Qashinka caagagu wuu sii kordhayaa, iyadoo ilaa 400 milyan oo tan laga soo saaray caalamka 2022. Kaliya 9% ayaa dib loo warshadeeyay, sida hoos ku cad.

Kala doorashada aMashiinka Granulator caaga ahiyo aShredder caag ahisbedelo sidaMashiinnada dib-u-warshadaynta caagga ahshaqayn

- Granulatorwaxay samaysaa qaybo yaryar oo lebis ah oo dib u warshadayn fudud ah.

- Shredder balaastiiggu wuxuu qabtaa qashinka culus iyo walxaha adag.

Doorashada mashiinka saxda ah waxay kor u qaadaysaa waxtarka.

| Tirakoobka / Gobolka | Qiimaha / Sharaxaada |

|---|---|

| Jiilka qashinka caagagga ah ee caalamiga ah | ~400 milyan oo tan sanadka 2022 |

| Heerka dib u warshadaynta caalamiga ah | Ku dhawaad 9% ( fadhiid ah) |

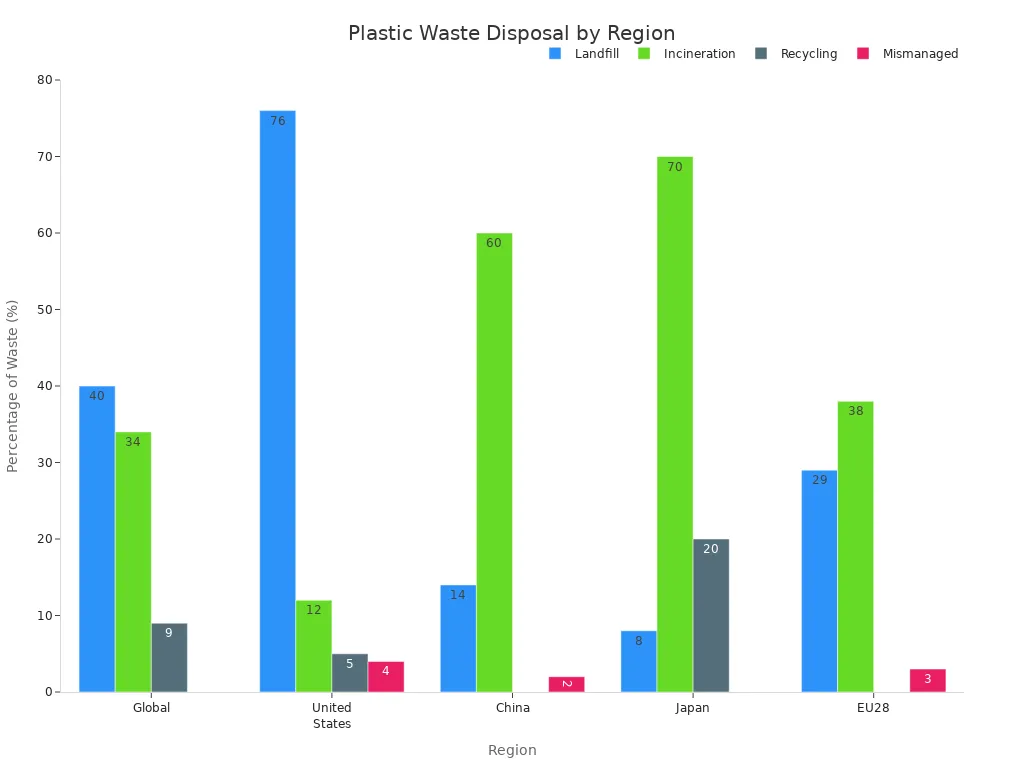

| Heerka dib u warshadaynta Maraykanka | 5% dib loo warshadeeyay, 76% qashinka lagu shubay, 12% waa la gubay, 4% si xun loo maamulay |

| Heerka gubashada Japan | 70%, qashinka 8%, dib u warshadaynta ~ 20% |

Qaadashada Furaha

- Goynta caaga ahU kala jejebi qashinka waaweyn, adag ee balaastigga ah qaybo waaweyn, taas oo ka dhigaysa kuwa ku habboon in lagu xakameeyo walxaha waaweyn ama isku dhafan bilowga dib-u-warshadaynta.

- granulator caag ahmashiinadu waxay u jeexjeexaan balaastiig yaryar oo isku mid ah, oo ku habboon nadiifinta, qashinka la kala soocay oo diyaar u ah dib u isticmaalka samaynta ama extrusion.

- Doorashada mashiinka saxda ah waxay kuxirantahay nooca caaggaga ah iyo xajmigaaga: u isticmaal shredders alaabta waaweyn, culus iyo granulators si aad u nadiifisid qaybo yaryar oo u dhigma granules joogto ah.

Mashiinka Granulator Plastic vs. Shredder caag ah: Qeexitaannada iyo Mabaadi'da Shaqada

Waa maxay Mashiinka Granulator-ka Caagga ah?

A Mashiinka Granulator caaga ahwaa qalab u gooya qashinka balaastiigga ah oo u kala gooya granulo yaryar oo isku mid ah. Mashiinnadani waxay caawiyaan xarumaha dib u warshadaynta iyo warshaduhu waxay u beddelaan baco qashinka ah oo diyaar u ah dib u isticmaalidda. Waxay si fiican ugu shaqeeyaan alaabta sida sprues, orodyahanada, geesaha filimka, iyo qashinka bilawga ah. Inta badan granulators waxay isticmaalaan hal rotor oo leh mindiyo fiiqan si ay u jarjaraan caagga.

Granulators ayaa caan ku ah farsamaynta balaastikada caadiga ah sida polyetylen, polypropylene, iyo polystyrene.

Sidee u Shaqeeyaa Mashiinka Granulator-ka Caaga ah?

Nidaamku wuxuu bilaabmaa marka shaqaaluhu ay ku quudiyaan balaastiigga hopper-ka. Gudaha qolka goynta, daab-wareegaya waxay ku jarjaraan walxaha ka soo horjeeda biraha go'an. Shaashadda ama mesh ayaa shaandhaysa granules-ka, taas oo u oggolaanaysa in cabbirka saxda ahi uu dhex maro. Qaybo waaweyn ayaa dib ugu noqda goyn dheeraad ah. Matoorku waxa uu awood u leeyahay daabadaha waxana uu xakameeyaa xawaaraha. Granules-ka la dhammeeyay waxay ku ururiyaan qashin-qubka, oo diyaar u ah wax-u-qaabaynta ama extrusion.

- Qaybaha ugu muhiimsan:

- Hopper

- Goynta qolka

- Wareega iyo garbaha go'an

- Shaashadda ama mesh

- Mootada iyo nidaamka wadista

- Kaydka aruurinta

Waa maxay Shredder caag ah?

A jeexjeex caag ahwaa mishiin loo dhisay in lagu burburiyo qashinka balaastiga ah ee culus, adag. Shredders waxay qabtaan alaabta sida bambarrada baabuurta, durbaannada, iyo tuubooyinka. Waxay adeegsadaan xawli gaabis ah iyo torque sare si ay u jeexjeexaan balaastiigyo waaweyn oo aan sinnayn. Shredders waxay ku yimaadaan noocyo kala duwan, sida hal-shaft, labajibbaaran, iyo moodooyinka afar-geeska ah.

| Nooca Shredder | Noocyada qashinka caaga ah ee ugu habboon |

|---|---|

| Shiiqiyaha | Caagag adag oo waaweyn |

| Chippers | Caagag adag; alaabta waaweyn sida sanduuqyada, sariiraha |

| Shear Shredders | balaastiig waaweyn, qaro weyn; durbaannada, tuubooyinka |

| Burburinta Ujeedo Dhan | Qashin caag ah oo isku dhafan |

Sidee buu u shaqeeyaa Shredder caag ah?

Jeexjeexyada balaastikada ah waxay adeegsadaan baalal awood leh oo lagu dhejiyay biraha. Mashiinku wuu qabtaa oo jiidaya balaastiigga, ka dibna kala jeexjeexay. Wax-soo-saarku wuu ka weyn yahay oo wuu ka yar yahay lebbiska granulators. Shredders inta badan waxay u adeegaan talaabada ugu horeysa ee dib u warshadaynta, iyaga oo ka dhigaya qaybo waaweyn oo yaryar oo ku filan habayn dheeraad ah.

Shredders waxay u shaqeeyaan si degan oo ay ku jiraan sifada badbaadada sida leexinta tooska ah iyo xadeeyayaasha torque.

Isbarbardhigga Mashiinka Granulator-ka Caagga ah iyo Shredder Caagga: Farqiga Muhiimka ah

Farsamaynta iyo Goynta

Habka ay labadan mishiin u gooyaan balaastiiggu aad bay u kala duwan yihiin. Granulators waxay adeegsadaan baalal fiiqan oo degdeg ah oo balaastiig u kala googooya qaybo yaryar. Waxay ku shaqeeyaan xawaare sare, badiyaa inta u dhaxaysa 400 iyo 800 rpm, waxayna adeegsadaan qulqulka hoose. Daabkoodu waa dhuuban oo si sax ah loo sameeyay. Naqshadani waxay ka caawisaa inay gooyaan qashinka nadiifka ah, ee la soocay ee balaastigga ah ee loo yaqaan granules.

Dhanka kale, shredders, waxay adeegsadaan baalooyin dhumuc weyn leh oo si tartiib ah u socda laakiin leh xoog badan. Waxay badanaa ku ordaan 10 ilaa 130 rpm. Baabooyinkoodu waxay leeyihiin qabsatooyin ama ilko waxayna xamili karaan qashinka balaastiga ah ee waaweyn ama isku dhafan. Shredders ayaa jeexjeexa oo jebiya alaabada adag, iyaga oo ka dhigaya kuwo aad u fiican talaabada ugu horeysa ee dib u warshadaynta.

Halkan waxaa ah muuqaal degdeg ah oo ku saabsan sida ay baalashooda is barbar dhigaan:

| Muuqaal | Caagagga Granulator Blades | Caagagga Shredder Blades |

|---|---|---|

| Xawaaraha hawlgalka | Xawaaraha sare (400-800 rpm) | Xawaaraha hooseeya (10-130 rpm) |

| Habka Goynta | Ku xiirashada mindida sariirta taagan | Ku jeex jeexjeexyada iligga ah ama ilka leh ee ku yaal dhowr ulood |

| Qaabka daabka | Midiyo fiiqan, saxan-engineered | Gooyo ka sii dhumuc weyn, ka xoog badan |

| Qallafsanaanta Shayga | Biraha adag sida D2 ama SKD11 | Saamaynta u adkaysata, looguna talagalay adkeysiga |

| Codsiga | Nadiifi, balaastiig hore loo kala soocay (tusaale, qaybo la isku duray) | Qashin caag ah oo culus, wasakhaysan ama adag |

| Ujeedo | Waxay soo saartaa granules yaryar oo isku mid ah si dib loogu isticmaalo | U kala jejebiya agabka waaweyn ama adag ee qaybo |

Talo: Granulators ayaa ugu fiican caag nadiif ah oo la kala soocay. Jeexjeexyadu waxay u fiican yihiin balaastiig weyn, isku qasan, ama wasakh ah.

Cabbirka Soo-saarka iyo Joogteynta

Granulators iyo shredders waxay soo saaraan natiijooyin aad u kala duwan. Granulators waxay sameeyaan qaybo yaryar, xitaa qaybo. Inta badan granules waxay ku saabsan yihiin 10mm by 10mm, cabbirkana waxaa lagu hagaajin karaa iyadoo la beddelo shaashadda. Cabbirka caadiga ah wuxuu ku dhow yahay 12mm, laakiin wuxuu u dhexeeyaa 8mm ilaa 20mm. Cabbirkan labbiska ah ayaa ka dhigaya granules si fudud in dib loogu isticmaalo alaabada cusub.

Shredders waxay abuuraan qaybo waaweyn oo qallafsan. Gooyadu badanaa waxay ku dhow yihiin 40mm waxayna ku kala duwanaan karaan cabbirka iyo qaabka. Qaybahani waxay inta badan u baahan yihiin farsamayn dheeraad ah ka hor inta aan mar kale la isticmaalin. Granulators waxay bixiyaan wax soo saar joogto ah, halka shredders ay diiradda saaraan burburinta alaabta waaweyn si degdeg ah.

- Granulators: Gawaarida yaryar, lebbiska (qiyaastii 10mm x 10mm)

- Jeexjeexyada: Qaybo waaweyn oo aan sinnayn (qiyaastii 40mm), aan joogto ahayn

Awoodaha Maareynta Agabka

Shredders waxay xamili karaan wax kastawaxaad ku tuurtaa. Waxay ku shaqeeyaan caag qaro weyn, weyn ama qaab aan caadi ahayn. Cabbirka wax gelinta ugu badan wuxuu ku xiran yahay dekedda quudinta iyo awoodda matoorka. Qaar ka mid ah shredders waxay qaadan karaan qaybo waaweyn sida 1000 × 500 mm. Waxay ku farsamayn karaan balaastikada leh dhumucda qiyaastii 0.7 mm ilaa 12 mm ama ka badan, taas oo ku xidhan mashiinka.

Granulators waxay u baahan yihiin qaybo yaryar oo nadiif ah. Waxay si fiican ugu shaqeeyaan alaabta sida sprues, orodyahannada, dhalooyinka, iyo geesaha filimka. Alaabta waaweyn ama aadka u dhumuc weyn waa in la burburiyaa ka hor inta aan la gelin granulator-ka. Haddii balaastiggu aad u dhuuban yahay, sida filimaanta, waxaa laga yaabaa inay ka dhex simbiriirto garbaha goynta halkii laga jari lahaa.

Fiiro gaar ah: Shredders ayaa ah meelaha loogu talagalay shaqooyin waaweyn oo adag. Granulator-yadu waxay ku fiican yihiin sifaynta qashinka yaryar ee nadiifka ah.

Codsiyada Caadiga ah iyo Kiisaska Isticmaalka

Granulators iyo shredders labaduba waxay ka ciyaaraan door muhiim ah dib u warshadaynta, laakiin waxay ku haboon yihiin qaybaha kala duwan ee habka.

Mashiinka Granulator caaga ahwaxay ku badan tahay:

- Dhirta qaabaynta durdurka (dib u isticmaalida sprues, orodyahanada, iyo qaybaha cilladaysan)

- Unugyada wax-soo-saarka ( dhalooyinka dib-u-warshadaynta iyo weelasha)

- Unugyada soo saarista (soo kabashada gooynta iyo muuqaallada aan si gaar ah loo lahayn)

- Cutubyada samaynta danaca caaga ah ( samaynta granules si loo pelleting)

- Dhirta dib-u-warshadaynta caagga ah (oo u beddeleysa balaastii macaamiisha ka dib alaab ceeriin ah)

- Warshadaha baakadaha (dib-u-habaynta qashinka filimada iyo qashinka xaashida)

| Qaybta Warshadaha | Codsiyada Caadiga ah ee Mashiinnada Granulator-ka |

|---|---|

| Dhirta wax-qabashada ee duritaanka | Dib u isticmaalida sprues, orodyahanada, iyo qaybaha calaacalaha ah ee cilladaysan |

| Unugyada wax-qabashada | Dhalooyinka, durbaannada, iyo weelasha bannaan ee dib loo warshadeeyo |

| Unugyada Extrusion | Soo kabashada gooynta iyo profiles-ka ama xaashida |

| Unugyada samaynta Dana caaga ah | Habka quudinta si loo soo saaro granules si loo pelleting |

| Dhirta dib-u-warshadaynta caagga ah | U beddelashada caagga ka dambeeya macaamiisha una beddelo alaabta ceeriin sare |

| Warshadaha Baakadaha | Dib-u-habaynta qashinka filimka, duubka xumbo, iyo qashinka xaashida |

Shredders waxaa loo isticmaalaa:

- Xarumaha dib-u-warshadaynta ( nadiifinta bilawga ah, sanduuqyada, gogosha, tuubooyinka, weelasha)

- Qalabka wax soo saarka (wax ka qabashada qaybaha la qurxiyey iyo qashinka ka dib isticmaalka)

- Maareynta qashinka macaamiisha ( dhalooyinka PET, baakadaha)

- Warshadaha baabuurta iyo elektiroonigga ah (ka-shaqaynta bacaha adag iyo qashinka isku dhafan)

- Daawooyinka iyo habaynta cuntada (khashinka caaga ah oo si badbaado leh loo tuuro)

- Dib u warshadaynta filimada beeraha

- Shredders waxay qabtaan balaastiigyo kala duwan, caag, fiyuusyo, iyo xitaa walxo adag sida Kevlar iyo kaarboon.

- Waxa kale oo loo isticmaalaa dib u warshadaynta taayirka, qashinka khatarta ah, iyo farsamaynta biraha qashinka ah.

Shredders waxay bilaabaan habka dib-u-warshadaynta iyagoo jajabinaya alaabta waaweyn. Granulators waxay dhammeeyaan shaqada iyagoo samaynaya granules yaryar oo dib loo isticmaali karo.

Jadwalka Isbarbardhigga Dhinac-ka-dhinac

Waa kan miis kaa caawinaya inaad aragtid kala duwanaanshaha ugu weyn:

| Qiyaasta waxqabadka | Mashiinka Granulator caaga ah | Shredder caag ah |

|---|---|---|

| Habka Goynta | Xawaaraha sare, goynta saxda ah | Xawaaraha hooseeya, jeexjeexa qulqulka sare |

| Cabirka wax soo saarka | Duub yar, lebis (8-20mm) | Qaybo waaweyn oo aan caadi ahayn (ilaa 40mm+) |

| Maareynta Agabka | Nadiifi, horay loo kala soocay, qaybo yaryar | Balaastikyo waaweyn, isku qasan, ama wasakhaysan |

| Codsiyada caadiga ah | Qaabaynta duritaanka, extrusion, baakadaha | Xarumaha dib u warshadaynta, maareynta qashinka, baabuurta |

| Baahiyaha Dayactirka | Hoose, qaybo si fudud loo geli karo | Sare, beddelka daabka caadiga ah |

| Awoodda wax-soo-saarka | Dhexdhexaad (200-300 kg/saacaddii) | Sare (ilaa 2 tan/saacaddii) |

| Qiimaha hawlgalka | Tamar hoose iyo dayactir | Kharashyada shaqada oo sarreeya iyo qayb ahaan |

| Is dhexgalka | Hal-abuurka ama granulators dhexe | Keliya ama lagu dhex daray granulators |

Doorashada mashiinka saxda ah waxay kuxirantahay nooca alaabtaada, wax soo saarka aad rabto, iyo meesha aad ku haboon tahay habka dib u warshadaynta.

Doorashada Inta u dhaxaysa Mashiinka Granulator-ka Caaga ah iyo Shredder caag ah

Nooca Walxaha iyo Cabbirka Tixgelinta

Doorashada mashiinka saxda ah waxay ka bilaabataa fiirinta nooca iyo xajmiga qashinka caagga ah. Shredders waxay si fiican ugu shaqeeyaan alaabada waaweyn, sida durbaannada, tuubooyinka, ama bambarrada baabuurta. Waxay u kala jajabiyaan kuwan qaybo yaryar, taas oo u sahlaysa in wax laga qabto. Granulators ayaa la wareegaya marka balaastiggu uu hore u ahaa qaybo yaryar ama ka dib jeexjeex. Waxay walxaha ku sifeeyan granules isku mid ah. Jadwalka hoose wuxuu muujinayaa sida mashiin kasta ugu habboon yahay baahiyaha kala duwan:

| Qodob | Mashiinka Granulator caaga ah | Shredder caag ah |

|---|---|---|

| Baaxadda qashinka & Heerka Quudinta | Iftiin ilaa dhexdhexaad ah | Iskaro weyn oo weyn |

| Cabbirka Soo-saarka & Ujeedada | Granules lebbiska | Gooyo aan dhab ahayn |

| Tilmaamaha Hawlgalka | Sare-RPM, wareeg yar | Hirar-sare, hoose-RPM |

| Xaddid | La halgamaya qaybo culus | Aan ku habboonayn qashinka iftiinka |

Talo: Balaastigga injineernimada ee qaabka ul ama saxan, jeexjeexu waa inuu marka hore tago, oo uu ku xigaa granulator si loo helo natiijooyinka ugu fiican.

Soo saarista la rabo iyo Isticmaalka Dhamaadka

Isticmaalka ugu dambeeya ee balaastikada dib loo warshadeeyay ayaa hagaya kala doorashada mishiinada. Granulator-yadu waxay soo saaraan yaryar, xitaa granules, oo ku habboon qaabaynta duritaanka, extrusion, ama qaabaynta dharbaaxada. Shredders waxay abuuraan qaybo waaweyn oo qallafsan oo inta badan u baahan habayn dheeraad ah. Jadwalka hoose wuxuu muujinayaa cabbirrada wax-soo-saarka lagu taliyey ee isticmaalka kala duwan:

| Dhamaadka Isticmaalka / Habka | Cabbirka soo-saarka lagu taliyay (mm) | Ujeedada / Faa'iidada |

|---|---|---|

| Qaabaynta duritaanka, extrusion | 6.35 - 9.5 | Dib u isticmaalka tooska ah ee wax soo saarka |

| WEEE jajabyada balaastiga ah kala soocida | 10 - 20 | Waxay hagaajisaa kala-soocidda iyo dib-u-warshadaynta |

Habka tallaabo-tallaabo ah wuxuu caawiyaa in mashiinka uu ku habboon yahay shaqada:

- Hubi in balaastiggu yahay mid dabacsan ama adag.

- Eeg xajmiga iyo qaabka.

- Ka fakar wasakhowga.

- Ku dhig mishiinka agabka iyo baahiyaha wax soo saarka.

- Tixgeli qiimaha iyo booska.

Qodobbada Hawlgelinta: Xawaaraha, Dayactirka, iyo Qiimaha

Xawaaraha, kor u qaadida, iyo qiimaha waa arrin marka la soo dooranayo mishiinka. Granulators waxay ku ordaan xawaare sare waxayna sameeyaan qaybo aad u fiican. Waxay u baahan yihiin afayn joogto ah laakiin waxay isticmaalaan awood yar. Shredders waxay u shaqeeyaan si tartiib tartiib ah, isticmaal xoog badan, waxayna qabtaan shaqooyin adag. Waxay ku kacayaan kharash badan si ay u ordaan oo loo ilaaliyo, gaar ahaan moodooyinka hawl-culus. Shaxda hoose ayaa is barbar dhig ku samaynaysa arrimahan:

| Muuqaal | Mashiinka Granulator caaga ah | Shredder caag ah |

|---|---|---|

| Xawaaraha shaqada | Sare | Hoose |

| Cabirka wax soo saarka | Yar, labis | Weyn, kala duwan |

| Dayactirka | Daryeelka daab joogta ah | Beddelka daabka soo noqnoqda |

| Qiimaha | Hoose | Sareeye |

Fiiro gaar ah: Xarumaha leh qashin badan oo waaweyn ayaa laga yaabaa inay door bidaan shredders, halka kuwa u baahan ganaax, granules dib loo isticmaali karo ay badanaa doortaan granulators.

Doorashada mashiinka saxda ah ayaa muhiim ah. Shredders ayaa marka hore jebiya balaastikada waaweyn, halka granulators ay abuuraan qaybo yaryar oo isku mid ah si dib loogu isticmaalo. Labaduba waxay door muhiim ah ka ciyaaraan dib u warshadaynta. Tixraac degdeg ah, ka eeg shaxdan talooyinka khubarada ah ee ku saabsan xulashada ta ugu habboon ee qashinkaaga iyo habkaaga:

| Qodob | Granulator | Shredder |

|---|---|---|

| Xawaaraha | Sare | Hoose |

| Mugga qashinka | Cabbir kasta | Ugu fiican ee xaddi badan |

| Cabirka wax soo saarka | Yar, labis | Weyn, qallafsan |

FAQ

Waa maxay balaastikada mashiinka granulator-ka uu farsameyn karo?

Granulator-ku wuxuu qabtaa balaastiig nadiif ah, oo la kala soocay sida dhalooyinka, sprues, iyo geesaha filimka. Waxay si fiican ugu shaqeysaa qalabka sida polyetylen, polypropylene, iyo polystyrene.

Ma wada shaqayn karaan shredder iyo granulator?

Haa! Dhirta dib-u-warshadaynta badan ayaa marka hore u isticmaala shredder alaabta waaweyn. Kadibna, waxay isticmaalaan granulator si ay u sameeyaan granulo yaryar oo isku mid ah.

Intee jeer ayay tahay in hawl-wadeenadu dayactiraan mishiinadan?

Hawl-wadeenadu waa inay eegaan daabka toddobaad kasta. Waa inay afeeyaan ama beddelaan haddii loo baahdo. Nadiifinta joogtada ah waxay ka dhigtaa labada mashiinba inay si habsami leh oo badbaado leh u shaqeeyaan.

Waqtiga boostada: Agoosto-14-2025