Ukukhetha elilungileUmshini Wokubumba Wepulasitikiibalulekile empumelelweni yephrojekthi kanye nokukhula kwebhizinisi esikhathini esizayo. Ukuhlolwa okuphelele kwezidingo eziqondene nephrojekthi kanye namakhono omshini kuqinisekisa ukutshalwa kwezimali okunesu. Cabangela okubalulekileUmshini Wokubumba Umjovoimakethe:

| Ingxenye Yemakethe | Ivelu ngo-2024 (USD) | Inani Elibikezelwe ngo-2030 (USD) | I-CAGR (2025-2030) |

|---|---|---|---|

| Umshini Wokubumba wePlastiki | 3.1829 billion | 4.0477 billion | 4.2% |

| Umshini Wokubumba Umjovo Wepulasitiki | 11.98 billion | 14.78 billion | 3.5% |

Imakethe yomshini wokubumba wepulasitiki ilindele aI-CAGR engu-5.2% ukusuka ku-2024 kuya ku-2032, ikhula isuka ku-USD 5.6 billion yaya ku-USD 8.9 billion. Lokhu kukhula kugqamisa isidingo sokukhetha imishini ehlakaniphile. Ukuqonda ukucaciswa okubalulekile kwezobuchwepheshe kuqinisekisa ukuhambisana nemigomo yokukhiqiza. IlungeloUmshini Wokubumba Umjovo Wepulasitikikubalulekile ekusebenzeni kahleI-Plastic Injection Molding. Amabhizinisi nawo acabangeleImishini Yokwenza kabusha Ipulasitikiukuhlela okuphelele.

Okuthathwayo Okubalulekile

- Khetha ilungelouhlobo lomshini wokubumba wepulasitiki. Imishini kagesi inikeza ukunemba futhi yonga amandla. Imishini ye-hydraulic inikeza amandla aqinile ezingxenyeni ezinkulu. Imishini yeHybrid ihlanganisa zombili izinzuzo.

- Qonda izindlela zokubopha. Amapulani amabili agcina isikhala futhi afake isikhunta esikhulu. Amasistimu okuguqula alungele ukukhiqizwa okusheshayo. Isistimu ngayinye inezinzuzo ezihlukile.

- Hlola imininingwane ebalulekile yobuchwepheshe. Isikhala se-tie-bar sibonisa isikhunta esikhulu kunazo zonke umshini ongasibamba. I-clamping force ivimba ipulasitiki ukuthi ingavuzi. Usayizi wepuleti uqinisekisa ukuthi isikhunta silingana kahle.

- Qondanisa usayizi womshini nezingxenye zakho. I-stroke yokuvula nokukhanya kwemini kufanele kube kukhulu ngokwanele. Lokhu kusiza izingxenye ziphume kalula. Umshini wosayizi ongalungile ungabangela izinkinga nokumosha.

- Khetha umshini ofanelana nezidingo zephrojekthi yakho. Umshini ongcono kakhulu usiza ngomsebenzi wamanje. Iphinde isekele ukukhula kwesikhathi esizayo. Lokhu kukhetha kuholela empumelelweni yesikhathi eside.

Ukuqonda Izinhlobo Eziyisisekelo Zomshini Wokubumba Wepulasitiki

Ukukhetha umshini wokubumba wepulasitiki ofanele kuqala ngokwazi izinhlobo eziyisisekelo. Umshini ngamunye unikeza izinzuzo ezihlukile zezidingo ezahlukene zokukhiqiza. Ake sihlole izigaba eziyinhloko.

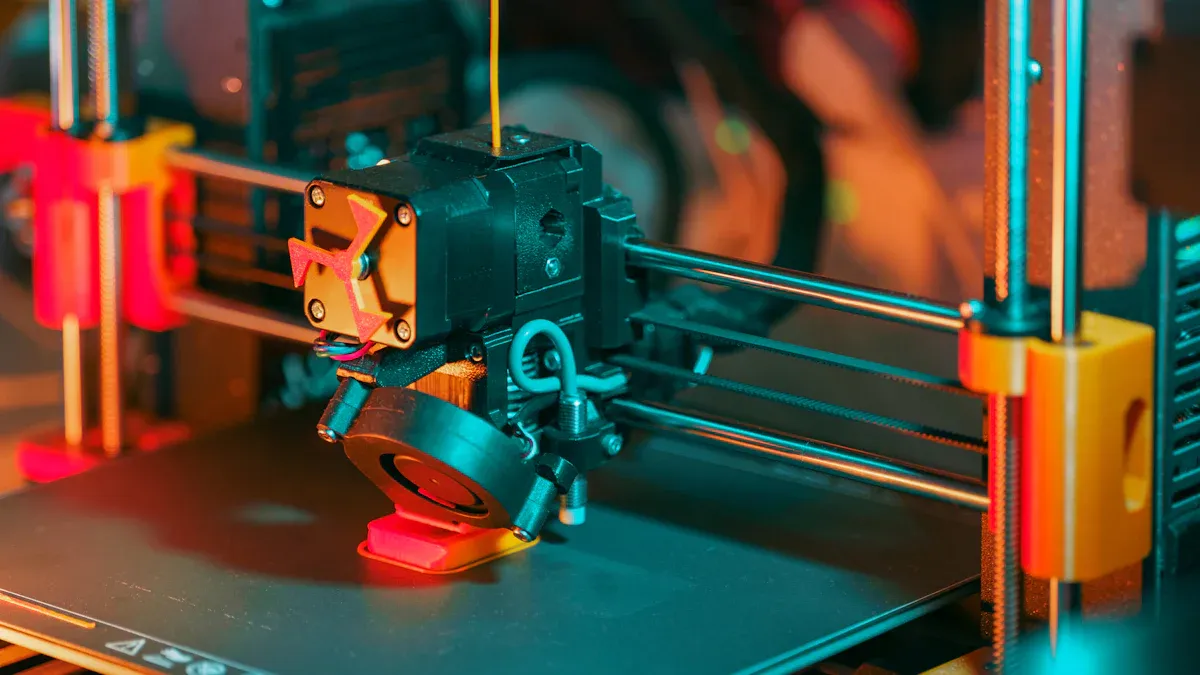

Imishini Yokubumba Yepulasitiki Kagesi

Imishini kagesi yokubumba ipulasitiki ingompetha bokunemba nokusebenza kahle. Bonasebenzisa ama-servo motors kagesi kukho konke ukunyakaza. Lo mklamo usho ukuthi basebenzisa amandla kuphela uma besebenza ngenkuthalo, okuholela ekongeni amandla okubalulekile. Isibonelo, le mishini ingakwaziyonga amandla angama-50% ngaphezulu uma kuqhathaniswa nezinhlelo zamahydraulic ezindala kanye no-20-30% ngaphezu kwama-servo-hydraulics. Izinhlelo zabo zokulawula idijithali zinikeza ukunemba okumangalisayo, ithola ukuphindaphinda kokuma okungu-±0.01 mm. Lokhu kunemba kuzenza zilungele izingxenye ezincane, eziyinkimbinkimbi kanye nezinhlelo zokusebenza ezidinga ukungaguquguquki okuphezulu. Cabanga ngalokhuImishini yezokwelapha, izingxenye ze-elekthronikhi, noma amalensi okubona. Le mishinizihamba phambili ezindaweni ezihlanzekile ngoba azisebenzisi uketshezi olunamanzi, ukuvimbela ukungcola.

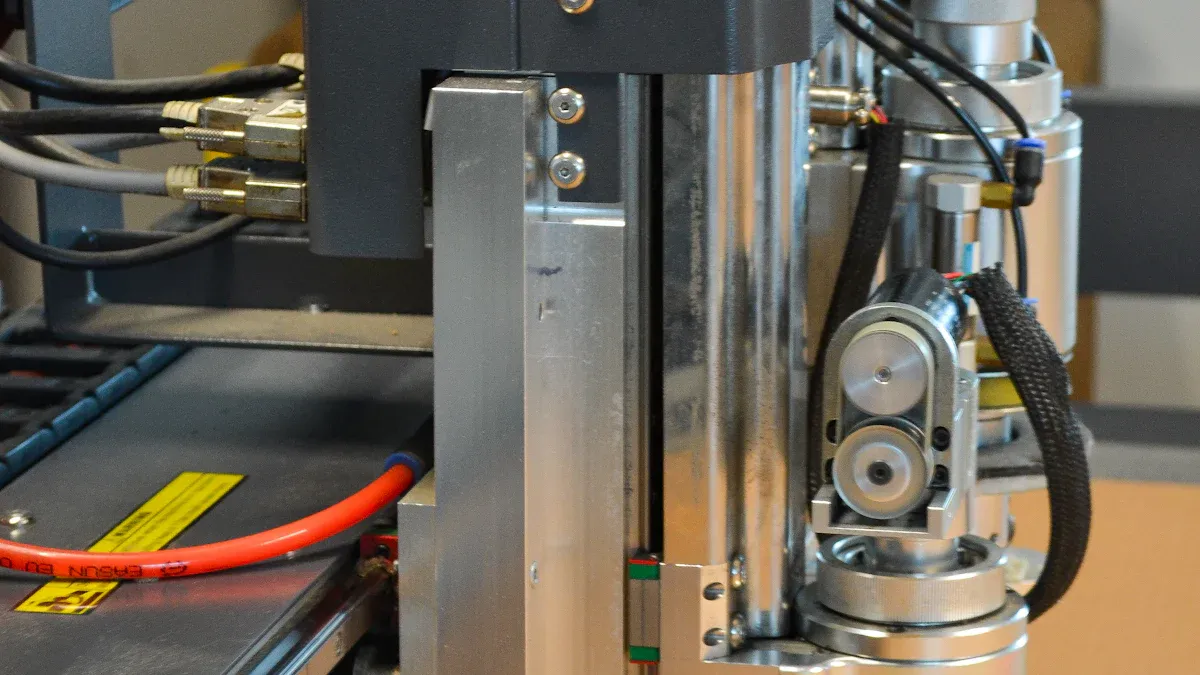

Imishini yokubumba ye-Hydraulic Plastic

Imishini yokubumba ipulasitiki eyi-Hydraulic iyaziwa ngezaboamandla aqinile nokuqina. Basebenzisa uketshezi olunamanzi ukuze benze amandla, ikakhulukazi ekubambeni. Le mishini ihle kakhulu ekusetshenzisweni kwe-high-tonnage kanye nokubumba izingxenye ezinkulu, ezinzima ezinemininingwane eyinkimbinkimbi. Bangakwazi ukuzikhandlaamandla amakhulu okubamba, okubenza bafanelekele izinto ezifanaobhampa bezimoto noma isikhunta esikhulu, esinezingcezu eziningi. Nakuba zingase zihambe kancane futhiukunemba kancane kunemishini kagesi ngenxa yamandla oketshezi, amandla abo nokuguquguquka ekuphatheni izinto ezihlukahlukene kubenza babe ukukhetha okungabizi kakhuluizingxenye ezinkuluezimbonini ezifanaukukhiqizwa kwezimoto nezimboni.

Imishini Yokubumba Yepulasitiki Ehlanganisiwe

Imishini yokubumba yepulasitiki eyi-Hybrid ihlanganisa izici ezinhle kakhulu zombili izinhlelo zikagesi kanye ne-hydraulic. Bonahlanganisa ukunemba kukagesi namandla we-hydraulic. Lokhu kusho ukuthi banikeza amandla okusebenza kahle kanye nokunemba kwemishini kagesi, kanye namandla okubamba aphezulu kanye nokuqina kwalawo asebenza ngamanzi. Amamodeli we-Hybrid ahlukahlukene kakhulu. Bangakwazi ukugoqa nge-hydraulic ngomjovo kagesi, noma ngokuphambene nalokho. Lokhu kuzivumelanisa nezimo kuzivumela ukuba zikwazi ukusingatha uhla olubanzi lwemisebenzi yokubumba, kusukela ezingxenyeni eziqondile eziqondile kuye kwezinkulu, izingxenye eziyinkimbinkimbi. Isibonelo, zidumile ku-imboni yezimoto yamaphaneli edeshibhodi namabhampa, nasemikhakheni yezokwelapha neyokupakishangokulinganisela kokusebenza nokusebenza kahle. Le mishini ingakwazi futhiphatha imisebenzi ye-hydraulic efana nokudonsa okuyisisekelo ngaphandle kokudinga iyunithi ehlukile, engcolile ye-hydraulic, okuyinhlanganisela enkulu yezindawo ezihlanzekile.

Ukuhlola Izindlela Zokubamba Zemishini Yokubumba Yepulasitiki

Ukukhetha indlela yokubopha efanele kuyisinqumo esikhulu kunoma yimuphi umshini wokubumba wepulasitiki. Kuthinta ngokuqondile ukusebenza kahle kokukhiqiza kanye nezinhlobo zezingxenye ongayenza. Izinhlelo ze-Quick Mold Change (QMC), ngokwesibonelo, zibalulekile ekunciphiseni izikhathi zokushintsha isikhunta. Lezi zinhlelo zingakwazinciphisa isikhathi sokuphumula kusuka emahoreni kuya kumaminithi nje. Nabo futhiqinisa ukuphepha ngokususa isidingo sokuthi abasebenzi banamathisele ama-clamp ngaphakathi emshinini. Lokhu kushoumsebenzi wezandla omncane kanye nezingozi ezimbalwa.

Amasistimu Wokubamba Amapulangwe Amabili

Ama-clamping amapulani amabili ayaziwa ngomklamo wawo ohlangene. Basebenzisa amapuleti amabili ukuze bafake amandla esikhunjeni. Lo mklamoiqeda isidingo se-clamping platen yangemuva, ukunikeza umshini aizinyawo ezincane kakhulu. Lokhu kuhle kubakhiqizi abanendawo elinganiselwe yaphansi. Lezi zinhlelo nazo zinikezaukuguquguquka kwesikhunta esikhulu. Banikeza aIbanga le-tie bar evulekile kanye nokuvulwa kwasemini. Lokhu kuvumela amathuluzi e-multi-cavity kanye namajiyometri ezingxenye eziyinkimbinkimbi. Ungakwazi ukubumba izingxenye ezinkulu noma izingxenye eziningi ezincane ngesikhathi esisodwa. Ama-plan plate amabili aphinde anciphise ukuchezuka kwesikhunta futhi anikeze izikhathi zomjikelezo osheshayo.Baziwa futhi ngokonga kwabo amandla.

Guqula ama-Clamping Systems

Amasistimu okubamba ama-Toggle asebenzisa ama-lever emishini nokuxhumana ukuze enze amandla okubamba. Zinhle kakhulu ekubumbeni umjovo wesivinini esikhulu.Iyunithi yokuguqula ihlanganisa isixhumanisi sokuguqula, i-crosshead, nedivayisi yokushayela. Lokhu kusetha kuyakuvumelaukuxoxisana ngokushesha nokungahlangani, okubenza baphelele ekukhiqizeni okuphindaphindiwe. I-Toggle clamp inikeza amandla okubamba angaguquki. Aklanyelwe “ukubamba ngokweqile,” avaleleke endaweni ngaphandle kokudinga ukucindezela kwe-hydraulic okuqhubekayo. Lokhu kusiza ukugcina amandla ngisho nezinkinga zokubekezelela ukukhiqiza noma ukudlidliza. Lolu hleloiqala ngokugudluza okusheshayo, okukhulu namandla aphansi, bese iqeda ngamandla ahamba kancane, aphezulu.

Nokho,amasistimu okuguqula endabuko avame ukuba nonyawo olukhulu ngenxa yezingxenye zawo eziya ngaphakathi. Lokhu kungenza izinguquko zesikhunta zibe lula. Ngakolunye uhlangothi, amasistimu okuguqula angaphandle, anikeza idizayini yokonga isikhala kanye nokufinyelela isikhunta okulula. Ukuze ulungise, i-toggle clamps idingaukuhlolwa okuvamile kokuguga nokulimala. Kumelezihlanze njalo futhi usebenzise okokugcoba ezingxenyeni ezihambayo. Ukushintsha izingxenye ezigugile ngokushesha kusiza ukugcina ukusebenza kahle nokuphepha kwazo. Yaboukuqina kuncike kwikhwalithi yezinto zokwakha nokuthi uhlelo lokuxhuma lwakhiwe kanjani.

Imininingwane Ebalulekile Yezobuchwepheshe Yokukhetha Umshini Wokubumba Wepulasitiki

Ukukhetha umshini wokubumba wepulasitiki ofanele kusho ukubhekisisa imininingwane yawo yobuchwepheshe. Lezi zicaciso zikutshela ukuthi umshini ongakwenza futhi uma ulingana nephrojekthi yakho. Ukuziqonda kukusiza ukuthi wenze ukutshalwa kwezimali okuhlakaniphile.

I-Tie-Bar Isikhala Sendawo yokuhlala yeMold

Ukuhlukaniswa kwe-tie-bar kuyisilinganiso esibalulekile. Ikutshela ubukhulu bobukhulu besikhunta umshini ongasibamba. Cabanga ngemigoqo yokubopha njengezinsika eziphakamise ukwakheka komshini. Isikhunta kufanele singene phakathi kwalezi zinsika. Uma isikhunta sikhulu kakhulu isikhala phakathi kwama-tie-bar, ngeke nje sisebenze nalowo mshini.Imishini ejwayelekile ivame ukuphatha isikhunta kufika ku-4 izinyawo ngamamitha angu-4. Kodwa-ke, isikhunta esikhudlwana sidinga imishini ekhethekile enezikhala ezibanzi ze-tie-bar.

Nazi ezinye iziqondiso zokufaka isikhunta:

- Isikhunta Ubukhulu:

- Ububanzi besikhunta kufanele bube ngaphansi kwengxenye yesikhala sebha ewuthayi evundlile.

- Ubude besikhunta kufanele bube ngaphansi kwengxenye yesikhala sebha eqondile eqondile.

- Ukusula Ukuphepha:

- Ezikhunjini ezincane, vumela okungenani isikhala esingu-25mm ohlangothini ngalunye.

- Ezikhunjini ezinkulu, vumela okungenani isikhala esingu-50mm ohlangothini ngalunye.

- Ukuqina Kwesikhunta: Ukujiya kwesikhunta kufanele kulingane phakathi kobubanzi obuncane nobukhulu bobukhulu bomshini.

Abaqambi besikhunta baphinde bacabangele la maphuzu:

- Ububanzi besikhunta noma ukuphakama kufanele okungenani kube yi-intshi engu-1/2 (cishe u-1.27 cm) ububanzi kunosayizi womgodi wamandla.

- Ukujiya kwesikhunta kufanele kuphindwe izikhathi ezingu-2.5 ukujula komgodi ukuze kuqinisekiswe ukumbozeka okugcwele uma kuvaliwe.

I-Tonnage Range kanye Nosayizi Wengxenye

I-clamping force, noma i-tonnage, ingakanani amandla asetshenziswa umshini ukugcina amahhafu esikhunta evaliwe ngesikhathi sokujova. Lokhu kuvimbela upulasitiki ukuthi ungaphumi, abantu abawubiza ngokuthi “flashing.”Ibanga lamandla okubamba imishini efana ne-Topstar yi-90T-2800T. Uyibala ngokusekelwe endaweni engaphezulu ehlongoziwe yengxenye kanye nogqinsi lwezinto zepulasitiki.

Nansi indlela abantu ababala ngayo amandla okubamba adingekayo:

- Dwebela ushiye isithupha: Le ndlela ilinganisela amathani kusetshenziswa indawo yengxenye, uhlobo lwepulasitiki, ukujiya kwayo, kanye'i-clamp factor' (imvamisa engu-2 ukuya ku-8, noma isilinganiso esingu-5). Nokho, lokhu kungase kube okungalungile. Amandla amancane kakhulu adala izinkinga zekhwalithi, futhi kakhulu kwandisa izindleko zesikhunta.

- Isikhunta Flow Simulations: Lezi zinhlelo zekhompiyutha zibikezela inani eliqondile lamathoni adingekayo phakathi nesigaba sokuklama.Isibonelo, ukulingisa kwengxenye eyodwa kubikezele amathani angama-509.

- Ukubala kwetiyetha: Ungasebenzisa ifomula:I-clamping force (T) = I-clamping force engaguquki (Kp) ✕ Indawo eklanyelwe (S in cm²). Isibonelo, uma ipulasitiki ye-PE inenani le-Kp elingu-0.32 futhi indawo ehlongozwayo ingu-410 cm², amandla okubamba angaba ngu-0.32 ✕ 410 = 131.2 T.

- Ukuhlaziywa Kokugcwalisa Isikhunta: Lena indlela enembe kakhudlwana. Inquma isici se-tonnage. Ukwengeza isici sokuphepha esingamaphesenti angu-15 kule miphumela kunikeza amandla okubamba anembe kakhulu futhi kuvimbela ukukhanya. Lokhu kuhlaziywa kubonisa nokuthi ezinye izici, njengenani lamasango (amasango amaningi asho amathani aphansi) nobude bokugeleza (ukugeleza okude kudinga amathani aphezulu), kuthinta inqubo.

Kwenzekani uma amandla okubamba engalungile?

| Isici | Amandla Okucindezela Anganele | Amandla Okuqinisa Kakhulu |

|---|---|---|

| Ikhwalithi Yengxenye | I-Flash, ukungalingani kahle, amashothi amafushane, ubukhulu obungalungile, imigqa yokushisela ebuthaka | Akukho flash, kodwa ukupakisha ngokweqile kubangela ukucindezeleka kwangaphakathi noma izimpawu zokucwila; ukuchezuka kwesikhunta, ukunamathela kwengxenye, noma amabala angaphezulu |

| Isikhunta & Umthelela Womshini | Ukuguga kwesikhunta emigqeni yokuhlukanisa kusukela ekukhanyeni okuphindaphindiwe; i-clamping engalingani ilimaza izikhonkwane/izihlahla | Ukulimala kwesikhunta ngaphambi kwesikhathi (imifantu, ukugqokwa kwezikhonkwane/amapuleti); amapuleti akhubazekile, ukufakwa okuqhekekile |

| Izindleko Zokukhiqiza | Okuningi okulahliwe, ukusebenza kabusha, nesikhathi sokuphumula sokuhlanza isikhunta | Izindleko zokulungisa eziphakeme kanye nengozi yokuphuka kwemishini |

| Ukusebenza Kwamandla | Ukumosha amandla okuncane, kodwa amanani e-scrap aphezulu | Ukusetshenziswa kwamandla okungadingekile kusuka ekulayisheni ngokweqile komshini |

| Isikhathi Somjikelezo | Imijikelezo emide yokulungisa amaphutha (njengokususa iflash) | Akukho ngcono esikhathini somjikelezo; ukubambezeleka okungaba khona ekulimaleni kwesikhunta |

I-clamping tonnage enganele iguga isikhunta ngokushesha. I-clamping engalingani ingalimaza izikhonkwane zomholi namahlahla. Lokhu kusho isikhathi esiningi sokuphumula kanye nezindleko zokunakekela eziphezulu. I-clamping tonnage eyeqile ingabangela izimpawu zokusha ezingxenyeni ezithile ngoba umoya awukwazi ukuphuma. Iphinde ikhulise ukucindezela kwesikhunta sangaphakathi, okwenza inqubo yomjovo ingahambisani.

Usayizi we-Platen kanye nesakhiwo se-Mold Fit

Usayizi wepuleti kanye nesakhiwo kufana nomlindisango wokuhambisana kwesikhunta.Isikhunta kufanele singene ngaphakathi kwamapuleti omshini. Ububanzi nobude bawo, okuhlanganisa namapuleti okufaka, kufanele kube kuncane kunesikhala phakathi kwezinsimbi zothayi zomshini. Uma isikhunta sibanzi kakhulu, ngeke silingane.Isikhunta esiklanyelwe umshini omkhulu (ofana namathani angu-500) asikwazi ukulingana ngokomzimba noma ukusebenza kokuncane (okufana namathani angama-200).

Cabanga ukuthi ukwakheka kwengxenye kusithinta kanjani isakhiwo sesikhunta:

- Ububanzi bentamo ye-preform enkulu budinga isikhala esengeziwe phakathi kwama-cavities epuleti lesikhunta. Lokhu kwandisa usayizi wesisekelo sesikhunta.

- Ngosayizi wepuleti ongashintshi, intamo engu-28mm PCO1881 (evamile emabhodleleni amanzi) ingase ivumele iphimbo elingu-50mm. Lokhu kungasho isakhiwo esingu-8×9 sesikhunta se-72-cavity.

- Nokho, intamo ye-Bericap engu-38mm (yejusi) ingase idinge iphimbo elingu-70mm ngobubanzi bayo obukhulu. Lokhu kunganciphisa isakhiwo sibe ngu-6×6, okuholela ekubunjweni kwe-36-cavity kuphela endaweni efanayo ebonakalayo.

Lokhu kubonisa ukuthi ubukhulu bentamo ebanzi buphoqa isisekelo sesikhunta esikhudlwana senani elifanayo lemigodi. Lokhu ekugcineni kusho inani eliphansi eliphezulu lemigodi yomshini wokubumba wepulasitiki onikeziwe.

Ukufana kwe-plate kanye nokuqina nakho kubaluleke kakhulu. Baqinisekisa ikhwalithi yengxenye engaguquki.Amasistimu okulinganisa ahlakaniphile kanye nokulawula okuqondile kwe-platenukusiza ukugcina amapuleti flat ngokuphelele futhi parallel. Lokhu kuvimbela ukukhubazeka ekucindezelweni kwe-clamping okungalingani. Ukugaya okungaphezulu kudala indawo eyisicaba, ehambisanayo kumapuleti esisekelo sesikhunta ngaphakathi kokubekezelelana okuqinile, ngokuvamile0.005mm ngo-100mm wobude.

Ukuvula i-Stroke kanye ne-Daylight for Ejection Efficiency

I-stroke yokuvula nokukhanya kwasemini kuyizilinganiso ezibalulekile kunoma yimuphi umshini wokubumba wepulasitiki. Zithinta ngqo ukuthi ingxenye ebunjiwe iphuma kalula futhi ngempumelelo kanjani esikhunjeni. I-stroke yokuvula ibhekisela ebangeni elihanjwa yi- platen ehambayo. Ukukhanya kwasemini indawo enkulu evulekile phakathi kwamahhafu esikhunta lapho umshini usuvuleke ngokuphelele. Kokubili kufanele kube kukhulu ngokwanele ukuze ingxenye isuse isikhunta ngaphandle kwezinkinga.

Uma indawo evulekile, noma ukukhanya kwemini, phakathi kwama-mold halves akwanele ukuze ingxenye ikhishwe kahle, kudala izinkinga eziningana. Abakhiqizi bangase badinge umshini omkhulu, obiza kakhulu one-stroke enkulu yokuvula. Lokhu kungaholela ekungasebenzini kahle okuhlukahlukene:

- Ukonakala kwezinto kwenzeka ngoba ipulasitiki ihlala emgqonyeni isikhathi eside.

- Ukugqokwa kwesikhunta kuyanda ngenxa yengcindezi ephezulu yokubopha.

- Ukukhanyisa kwezakhi kwenzeka lapho ama-platens ezamazama ngoba isikhunta esincane sisemshinini omkhulu.

- Imiphumela yokushayisana kwesibhamu lapho iyunithi yomjovo enkulu iletha ivolumu encane yokushutha.

- Izikhathi zomjikelezo ziyakhuphuka ngoba imishini emikhulu ivamise ukusebenza kancane.

Ukushaywa kwe-ejection nakho kubaluleke kakhulu. Leli yibanga lapho izikhonkwane ze-ejector ziphusha ingxenye iphuma esikhunjeni. I-stroke yokukhipha edingekayo kufanele ilingane namakhono omshini. Izingxenye ezinokujula okukhulu kokudonsa, njengamashubhu noma iziqukathi ezijulile, zidinga imivimbo emide yokukhipha ukuze zikhishwe kahle. Ubude besilinda ejector bunquma ubukhulu obutholakalayo be-ejection stroke. Abaklami besikhunta bahlale beqinisekisa lokhu uma benokungabaza ngokwanela kwayo. Baqinisekisa ukuthi umshini ungaphusha ingxenye ngokuphelele futhi ngokuhlanzekile.

Ukukhetha Umshini Wokubumba Wepulasitiki kuyinqubo eqhubekayo. Ihambisana nezidingo zephrojekthi nezicaciso zomshini. Umshini ongcono kakhulu uhambisana nezidingo zamanje zokukhiqiza futhi usekela ukunwetshwa okuzayo. Ukutshalwa kwezimali kwamasu emshinini ofanele kubaluleke kakhulu ukuze kube nempumelelo yokusebenza kwesikhathi eside kanye nenzuzo. Lokhu kuhlanganisaukwamukela izimiso zokukhiqiza ezithambile ukuze kunqanyulwe imfucuza kanye nokusebenzisa ukukhiqizwa kwedijithali kokuqapha kwesikhathi sangempela. Izinkampani ziphinde zihlukanise isisekelo samakhasimende azo futhi zitshale imali kubasebenzi abanamakhono. Lezi zinyathelo ziqinisekisa ukukhula nokusebenza kahle okusimeme.

FAQ

Uyini umehluko omkhulu phakathi kwemishini yokubumba yepulasitiki kagesi neye-hydraulic?

Imishini kagesi inikeza ukunemba nokonga amandla. Basebenzisa ama-servo motors kukho konke ukunyakaza. Imishini ye-hydraulic inikeza amandla aqinile ezingxenyeni ezinkulu. Basebenzisa umfutho we-fluid. Imishini ye-Hybrid ihlanganisa zombili izinzuzo, inikeza ukuguquguquka.

Kungani ukuhlukaniswa kwe-tie-bar kubalulekile ekukhetheni umshini?

Isikhala se-tie-bar sinquma ubukhulu bosayizi wesikhunta umshini ongawubamba. Isikhunta kufanele singene phakathi kwalezi zinsika. Isikhala esingalungile sisho ukuthi isikhunta ngeke sisebenze nalowo mshini. Kuyisilinganiso esibalulekile sokuhlala kwesikhunta.

I-clamping force ithinta kanjani ikhwalithi yezingxenye ezibunjiwe?

I-clamping force igcina izingxenye zesikhunta zivaliwe ngesikhathi sokujova. Amandla amancane kakhulu adala "ukukhanya" noma ingxenye yekhwalithi ephansi. Amandla amaningi angalimaza isikhunta noma abangele ukonakala kwezingxenye ezifana nezimpawu zokucwila. I-clamping efanele iqinisekisa imiphumela engaguquki.

Yiziphi izinzuzo zesistimu yokubopha amapuleti amabili?

Amasistimu angamapulangwe amabili ahlinzeka ngomklamo ohlangene, osindisa indawo yaphansi. Bahlinzeka ngebanga elibanzi le-tie-bar kanye nokuvulwa kwasemini kwesikhunta esikhulu. Lezi zinhlelo zinciphisa nokuchezuka kwesikhunta futhi zingaholela ezikhathini zomjikelezo osheshayo.

Ngabe ibhizinisi kufanele licabangele nini umshini wokubumba wepulasitiki oyi-hybrid?

Amabhizinisi kufanele acabangele imishini eyingxube lapho edinga kokubili ukunemba namandla. Le mishini ihlanganisa ukunemba kukagesi namandla we-hydraulic. Ziyakwazi ukwenza izinto ezihlukahlukene, zisingatha kahle izinhlobonhlobo zemisebenzi yokubumba.

Isikhathi sokuthumela: Oct-14-2025