanisa isigqi sokufaka irobhothi ngokuphelele futhi kunciphisa udoti wezinto ezibonakalayo obangelwa ukuphatha mathupha kusuka ku-2.1% kuye0.3%.

- Ukubuyiswa Kwengxenye Yerobhothi Nokusikwa Kwezicucu: Ngemva kwenqubo yokubumba, irobhothi alitholi nje kuphela amapayipi endololwane e-PPR aqediwe kodwa futhi liphungula izinsalela ezisele ngesikhathi esisodwa. Lesi sinyathelo esisebenza kabili sehlisa ingqikithi yesikhathi sokucubungula ucezu ngalunye ukusuka kumasekhondi angu-15 (ukubuyisa ngesandla + ukusika okuhlukile) ukuze4 imizuzwana (ukusebenza okuzenzakalelayo okuhlanganisiwe). Ngokuhamba kwamahora angu-8, lokhu kusindisaAmahora okusebenza angu-128 ngenyangaokweklayenti.

Okwamanje, lesi sixazululo sokuzenzakalela sisetshenziswe ngokugcwele efekthri yeklayenti izinyanga ezi-3, sisebenza ngesitebele.Imishini ikhuphuke ngo-98.5%. isikhathi(ngaphandle kokulungisa okuhleliwe). Iguqule ngempumelelo imodi yokukhiqiza yekhasimende: inani labasebenzi elidingekayo kulayini wokukhiqiza indololwane we-PPR lehlile lisuka ku-8 laya ku-2 (libhekene nokuqondisa nokunakekela kuphela), kuyilapho okukhishwayo kwansuku zonke kweqe kusuka ezingxenyeni eziyi-1,800 kuya ku-2.12,600 izingcezu-aUkunyuka okungu-600% kumthamo wokukhiqiza wansuku zonke.

Kubakhiqizi bokufaka amapayipi abafuna ukuthuthukisa i-automation, leli cala libeka ibhentshimakhi ecacile nechazekayo enemiphumela elinganisekayo.

#PPRFittingAutomation #PipeFittingIndustrySolution #IndustrialAutomationCase #SmartManufacturingForPipes #CustomAutomationEquipment

Isikhathi sokuthumela: Oct-22-2025