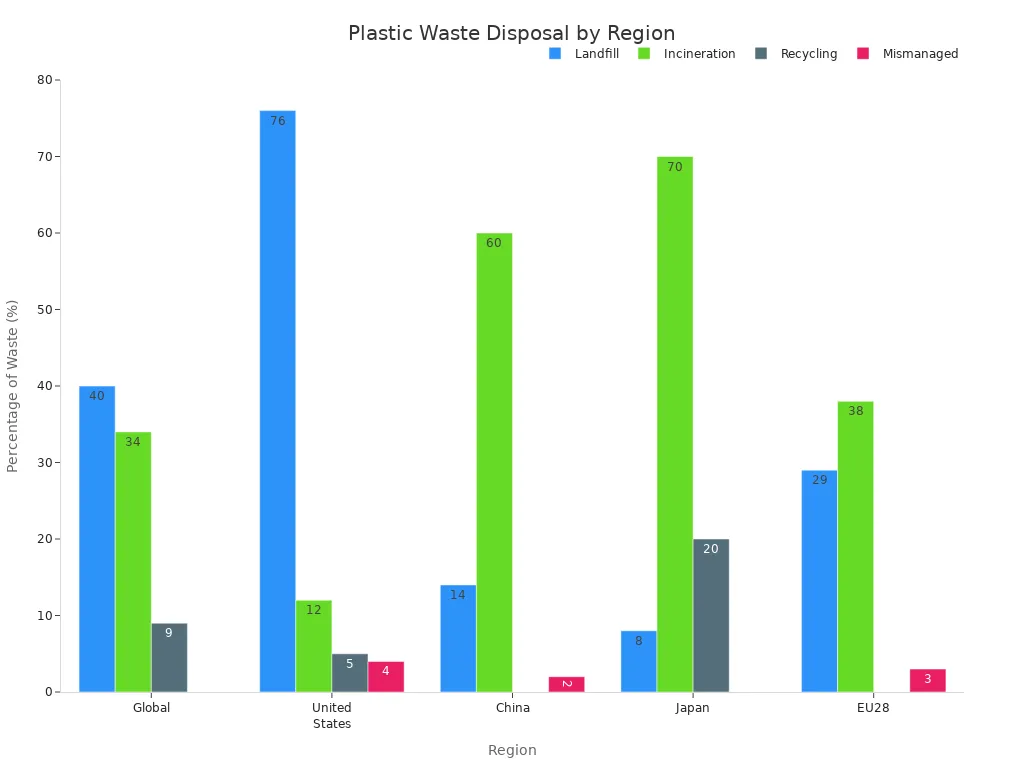

Imfucuza yepulasitiki ilokhu ikhula, cishe amathani ayizigidi ezingama-400 akhiqizwa emhlabeni wonke ngo-2022. Ama-9% kuphela agaywa kabusha, njengoba kuboniswe ngezansi.

Ukukhetha phakathi kuka-aUmshini wePlastiki weGranulatorkanye aI-Plastic Shredderkushintsha kanjaniImishini Yokwenza kabusha Ipulasitikiumsebenzi.

- I-Granulatoryenza izingcezu ezincane, ezifanayo ukuze zigaywe kabusha kalula.

- I-Plastic Shredder iphatha izinsalela ezinkulu nezinto eziqinile.

Ukukhetha umshini ofanele kuthuthukisa ukusebenza kahle.

| Izibalo / Isifunda | Inani / Incazelo |

|---|---|

| Ukukhiqizwa kwemfucuza yepulasitiki yomhlaba wonke | ~ amathani ayizigidi ezingama-400 ngo-2022 |

| Izinga lokugaywa kabusha komhlaba wonke | Cishe u-9% (amile) |

| Izinga lokugaywa kabusha lase-United States | U-5% ugaywe kabusha, u-76% ugcwalisiwe, u-12% ushisiwe, u-4% awuphathwanga kahle |

| Izinga lokushiswa kwe-Japan | 70%, indawo yokulahla udoti 8%, ukugaywa kabusha ~ 20% |

Okuthathwayo Okubalulekile

- Amapulangwe epulasitikiphula udoti wepulasitiki omkhulu, oqinile ube yizingxenyana ezinkulu, uzenze zilungele ukuphatha izinto ezinkulu noma ezixutshiwe ekuqaleni kokugaywa kabusha.

- I-granulator yepulasitikiimishini isika ipulasitiki ibe yizinhlamvana ezincane, ezifanayo, ezilungele izinsalela ezihlanzekile, ezihlungiwe futhi ezilungele ukusetshenziswa kabusha ekubumbeni noma ekukhipheni.

- Ukukhetha umshini ofanele kuncike ohlotsheni lwakho lwepulasitiki nosayizi: sebenzisa ama-shredders wezinto ezinkulu, ezisindayo kanye nama-granulator ukuze ucwenge izingcezu ezincane zibe ama-granules angashintshi.

Umshini Wezimbotshana Wepulasitiki vs. I-Plastic Shredder: Izincazelo kanye Nezimiso Zokusebenza

Uyini Umshini Wezimbotshana Wepulasitiki?

A Umshini wePlastiki weGranulatoriyithuluzi elisika imfucuza yepulasitiki ibe yizinhlamvana ezincane, ezifanayo. Le mishini isiza izikhungo zokugaywa kabusha kanye nezimboni ziguqule amapulasitiki alahliwe abe yizicucu ezilungele ukusetshenziswa kabusha. Basebenza kahle kakhulu ngezinto ezifana ne-sprues, abagijimi, imiphetho yefilimu, nezinsimbi zokuqalisa. Ama-granulator amaningi asebenzisa i-rotor eyodwa enemimese ebukhali ukusika ipulasitiki.

Ama-granulator adumile ngokucubungula amapulasitiki ajwayelekile njenge-polyethylene, i-polypropylene, ne-polystyrene.

Usebenza Kanjani Umshini We-Plastic Granulator?

Inqubo iqala lapho abasebenzi befaka ipulasitiki ku-hopper. Ngaphakathi kwegumbi lokusika, izindwani ezizungezayo zisika impahla ngokuhambisana nezindwani ezingaguquki. Isikrini noma i-mesh ihlunga ama-granules, ivumele kuphela usayizi olungile ukuthi udlule. Izingcezu ezinkulu zibuyela emuva ukuze zisikwe okwengeziwe. Injini inika amandla ama-blade futhi ilawula isivinini. Ama-granules aqediwe aqoqa emgqonyeni, alungele ukubunjwa noma ukukhishwa.

- Izingxenye eziyinhloko:

- I-Hopper

- Igumbi lokusika

- Ama-blades ajikelezayo futhi angaguquki

- Isikrini noma i-mesh

- Motor kanye nesistimu yokushayela

- Umgqomo wokuqoqa

Iyini I-Plastic Shredder?

A ipulastiki shredderungumshini owakhelwe ukudiliza imfucumfucu eqinile, eqinile. Ama-shredders aphatha izinto ezifana namabhampa emoto, izigubhu, namapayipi. Basebenzisa ijubane eliphansi kanye ne-torque ephezulu ukuze baklebhule amapulasitiki abe izingcezu ezinkulu, ezingalingani. Ama-shredders afika ngezinhlobo ezahlukene, njenge-single-shaft, i-double-shaft, namamodeli ane-shaft amane.

| Uhlobo lwe-Shredder | Izinhlobo Ezinhle Kakhulu Zemfucumfucu Yepulasitiki |

|---|---|

| Igrinder | Amapulasitiki aqinile futhi amakhulu |

| Ama-Chippers | Amapulasitiki aqinile; izinto ezinkulu njengamakhreyithi, amaphalethi |

| Ama-Shear Shredders | Amapulasitiki amakhulu, aminyene; izigubhu, amapayipi |

| Ama-Shredders Wezinjongo Zonke | Imfucuza yepulasitiki ehlanganisiwe |

Isebenza Kanjani I-Plastic Shredder?

Ama-shredders epulasitiki asebenzisa ama-blade anamandla afakwe ku-shafts. Umshini uyawubamba udonse upulasitiki, bese uwudabula. Okukhiphayo kukhulu futhi kuncane okufanayo kunezinhlayiya ze-granulator. Ama-shredders ngokuvamile asebenza njengesinyathelo sokuqala sokugaywa kabusha, okwenza izingcezu ezinkulu zibe zincane ngokwanele ukuze ziqhubeke zicutshungulwa.

Ama-Shredders asebenza ngokuthula futhi afaka izici zokuphepha njengokuhlehla okuzenzakalelayo nezikhawuli ze-torque.

Ukuqhathanisa Umshini We-Plastic Granulator kanye Ne-Plastic Shredder: Umehluko Obalulekile

Indlela Yokusebenza Nokusika

Indlela le mishini emibili esika ngayo ipulasitiki ihluke kakhulu. Ama-granulator asebenzisa izindwani ezibukhali, ezihamba ngokushesha ezisika ipulasitiki ibe izingcezu ezincane. Basebenza ngesivinini esiphezulu, ngokuvamile phakathi kuka-400 no-800 rpm, futhi basebenzisa i-torque ephansi. Izindwani zazo zincane futhi zenzelwe ukunemba. Lo mklamo ubasiza ukuthi banqume izinsalela zepulasitiki ezihlanzekile, ezihlungiwe zibe yizinhlayiyana ezifanayo.

Ngakolunye uhlangothi, ama-shredders asebenzisa izindwani eziwugqinsi, eziqinile ezihamba kancane kodwa ngamandla amaningi. Ngokuvamile zigijima ku-10 kuya ku-130 rpm. Izindwani zazo zinamahhuku noma amazinyo futhi zingakwazi ukuphatha imfucuza yepulasitiki eningi noma exubile. Ama-shredders adabula futhi aphule izinto eziqinile, azenze zibe zinhle esinyathelweni sokuqala sokugaywa kabusha.

Nakhu ukubuka okusheshayo kokuthi ama-blades awo aqhathaniswa kanjani:

| Isici | Plastic Granulator Blades | Ama-Plastic Shredder Blades |

|---|---|---|

| Isivinini sokuSebenza | Isivinini esikhulu (400–800 rpm) | Isivinini esiphansi (10–130 rpm) |

| Cutting Mechanism | Ukugunda ngommese wombhede onganyakazi | Ukudabula ngama-hook noma izindwani ezinama-toothed kuma-shaft amaningi |

| I-Blade Shape | Imimese ebukhali, eyenziwe ngokunemba | Abasiki abakhulu, abaqinile |

| Ukuqina Kwezinto Ezibalulekile | Izinsimbi ezinokuqina okuphezulu njenge-D2 noma i-SKD11 | Ingazweli, idizayinelwe ukuqina |

| Isicelo | Amapulasitiki ahlanzekile, ahlungwe ngaphambili (isb, izingxenye ezibunjwe ngomjovo) | Imfucumfucu eqinile, engcolile, noma eqinile |

| Inhloso | Ikhiqiza ama-granules amancane, afanayo ukuze aphinde asetshenziswe | Ihlukanisa izinto ezinkulu noma eziqinile zibe izingcezu |

Ithiphu: Ama-granulator angcono kakhulu kupulasitiki ohlanzekile, ohlungiwe. Ama-shredders angcono kumapulasitiki amakhulu, axubile, noma angcolile.

Usayizi Wokuphuma Nokungaguquguquki

Ama-granulator nama-shredders akhiqiza imiphumela ehluke kakhulu. Ama-granulator enza izingcezu ezincane, ezilinganayo. Ama-granules amaningi angaba ngu-10mm ngo-10mm, futhi ubukhulu bungalungiswa ngokushintsha isikrini. Usayizi ojwayelekile uzungeze u-12mm, kodwa ungasukela ku-8mm kuya ku-20mm. Lo sayizi ofanayo wenza ama-granules asetshenziswe kalula emikhiqizweni emisha.

Ama-shredders akha izingcezu ezinkulu, ezimahhadlahhadla. Izingcezu ngokuvamile ziba ngu-40mm futhi zingahluka kakhulu ngobukhulu nokuma. Lezi zingcezu ngokuvamile zidinga ukucutshungulwa okwengeziwe ngaphambi kokuba zisetshenziswe futhi. Ama-granulator anikeza okukhiphayo okungaguquki, kuyilapho ama-shredders egxila ekuphuleni izinto ezinkulu ngokushesha.

- Ama-Granulator: Ama-granule amancane, afanayo (cishe 10mm x 10mm)

- Ama-Shredders: Izingcezu ezinkulu, ezingalingani (cishe 40mm), azihambisani kancane

Amakhono Okuphatha Okubalulekile

Ama-shredders angakwazi ukuphatha cishe noma yiniuyabajikijela. Zisebenza ngepulasitiki ewugqinsi, emikhulu, noma emise okwenqaba. Usayizi omkhulu wokufaka uncike embobeni yokuphakelayo namandla enjini. Amanye ama-shredders angathatha izingcezu ezinkulu njengo-1000×500 mm. Bangakwazi ukucubungula amapulasitiki anogqinsi ukusuka ku-0.7 mm kuya ku-12 mm noma ngaphezulu, kuye ngomshini.

Ama-granulator adinga izingcezu ezincane, ezihlanzekile. Basebenza kahle kakhulu ngezinto ezifana ne-sprues, abagijimi, amabhodlela, nemiphetho yefilimu. Izinto ezinkulu noma eziwugqinsi kakhulu kufanele zehliswe ngaphambi kokungena ku-granulator. Uma ipulasitiki izacile kakhulu, njengefilimu, ingase ishelele phakathi kwezicucu ze-shredder esikhundleni sokusikwa.

Qaphela: Ama-shredders ayindlela yokwenza imisebenzi emikhulu, enzima. Ama-granulator alungele ukucwenga izinsalela ezincane, ezihlanzekile.

Izicelo Ezijwayelekile Nezimo Zokusebenzisa

Ama-granulator nama-shredders womabili adlala indima ebalulekile ekugayweni kabusha, kodwa angena ezingxenyeni ezihlukene zenqubo.

Umshini wePlastiki weGranulatorijwayelekile ku:

- Izitshalo zokubumba umjovo (ukusebenzisa kabusha ama-sprues, ama-runner, nezingxenye ezingenasici)

- Amayunithi okubumba (amabhodlela okugaywa kabusha neziqukathi)

- Amayunithi we-Extrusion (ukubuyisela ukucushwa kanye namaphrofayili angekho ku-spec)

- Amayunithi okwenza i-dana yepulasitiki (ukwenza ama-granules for pelletizing)

- Izitshalo zokugaywa kabusha kwepulasitiki (ukuguqula ipulasitiki yangemva komthengi ibe yimpahla eluhlaza)

- Imboni yokupakisha (ukucubungula kabusha izinsalela zefilimu kanye nodoti weshidi)

| Umkhakha Wezimboni | Izicelo Ezivamile Zemishini Yezimbotshana Yepulasitiki |

|---|---|

| Izitshalo Zokubumba Umjovo | Ukusetshenziswa kabusha kwama-sprues, ama-runner, nezingxenye ezibunjiwe ezinesici |

| Amayunithi okubumba aqhume | Ukugaywa kabusha kwamabhodlela, izigubhu, nezitsha ezingenalutho |

| Extrusion Units | Ukutholwa kokusikwa kanye namaphrofayili noma amashidi angekho ku-spec |

| Amayunithi Okwenza I-Dana Yepulasitiki | Uhlelo lokudla lokukhiqiza ama-granules we-pelletizing |

| Plastic Recycling Plants | Ukuguqulwa kwepulasitiki yangemuva komthengi ibe izinto zokusetshenziswa zesibili |

| Imboni yokupakisha | Icubungula kabusha izinsalela zefilimu, ukugoqa kwebhamuza, nodoti weshidi |

Ama-shredders asetshenziswa ku:

- Izikhungo zokugaywa kabusha (ukuhlanza kokuqala, amakhreyithi, amaphalethi, amapayipi, izitsha)

- Izinsiza zokukhiqiza (ukuphatha izingxenye ezibunjiwe kanye nemfucuza yangemva komthengi)

- Ukuphathwa kwemfucuza yabathengi (amabhodlela e-PET, ukupakisha)

- Izimboni zezimoto neze-elekthronikhi (ukucubungula amapulasitiki aqinile kanye nodoti oxubile)

- Ukucubungula kwezokwelapha nokudla (ukulahlwa okuphephile kwemfucuza yepulasitiki)

- Ukugaywa kabusha kwefilimu yezolimo

- Ama-shredders aphatha izinhlobonhlobo zamapulasitiki, irabha, imicu, ngisho nezinto eziqinile njenge-Kevlar ne-carbon.

- Zibuye zisetshenziswe ekugayweni kabusha kwamasondo, udoti oyingozi, nasekucubunguleni izinsimbi ezilahliwe.

Ama-shredders aqala inqubo yokugaya kabusha ngokuphula izinto ezinkulu. Ama-granulator aqeda umsebenzi ngokwenza ama-granules amancane, asebenziseka kabusha.

Ithebula Lokuqhathanisa Ngamaceleni

Nali ithebula elizokusiza ukuthi ubone umehluko oyinhloko lapho uthi nhla:

| Imethrikhi yokusebenza | Umshini wePlastiki weGranulator | I-Plastic Shredder |

|---|---|---|

| Cutting Mechanism | Isivinini esikhulu, ukusika ngokunemba | Isivinini esiphansi, ukuklebhuka kwetorque ephezulu |

| Usayizi Wokuphuma | Ama-granules amancane, afanayo (8-20mm) | Izingcezu ezinkulu, ezingajwayelekile (kufika ku-40mm+) |

| Ukuphatha Izinto | Izingcezu ezihlanzekile, ezihlungwe ngaphambili, ezincane | Amapulasitiki amaningi, axubile, noma angcolile |

| Izicelo Ezijwayelekile | Ukubumba umjovo, i-extrusion, ukupakisha | Izikhungo zokugaywa kabusha, ukuphathwa kwemfucuza, okuzenzakalelayo |

| Izidingo Zesondlo | Izingxenye eziphansi, ezifinyeleleka kalula | Okuphakeme, okujwayelekile kweblade esikhundleni |

| Amandla okusebenzisa | Okulingene (200–300 kg/ihora) | Phezulu (kufika ku-2 amathani/ihora) |

| Izindleko Zokusebenza | Amandla aphansi nokugcinwa | Izindleko eziphezulu zokusebenza kanye nengxenye |

| Ukuhlanganisa | Ama-standalone noma ama-granulator amaphakathi | Izimele noma ihlanganiswe nama-granulator |

Ukukhetha umshini ofanele kuncike ohlotsheni lwakho lwezinto ezibonakalayo, okukhiphayo okufunayo, nokuthi ungena kuphi enqubweni yokugaywa kabusha.

Ukukhetha Phakathi Komshini We-Plastic Granulator kanye Ne-Plastic Shredder

Ukucatshangelwa Kohlobo Lwempahla Nosayizi

Ukukhetha umshini ofanele kuqala ngokubheka uhlobo nosayizi wemfucuza yepulasitiki. Ama-shredders asebenza kahle kakhulu ezintweni ezinkulu, ezinkulu njengezigubhu, amapayipi, noma obhampa bezimoto. Zizihlephula zibe izingcezu ezincane, okwenza kube lula ukuzibamba. Ama-granulator athatha izintambo lapho ipulasitiki isivele izingcezu ezincane noma ngemva kokusikwa. Bacwenga okubalulekile kube ama-granules afanayo. Ithebula elingezansi libonisa ukuthi umshini ngamunye uhlangabezana kanjani nezidingo ezahlukene:

| Isici | Umshini wePlastiki weGranulator | I-Plastic Shredder |

|---|---|---|

| Usayizi Wezicucu & Izinga lokuphakelayo | Okulula kuya kokuphakathi | Izicucu ezinkulu, ezinkulu |

| Usayizi Wokukhipha & Inhloso | Ama-granules afanayo | Amahhadlahhadla amahhafu |

| Izici Zokusebenza | I-high-RPM, i-torque ephansi | I-torque ephezulu, i-low-RPM |

| Ukulinganiselwa | Ukulwa nezingxenye ezinzima | Ayilungele izinsalela ezilula |

Ithiphu: Kumapulasitiki obunjiniyela ayinduku noma ifomu lepuleti, i-shredder kufanele ihambe kuqala, ilandelwe yi-granulator ukuze uthole imiphumela engcono kakhulu.

Okukhiphayo Okufunayo Nokuqeda Ukusetshenziswa

Ukusetshenziswa kokugcina kwepulasitiki egaywe kabusha kuqondisa ukukhetha phakathi kwemishini. Ama-granulator akhiqiza ama-granules amancane, aphelele, alungele ukubumba umjovo, ukukhishwa, noma ukubunjwa kokushaywa. Ama-shredders akha izingcezu ezinkulu, ezimahhadlahhadla ezivame ukudinga ukucutshungulwa okwengeziwe. Ithebula elingezansi ligqamisa osayizi abanconyiwe bokukhiphayo bokusetshenziswa okuhlukile:

| Qeda Ukusetshenziswa / Inqubo | Usayizi Wokukhiphayo onconyiwe (mm) | Inhloso / Inzuzo |

|---|---|---|

| Ukubumba umjovo, i-extrusion | 6.35 – 9.5 | Ukusetshenziswa kabusha okuqondile ekukhiqizeni |

| I-WEEE ihlunga ama-flakes epulasitiki | 10-20 | Ithuthukisa ukuhlunga kanye nokusetshenziswa kabusha |

Indlela yesinyathelo ngesinyathelo isiza ukufanisa umshini nomsebenzi:

- Hlola ukuthi ipulasitiki iyagobeka yini noma iqinile.

- Bheka ubukhulu nesimo.

- Cabanga ngokungcola.

- Qondanisa umshini nezidingo zempahla nezokuphumayo.

- Cabangela izindleko nendawo.

Izici Zokusebenza: Isivinini, Isondlo, kanye Nezindleko

Isivinini, ukugcinwa, kanye nezindleko kubalulekile lapho ukhetha umshini. Ama-Granulator asebenza ngesivinini esiphezulu futhi enze izinhlayiya ezingcono. Badinga ukulola ama-blade njalo kodwa basebenzise amandla amancane. Ama-shredders asebenza kancane, asebenzisa i-torque eningi, futhi abambe imisebenzi enzima. Zibiza kakhulu ukuzisebenzisa nokuyinakekela, ikakhulukazi kumamodeli asindayo. Ithebula elingezansi liqhathanisa lezi zici:

| Isici | Umshini wePlastiki weGranulator | I-Plastic Shredder |

|---|---|---|

| Isivinini sokuSebenza | Phezulu | Phansi |

| Usayizi Wokuphuma | Encane, iyunifomu | Okukhulu, okuhlukahlukene |

| Isondlo | Ukunakekelwa kwe-blade okuvamile | Ukushintshwa kwe-blade njalo |

| Izindleko | Phansi | Phezulu |

Qaphela: Izinsiza ezinodoti omningi zingakhetha ama-shredders, kuyilapho lezo ezidinga ama-granules amahle, asebenziseka kabusha ngokuvamile zikhetha izimbumbulu.

Ukukhetha umshini ofanele kubalulekile. Ama-shredders adiliza amapulasitiki amakhulu kuqala, kuyilapho ama-granulator enza izingcezu ezincane, ezifanayo ukuze ziphinde zisetshenziswe. Zombili zidlala indima ebalulekile ekugayweni kabusha. Ukuze uthole ireferensi esheshayo, hlola leli thebula ukuze uthole amathiphu ochwepheshe ekukhetheni okulingana kahle kakhulu kwe-scrap yakho nenqubo:

| Isici | I-Granulator | I-Shredder |

|---|---|---|

| Isivinini | Phezulu | Phansi |

| I-Scrap Volume | Noma yimuphi usayizi | Okuhle kakhulu ngamanani amakhulu |

| Usayizi Wokuphuma | Encane, iyunifomu | Enkulu, enzima |

FAQ

Yimaphi amapulasitiki angakwazi inqubo yomshini we-granulator?

I-granulator iphatha amapulasitiki ahlanzekile, ahlungiwe njengamabhodlela, ama-sprues, nemiphetho yefilimu. Isebenza kangcono ngezinto ezifana ne-polyethylene, i-polypropylene, ne-polystyrene.

Ingabe i-shredder ne-granulator ingasebenza ndawonye?

Yebo! Izitshalo eziningi ezigaywa kabusha zisebenzisa i-shredder kuqala ezintweni ezinkulu. Bese, basebenzisa i-granulator ukwenza ama-granules amancane, afanayo.

Ngabe opharetha kufanele bayinakekele kangaki le mishini?

Abasebenzi kufanele bahlole ama-blades masonto onke. Kufanele zicije noma zishintshe njengoba kudingeka. Ukuhlanza okuvamile kugcina yomibili imishini isebenza kahle futhi iphephile.

Isikhathi sokuthumela: Aug-14-2025