Kusankha mulingo woyenera kwambiriMakina Omangira Pulasitikindizofunikira kwambiri kuti projekiti ikhale yopambana komanso kukula kwa bizinesi yamtsogolo. Kuwunika mozama za zosowa zenizeni za polojekiti komanso kuthekera kwa makina kumatsimikizira kusungitsa ndalama mwanzeru. Taganizirani zazikuluMakina Opangira Majekesenimsika:

| Gawo la Msika | Mtengo wa 2024 (USD) | Mtengo Woyembekezeredwa pofika 2030 (USD) | CAGR (2025-2030) |

|---|---|---|---|

| Makina opangira pulasitiki | 3.1829 biliyoni | 4.0477 biliyoni | 4.2% |

| Makina opangira jekeseni apulasitiki | 11.98 biliyoni | 14.78 biliyoni | 3.5% |

Msika wamakina opangira pulasitiki ukuyembekezera a5.2% CAGR kuyambira 2024 mpaka 2032, ikukula kuchokera $ 5.6 biliyoni kufika $ 8.9 biliyoni. Kukula uku kukuwonetsa kufunikira kosankha zida zanzeru. Kumvetsetsa zofunikira zaukadaulo kumatsimikizira kulumikizana ndi zolinga zopanga. UfuluJekeseni Woumba Makina a Pulasitikindizofunikira kuti zithekePulasitiki jakisoni Kumangira. Mabizinesi amaganiziransoMakina Ogwiritsa Ntchito Pulasitikipakukonzekera kwathunthu.

Zofunika Kwambiri

- Sankhani choyenerapulasitiki akamaumba makina mtundu. Makina amagetsi amapereka molondola komanso kusunga mphamvu. Makina a Hydraulic amapereka mphamvu zolimba pazigawo zazikulu. Makina osakanizidwa amaphatikiza zabwino zonse ziwiri.

- Kumvetsetsa njira zochepetsera. Machitidwe a matabwa awiri amasunga malo ndikukhala ndi nkhungu zazikulu. Makina osinthira ndi abwino kupanga mwachangu. Dongosolo lililonse lili ndi mapindu osiyanasiyana.

- Onani zambiri zaukadaulo. Kutalikirana kwa mipiringidzo kumawonetsa nkhungu yayikulu kwambiri yomwe makina angagwire. Mphamvu yothina imayimitsa pulasitiki kuti isatayike. Kukula kwa mbale kumatsimikizira kuti nkhungu ikwanira bwino.

- Fananizani kukula kwa makina ndi magawo anu. Kuwala koyambira ndi masana kuyenera kukhala kwakukulu kokwanira. Izi zimathandiza kuti ziwalo zituluke mosavuta. Kukula kolakwika kwa makina kumatha kuyambitsa zovuta komanso kuwononga.

- Sankhani makina oyenerera polojekiti yanu. Makina abwino kwambiri amathandiza ndi ntchito zamakono. Zimathandiziranso kukula kwamtsogolo. Kusankha kumeneku kumabweretsa kupambana kwa nthawi yaitali.

Kumvetsetsa Mitundu Yoyambira Yamakina a Pulasitiki

Kusankha makina opangira pulasitiki oyenera kumayamba ndi kudziwa mitundu yoyambira. Makina aliwonse amapereka phindu lapadera pazosowa zosiyanasiyana zopanga. Tiyeni tifufuze magulu akuluakulu.

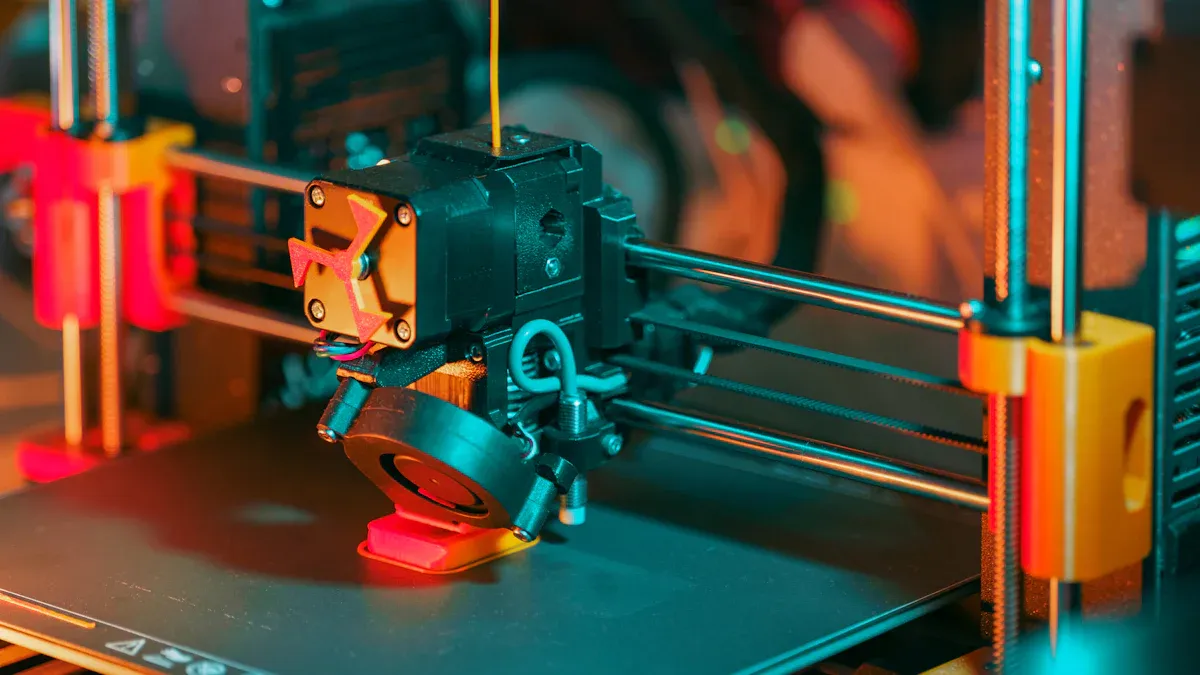

Makina Omangira Pulasitiki Amagetsi

Makina opangira pulasitiki amagetsi ndi akatswiri olondola komanso ochita bwino. Iwogwiritsani ntchito ma servo motors amagetsi pamayendedwe onse. Mapangidwe awa amatanthauza kuti amagwiritsa ntchito mphamvu pokhapokha akugwira ntchito mwakhama, zomwe zimabweretsa kupulumutsa mphamvu kwambiri. Mwachitsanzo, makina awa akhozasungani mphamvu zochulukirapo 50% poyerekeza ndi makina akale a hydraulic ndi 20-30% kuposa ma servo-hydraulics. Makina awo owongolera digito amapereka kulondola kodabwitsa, kukwaniritsa malo obwerezabwereza a ± 0.01 mm. Kulondola uku kumawapangitsa kukhala abwino pazigawo zing'onozing'ono, zovuta komanso ntchito zomwe zimafunikira kusasinthasintha kwakukulu. Ganizilani zazipangizo zachipatala, zipangizo zamagetsi, kapena magalasi a kuwala. Makina awaamapambana m'malo oyeretsa chifukwa sagwiritsa ntchito madzi amadzimadzi, kupewa kuipitsidwa.

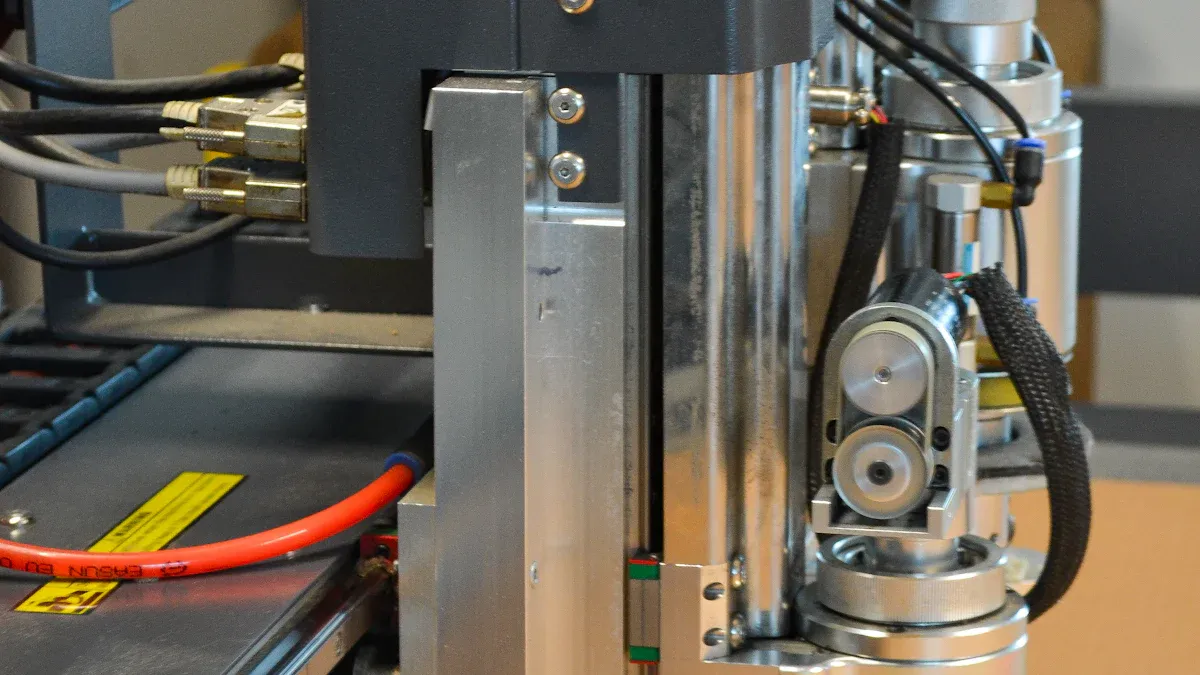

Makina Opangira Mapulasitiki a Hydraulic

Makina opangira pulasitiki a Hydraulic amadziwika ndi awomphamvu yamphamvu ndi kukhazikika. Amagwiritsa ntchito ma hydraulic fluid kuti apange mphamvu, makamaka pa clamping. Makinawa ndi abwino kwambiri pakugwiritsa ntchito matani apamwamba komanso kuumba magawo akulu, olemetsa okhala ndi zovuta zambiri. Akhoza kuyesetsachachikulu clamping mphamvu, kuwapanga kukhala abwino kwa zinthu ngatimabampa agalimoto kapena zazikulu, zoumba zamitundu yambiri. Ngakhale iwo akhoza kukhala pang'onopang'ono ndizosalondola kwambiri kuposa makina amagetsi chifukwa cha mphamvu zamadzimadzi, mphamvu zawo ndi kusinthasintha pogwiritsira ntchito zipangizo zosiyanasiyana zimawapangitsa kukhala okwera mtengozigawo zikuluzikulum'mafakitale ngatikupanga magalimoto ndi mafakitale.

Makina Opangira Mapulasitiki Ophatikiza

Makina opangira pulasitiki ophatikizana amaphatikiza zinthu zabwino kwambiri zamakina amagetsi ndi ma hydraulic. Iwokuphatikiza kulondola kwamagetsi ndi mphamvu ya hydraulic. Izi zikutanthauza kuti amapereka mphamvu zogwiritsira ntchito mphamvu komanso kulondola kwa makina amagetsi, pamodzi ndi mphamvu yokhotakhota komanso kulimba kwa ma hydraulic. Mitundu ya Hybrid ndi yosunthika kwambiri. Atha kukhala ndi hydraulic clamping ndi jakisoni wamagetsi, kapena mosinthanitsa. Kusinthasintha kumeneku kumawathandiza kugwira ntchito zosiyanasiyana zoumba, kuchokera ku tizigawo tating'ono ting'ono mpaka zazikulu, zovuta. Mwachitsanzo, iwo ndi otchuka mumakampani opanga magalimoto pamapanelo a dashboard ndi mabampa, komanso m'magawo azachipatala ndi zonyamulachifukwa cha momwe amagwirira ntchito komanso kuchita bwino. Makina awa akhozansogwirani ntchito zama hydraulic ngati zokoka pachimake popanda kufunikira kosiyana, kosokoneza ma hydraulic unit, yomwe ndi kuphatikiza kwakukulu kwa malo oyera.

Kuwunika Njira Zothirira Pamakina Omangira Pulasitiki

Kusankha njira yoyenera yolumikizira ndi chisankho chachikulu pamakina aliwonse opangira pulasitiki. Zimakhudza mwachindunji kupanga bwino komanso mitundu ya magawo omwe mungapange. Makina a Quick Mold Change (QMC), mwachitsanzo, ndi ofunikira pakuchepetsa nthawi yosintha nkhungu. Machitidwe awa akhozakuchepetsa nthawi yopuma kuyambira maola mpaka mphindi zochepa. Iwonsoonjezerani chitetezo pochotsa kufunikira kwa ogwira ntchito kuti azitha kumangirira ma clamp mkati mwa makina. Izi zikutanthauzantchito zochepa zamanja komanso zoopsa zochepa.

Ma Platen Clamping Systems

Makina okhomerera amitundu iwiri amadziwika ndi mapangidwe ake ophatikizika. Amagwiritsa ntchito mbale ziwiri kuti agwiritse ntchito mphamvu pa nkhungu. Mapangidwe awakumathetsa kufunika kwa kumbuyo clamping platen, kupereka makina achopondapo chaching'ono kwambiri. Izi ndi zabwino kwa opanga omwe ali ndi malo ochepa pansi. Machitidwewa amaperekansokusinthasintha kwa nkhungu zazikulu. Iwo amapereka amtunda wowolowa manja komanso kutseguka kwa masana. Izi zimalola zida zamitundu yambiri komanso magawo ovuta a geometri. Mutha kuumba zigawo zazikulu kapena zing'onozing'ono zambiri nthawi imodzi. Machitidwe a mbale ziwiri amachepetsanso kupotoza kwa nkhungu ndipo amapereka nthawi yozungulira mofulumira.Amadziwikanso chifukwa chopulumutsa mphamvu.

Sinthani Ma Clamping Systems

Makina osinthira ma clamping amagwiritsa ntchito ma levers amakina ndi maulalo kuti apange mphamvu yoletsa. Ndiabwino kwambiri popanga jakisoni wothamanga kwambiri.Chosinthira chimakhala ndi ulalo wosinthira, cholumikizira, ndi chipangizo choyendetsa. Kukonzekera uku kumalolakusamvana mwachangu komanso kusamvana, kuwapanga kukhala abwino kupanga mobwerezabwereza. Ma toggle clamps amapereka mphamvu yolumikizira mosasinthasintha. Amapangidwa kuti "achepetse-kuchepetsa," kutsekeka m'malo osafunikira kuthamanga kwa hydraulic mosalekeza. Izi zimathandiza kusunga mphamvu ngakhale pakupanga kulekerera kapena kugwedezeka. Dongosolo iliimayamba ndi kuthamanga, kusamuka kwakukulu ndi mphamvu yochepa, kenako imamaliza ndi pang'onopang'ono, mphamvu yaikulu.

Komabe,makina osinthira achikhalidwe nthawi zambiri amakhala ndi chopondapo chachikulu chifukwa cha magawo awo osunthira mkati. Izi zingapangitse kusintha kwa nkhungu kukhala kosavuta. Makina osinthira akunja, kumbali ina, amapereka mawonekedwe opulumutsa malo komanso mosavuta nkhungu. Pofuna kukonza, ma toggle clamps amafunikirakuyang'anitsitsa nthawi zonse kuti awonongeke ndi kuwonongeka. Muyeneraziyeretseni pafupipafupi ndikuthira mafuta pazigawo zosuntha. Kusintha zinthu zomwe zidatha mwachangu kumathandizira kuti zikhale zogwira mtima komanso zotetezeka. Zawokukhazikika kumadalira mtundu wa zida ndi momwe njira yolumikizirana imapangidwira.

Zofunikira Zaukadaulo Zakusankha Makina Opangira Pulasitiki

Kusankha makina opangira pulasitiki oyenera kumatanthauza kuyang'anitsitsa zaukadaulo wake. Izi zimakuuzani zomwe makinawo angachite komanso ngati akugwirizana ndi polojekiti yanu. Kuwamvetsetsa kumakuthandizani kupanga ndalama mwanzeru.

Tie-Bar Spacing kwa Mold Accommodation

Kutalikirana kwa mipiringidzo ndi gawo lofunikira. Imakuuzani kukula kwakukulu kwa nkhungu yomwe makina angagwire. Tangoganizani zomangirazo ngati mizati yokweza makinawo. Chikombolecho chiyenera kulowa pakati pa mizati iyi. Ngati nkhungu ndi yayikulu kwambiri kuti ipangike pakati pa zomangira, sizingagwire ntchito ndi makinawo.Makina okhazikika nthawi zambiri amagwira nkhungu mpaka 4 mapazi ndi 4 mapazi. Komabe, nkhungu zazikulu zimafunikira zida zapadera zokhala ndi matayala otalikirapo.

Nawa malangizo amomwe mungapangire:

- Makulidwe a nkhungu:

- M'lifupi mwa nkhungu sayenera kupitirira theka la matayala opingasa a tie-bar.

- Utali wa nkhungu uyenera kukhala wochepera theka la katalikirana ka mipiringidzo yowongoka.

- Chitetezo Chilolezo:

- Kwa nkhungu zazing'ono, lolani malo osachepera 25mm mbali iliyonse.

- Kwa nkhungu zazikulu, lolani malo osachepera 50mm mbali iliyonse.

- Makulidwe a nkhungu: makulidwe a nkhungu ayenera kukhala mkati mwa makina osachepera ndi makulidwe osiyanasiyana.

Okonza nkhungu amaganiziranso mfundo izi:

- M'lifupi kapena kutalika kwa nkhungu kuyenera kukhala 1/2 inchi (pafupifupi 1.27 cm) m'lifupi kuposa kukula kwa mphako kuti ikhale yolimba.

- Kukhuthala kwa nkhungu kuyenera kukhala 2.5 kuwirikiza pang'onopang'ono kuzama kuti zitsimikizire kuphimba kwathunthu zikatsekedwa.

Tonnage Range ndi Gawo Kukula

Mphamvu ya clamping, kapena tonnage, ndi kuchuluka kwa mphamvu yomwe makina amagwiritsa ntchito kuti ma halves a nkhungu atsekedwe panthawi ya jekeseni. Izi zimalepheretsa pulasitiki kuti isatuluke, zomwe anthu amazitcha "kuthwanima".Mitundu yamphamvu yoletsa makina ngati Topstar ndi 90T-2800T. Mumawerengetsera kutengera gawo lomwe likuyembekezeredwa komanso makulidwe azinthu zapulasitiki.

Umu ndi momwe anthu amawerengera mphamvu yolumikizira yofunikira:

- Ulamuliro wa Thumb: Njira iyi imayerekezera matani pogwiritsa ntchito gawo la gawo, mtundu wa pulasitiki, makulidwe ake, ndi'clamp factor' (nthawi zambiri 2 mpaka 8, kapena avareji ya 5). Komabe, izi zikhoza kukhala zolakwika. Mphamvu yochepa kwambiri imayambitsa mavuto abwino, ndipo kuchulukitsitsa kumawonjezera mtengo wa nkhungu.

- Mold Flow Mafanizidwe: Mapulogalamu apakompyutawa amaneneratu matani enieni omwe amafunikira panthawi yojambula.Mwachitsanzo, kuyerekezera kwa gawo limodzi kunaneneratu matani 509.

- Mawerengedwe Ongoganizira: Mutha kugwiritsa ntchito fomula:Clamping Force (T) = Clamping Force constant (Kp) ✕ Dera Lolonjezedwa (S in cm²). Mwachitsanzo, ngati pulasitiki ya PE ili ndi mtengo wa Kp wa 0.32 ndipo malo omwe akuyembekezeredwa ndi 410 cm², mphamvu yothirira ingakhale 0.32 ✕ 410 = 131.2 T.

- Kusanthula Kudzaza Mold: Iyi ndi njira yolondola kwambiri. Imasankha tonnage factor. Kuphatikizira pafupifupi 15 peresenti yachitetezo pazotsatira izi kumapereka mphamvu yolumikizira yolondola ndikuletsa kung'anima. Kusanthula uku kukuwonetsanso momwe zinthu zina, monga kuchuluka kwa zipata (zipata zambiri zimatanthawuza matani otsika) ndi kutalika kwa kuyenda (kuthamanga kwautali kumafuna matani apamwamba), kumakhudza ndondomekoyi.

Nanga bwanji ngati clamping mphamvu ndi yolakwika?

| Mbali | Mphamvu Yosakwanira Yothirira | Kugwiritsa Ntchito Mphamvu Kwambiri |

|---|---|---|

| Gawo Quality | Kung'anima, kusafanana bwino, kuwombera mwachidule, miyeso yolakwika, mizere yowotcherera yofooka | Palibe kung'anima, koma kudzaza kwambiri kumayambitsa kupsinjika kwamkati kapena zizindikiro zakuya; kupotoza nkhungu, kumamatira mbali, kapena zipsera pamwamba |

| Mold & Machine Impact | Nkhungu imavala pamizere yolekanitsa kuchokera pakuthwanima mobwerezabwereza; kuphwanya kosagwirizana kumawononga zikhomo/zitsamba | Kuwonongeka kwa nkhungu msanga (ming'alu, kuvala zikhomo / mbale); mbale zopunduka, zoyikapo zosweka |

| Ndalama Zopanga | Zowonjezera zambiri, kukonzanso, ndi nthawi yochepa yoyeretsa nkhungu | Kukwera mtengo wokonza komanso chiopsezo cha kuwonongeka kwa makina |

| Mphamvu Mwachangu | Kuwononga mphamvu pang'ono, koma kuchuluka kwa zinyalala | Kugwiritsa ntchito mphamvu kosafunikira kuchokera pakudzaza makina |

| Nthawi Yozungulira | Kuzungulira kotalikirapo kukonza zolakwika (monga kuchotsa kung'anima) | Palibe kusintha kwa nthawi yozungulira; zotheka kuchedwa kuwonongeka nkhungu |

Kusakwanira clamping tonnage kumawononga nkhungu mwachangu. Kukaniza kosagwirizana kumatha kuwononga mapini otsogolera ndi tchire. Izi zikutanthauza kuti nthawi yocheperako komanso yokwera mtengo yokonza. Kumangirira kochulukira kungayambitse zizindikiro zowotchedwa chifukwa mpweya sumatha kuthawa. Zimawonjezeranso kuthamanga kwa nkhungu yamkati, zomwe zimapangitsa kuti jekeseni ikhale yosagwirizana.

Kukula kwa Platen ndi Mapangidwe a Mold Fit

Kukula kwa mbale ndi masanjidwe ali ngati mlonda wa pakhomo kuti agwirizane ndi nkhungu.Chikombolecho chiyenera kulowa mkati mwa mbale za makina. M'lifupi ndi kutalika kwake, kuphatikizapo mbale zoyikapo, ziyenera kukhala zazing'ono kusiyana ndi malo omwe ali pakati pa tayi ya makina. Ngati nkhungu ndi yotambasula pang'ono, sikwanira.Chikombole chopangidwira makina okulirapo (monga matani 500) sichingafanane kapena kugwira ntchito yaying'ono (monga matani 200).

Ganizirani momwe gawolo limakhudzira mawonekedwe a nkhungu:

- Khosi lalikulu la preform lalikulu limafunikira malo ochulukirapo pakati pa mapanga pa mbale ya nkhungu. Izi zimawonjezera kukula kwa nkhungu yonse.

- Pakukhazikika kwa mbale, khosi la 28mm PCO1881 (lofala pamabotolo amadzi) limatha kuloleza phula la 50mm. Izi zitha kutanthauza masanjidwe a 8 × 9 a nkhungu ya 72-cavity.

- Komabe, khosi la 38mm Bericap (la timadziti) lingafunike phula la 70mm kuti likhale lokulirapo. Izi zitha kuchepetsa masanjidwewo kukhala 6 × 6, zomwe zimapangitsa kuti pakhale nkhungu ya 36-cavity mkati mwa malo omwewo.

Izi zikuwonetsa kuti kukula kwa khosi kokulirapo kumakakamiza nkhungu yokulirapo pamlingo womwewo wa ma cavities. Izi zikutanthauza kutsika kwakukulu kwa zibowo zamakina opangira pulasitiki.

Kufanana kwa mbale ndi kukhazikika ndizofunikira kwambiri. Iwo amaonetsetsa kusasinthasintha mbali khalidwe.Makina owongolera anzeru komanso kuwongolera bwino kwa mapulanetizimathandizira kuti ma platen azikhala osalala komanso ofanana. Izi zimalepheretsa kuwonongeka kwa kuthamanga kwa clamping. Kugaya pamwamba kumapanga malo athyathyathya, ofanana pazipinda za nkhungu zomwe zimakhala zolimba, nthawi zambiri0.005mm pa 100mm kutalika.

Kutsegula Stroke ndi Masana Kuti Ejection Efficiency

Sitiroko yotsegulira ndi masana ndi miyeso yofunikira pamakina aliwonse omangira pulasitiki. Zimakhudza mwachindunji momwe gawo lopangidwira limatuluka mosavuta komanso moyenera. Sitiroko yotsegulira imatanthawuza mtunda womwe mbale yosuntha imayenda. Kuwala kwa masana ndi malo otseguka kwambiri pakati pa ma halves a nkhungu pamene makina atsegulidwa kwathunthu. Zonsezi ziyenera kukhala zazikulu mokwanira kuti gawolo lichotse nkhungu popanda zovuta.

Ngati malo otseguka, kapena masana, pakati pa hafu ya nkhungu sikokwanira kuti gawolo lituluke bwino, zimabweretsa mavuto angapo. Opanga angafunike makina okulirapo, okwera mtengo okhala ndi sitiroko yokulirapo. Izi zingayambitse kusagwira ntchito mosiyanasiyana:

- Kuwonongeka kwa zinthu kumachitika chifukwa pulasitiki imakhala mu mbiya nthawi yayitali.

- Kuvala kwa nkhungu kumawonjezeka chifukwa cha kupanikizika kwakukulu kwa clamping.

- Kuwala kwa zigawo kumachitika pamene ma platens agwedezeka chifukwa nkhungu yaying'ono imakhala mu makina akuluakulu.

- Kusagwirizana kwa kuwombera kumabweretsa pamene gawo lalikulu la jakisoni limapereka voliyumu yaying'ono yowombera.

- Nthawi zozungulira zimawonjezeka chifukwa makina akuluakulu amagwira ntchito pang'onopang'ono.

The ejection stroke ndi yofunika kwambiri. Uwu ndi mtunda womwe zikhomo za ejector zimakankhira gawolo kuchokera mu nkhungu. Sitiroko yofunikira ya ejection iyenera kugwirizana ndi mphamvu zamakina. Zigawo zokhala ndi kuzama kwakukulu, monga machubu kapena zotengera zakuya, zimafunikira zikwapu zazitali zotulutsa kuti zichotsedwe bwino. Kutalika kwa silinda ya ejector kumatsimikizira kuchuluka kwa ejection stroke. Okonza nkhungu nthawi zonse amatsimikizira izi ngati akukayikira kukwanira kwake. Amawonetsetsa kuti makina amatha kukankhira mbaliyo kwathunthu komanso mwaukhondo.

Kusankha Makina Omangira Pulasitiki ndi njira yopitilira. Imafanana ndi zosowa zamakina ndi makina. Makina abwino kwambiri amagwirizana ndi zomwe akupanga pano ndipo amathandizira kukulitsa kwamtsogolo. Kuyika ndalama zamakina pamakina oyenera ndikofunikira kwambiri pakupambana kwanthawi yayitali komanso kupindula. Izi zikuphatikizapokutsata mfundo zowonda zochepetsera zinyalala komanso kugwiritsa ntchito njira zopangira digito kuti ziwonere zenizeni zenizeni. Makampani amaphatikizanso makasitomala awo ndikuyika ndalama zawo pantchito zaluso. Masitepewa amatsimikizira kukula kokhazikika komanso kuchita bwino.

FAQ

Kodi pali kusiyana kotani pakati pa makina opangira pulasitiki amagetsi ndi ma hydraulic?

Makina amagetsi amapereka molondola komanso kupulumutsa mphamvu. Amagwiritsa ntchito ma servo motors pamayendedwe onse. Makina opangira ma hydraulic amapereka mphamvu zolimba pazigawo zazikulu. Amagwiritsa ntchito kuthamanga kwamadzimadzi. Makina osakanizidwa amaphatikiza maubwino onse awiri, opatsa kusinthasintha.

Chifukwa chiyani kusiyana pakati pa tie-bar kuli kofunikira pakusankha makina?

Kutalikirana kwa tayi-bar kumatsimikizira kukula kwa nkhungu komwe makina angagwire. Chikombolecho chiyenera kulowa pakati pa mizati iyi. Kutalikirana kolakwika kumatanthauza kuti nkhungu sigwira ntchito ndi makinawo. Ndilo muyeso wofunikira pakukhazikika kwa nkhungu.

Kodi clamping force imakhudza bwanji mtundu wa zida zowumbidwa?

Mphamvu ya clamping imasunga ma theka a nkhungu otsekedwa panthawi ya jekeseni. Mphamvu yochepa imayambitsa "kuthwanima" kapena kusakhala bwino kwa gawo. Mphamvu zambiri zimatha kuwononga nkhungu kapena kupangitsa kuti mbali zina ziwonongeke, monga zolembera zakuya. Kuthirira koyenera kumatsimikizira zotsatira zokhazikika.

Ubwino wa njira yokhomerera yokhala ndi matabwa awiri ndi yotani?

Machitidwe a matabwa awiri amapereka mapangidwe osakanikirana, kupulumutsa malo apansi. Amapereka mtunda wowolowa manja komanso kutseguka kwa masana kwa nkhungu zazikulu. Machitidwewa amachepetsanso kuwonongeka kwa nkhungu ndipo angayambitse nthawi yothamanga kwambiri.

Ndi liti pamene bizinesi iyenera kuganizira makina opangira pulasitiki wosakanizidwa?

Mabizinesi ayenera kuganizira makina osakanizidwa akafuna kulondola komanso mphamvu. Makinawa amaphatikiza kulondola kwamagetsi ndi mphamvu ya hydraulic. Amagwira ntchito zosiyanasiyana, amagwira ntchito zosiyanasiyana zoumba bwino.

Nthawi yotumiza: Oct-14-2025