.png)

Doorashada saxda ahjeexjeex caag ahmacneheedu waxa weeye in laga fikiro iswaafajinta walxaha, nooca shredder, iyo tafaasiisha muhiimka ah. Marka astaamuhu ay ku habboon yihiin baahiyaha caaggaaga, mishiinnada sida amashiinka burburiyaha caaga ah or granulator caag ahsi fiican u shaqeeyaan. Haddii qof uu is-khilaafo amashiinka samaynta caag ah, waxay halis u yihiin kharashyo badan, waqti-dhimis, ama xitaa waxyeelo qalabeed.

Qaadashada Furaha

- Aqoonso nooca balaastigga ah, cabbirka, iyo mugga maalinlaha ah si aad u dooratid jeexjeex ku habboon qallafsanaanta alaabtaada iyo qaabka waxqabadkaaga wanaagsan iyo wakhtiga dhimista.

- Dooronooca shredder midigiyo walxo daab ah oo ku salaysan adkaanta balaastikadaada iyo cabbirka wax soo saarka ee aad rabto si loo hagaajiyo waxtarka jajabinta iyo tayada alaabta.

- Hubi awoodda shredder, sifooyinka badbaadada, iyobaahiyaha dayactirkasi loo hubiyo habsami u socodka shaqada, ilaalinta shaqaalaha, loona yareeyo burburka qaaliga ah.

Aqoonso Walxahaaga Balaastigga ah iyo Shuruudaha Shredder

Go'aami Nooca Caagga ah, Adag, iyo Wasakhowga

Mid kastacaag ahwaa ka duwan yahay. Qaar waxay ka yimaadaan warshado, qaar kalena waxay ka yimaadaan guryo ama ganacsiyo. Isha iyo qaabka walxaha caagga ah sababtoo ah mid kastaa wuxuu u baahan yahay hab gaar ah oo la gooyo. Waa kan muuqaal degdeg ah:

| Qaybta | Sharaxaada/Tusaalo | Habka jeexjeexida ee lagu taliyay |

|---|---|---|

| Isha alaabta | Warshada kadib (qashin warshadeed oo nadiif ah, qalalan) | Jeexitaanka alaabta adag; habka fudud |

| Isticmaalka ka dib (qalabka la isticmaalo oo leh xoogaa qoyaan ah) | Cutter-compactors si ay u xakameeyaan qoyaanka iyo jilicsanaanta | |

| Qaabka/Foomka | Filimada, jajabyada qalafsan, xumbo PE, tuubooyinka waraabka | Cutter-compactors oo loogu talagalay walxaha jilicsan, qoyan |

| Raffia, bacaha tolmada leh/aan-dhuubka ahayn, jawaannada, balaastikada adag | Qalabyada lagu jeexjeexo alaabada ka adag, ka weyn |

Adaggu sidoo kale door weyn ayuu ka ciyaaraa. Bacaha jilicsan sida bacaha waxay u baahan yihiin baco ka duwan kuwa adag sida bacaha qaro weyn. Tusaale ahaan, biraha kaarboonku waxay si fiican ugu shaqeeyaan balaastikada jilicsan, halka birta qalabka ama tungsten carbide bacaha ay gacanta ku hayaan balaastiig aad u adag. Wasakhowga sida cuntada, sumadaha, ama wasakhda ayaa xidhi kara mishiinada ama hoos u dhigi kara qiimaha balaastikada dib loo warshadeeyay. Bacaha nadiifka ah waxay caawiyaan qashinka balaastikada ah inuu si fiican u shaqeeyo oo uu sii dheeraado.

Talo: Had iyo jeer iska hubi oo ka saar waxyaalaha wasakhaysan sida cuntada, sumadaha, ama biraha ka hor inta aanad xoqin.

Qiimee Cabbirka Shayga, Qaabka, iyo Mugga Maalinlaha ah

Baaxadda iyo qaabka qashinka caagga ah waxay saameeyaan shredderka sida ugu fiican u shaqeeya. Alaabooyinka waaweyn, kuwa waaweyn sida palette-yada ama tuubooyinka waxay u baahan yihiin mashiino leh gooyo qaro weyn iyo awood sare. Caagag yar yar ama dhuuban, sida dhalooyinka ama filimada, waxay ku fiican yihiin granulators ama shredders leh biro badan oo jeexan.

- Balaastikyo waaweyn oo qaro weyn leh: Isticmaal jeexjeexyada xiiraya ama wax shiidiyaasha.

- Aflaan khafiif ah ama qaybo la shubay: U adeegso granulators si aad u sameysid jajabyo isku mid ah.

- Balaastiig isku dhafan ama adag: Burburayaal ujeedo leh oo dhan leh oo leh goobo la hagaajin karo.

Mugga maalinlaha ah sidoo kale waa muhiim. Tusaale ahaan, haddii xaruntu ay ku shaqeyso 8 tan oo caag ah 8 saacadood gudahood, waxay u baahan tahay shredder leh ugu yaraan 1.2 tan saacaddii. Isbarbardhigga wax soo saarka shredder-ga iyo baahiyaha maalinlaha ah waxay ilaalinaysaa hawlgallada.

Qeex Cabbirka Soo-saarka La Rabo iyo Labbiska

Nidaamyada dib-u-warshadaynta kala duwan waxay u baahan yihiin cabbirro wax-soo-saar oo kala duwan. Qaar ka mid ah waxay rabaan yar yar, xitaa jajabyo, qaar kalena waxay u baahan yihiin qaybo waaweyn. Jeexjeexyada hal-shaft ee leh shaashadaha waxay samayn karaan qaybo isku mid ah oo sax ah. Granulators waxay abuuraan jajabyo yaryar oo nadiif ah si dib loogu isticmaalo alaabada cusub. Jeexjeexyada afar geesoodka ah waxay bixiyaan xitaa xakameyn dheeraad ah shaqooyinka gaarka ah.

| Nooca Shredder | Tilmaamaha Xakamaynta Cabbirka Soo-saarka | Kiis Isticmaalka Ugu Wanaagsan |

|---|---|---|

| jeexjeexyada afar geesoodka ah | Ulaha isku dhafan ee qaybaha labbiska | Caagag adag, jeexid ammaan sare leh |

| Jeexjeexyada hal-shaft | Shaashada cabbirka cabbirrada saxda ah, lebbiska | Wax soo saar joogto ah ayaa loo baahan yahay |

| Granulators | Rotors-xawaaraha sarreeya ee jajabyada yaryar, lebbiska | Nadiifi kaydka quudinta ee wax soo saarka |

Cabbirrada wax-soo-saarka yar-yar ayaa ka caawinaya kala-soocidda, nadiifinta, iyo dib-u-isticmaalka caagga ah. Qalfoofka caagga ah ee saxda ah ayaa ka dhigaya dib u warshadaynta mid sahlan oo waxtar badan.

Isku hagaaji Nooca Shredder caagga ah iyo waxqabadka baahiyahaaga

Is barbar dhig Noocyada Shredder: Hal Shaft, Double Shaft, Granulators

Doorashada shreder saxda ah waxay ka bilaabataa fahamka noocyada ugu muhiimsan. Nooc kastaa wuxuu si fiican ugu shaqeeyaa balaastikada iyo hawlaha qaarkood. Waa kan isbarbardhigga degdega ah:

| Nooca Shredder | Naqshadeynta Dhismaha & Hawlgalka | Qalabka ku haboon & Codsiyada | Tilmaamaha Muhiimka ah & Faa'iidooyinka |

|---|---|---|---|

| Hal Shaft Shredder | Hal usheeda dhexe oo wareeg ah oo leh garbaha ka soo horjeeda mindiyaha taagan | Qalab jilicsan, khafiif ah, labis ah sida filim caag ah, fiber, qashinka | Dayactirka sahlan, isticmaalka tamarta hoose, xakamaynta wax soo saarka wanaagsan |

| Shaft Double Shredder | Laba ulood oo rogaal celis ah oo leh daabyo isku xidhan | Qashin weyn, adag, isku dhafan sida tuubooyinka, durbaannada, qashinka elektaroonigga ah | Dhaqdhaqaaqa sare, wuxuu qabtaa shaqooyin adag, aad u adag |

| Granulator | Rotor-xawaare sare leh, ficil goyn | Sprues, orodyahannada, qashinka laga soo qaado khadadka wax soo saarka | granulation Fine, ugu fiican ee dhimista cabbirka |

Jeexjeexyada kelida ah waxay si fiican ugu shaqeeyaan balaastikada jilicsan waxayna siinayaan xakameyn dheeraad ah cabbirka wax soo saarka. Jeexjeexyada labajibbaaran waxay qabtaan balaastiig qaro weyn, adag, ama isku dhafan. Granulators waxay u gooyaan balaastikada qaybo yaryar oo isku mid ah, taasoo ka dhigaysa mid ku habboon dib u warshadaynta qashinka nadiifka ah.

Markaad la shaqaynayso polyetylen cufnaanta sare leh (HDPE), afar shaft shredders ayaa bixiya awooda ugu xoogan ee burburinta iyo waxtarka, gaar ahaan qaybaha adag ama kuwa waaweyn. Jeexjeexyada labajibbaaran waxay sidoo kale si fiican ugu shaqeeyaan wax soo saarka ballaaran haddii cabbirka fiican aan loo baahnayn.

Dooro Nooca Blade, Awoodda Matoorka, iyo Tilmaamaha Badbaadada

Daabka saxda ah wuxuu sameeyaa farqi weyn. Caagag adag ama caag ah waxay u baahan yihiin dabo adag. Waa kan waxa ugu fiican:

| Nooca daabka / Qalabka | Sharaxaada / Guryaha | Kiis Isticmaalka Ugu Wanaagsan |

|---|---|---|

| Hook Blades | Ilkaha qaloocan waxay qabtaan oo soo jiidaan alaabta | Tuubooyinka qaro weyn, go'yaal cufan |

| Birta Xawaaraha Sare leh (HSS) | Adag, kulaylka u adkaysta | Caagag adag, xawaarihiisa sareeyo |

| Qalabka Birta | Adag, iska caabbinta xirashada | Caagag adag |

| Alloy Steel | Waarta, waxay ka hortagtaa daxalka | Jeexitaanka guud, balaastiig ka timaadda |

| Caleemaha Carbide-Tipped | Aad u adag, xirashada u adkaysata | Qalab culus oo culus |

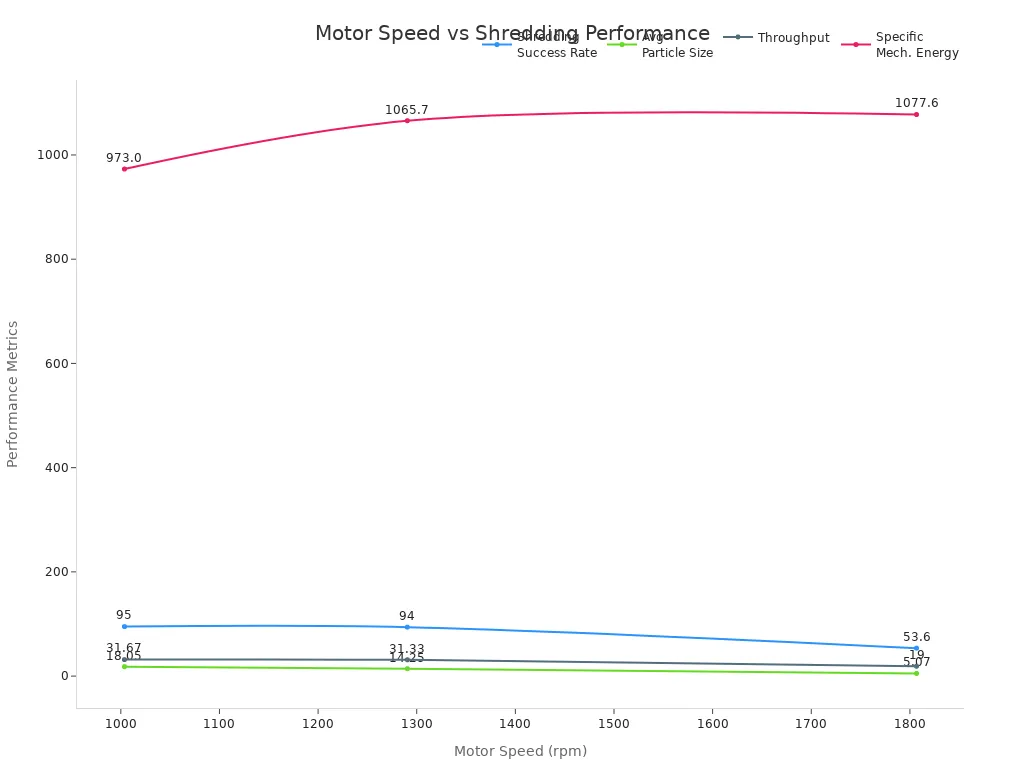

Awoodda matoorka sidoo kale waa muhiim. Awood badan waxay la macno tahay shredder-ku inuu xamili karo balaastiig ka dhumuc weyn ama ka adag. Tusaale ahaan, matoor 10 Hp ah oo xawaare sare ku socda ayaa balaastiga u jeexjeexa si degdeg ah oo qaybo yaryar ah. Shaxda hoose waxay tuseysaa sida xawaaraha matoorku u saameeyo natiijooyinka kala-jaridda:

Tilmaamaha badbaadada ayaa ilaaliya shaqaalaha iyo qalabka. Qalabyada casriga ah waxaa badanaa ka mid ah:

- Badhamada joogsiga degdega ah

- Ilaalada iyo biraha

- Si toos ah u xidhida saxmada ama kulaylka

- Nidaamyada ogaanshaha iyo xakamaynta dabka

- Dareemayaasha joojiya mashiinka haddii qolka quudinta uu furan yahay

- Culayska xad dhaafka ah iyo ogaanshaha walxaha shisheeye

- Naqshadaynta Ergonomic ee quudinta iyo dayactirka fudud

Talo: Had iyo jeer iska hubi sifooyinkan nabdoonaanta ka hor intaadan iibsan shredder balaastiig ah.

Qiimee Wakhtiga, Waarta, iyo Baahiyaha Dayactirka

Wax soo saarka ayaa sheegaya inta balaastiga ah ee shredder uu shaqayn karo saacaddii. Jeexjeexyada labajibbaaran waxay xamili karaan 30 ilaa 100,000 kg/h, halka moodooyinka hal shafka ahi u dhexeeyaan 100 ilaa 9,000 kg/h. Granulators waxay caadi ahaan farsameeyaan qadar yar laakiin waxay sameeyaan jajabyo yaryar.

| Nooca Shredder | Inta u dhaxaysa (kg/saacaddii) | Tusaalooyinka Tusaalooyinka iyo Faahfaahinta Wax-soo-saarka |

|---|---|---|

| Shaft kali ah | 100 - 9,000 | Zibo United Tech: 100 - 1,000 kg / h; WANROOE-TECH: 450 - 1,500 kg / h; Moodooyinka qaarkood ilaa 9,000 kg/h |

| Shaf labanlaab ah | 30 - 100,000 | Taxanaha Harden TS: 3,000 - 15,000 kg / h; ARJES COMPAKTOR 300: 6,000 - 100,000 kg / h; Moodooyinka yaryar: 30 - 135 kg / h |

Waarta waxay kuxirantahay walxaha daabka iyo dhismaha mashiinka. Biraha daawaha ah iyo birta-caarad-ka-caaradku waxay ku sii jiraan balaastiig adag. Daawaynta kulaylka iyo been-abuurista ayaa ka dhigaysa daab adag oo adkaysi u leh xidhashada.

Baahiyaha dayactirka ayaa ku kala duwan nooca. Shredders waxay u baahan yihiin hubin joogto ah oo ku saabsan qaybaha shaqada culus, afaynta daabka, iyo nidaamyada hawo-mareenada. Granulators waxay u baahan yihiin quudin taxadir leh iyo hubinta daabka oo joogto ah si looga fogaado saxmada. La socoshada dayactirka waxay yaraynaysaa wakhtiga dhimista waxayna ka dhigtaa shredder balaastikada inay si habsami leh u socoto.

Sababaha caadiga ah ee wakhtiga dhimista waxaa ka mid ah:

- Dhibaatooyinka quudinta ama xannibaadda

- Culays badan ama saxmad

- Qalabaynta mashiinka liidata

- La'aanta dayactir joogto ah

- Qaladaadka hawlwadeenka

Si loo yareeyo wakhtiga dhimista:

- Isticmaal hababka quudinta tooska ah

- Mashiinnada calibrate ee cabbirka saxda ah ee wax soo saarka

- Si fiican u tababar hawl wadeenada

- Jadwal u samee dayactir joogto ah

Liiska hubinta ku habboonaanta degdega ah ee Xulashada Shredder caag ah

Kahor intaadan dooran shredder balaastiig ah, dhex mari liiskan hubinta:

- Ogow balaastikadaada: nooca, cabbirka, iyo mugga maalinlaha ah

- Hubi awoodda mashiinka iyo wax soo saarka

- Raadi waxtarka tamarta iyo dayactirka fudud

- Dib u eeg sifooyinka iyo shahaadooyinka badbaadada

- Is barbar dhig moodooyinka farsamooyinka farsamada iyo jawaab celinta isticmaalaha

- Qorshee tababbarka hawlwadeenka iyo taageerada iibka kadib

- Tixgeli wadarta kharashka, oo ay ku jiraan dayactirka iyo isticmaalka tamarta

- Weydiiso bandhigyo toos ah ama tixraacyo isticmaalayaasha kale

Fiiro gaar ah: La hadalka khabiirka ama soo saaraha waxay kaa caawin kartaa xaqiijinta ku habboon baahiyahaaga.

Doorashada saxda ahjeexjeex caag ahMacnaheedu waa hubinta alaabtaada, dib u eegis liiska hubinta, iyo waydiinta caawimada khabiirka haddii loo baahdo. Isticmaalayaal badan ayaa la kulma khalkhal ama jajab marka ay ka boodaan hubinta ku habboonaanta:

| Arrin | Sababta Caadiga ah |

|---|---|

| Garaacid | Culayska xad dhaafka ah, garbaha caajiska ah |

| Burburka daabka | Daab tayo liidata, si xun u isticmaal |

Tababarka joogtada ah ee hawlwadeenada iyo hubinta badbaadada waxay caawiyaan ka hortagga dhibaatooyinkan.

FAQ

Intee jeer ayay tahay in qof uu afeeyo daabyada jeexjeexyada?

Caleemaha waxay u baahan yihiin afaynta dhawrkii toddobaadba mar haddii la isticmaalo maalin kasta. Caleemaha caajisku waxay hoos u dhigaan shaqada waxayna keeni karaan saxmad.

Goynta balaastiigga ah ma xamili karaa walxaha isku dhafan?

Inta badan kuwa wax gooya waxay farsamayn karaan balaastikada isku dhafan, laakiin birta ama quraarada waxay dhaawici karaan daabyada. Had iyo jeer kala saar waxyaabaha aan caaga ahayn marka hore.

Waa maxay qalabka badbaadada ee ay tahay in hawlwadeenadu xidhaan?

Hawl-wadeenadu waa inay xidhaan galoofyada, muraayadaha badbaadada, iyo ilaalinta dhegta. Waxyaabahani waxay kaa caawinayaan inay ka hortagaan dhaawacyada ka yimaadda qaybo balaastig ah oo fiiqan ama dhawaaq dheer.

Waqtiga boostada: Jul-30-2025