.png)

Ho khetha se nepahetsengpolasitiki shreddere bolela ho nahana ka tšebelisano ea thepa, mofuta oa shredder, le lintlha tsa bohlokoa. Ha likarolo li lumellana le litlhoko tsa polasetiki ea hau, mechine e kang amochini o senyang polasetiki or polasetiki ea granulatorsebetsa hantle. Haeba motho a sa tsamaisane le amochini o etsang polasetiki, ba ipeha kotsing ea litšenyehelo tse phahameng, ho fokotsa nako, kapa esita le tšenyo ea thepa.

Lintlha tsa bohlokoa

- Hlalosa mofuta oa polasetiki ea hau, boholo, le bophahamo ba letsatsi le letsatsi ho khetha shredder e lumellanang le boima ba thepa ea hau le sebōpeho sa ts'ebetso e ntle le nako e fokolang.

- Khetha eamofuta oa shredder o nepahetsengle lisebelisoa tsa blade tse ipapisitseng le ho tiea ha polasetiki ea hau le boholo bo lakatsehang ba tlhahiso ho ntlafatsa ts'ebetso ea ho senya le boleng ba sehlahisoa.

- Lekola bokhoni ba shredder, likarolo tsa polokeho, lelitlhoko tsa tlhokomeloho etsa bonnete ba hore ho sebetsa ka thelelo, ho sireletsa basebetsi, le ho fokotsa ho senyeha ha chelete e ngata.

Tseba Litlhoko tsa Hau tsa Plastiki le Litlhoko tsa Shredder

Etsa qeto ea mofuta oa polasetiki, ho thatafala le litšila

Emong le emongpolasetikie fapane. Ba bang ba tsoa lifemeng, ha ba bang ba tsoa malapeng kapa likhoebong. Mohloli le mofuta oa taba ea polasetiki hobane e mong le e mong o hloka mokhoa o khethehileng oa ho senya. Mona ke ponahalo e potlakileng:

| Sehlopha | Tlhaloso/Mehlala | Mokhoa o khothalelitsoeng oa Shredding |

|---|---|---|

| Mohloli oa Lintho | Ka mor'a indasteri (litsila tse hloekileng, tse omeletseng tsa feme) | Li-shredders bakeng sa lisebelisoa tse thata; mokhoa o bonolo |

| Post-consumer (lisebelisoa tse sebelisitsoeng tse nang le mongobo o itseng) | Li-cutter-compactors ho sebetsana le mongobo le li-flakes | |

| Sebopeho/Sebopeho | Lifilimi, li-flakes tse fluffy, foam ea PE, liphaephe tsa ho nosetsa | Li-cutter-compactors bakeng sa lisebelisoa tse bonolo, tse mongobo |

| Raffia, mekotla e lohiloeng/e sa lohiloeng, mekotla, lipolasetiki tse thata | Li-shredders bakeng sa lisebelisoa tse thata, tse ngata |

Ho thatafala le hona ho phetha karolo e kholo. Lipolasetiki tse bonolo joalo ka mekotla li hloka li-blades tse fapaneng ho feta lipolasetiki tse thata joalo ka lishiti tse teteaneng. Ka mohlala, li-blades tsa carbon steel li sebetsa hantle bakeng sa li-plastiki tse bonolo, ha lisebelisoa tsa tšepe kapa li-tungsten carbide li tšoara li-plastiki tse thata haholo. Lintho tse silafatsang tse kang lijo, lileibole kapa litšila li ka koala mechini kapa tsa theola boleng ba polasetiki e nchafalitsoeng. Lipolasetiki tse hloekileng li thusa shredder ea polasetiki hore e sebetse hantle le ho tšoarella nako e telele.

Keletso: Kamehla hlahloba le ho tlosa lintho tse silafatsang tse kang lijo, lileibole kapa litšepe pele u qhetsola.

Lekola Boholo ba Boitsebiso, Sebopeho, le Bolumo ea Letsatsi le Letsatsi

Boholo le sebopeho sa litšila tsa polasetiki li ama hore na shredder e sebetsa hantle hakae. Lintho tse kholo, tse ngata tse kang liphalete kapa liphaephe li hloka mechine e nang le li-cutters tse teteaneng le matla a phahameng. Li-plastiki tse nyenyane kapa tse tšesaane, tse kang libotlolo kapa lifilimi, li sebetsa hantle ka li-granulator kapa li-shredders tse nang le li-blade tse ngata bakeng sa ho khaola hantle.

- Lipolasetiki tse kholo, tse teteaneng: Sebelisa li-shear shredders kapa grinders.

- Lifilimi tse tšesaane kapa likarolo tse bōpiloeng: Sebelisa li-granulator bakeng sa li-flakes tse tšoanang.

- Li-plastiki tse tsoakiloeng kapa tse thata: Li-shredders tsa merero eohle tse nang le li-setting tse feto-fetohang.

Molumo oa letsatsi le letsatsi o bohlokoa hape. Mohlala, haeba setsi se sebetsa lithane tse 8 tsa polasetiki ka lihora tse 8, se hloka shredder e nang le bonyane lithane tse 1.2 ka hora. Ho bapisa tšebetso ea shredder le litlhoko tsa letsatsi le letsatsi ho boloka ts'ebetso e le bonolo.

Hlalosa Bongata bo Lakatsehang ba Sephetho le ho Tšoanang

Mekhoa e fapaneng ea ho tsosolosa e hloka boholo bo fapaneng ba tlhahiso. Ba bang ba batla li-flakes tse nyane, ha tse ling li hloka likotoana tse kholoanyane. Li-shredders tse nang le shaft e le 'ngoe tse nang le li-skrini li ka etsa likaroloana tse nepahetseng, tse tšoanang. Li-granulator li etsa li-flakes tse nyenyane, tse hloekileng bakeng sa ho sebelisoa hape lihlahisoa tse ncha. Li-shredders tse nang le shaft tse 'nè li fana ka taolo le ho feta bakeng sa mesebetsi e khethehileng.

| Mofuta oa Shredder | Output Size Control Feature | Molemo ka ho fetisisa Sebelisa Nyeoe |

|---|---|---|

| Li-shredders tse nang le shaft tse 'nè | Intermeshing shafts bakeng sa likaroloana tse tšoanang | Li-plastics tse thata, tse nang le tšireletso e phahameng |

| Li-shredders tse nang le shaft e le 'ngoe | Ho etsa boholo ba li-skrini bakeng sa boholo bo nepahetseng, bo lekanang | Tlhahiso e tsitsitseng e hlokahalang |

| Li-granulator | Li-rotor tse lebelo le phahameng bakeng sa li-flakes tse nyane, tse tšoanang | Hloekisa lijo bakeng sa tlhahiso |

Lisaese tse nyane tse hlahisoang li thusa ka ho hlopha, ho hloekisa le ho sebelisa polasetiki hape. Shredder ea polasetiki e nepahetseng e etsa hore ho be bonolo ho sebelisa hape ho sebetsa hantle.

Bapisa mofuta oa Plastic Shredder le Ts'ebetso ho Litlhoko tsa Hao

Bapisa Mefuta ea Shredder: Shaft e le 'ngoe, Shaft e habeli, Granulators

Ho khetha shredder e nepahetseng ho qala ka ho utloisisa mefuta e meholo. Mofuta o mong le o mong o sebetsa hantle bakeng sa lipolasetiki le mesebetsi e itseng. Papiso e potlakileng ke ena:

| Mofuta oa Shredder | Moralo oa Sebopeho le Ts'ebetso | Lisebelisoa le Lisebelisoa tse Loketseng | Lintlha tsa Bohlokoa le Melemo |

|---|---|---|---|

| Shredder ea Shaft e le 'ngoe | Shaft e le 'ngoe e bilikang e nang le li-blades e sehang khahlanong le lithipa tse emeng | Lisebelisoa tse bonolo, tse bobebe, tse ts'oanang joalo ka filimi ea polasetiki, fiber, litšila | Tlhokomelo e bonolo, tšebeliso e tlase ea matla, taolo e ntle ea tlhahiso |

| Shredder ea Shaft habeli | Li-shaft tse peli tse pota-potileng tse nang le mahare a hokahaneng | litšila tse ngata, tse thata, tse tsoakiloeng joalo ka liphaephe, meropa, litšila tsa elektronike | Torque e phahameng, e sebetsana le mesebetsi e thata, e rarahaneng ho feta |

| Granulator | Rotor e lebelo le phahameng, ketso ea slicing | Li-sprues, limathi, likhechana tse tsoang mehala ea tlhahiso | Granulation e ntle, e ntle ka ho fetisisa bakeng sa ho fokotsa boholo |

Li-shredders tsa shaft tse le 'ngoe li sebetsa hantle bakeng sa li-plastiki tse bonolo 'me li fana ka taolo e eketsehileng holim'a boholo ba tlhahiso. Li-shaft shredders tse peli li tšoara lipolasetiki tse teteaneng, tse thata kapa tse tsoakiloeng. Li-granulator li khaola lipolasetiki likotoana tse nyane, tse ts'oanang, ho li etsa hore e be tse loketseng ho sebelisoa hape likhechana tse hloekileng.

Ha u sebetsa ka polyethylene e phahameng haholo (HDPE), li-shaft shredders tse 'nè li fana ka matla a matla a ho senya le ho sebetsa hantle, haholo-holo bakeng sa likotoana tse thata kapa tse kholo. Li-shaft shredders tse peli le tsona li sebetsa hantle bakeng sa tlhahiso e kholo haeba boholo bo botle bo sa hlokahale.

Khetha Mofuta oa Blade, Matla a Motlakase, le Likarolo tsa Tšireletseho

Lehare le nepahetseng le etsa phapang e kholo. Li-plastiki tse thata kapa tse hlabang li hloka li-blades tse matla. Mona ke se sebetsang hantle:

| Mofuta oa Blade / Boitsebiso | Tlhaloso / Thepa | Molemo ka ho fetisisa Sebelisa Nyeoe |

|---|---|---|

| Li-Blades tsa Hook | Meno a kobehileng a tšoara le ho hula lisebelisoa | Liphaephe tse teteaneng, maqephe a teteaneng |

| Tshipi ya Lebelo le Leholo (HSS) | E thata, e mamella mocheso | Lipolasetiki tse thata, tse pshatlang ka lebelo le holimo |

| Tool Steel | E thata, e hanela ho apara | Li-plastiki tse thata |

| Alloy Steel | E tšoarella, e hanela ho bola | Kakaretso ea ho pshatla, lipolasetiki tse hlabang |

| Li-blades tsa Carbide-Tipped | E thata haholo, e sa senyeheng | Lintho tse boima, tse senyang |

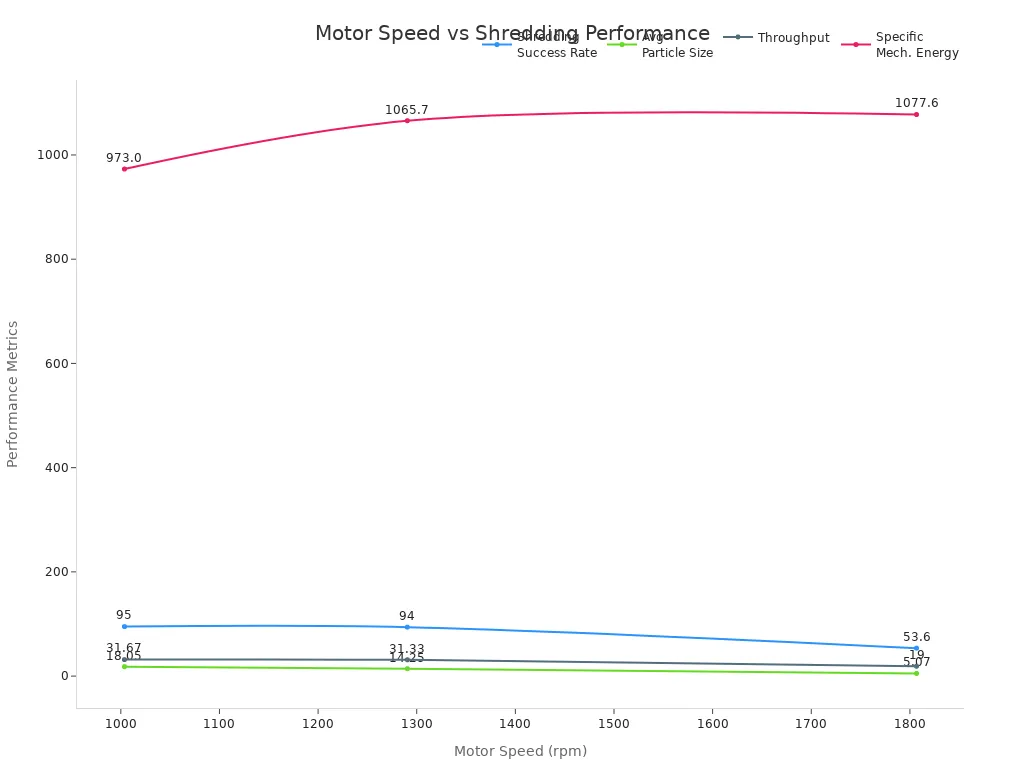

Matla a motlakase a bohlokoa hape. Matla a eketsehileng a bolela hore shredder e khona ho sebetsana le lipolasetiki tse teteaneng kapa tse thata. Mohlala, enjene ea 10 Hp ka lebelo le holimo e pshatla lipolasetiki kapele le likotoana tse nyane. Chate e ka tlase e bonts'a hore na lebelo la enjine le ama liphetho tsa shredding joang:

Likarolo tsa polokeho li sireletsa basebetsi le lisebelisoa. Li-shredders tsa sejoale-joale hangata li kenyelletsa:

- Likonopo tsa ho emisa ka tšohanyetso

- Balebeli ba tšireletso le liporo

- Ho tima ka tsela e iketsang bakeng sa jeme kapa ho futhumala ho feteletseng

- Mekhoa ea ho lemoha le ho thibela mollo

- Li-sensor tse emisang mochini haeba kamore ea phepelo e butsoe

- Ho fumana lintho tse ngata haholo le tse tsoang kantle ho naha

- Meetso ea ergonomic bakeng sa ho fepa le ho hlokomela habonolo

Keletso: Kamehla hlahloba likarolo tsena tsa polokeho pele u reka shredder ea polasetiki.

Hlahlobisisa Litlhoko tsa Bophelo, Nako e Tšoarellang, le Tlhokomelo

Throughput e bolela hore na shredder e ka sebetsa polasetiki e kae ka hora. Li-shredders tse peli tsa shaft li ka sebetsa ho tloha ho 30 ho isa ho 100,000 kg / h, ha mefuta ea shaft e le 'ngoe e tloha ho 100 ho isa ho 9,000 kg /h. Hangata li-granulator li sebetsa ka tekanyo e nyane empa li etsa li-flakes tse ntle.

| Mofuta oa Shredder | Boemo ba ho fetisoa (kg/h) | Mehlala ea Mehlala le Lintlha tsa Phatlalatso |

|---|---|---|

| Shaft e le 'ngoe | 100 - 9,000 | Zibo United Tech: 100 - 1,000 kg / h; WANROOE-TECH: 450 - 1,500 kg / h; Mefuta e meng e fihla ho 9,000 kg / h |

| Double Shaft | 30 - 100,000 | Harden TS letoto: 3,000 - 15,000 kg / h; ARJES COMPAKTOR 300: 6,000 - 100,000 kg / h; Mehlala e menyenyane: 30 - 135 kg / h |

Ho tšoarella ho itšetlehile ka thepa ea lehare le mohaho oa mochine. Litšepe tsa alloy le li-blades tse nang le carbide li tšoarella nako e telele ka li-plastiki tse thata. Phekolo ea mocheso le ho forging li etsa hore li-blade li be matla le ho hana ho apara.

Litlhoko tsa tlhokomelo li fapana ho ea ka mefuta. Li-shredders li hloka ho hlahlojoa khafetsa likarolo tsa mosebetsi o boima, ho chorisa lehare, le sistimi ea hydraulic. Li-granulator li hloka ho fepa ka hloko le ho hlahlojoa khafetsa lehare ho qoba jeme. Ho tsamaisana le tlhokomelo ho fokotsa nako ea ho theoha 'me ho boloka shredder ea polasetiki e sebetsa hantle.

Lisosa tse tloaelehileng tsa ho fokotsa nako li kenyelletsa:

- Mathata a ho fepa kapa ho thibela

- Ho tlala kapa ho jame

- Tekanyetso e fosahetseng ea mochini

- Ho hloka tlhokomelo ea kamehla

- Liphoso tsa opereishene

Ho fokotsa nako:

- Sebelisa mekhoa ea ho fepa ka boiketsetso

- Beakanya metjhini bakeng sa boholo bo nepahetseng ba tlhahiso

- Koetlisa basebetsi hantle

- Rulahanya tlhokomelo ea kamehla

Lethathamo la Potlako la ho Tšoaneleha bakeng sa Khetho ea Plastic Shredder

Pele u khetha shredder ea polasetiki, sheba lethathamong lena:

- Tseba lipolasetiki tsa hau: mofuta, boholo, le molumo oa letsatsi le letsatsi

- Lekola bokhoni ba mochini le ho feta

- Sheba matla a sebetsang hantle le tlhokomelo e bonolo

- Lekola likarolo tsa polokeho le litifikeiti

- Bapisa mefuta ea lintlha tsa tekheniki le maikutlo a basebelisi

- Etsa moralo oa koetliso ea basebetsi le tšehetso ea ka mor'a thekiso

- Nahana ka litšenyehelo tsohle, ho kenyelletsa tlhokomelo le tšebeliso ea matla

- Kopa li-demos kapa litšupiso ho tsoa ho basebelisi ba bang

Tlhokomeliso: Ho bua le setsebi kapa moetsi ho ka u thusa ho netefatsa hore na o lekana hantle hakae le litlhoko tsa hau.

Ho khetha se nepahetsengpolasitiki shredderho bolela ho hlahloba boitsebiso ba hao, ho hlahloba lethathamo, le ho kōpa thuso ea litsebi ha ho hlokahala. Basebelisi ba bangata ba tobane le ho phatloha kapa ho robeha ha lehare ha ba tlola licheke tsa ho lumellana:

| Hlahisa | Lebaka le Tloaelehileng |

|---|---|

| Jamming | Li-blades tse ngata, tse lerootho |

| Ho robeha ha Blade | Boleng bo bobe ba lehare, tšebeliso e mpe |

Lithupelo tsa kamehla le tlhahlobo ea polokeho li thusa ho thibela mathata ana.

LBH

Ke hangata hakae motho a lokelang ho leotsa li-blade tsa shredder?

Li-blades li hloka ho chorisoa libeke tse ling le tse ling tse 'maloa haeba li sebelisoa letsatsi le letsatsi. Li-blades tse lerootho li liehisa mosebetsi 'me li ka baka jeme.

A na shredder ea polasetiki e ka sebetsana le lisebelisoa tse tsoakiloeng?

Li-shredders tse ngata li ka sebetsa li-plastiki tse tsoakiloeng, empa tšepe kapa khalase li ka senya li-blades. Kamehla lokisa lintho tseo e seng tsa polasetiki pele.

Basebelisi ba lokela ho apara lisebelisoa life tsa tšireletso?

Basebelisi ba lokela ho roala liatlana, likhalase tsa tšireletso le ho sireletsa litsebe. Lintho tsena li thusa ho thibela likotsi tsa likotoana tsa polasetiki tse bohale kapa lerata le leholo.

Nako ea poso: Jul-30-2025