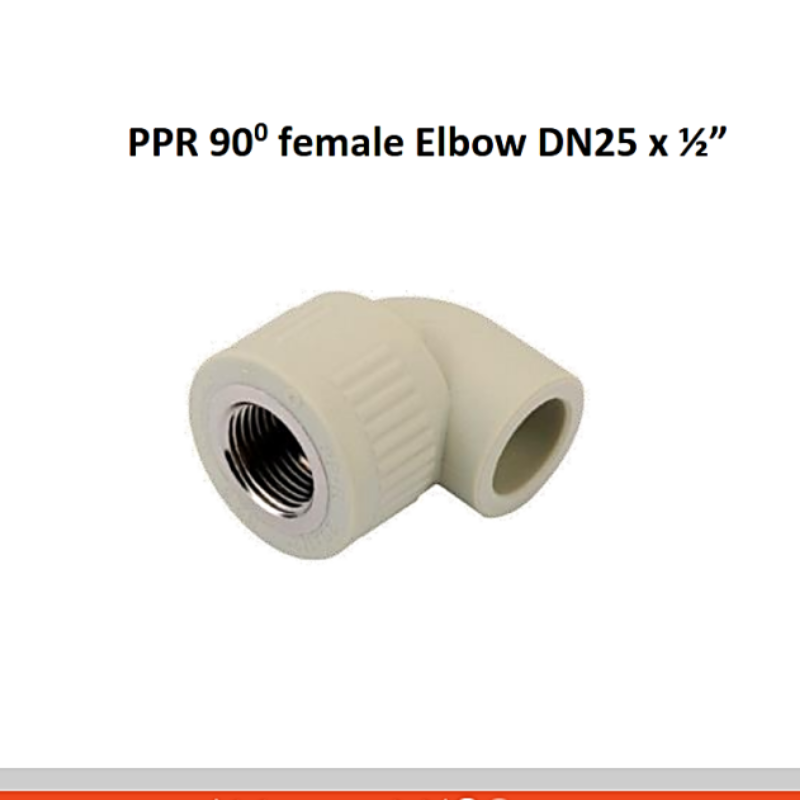

A cikin gasa mai fa'ida na masana'antar dacewa da bututu, muna farin cikin raba wani ci gaba mai mahimmanci-maganin sarrafa kansa wanda aka kera wanda ya zama mai canza wasa ga ɗaya daga cikin abokan cinikinmu, musamman an ƙera shi don shigar da kayan aikin bututun gwiwar hannu na PPR da sarrafa tarkace. Wannan maganin ba wai kawai ya inganta aikin samar da abokin ciniki ba amma kuma ya isar da fa'idar ingantaccen aiki wanda zai sake fayyace matsayin aiki a sashin.

TMaganin sa na yankan-baki ya juyas kusan biyucore custom components: anBude-nau'in bijimin kairobot hannu gyare-gyare don babban jituwa (goyan bayan 8-20mm PPR ƙayyadaddun bututun gwiwar gwiwar hannu, yana rufe sama da 90% na samfuran samfuran babban abokin ciniki) daƘarshen mutum-mutumi na musammankayan aikin hannuan gina shi don daidaito (daidaitaccen matsayi a cikin ± 0.2mm, yana tabbatar da kuskuren sifili a cikin haɗa kayan aiki). Tare, suna keta iyakokin samarwa na gargajiya ta hanyar ba da damar16-aiki ta atomatik don PPR gwiwar hannu bututu saka trimming - wannan yana nufin tsarin zai iya aiwatar da bututun gwiwar hannu na PPR 16 a cikin zagayowar samarwa guda ɗaya, idan aka kwatanta da guda 2-3 kawai a kowane zagaye tare da saitin atomatik na abokin ciniki na baya, yana yin alama700% karuwa a cikin fitowar sake zagayowar raka'a. Me yasa wannan bayani ya zama cikakke kuma mai amfani? Yana haɗa matakan samar da maɓalli guda uku ba tare da ɓata lokaci ba, tare da kowace hanyar haɗin yanar gizon tana ba da ingantaccen ingantaccen aiki:

- Shigar Hardware na Robotic: Ƙarshen EOAT na mutum-mutumi na musamman yana tabbatar da daidaito da kwanciyar hankali na kayan aiki a cikin bututun gwiwar hannu na PPR. Kafin yin aiki da kai, shigar da hannu ya haifar da ƙarancin lahani na 3.2% saboda kuskuren ɗan adam; yanzu, adadin lahani ya ragu zuwa0.15%, yayin da saurin shigarwa ya tashi daga guda 12 a minti daya (manual) zuwaguda 48 a minti daya(atomatik).

- Ciyarwar Hardware Automation: An sanye da tsarin tare da tire ɗin ciyarwar girgiza mai hankali wanda zai iya ɗaukar har zuwa guda 5,000 a lokaci ɗaya, yana kawar da buƙatar sake cika kayan aikin hannu kowane minti 30. Yana kula da ci gaba da ciyar da gudunguda 60 a minti daya, Daidaita tsarin shigar mutum-mutumi daidai da rage sharar kayan da aka yi ta hanyar sarrafa hannu daga 2.1% zuwa0.3%.

- Maido da Sashe na Robotic & Gyaran Scrap: Bayan aiwatar da gyare-gyaren, mutum-mutumi ba wai kawai ya dawo da bututun gwiwar hannu na PPR da aka gama ba amma kuma yana datse tarkacen da ya wuce gona da iri a tafi daya. Wannan mataki na aiki biyu yana yanke jimlar lokacin sarrafawa kowane yanki daga daƙiƙa 15 (dawowar hannu + datsa daban) zuwa4 seconds (aikin da aka haɗa ta atomatik). Sama da awa 8, wannan yana adanawa128 aiki hours na aiki a kowane wataga abokin ciniki.

A halin yanzu, wannan maganin sarrafa kansa ya kasance cikakke a cikin masana'antar abokin ciniki na tsawon watanni 3, yana aiki tare da barga.98.5% kayan aiki sun tashi lokaci(ban da tsarin kulawa). Ya sami nasarar canza yanayin samar da abokin ciniki: adadin ma'aikatan da ake buƙata don layin samar da gwiwar hannu na PPR ya ragu daga 8 zuwa 2 (mai alhakin kulawa da kulawa kawai), yayin da kayan yau da kullun ya tashi daga guda 1,800 zuwaguda 12,600-a600% karuwa a cikin ƙarfin samarwa yau da kullun.

Ga masu ƙera bututun da ke neman haɓaka aiki da kai, wannan shari'ar tana saita maƙasudin bayyananne kuma bayyananne tare da sakamako masu ƙididdigewa.

#PPRFittingAutomation #PipeFittingIndustrySolution #IndustrialAutomationCase #SmartManufacturingForPipes #CustomAutomationEquipment

Lokacin aikawa: Oktoba-22-2025