Xaiv qhov zoo tshaj plawsYas Moulding Tshuabyog qhov tseem ceeb rau txoj haujlwm ua tiav thiab kev loj hlob ntawm kev lag luam yav tom ntej. Kev ntsuam xyuas tag nrho ntawm qhov kev xav tau tshwj xeeb thiab lub peev xwm ntawm lub tshuab ua kom muaj kev nqis peev zoo. Xav txog qhov tseem ceebTxhaj Moulding Tshuabkev ua lag luam:

| Kev lag luam ntu | Tus nqi hauv 2024 (USD) | Tus nqi kwv yees los ntawm 2030 (USD) | CAGR (2025-2030) |

|---|---|---|---|

| Yas Tshuab Moulding Tshuab | 3.1829bn ua | 4,0477b ua | 4.2% |

| Yas Txhaj Moulding Tshuab | 11,98bn ua | 14.78 billion | 3.5% |

Kev lag luam yas molding tshuab kev lag luam xav tau a5.2% CAGR los ntawm 2024 txog 2032, loj hlob los ntawm USD 5.6 billion rau USD 8.9 billion. Qhov kev loj hlob no qhia txog qhov xav tau rau kev xaiv khoom siv ntse. Kev nkag siab txog cov kev qhia tshwj xeeb tseem ceeb ua kom muaj kev sib haum xeeb nrog cov hom phiaj tsim khoom. Txoj caiTxhaj Moulding Tshuab Yasyog qhov tseem ceeb rau kev ua haujlwm zooYas Txhaj Molding. Cov lag luam kuj xav txogYas Recycling Tshuabrau kev npaj txhij txhua.

Ntsiab Cai

- Xaiv txoj caiyas molding tshuab hom. Cov tshuab hluav taws xob muaj qhov tseeb thiab txuag hluav taws xob. Hydraulic tshuab muab lub zog muaj zog rau qhov loj. Hybrid tshuab muab ob qho tib si txiaj ntsig.

- Nkag siab txog clamping mechanisms. Ob-platen systems txuag chaw thiab haum cov pwm loj. Toggle systems yog qhov zoo rau kev tsim khoom sai. Txhua qhov system muaj cov txiaj ntsig sib txawv.

- Tshawb xyuas cov ntsiab lus tseem ceeb. Tie-bar sib nrug qhia tau tias pwm loj tshaj plaws uas lub tshuab tuaj yeem tuav tau. Clamping quab yuam nres cov yas los ntawm kev xau. Platen loj kom cov pwm haum kom raug.

- Match tshuab loj rau koj qhov chaw. Qhov qhib stroke thiab nruab hnub nrig yuav tsum loj txaus. Qhov no pab cov khoom tuaj tawm yooj yim. Lub tshuab loj tsis raug tuaj yeem ua rau muaj teeb meem thiab pov tseg.

- Xaiv lub tshuab uas haum koj qhov project xav tau. Lub tshuab zoo tshaj plaws pab nrog kev ua haujlwm tam sim no. Nws kuj txhawb kev loj hlob yav tom ntej. Qhov kev xaiv no ua rau muaj kev vam meej mus ntev.

Nkag siab Yam Tseem Ceeb Yas Moulding Tshuab Hom

Xaiv lub tshuab yas molding txoj cai pib nrog kev paub txog yam yooj yim. Txhua lub tshuab muaj cov txiaj ntsig tshwj xeeb rau kev xav tau ntau lawm. Cia peb tshawb xyuas cov pawg tseem ceeb.

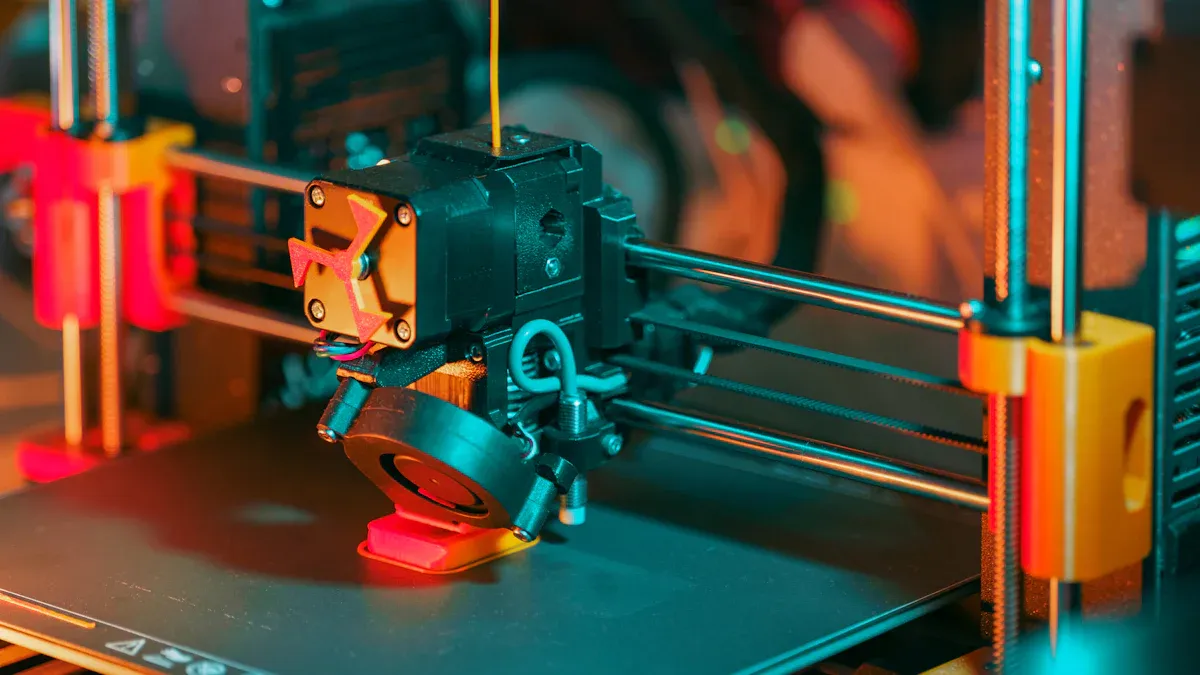

Electric Yas Moulding Tshuab

Hluav taws xob yas molding tshuab yog champions ntawm precision thiab efficiency. Lawvsiv hluav taws xob servo motors rau txhua qhov txav. Qhov kev tsim no txhais tau tias lawv tsuas yog siv lub zog thaum ua haujlwm, ua rau kev txuag hluav taws xob tseem ceeb. Piv txwv li, cov tshuab no tuaj yeem ua tautxuag 50% ntau zog piv rau cov laus hydraulic systems thiab 20-30% ntau tshaj servo-hydraulics. Lawv cov kev tswj hwm digital muab qhov tseeb tsis txaus ntseeg, Ua tiav qhov chaw rov ua haujlwm ntawm ± 0.01 hli. Qhov no precision ua rau lawv zoo tagnrho rau cov me me, intricate qhov chaw thiab daim ntawv thov xav tau siab sib xws. Xav txogCov khoom siv kho mob, cov khoom siv hluav taws xob, lossis cov khoom siv kho qhov muag. Cov tshuab noexcel nyob rau hauv ib puag ncig huv si vim lawv tsis siv cov kua dej hydraulic, tiv thaiv kev sib kis.

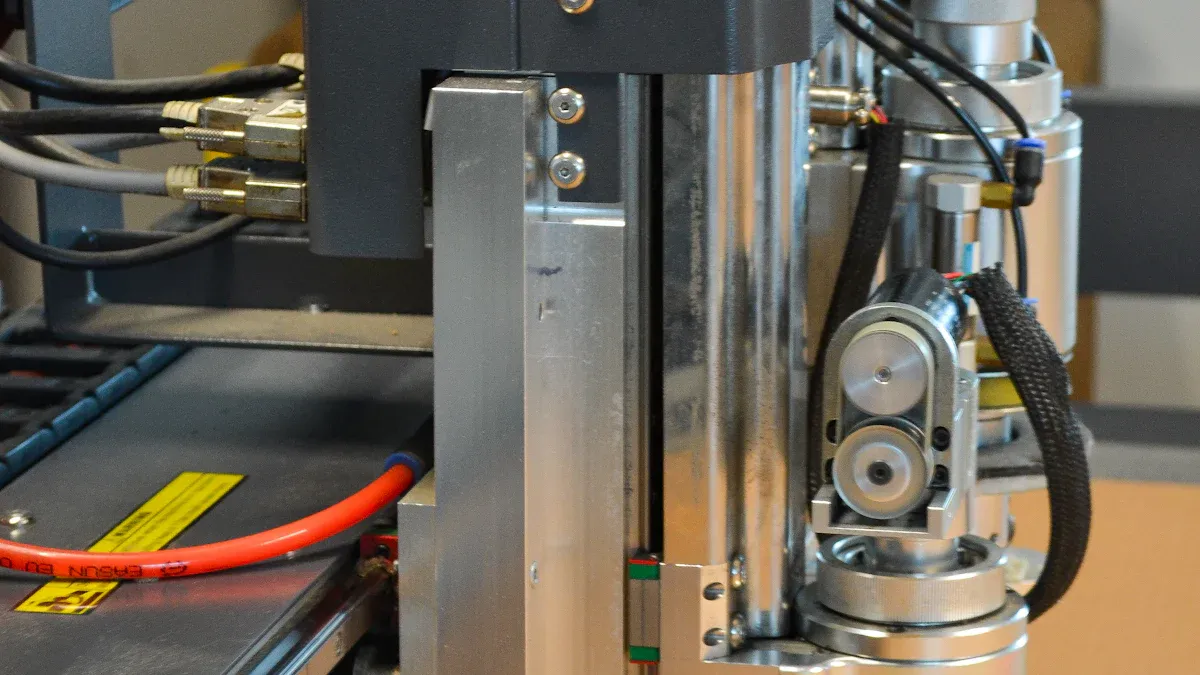

Hydraulic Yas Moulding Tshuab

Hydraulic yas molding tshuab paub txog lawvmuaj zog thiab durability. Lawv siv hydraulic kua los tsim kom muaj zog, tshwj xeeb tshaj yog rau clamping. Cov cav tov no zoo heev rau kev siv high-tonnage thiab molding loj, hnyav qhov chaw nrog cov ntsiab lus nyuaj. Lawv tuaj yeem ua haujlwmloj clamping quab yuam, ua rau lawv zoo meej rau cov khoom xws litsheb bumpers lossis loj, ntau daim pwm. Hos tej zaum lawv yuav qeeb qeeb thiabtsawg dua cov tshuab hluav taws xob vim muaj dej dynamics, lawv lub zog thiab ntau yam hauv kev tuav cov khoom sib txawv ua rau lawv xaiv tus nqi zoo raucov khoom loj lojhauv kev lag luam xws liautomotive thiab industrial manufacturing.

Hybrid Yas Moulding Tshuab

Hybrid yas molding tshuab muab cov yam ntxwv zoo tshaj plaws ntawm ob lub tshuab hluav taws xob thiab hydraulic. Lawvintegrate hluav taws xob precision nrog hydraulic zog. Qhov no txhais tau tias lawv muab lub zog efficiency thiab raug ntawm cov tshuab hluav taws xob, nrog rau lub siab clamping quab yuam thiab durability ntawm hydraulic sawv daws yuav. Hybrid qauv yog ntau yam. Lawv tuaj yeem muaj hydraulic clamping nrog hluav taws xob txhaj tshuaj, los yog vice versa. Qhov kev hloov pauv no tso cai rau lawv los tswj ntau yam ntawm cov haujlwm molding, los ntawm cov khoom me me mus rau cov khoom loj, cov khoom siv. Piv txwv li, lawv yog nrov nyob rau hauv lubautomotive kev lag luam rau dashboard panels thiab bumpers, thiab nyob rau hauv kev kho mob thiab ntim sectorsrau lawv qhov sib npaug ntawm kev ua tau zoo thiab kev ua haujlwm. Cov tshuab no tuaj yeem ua taukov hydraulic zog zoo li cov tub ntxhais rub tsis tas yuav tsum tau muaj kev sib cais, ntxhov siab hydraulic, uas yog qhov loj ntxiv rau qhov chaw huv..

Ntsuas Clamping Mechanisms rau Yas Moulding Tshuab

Xaiv txoj cai clamping mechanism yog qhov kev txiav txim siab loj rau txhua lub tshuab yas molding. Nws cuam tshuam ncaj qha rau kev tsim khoom lag luam thiab hom khoom koj tuaj yeem ua. Kev hloov pwm ceev (QMC), piv txwv li, yog qhov tseem ceeb rau kev txiav cov pwm hloov pauv lub sij hawm. Cov tshuab no tuaj yeem ua tautxiav downtime los ntawm teev mus rau mere feeb. Lawv kujboost kev nyab xeeb los ntawm kev tshem tawm qhov xav tau ntawm cov neeg ua haujlwm los tuav cov clamps hauv lub tshuab. Qhov no txhais tau tiastsawg zog ua haujlwm thiab muaj kev pheej hmoo tsawg dua.

Ob-Platen Clamping Systems

Ob-platen clamping tshuab paub txog lawv cov qauv tsim. Lawv siv ob lub platens siv zog rau pwm. Qhov no tsimtshem tawm qhov xav tau rau lub nraub qaum clamping platen, muab lub tshuab ame me hneev taw. Qhov no yog qhov zoo rau cov tuam txhab uas muaj qhov txwv hauv pem teb. Cov tshuab no kuj muajyooj rau pwm loj. Lawv muab ibdav khi bar nrug thiab nruab hnub qhib. Qhov no tso cai rau cov cuab yeej ntau kab noj hniav thiab cov ntu ntu geometry. Koj tuaj yeem pwm qhov loj dua lossis ntau qhov me me hauv ib qho mus. Ob-platen systems kuj txo cov pwm deflection thiab muab lub sij hawm voj voog sai.Lawv kuj paub txog lawv lub zog txuag.

Toggle Clamping Systems

Toggle clamping tshuab siv cov tshuab levers thiab txuas los tsim kom muaj zog clamping. Lawv yog cov zoo heev rau high-speed txhaj molding.Ib chav toggle muaj xws li qhov txuas toggle, crosshead, thiab tsav tsheb. Qhov kev teeb tsa no tso cai raukev koom tes sai thiab kev tsis sib haum xeeb, ua rau lawv zoo meej rau kev rov ua dua tshiab. Toggle clamps muab lub zog clamping zoo ib yam. Lawv tau tsim los rau "dhau-clamp," locking rau hauv txoj hauj lwm yam tsis tas yuav tsum tau hydraulic siab. Qhov no pab tswj kev quab yuam txawm tias muaj teeb meem kev tsim khoom los yog kev vibrations. Qhov no systempib nrog ceev, loj txav thiab tsis muaj zog, ces ua tiav nrog qeeb, siab zog.

Txawm li cas los xij,tsoos toggle systems feem ntau muaj cov hneev taw loj dua vim lawv qhov txav sab hauv. Qhov no tuaj yeem ua rau cov pwm hloov tsis hloov pauv. Sab nraud toggle systems, ntawm qhov tod tes, muab qhov chaw txuag tsim thiab yooj yim rau pwm nkag. Rau kev kho, toggle clamps xav taukev tshuaj xyuas tsis tu ncua rau kev hnav thiab kev puas tsuaj. Koj yuav tsumntxuav lawv ntau zaus thiab siv cov roj nplua nyeem rau cov khoom txav. Hloov cov khoom hnav tam sim ntawd pab tswj lawv cov txiaj ntsig thiab kev nyab xeeb. Lawvdurability nyob ntawm qhov zoo ntawm cov ntaub ntawv thiab yuav ua li cas lub linkage system tsim.

Ntsiab Technical Specifications rau yas Moulding tshuab xaiv

Xaiv lub tshuab yas molding txoj cai txhais tau tias saib ze ntawm nws cov lus qhia. Cov kev qhia tshwj xeeb no qhia koj tias lub tshuab tuaj yeem ua dab tsi thiab yog tias nws haum rau koj qhov project. Kev nkag siab txog lawv yuav pab koj ua kom muaj peev txheej ntse.

Tie-Bar Spacing rau Pwm Chaw Nyob

Tie-bar spacing yog qhov ntsuas tseem ceeb. Nws qhia koj qhov loj tshaj plaws ntawm pwm lub tshuab tuaj yeem tuav tau. Xav txog cov hlua khi li cov ncej tuav lub tshuab cov qauv. Cov pwm yuav tsum haum ntawm cov ncej no. Yog tias pwm loj dhau rau qhov chaw nruab nrab ntawm cov hlua khi, nws tsuas yog yuav tsis ua haujlwm nrog lub tshuab ntawd.Cov tshuab txheem feem ntau tuav cov pwm mus txog 4 ko taw los ntawm 4 ko taw. Txawm li cas los xij, cov pwm loj dua xav tau cov cuab yeej tshwj xeeb nrog qhov dav dua khi-bar sib nrug.

Nov yog qee cov lus qhia rau kev haum pwm:

- Mould Dimensions:

- Pwm dav yuav tsum tsawg tshaj li ib nrab ntawm kab rov tav khi-bar sib nrug.

- Pwm ntev yuav tsum tsawg tshaj li ib nrab ntawm txoj hlua khi-bar sib nrug.

- Kev Nyab Xeeb Kev Nyab Xeeb:

- Rau cov pwm me me, tso cai tsawg kawg 25 hli ntawm qhov chaw ntawm txhua sab.

- Rau cov pwm loj, tso cai tsawg kawg 50 hli ntawm qhov chaw ntawm txhua sab.

- Pwm Thickness: Cov pwm lub thickness yuav tsum haum nyob rau hauv lub tshuab qhov tsawg kawg nkaus thiab siab tshaj plaws thickness ntau yam.

Pwm designers kuj xav txog cov ntsiab lus no:

- Pwm dav lossis qhov siab yuav tsum yog tsawg kawg yog 1/2 nti (kwv yees 1.27 cm) dav dua qhov kab noj hniav loj rau lub zog.

- Pwm thickness yuav tsum yog 2.5 npaug ntawm kab noj hniav qhov tob kom paub meej tias tag nrho cov kev pab cuam thaum kaw.

Tonnage Range thiab Part Size

Clamping quab yuam, los yog tonnage, yog ntau npaum li cas quab yuam lub tshuab siv kom cov pwm halves kaw thaum txhaj tshuaj. Qhov no tiv thaiv cov yas los ntawm kev xau tawm, uas tib neeg hu ua "flashing."Lub clamping quab yuam ntau rau cov cav tov zoo li Topstar yog 90T-2800T. Koj xam nws raws li ib feem ntawm qhov projected nto cheeb tsam thiab cov khoom yas thickness.

Nov yog yuav ua li cas tib neeg xam qhov xav tau clamping quab yuam:

- Txoj cai ntawm Thumb: Txoj kev no kwv yees tonnage siv ib feem ntawm cheeb tsam, hom yas, nws thickness, thiab'clamp factor' (feem ntau yog 2 txog 8, lossis qhov nruab nrab ntawm 5). Txawm li cas los xij, qhov no tuaj yeem ua tsis raug. Kev quab yuam me dhau ua rau muaj teeb meem zoo, thiab ntau dhau ua rau cov nqi pwm.

- Pwm Flow Simulations: Cov khoos phis tawj no kwv yees qhov tseeb tonnage xav tau thaum lub sijhawm tsim.Piv txwv li, ib qho kev simulation rau ib feem kwv yees 509 Tons.

- Theoretical xam zauv: Koj tuaj yeem siv tus qauv:Clamping force (T) = Clamping force constant (Kp) ✕ Projected Area (S in cm²). Piv txwv li, yog tias PE yas muaj Kp tus nqi ntawm 0.32 thiab qhov projected cheeb tsam yog 410 cm², lub clamping quab yuam yuav yog 0.32 ✕ 410 = 131.2 T.

- Pwm Filling Analysis: Qhov no yog ib txoj hauv kev meej dua. Nws txiav txim siab tonnage factor. Ntxiv txog 15 feem pua ntawm kev nyab xeeb rau cov txiaj ntsig no muab qhov tseeb clamping quab yuam thiab tiv thaiv flash. Qhov kev tshuaj ntsuam no tseem qhia tau tias yuav ua li cas lwm yam, xws li tus naj npawb ntawm cov rooj vag (ntau lub rooj vag txhais tau tias qis tonnage) thiab ntws ntev (ntev ntws xav tau ntau dua tonnage), cuam tshuam rau cov txheej txheem.

Yuav ua li cas yog tias lub clamping quab yuam yuam kev?

| Yam | Tsis txaus Clamping Force | Tshaj Clamping Force |

|---|---|---|

| Qhov Zoo | Flash, tsis zoo symmetry, txhaj tshuaj luv luv, tsis raug qhov ntev, tsis muaj zog weld kab | Tsis muaj flash, tab sis overpacking ua rau muaj kev ntxhov siab sab hauv lossis cov cim dab dej; pwm deflection, ib feem sticking, los yog nto blemishes |

| Pwm & Tshuab cuam tshuam | Pwm hnav ntawm cov kab sib cais los ntawm kev rov ua dua; uneven clamping puas pins / bushings | Kev puas tsuaj rau pwm ua ntej (kev tawg, hnav ntawm phau ntawv qhia pins / platens); deformed platens, tawg inserts |

| Tus nqi tsim khoom | Ntau cov khoom seem, rework, thiab downtime rau pwm tu | Cov nqi kho mob siab dua thiab muaj kev pheej hmoo ntawm lub tshuab tawg |

| Zog Efficiency | Tsawg zog pov tseg, tab sis cov khoom seem siab | Kev siv hluav taws xob tsis tsim nyog los ntawm lub tshuab overloading |

| Lub Sijhawm Sijhawm | Lub voj voog ntev dua los kho qhov tsis xws luag (xws li tshem tawm flash) | Tsis muaj kev txhim kho nyob rau hauv lub sij hawm voj voog; muaj peev xwm ncua los ntawm pwm puas |

Tsis txaus clamping tonnage hnav tawm pwm sai dua. Tsis sib npaug clamping tuaj yeem ua rau tus thawj coj pins thiab bushings. Qhov no txhais tau tias ntau downtime thiab ntau dua cov nqi kho. Ntau dhau clamping tonnage tuaj yeem ua rau kub hnyiab ntawm qhov chaw vim tias huab cua tsis tuaj yeem khiav. Nws kuj ua rau cov pwm sab hauv siab, ua rau cov txheej txheem txhaj tshuaj tsis sib haum.

Platen Loj thiab Layout rau Pwm Haum

Platen loj thiab layout yog zoo li ib tug gatekeeper rau pwm compatibility.Cov pwm yuav tsum haum rau hauv lub tshuab platens. Nws qhov dav thiab qhov siab, suav nrog mounting daim hlau, yuav tsum me dua qhov chaw nruab nrab ntawm lub tshuab khi tuav. Yog tias pwm txawm tias dav me ntsis, nws yooj yim yuav tsis haum.Lub pwm tsim rau lub tshuab loj (xws li 500-tuj) tsis tuaj yeem haum lub cev lossis ua haujlwm ntawm ib qho me me (xws li 200-tuj).

Xav txog yuav ua li cas qhov tsim ib feem cuam tshuam rau pwm layout:

- Lub caj dab loj dua preform xav tau ntau qhov chaw ntawm kab noj hniav ntawm pwm phaj. Qhov no ua rau kom tag nrho pwm puag loj.

- Rau qhov loj me me, lub caj dab 28 hli PCO1881 (ib txwm rau cov fwj dej) yuav tso cai rau 50 hli suab. Qhov no tuaj yeem txhais tau tias 8 × 9 layout rau 72-kab kab noj hniav pwm.

- Txawm li cas los xij, 38mm Bericap caj dab (rau cov kua txiv hmab txiv ntoo) yuav xav tau 70mm suab rau nws txoj kab uas hla loj dua. Qhov no tuaj yeem txo qhov kev teeb tsa mus rau 6 × 6, uas ua rau tsuas yog 36-kab kab noj hniav hauv tib lub cev.

Qhov no qhia tau hais tias lub caj dab dav dav ua rau cov pwm loj dua rau tib cov kab noj hniav. Qhov no thaum kawg txhais tau tias tsawg dua cov kab noj hniav rau lub tshuab yas molding.

Platen parallelism thiab rigidity kuj tseem ceeb heev. Lawv xyuas kom zoo ib feem zoo.Intelligent leveling systems thiab precise platen tswjpab kom cov platens zoo kawg nkaus tiaj tus thiab sib npaug. Qhov no tiv thaiv qhov tsis xws luag los ntawm qhov tsis sib xws clamping siab. Nto milling tsim cov tiaj tus, sib npaug ntawm cov pwm hauv cov phaj hauv nruj nruj, feem ntau0.005mm rau 100mm ntawm qhov ntev.

Qhib Stroke thiab Hnub Ci rau Ejection Efficiency

Qhov qhib stroke thiab nruab hnub nrig yog qhov ntsuas tseem ceeb rau txhua lub tshuab yas molding. Lawv ncaj qha cuam tshuam li cas yooj yim thiab ua tau zoo ib feem molded los ntawm pwm. Qhov qhib stroke yog hais txog qhov kev ncua deb ntawm lub platen txav mus. Hnub ci yog qhov qhib siab tshaj plaws ntawm cov pwm halves thaum lub tshuab qhib tag nrho. Ob leeg yuav tsum loj txaus rau ib feem kom tshem cov pwm tsis muaj teeb meem.

Yog tias qhov chaw qhib, lossis nruab hnub, nruab nrab ntawm cov pwm halves tsis txaus rau qhov eject kom raug, nws tsim ntau yam teeb meem. Cov neeg tsim khoom yuav xav tau lub tshuab loj dua, kim dua nrog lub zog qhib ntau dua. Qhov no tuaj yeem ua rau muaj ntau yam tsis zoo:

- Cov khoom degradation tshwm sim vim tias cov yas nyob hauv lub thoob ntev dua.

- Pwm hnav nce vim muaj clamping siab dua.

- Cheebtsam flashing tshwm sim thaum platens pob zeb vim tias cov pwm me nyob hauv lub tshuab loj.

- Kev txhaj tshuaj tsis sib xws tau tshwm sim thaum lub tshuab txhaj tshuaj loj xa cov ntim me me.

- Lub sij hawm voj voog nce vim tias cov tshuab loj feem ntau ua haujlwm qeeb.

Lub ejection stroke kuj tseem ceeb heev. Qhov no yog qhov deb ntawm cov ejector pins thawb ib feem tawm ntawm pwm. Qhov xav tau ejection stroke yuav tsum haum rau hauv lub tshuab muaj peev xwm. Cov khoom uas muaj qhov tob tob dua, zoo li cov raj lossis cov thawv ntim sib sib zog nqus, xav tau kev tshem tawm ntev dua rau kev tshem tawm kom raug. Lub ejector lub tog raj kheej qhov ntev txiav txim siab qhov siab tshaj plaws muaj ejection stroke. Pwm tsim ib txwm txheeb xyuas qhov no yog tias lawv tsis ntseeg txog nws qhov txaus. Lawv xyuas kom lub tshuab tuaj yeem thawb qhov tawm kom huv thiab huv.

Xaiv lub tshuab Moulding yog ib txoj kev txuas mus ntxiv. Nws phim qhov project xav tau nrog lub tshuab specifications. Lub tshuab zoo tshaj plaws ua raws li qhov xav tau ntau lawm tam sim no thiab txhawb kev nthuav dav yav tom ntej. Kev nqis peev zoo hauv lub tshuab zoo yog qhov tseem ceeb rau kev ua haujlwm ntev thiab muaj txiaj ntsig zoo. Qhov no suav nrogembracing lean manufacturing hauv paus ntsiab lus los txiav pov tseg thiab leveraging digital manufacturing rau real-time xyuas. Cov tuam txhab kuj nthuav tawm lawv cov neeg siv khoom sib txawv thiab nqis peev hauv cov neeg ua haujlwm txawj. Cov kauj ruam no ua kom muaj kev loj hlob thiab kev ua tau zoo.

FAQ

Dab tsi yog qhov txawv ntawm hluav taws xob thiab hydraulic yas molding tshuab?

Cov tshuab hluav taws xob muaj qhov tseeb thiab txuag hluav taws xob. Lawv siv servo motors rau txhua qhov kev txav. Hydraulic tshuab muab lub zog muaj zog rau qhov loj. Lawv siv cov kua dej. Hybrid tshuab muab ob qho tib si cov txiaj ntsig, muab ntau yam.

Vim li cas khi-bar spacing tseem ceeb rau kev xaiv tshuab?

Tie-bar spacing txiav txim siab qhov siab tshaj plaws pwm loj lub tshuab tuaj yeem tuav. Cov pwm yuav tsum haum ntawm cov ncej no. Qhov sib txawv tsis raug txhais tau hais tias cov pwm yuav tsis ua haujlwm nrog lub tshuab ntawd. Nws yog ib qho kev ntsuas tseem ceeb rau pwm chaw nyob.

Yuav ua li cas clamping quab yuam cuam tshuam qhov zoo ntawm molded qhov chaw?

Clamping quab yuam ua kom pwm ib nrab kaw thaum txhaj tshuaj. Lub zog me dhau ua rau "flashing" lossis qhov tsis zoo. Kev quab yuam ntau dhau tuaj yeem ua rau cov pwm puas lossis ua rau muaj qhov tsis xws luag xws li cov cim dab dej. Kev clamping kom zoo ua kom cov txiaj ntsig zoo ib yam.

Dab tsi yog cov txiaj ntsig ntawm ob-platen clamping system?

Ob-platen systems muab cov qauv tsim, txuag chaw hauv pem teb. Lawv muab kev sib txuas-bar nrug thiab nruab hnub qhib rau cov pwm loj. Cov tshuab no kuj txo cov pwm deflection thiab tuaj yeem ua rau lub sijhawm voj voog nrawm dua.

Thaum twg ib lub lag luam yuav tsum xav txog hybrid yas molding tshuab?

Cov lag luam yuav tsum xav txog cov tshuab hybrid thaum lawv xav tau ob qho tib si precision thiab lub zog. Cov tshuab no ua ke cov hluav taws xob raug nrog lub zog hydraulic. Lawv muaj ntau yam, tuav ntau yam ntawm cov haujlwm molding zoo.

Post lub sij hawm: Oct-14-2025