Xaiv txoj caitxhaj tshuaj molding tshuabyog ib qho tseem ceeb rau kev ua tiav kev tsim khoom hauv thaj teb ntawmyas txhaj tshuaj molding. Ib qho haumyas molding tshuabtxhim khu kev ua tau zoo thiab cov khoom zoo. Cov kws tshaj lij pom zoo saib ntau yam tseem ceeb thaum xaiv ib qhotxhaj tshuaj moldingtshuab. Cov no suav nrog:

- Txhaj muaj peev xwm

- Clamping quab yuam

- Zog efficiency

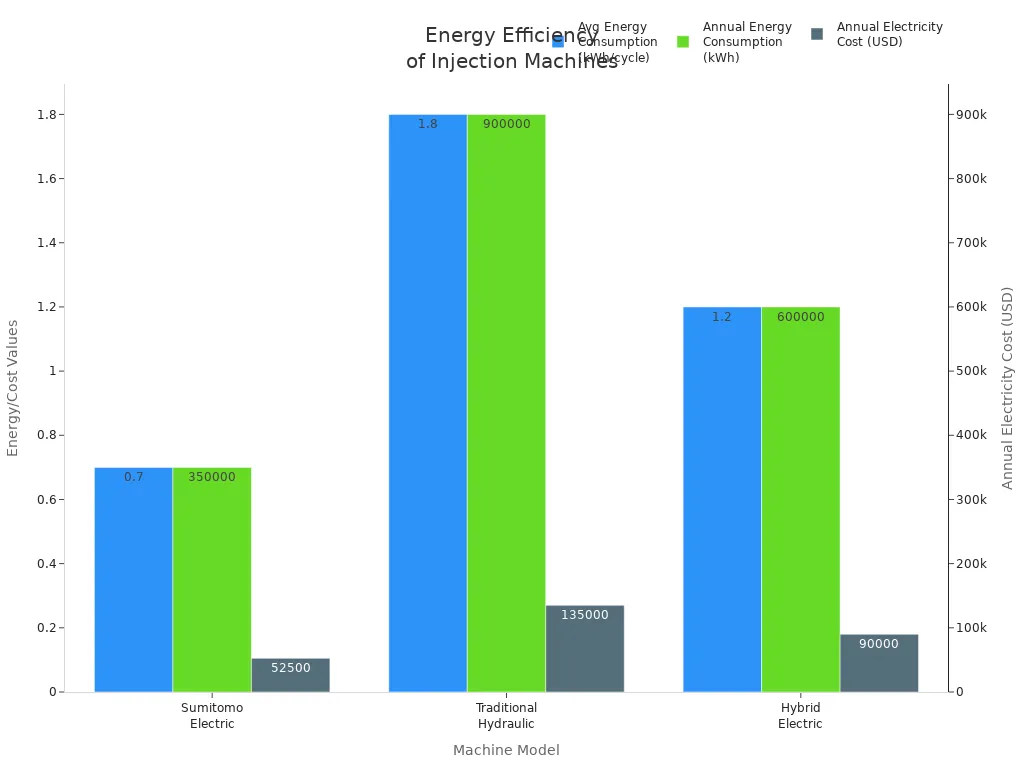

Niaj hnub nimno yas txhaj tshuaj molding tshuab tuaj yeem txuag hluav taws xob, qee zaum txog li 50% piv rau cov qauv qub. Kev nkag siab txog cov xwm txheej no pab ua kom paub kev xaiv rau koj cov kev xav tau ntawm cov yas txhaj tshuaj molding.

Ntsiab Cai

- Xaiv txoj cai txhaj tshuaj molding tshuab boosts ntau lawm efficiency thiab cov khoom zoo. Tsom ntsoov rau kev txhaj tshuaj muaj peev xwm, clamping quab yuam, thiab lub zog efficiency.

- Cov npe nrov tshaj plaws xws li Engel, Husky, thiab KraussMaffei muab cov cuab yeej siv siab tshaj plaws thiab txuag hluav taws xob. Tshawb nrhiav txhua lub npe kom pom qhov zoo tshaj plaws haum rau koj cov kev xav tau ntau lawm.

- Xav txog tag nrho cov nqi ntawm cov tswv cuab, suav nrog kev saib xyuas thiab kev siv hluav taws xob. Kev nqis peev ntau dua thawj zaug tuaj yeem ua rau txo cov nqi mus sij hawm ntev.

- Cov neeg siv khoom txaus siab muab kev nkag siab txog kev ntseeg siab ntawm lub tshuab. Nrhiav cov hom lag luam nrog kev txhawb nqa zoo thiab cov lus pom zoo rau cov neeg siv.

- Ntsuas koj qhov tshwj xeebcov kev cai ntau lawmua ntej xaiv lub tshuab. Teem koj qhov kev xaiv nrog cov khoom siv, ntim ntau lawm, thiab cov yam ntxwv xav tau.

Sab saum toj Pom Zoo Txhaj Moulding Tshuab Hom

Engel

Engel sawv tawm ua tus thawj coj hauvtxhaj tshuaj molding tshuab lag luam. Paub txog lawv cov thev naus laus zis tshiab, Engel cov cav tov muaj kev ua haujlwm siab thiab ua haujlwm zoo. Lawv muab ntau yam qauv tsim nyog rau ntau yam kev siv. Lawv cov tshuab feem ntau muaj cov txheej txheem tswj hwm qib siab, uas txhim kho cov neeg siv kev paub. Ntau tus neeg siv txaus siab rau Engel txoj kev cog lus rau kev siv hluav taws xob, uas tuaj yeem ua rau kom txuag tau nyiaj ntau lub sijhawm.

Tswv yim:Thaum xav txog Engel, nrhiav cov qauv uas haum rau koj cov kev xav tau tshwj xeeb. Lawv cov cav tov muaj ntau yam thiab tuaj yeem hloov mus rau cov txheej txheem tsim khoom sib txawv.

Husky

Husky yog lwm tus neeg sib tw sab saum toj hauv kev txhaj tshuaj molding tshuab kev lag luam. Lawv tshwj xeeb hauv kev tsim cov tshuab rau kev ntim khoom, tshwj xeeb tshaj yog rau PET preforms. Husky tshuab paub txog lawv qhov ceev thiab kev ntseeg tau. Cov neeg siv feem ntau qhia txog qhov yooj yim ntawm kev saib xyuas thiab kev tsim qauv zoo ntawm cov tshuab no. Hom no kuj tseem hais txog kev siv hluav taws xob zoo, ua rau nws yog qhov kev xaiv nrov rau cov tuam txhab nrhiav kom txo cov nqi ua haujlwm.

Koj puas paub?Husky cov cav tov tuaj yeem ua kom cov nqi ntau lawm, uas tuaj yeem yog qhov hloov pauv rau qhov kev xav tau siab.

KraussMaffei

KraussMaffei tau tsim lub koob npe nrov rau kev ua tau zoo thiab kev tsim kho tshiab. Lawv cov tshuab txhaj tshuaj molding yog tsim los rau ntau yam kev siv, los ntawm tsheb mus rau kev kho mob. KraussMaffei cov cav tov feem ntau tuaj nruab nrog cov cuab yeej siv thev naus laus zis, kom ntseeg tau tias muaj kev ua haujlwm siab thiab raug. Cov neeg siv khoom nquag qhuas lawv cov kav ntev thiab kev txhawb nqa los ntawm lub tuam txhab.

Nco tseg:Yog tias koj tab tom nrhiav rau lub tshuab uas tuaj yeem tswj qhov nyuaj, KraussMaffei yuav yog qhov kev xaiv zoo rau koj.

Arburg

Arburg yog lub npe zoo hauv kev txhaj tshuaj molding tshuab kev lag luam. Lawv cov cav tov paub txog lawv cov versatility thiab precision. Lawv muab ntau yam qauv tsim nyog rau ntau yam kev siv, los ntawm qhov me me mus rau cov khoom loj. Ntau tus neeg siv txaus siab rau cov neeg siv-phooj ywg interface thiab cov thev naus laus zis siab heev uas Arburg koom nrog hauv lawv cov tshuab.

Tswv yim:Yog tias koj xav tau lub tshuab uas tuaj yeem tswj cov geometry nyuaj, Arburg's Allrounder series yuav yog qhov haum zoo.

Arburg cov cav tov feem ntau tuaj nrog cov yam ntxwv uas txhim khu kev siv zog. Qhov no tsom mus rau kev ruaj khov pab cov tuam txhab txo lawv cov nqi ua haujlwm thaum tuav cov qauv tsim khoom siab. Cov neeg siv khoom feem ntau qhia txog qib siab, tshwj xeeb tshaj yog hais txog kev txhawb nqa thiab kev pabcuam los ntawm Arburg.

Demag

Demag yog lwm tus neeg tseem ceeb hauv kev lag luam txhaj tshuaj molding tshuab. Lawv paub txog lawv cov tshuab muaj zog thiab txhim khu kev qha. Demag tshuab ua tau zoo nyob rau hauv high-speed ntau lawm ib puag ncig, ua rau lawv zoo tagnrho rau kev lag luam xws li tsheb thiab cov neeg siv khoom.

Koj puas paub?Demag cov cav tov feem ntau muaj cov qauv tsim, uas txuag qhov chaw muaj txiaj ntsig hauv tsev tsim khoom.

Cov neeg siv feem ntau hais txog qhov ua tau ntev ntawm cov tshuab Demag. Lawv txaus siab rau qhov yuav tsum tau saib xyuas qis thiab lub neej ntev ntawm cov tshuab no. Cov kws tshaj lij cov tswv yim nquag qhuas Demag rau nws cov thev naus laus zis tshiab, uas txhim kho kev ua haujlwm thiab kev ua haujlwm zoo.

Sumitomo

Sumitomo tau lees paub rau nws cov tshuab txhaj tshuaj zoo tshaj plaws uas ua rau muaj qhov tseem ceeb thiab nrawm. Lawv cov tshuab yog tshwj xeeb tshaj yog nrov nyob rau hauv electronics thiab kev kho mob sectors. Sumitomo txoj kev cog lus rau kev tsim kho tshiab yog pom tseeb hauv lawv cov kev tswj hwm qib siab thiab cov yam ntxwv txuag hluav taws xob.

Nco tseg:Sumitomo cov cav tov feem ntau tuaj nruab nrog ntau yam kev hloov kho, tso cai rau cov lag luam los txiav cov tshuab rau lawv cov kev xav tau tshwj xeeb.

Cov neeg siv khoom tsis tu ncua ntsuas Sumitomo siab rau kev ntseeg siab thiab kev ua haujlwm. Cov kws tshaj lij feem ntau pom zoo lawv cov tshuab rau cov tuam txhab nrhiav kev txhim kho kev tsim khoom yam tsis muaj kev txi zoo.

WittmannBattenfeld

WittmannBattenfeld yog lub npe nrov hauv kev txhaj tshuaj molding tshuab kev lag luam. Lawv tsom mus rau muab cov kev daws teeb meem tshiab uas txhim kho cov khoom tsim tau. Lawv cov tshuab yog tshwj xeeb tshaj yog nrov rau lawv cov peev xwm automation. Ntau tus neeg siv txaus siab rau kev sib xyaw ua ke ntawm cov neeg hlau nrog lawv cov tshuab txhaj tshuaj molding. Cov yam ntxwv no tso cai rau cov txheej txheem ntau lawm thiab txo cov nqi zog.

Tswv yim:Yog tias koj tab tom nrhiav kev hloov pauv, WittmannBattenfeld muaj cov tshuab uas tuaj yeem hloov tau yooj yim rau cov kev xav tau ntau lawm.

Cov neeg siv khoom feem ntau hais txog cov neeg siv-phooj ywg interface ntawm WittmannBattenfeld cov cav tov. Qhov no ua rau nws yooj yim dua rau cov tswv lag luam los tswj cov haujlwm nyuaj. Cov tshuab kuj tuaj nrog cov kev xaiv txuag hluav taws xob, uas pab cov tuam txhab txuag ntawm cov nqi ua haujlwm.

Milacron

Milacron muaj lub koob npe nrov rau kev tsim cov tshuab txhaj tshuaj txhim khu kev qha. Lawv ua haujlwm rau ntau yam kev lag luam, suav nrog tsheb, khoom siv, thiab kev kho mob. Milacron cov cav tov paub txog lawv cov kav ntev thiab kev ua haujlwm siab. Cov neeg siv feem ntau qhuas lawv lub peev xwm los tswj cov khoom loj ntau yam tsis muaj kev cuam tshuam zoo.

Koj puas paub?Milacron muaj ntau lub tshuab uas tuaj yeem hloov kho kom tau raws li cov kev xav tau tshwj xeeb. Qhov kev hloov pauv no ua rau lawv nyiam ntawm cov tuam ntxhab.

Lub tuam txhab tseem hais txog kev siv hluav taws xob. Ntau lub tshuab Milacron tuaj nruab nrog cov thev naus laus zis uas txo qis kev siv zog. Qhov no tsom mus rau sustainability ua raws li qhov kev thov loj hlob rau eco-friendly manufacturing xyaum.

Haitian International

Haitian International yog ib lub tuam txhab loj tshaj plaws ntawm kev txhaj tshuaj molding tshuab thoob ntiaj teb. Lawv muab ntau hom qauv uas ua rau cov lag luam sib txawv. Haitian cov cav tov paub txog lawv cov nqi-zoo thiab kev ntseeg tau. Ntau tus neeg siv txaus siab rau qhov sib npaug ntawm kev ua tau zoo thiab kev them taus.

Nco tseg:Haitian International cov cav tov feem ntau muaj cov kev tswj xyuas siab heev, uas txhim kho qhov tseeb thiab kev ua haujlwm zoo hauv kev tsim khoom.

Cov neeg siv khoom nquag tshaj tawm cov qib siab siab nrog cov tshuab Haitian. Lawv txoj kev cog lus rau kev tsim kho tshiab kom ntseeg tau tias lawv nyob hauv kev sib tw hauv kev ua lag luam. Nrog rau kev tsom mus rau cov thev naus laus zis txuag hluav taws xob, Haitian cov cav tov pab cov lag luam txo lawv cov nqi tsim khoom tag nrho.

Cincinnati Milacron

Cincinnati Milacron tau txais lub koob npe nrov hauv kev txhaj tshuaj molding tshuab lag luam. Paub txog lawv txoj kev ntseeg siab, cov tshuab no ua haujlwm rau ntau yam kev lag luam, suav nrog tsheb, khoom siv, thiab kev kho mob. Ntau tus neeg siv txaus siab yuav ua li cas Milacron cov tshuab ua haujlwm loj ntau lawm yam tsis muaj kev txi zoo.

Ib qho tshwj xeeb ntawm Cincinnati Milacron yog lawv tsom mus rau kev siv hluav taws xob. Lawv cov tshuab feem ntau tuaj nruab nrog cov cuab yeej siv siab heev uas txo qis kev siv hluav taws xob. Qhov kev cog lus rau kev ruaj khov no ua raws li qhov xav tau ntau ntxiv rau kev tsim khoom hauv eco-phooj ywg.

Koj puas paub?Cincinnati Milacron muaj ntau lub tshuab uas tuaj yeem hloov kho kom tau raws li cov kev xav tau tshwj xeeb. Qhov kev hloov pauv no ua rau lawv nyiam ntawm cov tuam ntxhab.

Nyob rau hauv cov nqe lus ntawm kev ua tau zoo, Cincinnati Milacron tshuab ua tau zoo nyob rau hauv high-speed ntau lawm ib puag ncig. Lawv tau tsim los ua haujlwm kom zoo, uas pab cov lag luam ua kom lawv cov txiaj ntsig zoo tshaj plaws. Cov neeg siv feem ntau qhia txog qhov yooj yim ntawm kev ua haujlwm thiab kev saib xyuas, ua rau cov tshuab no siv tau zoo.

Cincinnati Milacron tseem muab kev txhawb nqa zoo rau cov neeg siv khoom. Ntau tus neeg siv khoom tshaj tawm cov kev paub zoo nrog lawv pab pawg pabcuam, uas ntxiv rau tag nrho kev txaus siab nrog lub hom.

Tswv yim:Thaum xav txog Cincinnati Milacron, xav txog koj cov kev xav tau ntau lawm. Lawv cov tshuab tuaj yeem hloov kho rau ntau yam kev siv, ua kom koj pom qhov haum rau koj txoj kev lag luam.

Zuag qhia tag nrho, Cincinnati Milacron sawv tawm rau nws cov kav ntev, lub zog ua haujlwm, thiab kev txhawb nqa cov neeg siv khoom. Cov qualities no ua rau nws muaj zog contender nyob rau hauv lub txhaj tshuaj molding tshuab lag luam.

Engel Txhaj Moulding Tshuab Nta

Cov ntsiab lus tseem ceeb

Engel txhaj tshuaj molding tshuab tuaj nrog ob peb qhov zoo tshaj plaws uas ua rau lawv sib nrug ntawm cov neeg sib tw. Ntawm no yog saib ceev ntawm qee qhov ntawm lawv qhov tshwj xeeb tshwj xeeb:

| Feature | Kev piav qhia |

|---|---|

| Zog efficiency | Proprietary e-motion thiab duo series rau txo lub zog noj. |

| Integrated automation | Integrated robots thiab automated solutions los txo cov kev cuam tshuam ntawm phau ntawv. |

| iQ software | Tsis siv neeg optimizes ntau lawm los ntawm kev kho qhov tsis zoo rau cov xwm txheej zoo. |

| Ntau yam kev siv | Haum rau ntau yam kev lag luam suav nrog tsheb, kev kho mob, thiab ntim khoom. |

Cov kev qhia tshwj xeeb no qhia txog Engel txoj kev cog lus rau kev tsim kho tshiab thiab kev ua haujlwm zoo, ua rau lawv cov tshuab yog qhov kev xaiv nrov ntawm cov tuam txhab.

Cov neeg siv khoom txaus siab

Cov neeg siv khoom tsis tu ncua ntsuas cov tshuab Engel siab heev rau lawv cov kev ua tau zoo thiab kev ntseeg tau. Ntau tus neeg siv txaus siab rau cov neeg siv-phooj ywg interface thiab cov thev naus laus zis siab heev uas Engel suav nrog rau hauv lawv cov tshuab. Qhov tseeb, kev tshawb fawb tsis ntev los no tau pom tias ntau dua 90% ntawm Engel cov neeg siv tau tshaj tawm kev txaus siab rau lawv lub tshuab ua haujlwm. Qhov siab siab ntawm kev txaus siab no feem ntau txhais mus rau hauv kev yuav khoom dua thiab muaj kev ntseeg siab rau cov khoom lag luam.

Tswv yim:Yog tias koj tab tom xav txog lub tshuab Engel, nrhiav kev tshuaj xyuas cov neeg siv khoom tshwj xeeb rau koj qhov kev lag luam. Qhov no tuaj yeem muab kev nkag siab zoo rau qhov ua tau zoo ntawm lub tshuab ua haujlwm hauv kev siv tiag tiag.

Cov tswv yim

Cov kws tshaj lij hauv thaj chaw nquag qhuas Engel rau nws txoj hauv kev tshiab rau kev txhaj tshuaj molding. Lawv nco ntsoov tias Engel tshuab ua tau zoo hauv kev siv hluav taws xob, feem ntau ua haujlwm zoo dua li cov qauv hydraulic. Piv txwv li, Engel's e-motion series siv zog tsawg dua piv rau cov tshuab qub.

Daim duab no qhia txog qhovnruab nrab siv zogntawm Engel cov cav tov piv rau cov tsoos hydraulic thiab hybrid hluav taws xob qauv. Cov ntaub ntawv qhia meej tias Engel qhov kom zoo dua hauv kev siv hluav taws xob, ua rau nws muaj kev xaiv ntse rau cov tuam txhab nrhiav kom txo cov nqi ua haujlwm.

Zuag qhia tag nrho, Engel kev sib xyaw ua ke ntawm cov thev naus laus zis siab heev, cov neeg siv khoom txaus siab, thiab cov kws tshaj lij pom zoo ua kom nws txoj hauj lwm ua lub lag luam ua lag luam hauv kev txhaj tshuaj molding tshuab.

SWOT Analysis

Thaum ntsuas Engel txhaj tshuaj molding tshuab, SWOT tsom xam muab cov kev pom zoo rau lawv txoj haujlwm ua lag luam. Nov yog qhov kev tawg ntawm qhov muaj zog, qhov tsis muaj zog, lub sijhawm, thiab kev hem thawj cuam tshuam nrog Engel tshuab:

Lub zog

- Kev Tsim Kho Tshuab: Engel machines feature advanced technology uas txhim khu kev ua tau zoo thiab precision.

- Zog Efficiency: Lawv txoj kev cog lus rau kev tsim hluav taws xob txuag hluav taws xob pab txo cov nqi ua haujlwm.

- Ntau yam: Engel muaj ntau yam qauv tsim nyog rau ntau yam kev siv, ua rau lawv hloov mus rau kev lag luam sib txawv.

Tsis muaj zog

- Tus nqi pib siab dua: Engel tshuab feem ntau tuaj nrog tus nqi siab dua piv rau qee tus neeg sib tw, uas tuaj yeem cuam tshuam cov neeg siv nyiaj txiag.

- nyuaj: Cov yam ntxwv siab heev tuaj yeem xav tau kev cob qhia ntxiv rau cov neeg ua haujlwm, uas ua rau muaj kev kawm nkhaus.

Muaj cib fim

- Kev loj hlob xav tau rau Automation: Raws li kev lag luam nce kev siv automation, Engel cov kev daws teeb meem sib xyaw ua ke lawv zoo los tuav lub khw no.

- Sustainability Trends: Nrog rau kev tsom mus rau kev siv hluav taws xob, Engel tuaj yeem nyiam cov tuam txhab nrhiav kom txo lawv cov pa roj carbon hneev taw.

Kev hem

- Kev sib tw khaus: Kev txhaj tshuaj molding tshuab kev lag luam yog cov neeg coob coob, nrog ntau lub npe muab cov yam ntxwv zoo sib xws ntawm cov nqi sib tw.

- Kev lag luam poob qis: Kev hloov pauv ntawm kev lag luam tuaj yeem cuam tshuam cov peev nyiaj tsim khoom, ua rau txo kev nqis peev hauv cov tshuab tshiab.

Engel lub zog hauv kev siv thev naus laus zis thiab kev siv hluav taws xob ua rau lawv ua tus neeg muaj zog hauv kev txhaj tshuaj molding tshuab lag luam. Txawm li cas los xij, lawv yuav tsum taug kev cov nyom xws li kev sib tw thiab kev hloov pauv nyiaj txiag los tswj lawv txoj haujlwm.

Husky Txhaj Moulding Tshuab Nta

Cov ntsiab lus tseem ceeb

Husky txhaj tshuaj molding tshuab paub txog lawv cov cuab yeej technology thiab kev ua haujlwm zoo. Nov yog qee qhovtseem ceeb nce qibuas teem lawv sib nrug:

| Hom kev nce qib | Ntsiab nta |

|---|---|

| Altanium® Pwm Controllers | - Kev lag luam 4.0 npaj kev koom ua ke - Advanced proprietary tswj technology - Kev txhim kho lub zog tseem ceeb - Superior diagnostic peev xwm - Kev saib xyuas lub sijhawm tiag tiag thiab kev ua kom zoo |

| Ua kom tiav System Integration | - Seamless tivthaiv kev sib txuas lus - Optimized system kev ua tau zoo - Kev ua haujlwm yooj yim thiab kev tswj hwm - Txhim kho kev daws teeb meem muaj peev xwm - Yav tom ntej-pov thawj technology platform |

| HyPET®6e Platform | - Cov txheej txheem siab tshaj plaws rau kev molding ruaj khov nrog kev muaj peev xwm zoo tshaj rPET |

| HyCAP™4 System | - Lub zog txuag dej haus kaw qhov system nrog txo lub sij hawm voj voog |

| Hylectric® Systems | - Ntau lub platform rau cov khoom lag luam, cov thawv ntim khoom noj, thiab cov khoom siv kho mob |

| HyperSync™ Systems | - Thawj qhov kev sib xyaw ua ke rau kev ntim khoom tshwj xeeb nrog rau hauv-pwm labeling |

| NexPET ™ Systems | - Yooj yim rau nruab nrab ntim PET preform ntau lawm nrog kev hloov pauv sai |

| ICHOR™ Systems | - Precision kho mob molding platform rau kev kuaj mob thiab kuaj daim ntawv thov |

Cov yam ntxwv no qhia txog Husky txoj kev cog lus rau kev tsim kho tshiab thiab kev ua haujlwm zoo hauv kev lag luam txhaj tshuaj molding tshuab.

Cov neeg siv khoom txaus siab

Cov neeg siv khoom feem ntau qhia kev txaus siab nrog Husky tshuab. Ntau tus neeg siv txaus siab rau qhov ceev thiab kev ntseeg siab ntawm cov tshuab no, tshwj xeeb tshaj yog nyob rau hauv qhov kev thov siab. Kev tshawb fawb tsis ntev los no tau qhia tias ntau dua 85% ntawm cov neeg siv Husky tau tshaj tawm tias txaus siab rau lawv lub tshuab ua haujlwm. Qhov kev txaus siab no feem ntau ua rau rov yuav khoom dua thiab muaj kev ntseeg siab rau cov khoom lag luam.

Tswv yim:Thaum xav txog lub tshuab Husky, xyuas cov neeg siv khoom xyuas tshwj xeeb rau koj qhov kev lag luam. Qhov no tuaj yeem muab kev nkag siab zoo rau qhov ua tau zoo ntawm lub tshuab ua haujlwm hauv kev siv tiag tiag.

Cov tswv yim

Cov kws tshaj lij feem ntau qhuas Husky rau nws txoj kev tsom mus rau kev tsim khoom nrawm thiab raug. Lawv paub Husky tshuab rau lawv cov khoom tsim tau siab thiab lub sijhawm luv luv, tshwj xeeb hauv kev lag luam ntim khoom. Ntawm no yog saib ceev npaum li cas lawv nyob rau hauv cov nqe lus ntawm ntau lawm ceev thiab precision:

| Yam ntxwv | Kev piav qhia |

|---|---|

| Ntau lawm ceev | Pom zoo rauhigh productivity thiab luv cycles, tshwj xeeb tshaj yog nyob rau hauv kev lag luam ntim khoom. |

| Precision | Cov ntsiab lus tshwj xeeb hais txog qhov tseeb tsis tau hais meej meej, qhia qhov sib txawv ntawm cov ntaub ntawv. |

Zuag qhia tag nrho, Husky kev sib xyaw ua ke ntawm cov thev naus laus zis siab heev, cov neeg siv khoom txaus siab, thiab cov kws tshaj lij pom zoo ua kom nws txoj haujlwm ua lag luam ua lag luam hauv kev txhaj tshuaj molding tshuab.

SWOT Analysis

Thaum ntsuam xyuas Husky txhaj tshuaj molding tshuab, SWOT tsom xam tuaj yeem muab kev nkag siab zoo rau lawv txoj haujlwm ua lag luam. Nov yog qhov kev tawg ntawm qhov muaj zog, qhov tsis muaj zog, lub sijhawm, thiab kev hem thawj cuam tshuam nrog Husky tshuab:

Lub zog

- High Productivity: Husky cov cav tov paub txog lawv cov kev ceev thiab kev ua tau zoo, ua rau lawv zoo tagnrho rau cov chaw tsim khoom loj.

- Kev ntseeg tau: Cov neeg siv feem ntau qhuas txog kev ua haujlwm ntev ntawm Husky cov cav tov, uas ua rau txo tus nqi kho.

- Advanced Technology: Kev sib koom ua ke ntawm cov yam ntxwv tshiab, zoo li Altanium® Pwm Controllers, txhim kho kev ua haujlwm thiab lub zog ua haujlwm.

Tsis muaj zog

- Tus nqi pib: Kev nqis peev ua ntej rau Husky tshuab tuaj yeem siab dua li qee tus neeg sib tw, uas tuaj yeem cuam tshuam cov neeg siv nyiaj txiag.

- nyuaj: Qee cov neeg siv pom cov thev naus laus zis siab heev xav tau kev cob qhia ntxiv, ua rau muaj peev xwm kawm nkhaus.

Muaj cib fim

- Kev loj hlob xav tau rau Automation: Raws li kev lag luam nce kev siv automation, Husky cov kev daws teeb meem tshiab ua rau lawv zoo los tuav lub khw no.

- Sustainability Trends: Nrog rau kev tsom mus rau kev siv hluav taws xob, Husky tuaj yeem nyiam cov tuam txhab nrhiav kom txo lawv cov kev cuam tshuam ib puag ncig.

Kev hem

- Kev sib tw khaus: Kev txhaj tshuaj molding tshuab kev lag luam yog cov neeg coob coob, nrog ntau lub npe muab cov yam ntxwv zoo sib xws ntawm cov nqi sib tw.

- Kev hloov pauv nyiaj txiag: Kev lag luam poob qis tuaj yeem cuam tshuam cov peev txheej tsim khoom, ua rau txo kev nqis peev hauv cov tshuab tshiab.

KraussMaffei Txhaj Moulding Tshuab Nta

Cov ntsiab lus tseem ceeb

KraussMaffei txhaj tshuaj molding tshuab paub txog lawv cov kev qhia tshwj xeeb. Lawv muab tus nqi tsim nyog tus nqi taw tes thiab muaj ceev ceev, ua rau lawv muaj kev xaiv nrov ntawm cov tuam ntxhab. Nov yog qee qhov tseem ceeblub zog ntawm KraussMaffei tshuab:

| Lub zog | Kev piav qhia |

|---|---|

| Nqi-zoo | Muab tus nqi tsim nyog tus nqi taw tes thiab muaj ceev ceev. |

| ntseeg tau | High precision thiab repeatability nrog ib tug proven thiab robust tshuab tsim. |

| Yooj yim | Yooj yim rau kev txuas nrog cov neeg hlau thiab txhawb nqa cov ntaub ntawv hloov pauv thiab taug qab. |

Cov yam ntxwv no ua rau KraussMaffei cov cav tov haum rau ntau yam kev lag luam, suav nrog tsheb, kev kho mob, thiab cov khoom siv.

Cov neeg siv khoom txaus siab

Cov neeg siv khoom feem ntau qhia kev txaus siab nrog KraussMaffei tshuab. Ntau tus neeg siv txaus siab rau lawv txoj kev ntseeg siab thiab precision. Qhov tseeb, cov tshuab no nquag qhuas rau lawv cov kev tu ncua tsawg thiab cov nqi ua haujlwm. KraussMaffei cov cav tov feem ntau poob nyob rau hauv tus nqi ntau ntawm$80,000 txog $120,000, zoo ib yam li lwm lub tuam txhab European zoo li Engel thiab Arburg.

- Cov neeg siv nco ntsoov tias cov tshuab no muab cov txiaj ntsig zoo hauv kev siv hluav taws xob, nrog kev txo qis ntawm 15-30% piv rau cov qauv qis dua.

- Lawv kuj tau tshaj tawm cov nqi qis dua, uas tuaj yeem ua rau txo cov nqi ua haujlwm ntev.

Cov tswv yim

Cov kws tshaj lij hauv thaj teb lees paub KraussMaffei rau nws txoj kev tsim kho tshiab thiab tsim qauv zoo. Lawv hais txog lub tshuab muaj peev xwm tswj tau qhov ruaj khov ntau lawm, ua rau lawv zoo tagnrho rau kev thov kev thov. Hauv qab noKev lag luam feem ntau siv KraussMaffei txhaj tshuaj molding tshuab:

| Kev lag luam |

|---|

| Automotive |

| Tshuaj |

| Circular Economy & Recycling |

| Cov khoom siv |

| Cua txias technology & rwb thaiv tsev |

| Hluav taws xob & Electronics |

| Infrastructure & Kev tsim kho |

| Kev kho mob technology |

| Kho qhov muag |

| Ntim & Logistics |

| Kev thauj mus los rau pej xeem & kev siv hluav taws xob |

Zuag qhia tag nrho, KraussMaffei cov cav tov sawv tawm rau lawv txoj kev ntseeg tau thiab kev ua tau zoo, ua rau lawv xaiv zoo tshaj plaws rau cov tuam txhab nrhiav los txhim kho lawv cov peev txheej ntau lawm.

SWOT Analysis

KraussMaffei txhaj tshuaj molding tshuab muaj lub koob npe nrov hauv kev lag luam. Ib qho SWOT tsom xam pab kom nkag siab txog lawv txoj kev lag luam zoo dua. Ntawm no yog ib qho kev sib cais:

Lub zog

- Siab Precision: KraussMaffei cov cav tov xa tawm qhov tseeb tshwj xeeb, ua rau lawv zoo tagnrho rau kev thov.

- Robust Design: Lawv cov cav tov tau tsim kom kawg, uas txo cov nqi txij nkawm thiab kev poob qis.

- Kev siv ntau yam: Cov tshuab no ua haujlwm rau ntau yam kev lag luam, suav nrog tsheb, kev kho mob, thiab cov khoom siv.

Tsis muaj zog

- Kev nqis peev siab dua: Tus nqi pem hauv ntej ntawm KraussMaffei cov cav tov tuaj yeem siab dua li qee tus neeg sib tw, uas tuaj yeem cuam tshuam cov neeg siv nyiaj txiag.

- Cov yam ntxwv nyuaj: Qee cov neeg siv pom cov thev naus laus zis siab heev xav tau kev cob qhia ntxiv, ua rau muaj peev xwm kawm nkhaus.

Muaj cib fim

- Kev loj hlob xav tau rau Automation: Raws li kev lag luam nce kev siv automation, KraussMaffei cov kev daws teeb meem tshiab ua rau lawv zoo los ntes cov lag luam no.

- Sustainability Trends: Nrog rau kev tsom mus rau kev siv hluav taws xob, KraussMaffei tuaj yeem nyiam cov tuam txhab nrhiav kom txo lawv cov kev cuam tshuam ib puag ncig.

Kev hem

- Kev sib tw khaus: Kev txhaj tshuaj molding tshuab kev lag luam yog cov neeg coob coob, nrog ntau lub npe muab cov yam ntxwv zoo sib xws ntawm cov nqi sib tw.

- Kev hloov pauv nyiaj txiag: Kev lag luam poob qis tuaj yeem cuam tshuam cov peev txheej tsim khoom, ua rau txo kev nqis peev hauv cov tshuab tshiab.

Arburg Txhaj Moulding Tshuab Nta

Cov ntsiab lus tseem ceeb

Arburg txhaj tshuaj molding tshuab tau paub txog lawv cov yam ntxwv tshiab thiab muaj kev ntseeg tau zoo. Nov yog qee qhov tshwj xeeb tseem ceeb uas qhia txog lawv lub peev xwm:

| Feature | Kev piav qhia |

|---|---|

| SELOGICA Direct Controller | Taw qhia lub touchscreen rau kev txhim kho yooj yim thiab tswj kev txhaj tshuaj molding txheej txheem. |

| Fast-switching valve technology | Ua kom nrawm ntawm kev hloov pauv li qub, txhim kho kev nrawm thiab pwm qhov zoo. |

| Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob | Tsom ntsoov rau kev siv hluav taws xob, muaj txiaj ntsig zoo rau ib puag ncig thiab cov tuam txhab cov nqi. |

| Dual Pump Technology | Tso cai rau tib lub sijhawm ua haujlwm ntawm lub ejector, ua rau lub sijhawm voj voog nrawm dua thiab cov zis ntau ntxiv. |

Arburg cov cav tov muaj los ntawm44 tons rau 220 tons, suav nrog cov yam ntxwv zoo li aXw Control Screw Pilot rau kev txhaj tshuaj zoo dua qub. GOLDEN EDITION thiab GOLDEN ELECTRIC kab ua piv txwv Arburg txoj kev mob siab rau kev ua tau zoo thiab kev tsim kho tshiab, muab cov tshuab thev naus laus zis rau ntau hom kev siv.

Cov neeg siv khoom txaus siab

Cov neeg siv khoom txaus siab nrog Arburg cov cav tov yog impressive. Cov kev tshawb fawb tsis ntev los no qhia tau tias:

- 96% ntawm cov neeg tshawb nrhiavpom Arburg hybrid 'Allrounder 470 H' haum raws li kev hloov rau cov tshuab hydraulic.

- 95% suav hais tias nws yog qhov tsim nyog hloov rau cov tshuab hluav taws xob.

- Lub tshuab thev naus laus zis tau txais cov qhab nia siab, qhia cov neeg siv khoom txaus siab.

Cov kev ntsuam xyuas no qhia txog cov neeg siv kev ntseeg siab nyob hauv Arburg txoj kev siv tshuab thiab kev ua haujlwm.

Cov tswv yim

Cov kws tshaj lij feem ntau qhuas Arburg rau nws cov automation siab heev thiab muaj peev xwm ua ke. Lawv qhia txog cov yam ntxwv xws li:

| Feature | Kev piav qhia |

|---|---|

| Tig-Key Capabilities | ARBURG muabkev daws teeb meem rau kev teeb tsa thiab optimizing cov kab ntau lawm. |

| Kev koom ua ke ntawm cov khoom siv Peripheral | Lawv tshwj xeeb hauv kev sib koom ua ke robotic systems, conveyor siv, thiab cov cuab yeej tshuaj xyuas zoo. |

| Software thiab Digital Solutions | ARBURG muaj software rau kev soj ntsuam ntau lawm, kev txheeb xyuas cov ntaub ntawv, thiab cov txheej txheem ua kom zoo. |

| Kev cob qhia thiab kev txhawb nqa | Kev cob qhia zoo rau cov neeg ua haujlwm thiab cov neeg ua haujlwm tu xyuas kom muaj kev hloov pauv tau zoo. |

| OPC UA Communication | Siv OPC UA rau kev sib txuas lus tsis sib haum xeeb ntawm cov cuab yeej siv khoom lag luam, txhim kho kev sib txuas. |

Cov yam ntxwv no ua rau Arburg cov cav tov yog qhov kev xaiv zoo tshaj plaws rau cov tuam txhab nrhiav kev txhim kho lawv cov kev ua tau zoo thiab kev tswj xyuas zoo.

SWOT Analysis

Thaum ntsuam xyuas Arburg txhaj tshuaj molding tshuab, SWOT tsom xam qhia lawv lub zog, tsis muaj zog, muaj peev xwm, thiab hem. Qhov kev tshuaj ntsuam no pab cov tuam txhab nkag siab tias cov tshuab no haum rau lawv cov kev xav tau li cas.

Lub zog

- Kev Tsim Kho Tshuab: Arburg machines feature advanced technology uas txhim khu kev ua tau zoo thiab precision.

- Ntau yam: Lawv haum rau ntau yam kev siv, ua rau lawv haum rau kev lag luam sib txawv.

- Txaus siab rau cov neeg siv khoom siab: Cov neeg siv feem ntau tshaj tawm cov qib siab siab vim muaj kev ntseeg siab thiab kev ua haujlwm.

Tsis muaj zog

- Tus nqi pib siab dua: Kev nqis peev ua ntej rau Arburg cov cav tov tuaj yeem muaj ntau dua li qee tus neeg sib tw, uas tuaj yeem cuam tshuam cov neeg yuav khoom siv nyiaj.

- Cov yam ntxwv nyuaj: Qee qhov kev ua haujlwm siab heev yuav xav tau kev cob qhia ntxiv rau cov neeg ua haujlwm, ua rau muaj peev xwm kawm nkhaus.

Muaj cib fim

- Kev loj hlob xav tau rau Automation: Raws li kev lag luam nce kev siv automation, Arburg cov kev daws teeb meem tshiab ua rau lawv zoo los tuav lub khw no.

- Sustainability Trends: Nrog rau kev tsom mus rau kev siv hluav taws xob, Arburg tuaj yeem nyiam cov tuam txhab nrhiav kom txo lawv cov kev cuam tshuam ib puag ncig.

Kev hem

- Kev sib tw khaus: Kev txhaj tshuaj molding tshuab kev lag luam yog cov neeg coob coob, nrog ntau lub npe muab cov yam ntxwv zoo sib xws ntawm cov nqi sib tw.

- Kev hloov pauv nyiaj txiag: Kev lag luam poob qis tuaj yeem cuam tshuam cov peev txheej tsim khoom, ua rau txo kev nqis peev hauv cov tshuab tshiab.

Los ntawm kev nkag siab txog cov xwm txheej no, cov tuam txhab lag luam tuaj yeem txiav txim siab paub txog seb Arburg txhaj tshuaj molding tshuab ua raws li lawv cov hom phiaj tsim khoom.

Demag Txhaj Moulding Tshuab Nta

Cov ntsiab lus tseem ceeb

Demag txhaj tshuaj molding tshuabpaub txog lawv cov yam ntxwv zoo uas txhim kho kev ua tau zoo thiab kev ntseeg tau. Ntawm no yog saib ceev ntawm qee qhov ntawm lawv qhov tshwj xeeb tshwj xeeb:

| Feature | Kev piav qhia |

|---|---|

| Txhaj Ceev | Txog li 500 mm / s |

| Txhaj Tshuaj | Txog li 41,191 psi (2897 kgf / cm²) |

| Linear Kev taw qhia System | Ua kom cov pwm ua haujlwm du thiab sib luag |

| Bushing-free Tie Bars | Khaws thaj chaw pwm kom huv si, zoo tagnrho rau kev siv tshuaj kho mob |

| Center Press Platen Design | Txo qhov siab ntawm qhov tsis sib xws |

| Clamp Force Feedback Control | Compensates rau thermal expansion ntawm pwm |

Demag cov cav tov kuj tseem muaj qhov chaw xaiv txuag hluav taws xob txuag hluav taws xob, uas txo qis kev siv hluav taws xob thaum tuav lub zog. Nrog rau qhov tsis tshua muaj kev sib hloov lub cev muaj zog thiab txo qis kev sib txhuam hauv cov txheej txheem kev taw qhia, cov tshuab no ua kom zoo dua. Tsis tas li ntawd, Demag suav nrog cov thev naus laus zis tshwj xeeb xws li Zero-Molding, uas txo qis qhov xav tau ntawm lub zog clamping thiab txhim kho qhov sib npaug nrog kev txhaj tshuaj qis.

Cov neeg siv khoom txaus siab

Cov neeg siv khoom feem ntau qhia kev txaus siab rau cov tshuab Demag. Ntau tus neeg siv txaus siab rau lawv txoj kev ntseeg siab thiab ntev ntev. Piv txwv li, Lub Sijhawm Nruab Nrab Nruab Nrab Tsis Ua Haujlwm (MTBF) rau IntElect2 tshuab nruab nrab4.4 xya, uas yog ob npaug ntawm qhov sib npaug ntawm cov tshuab hydraulic. Cov neeg siv kuj tseem nco ntsoov tias txhua lub tshuab hluav taws xob muaj tsawg dua qhov txav mus los, ua rau txo qis qis thiab kev xav tau kev saib xyuas. Cov kev pabcuam niaj hnub ua haujlwm rau lub tshuab hydraulic 130-tuj yuav siv sijhawm li 39 teev, thaum tus qauv sib npaug IntElect2 yuav tsum tsuas yog rau teev. Qhov sib txawv tseem ceeb no qhia txog kev ua tau zoo thiab kev ntseeg siab ntawm Demag tshuab.

Cov tswv yim

Cov kws tshaj lij feem ntau qhuas Demag rau nws txoj hauv kev tshiab rau kev txhaj tshuaj molding. Lawv hais txog qhov kev taw qhia ntawmntau lub tshuab hluav taws xob tag nrholos ntawm IntElect platform, tsim rau ntau yam kev lag luam. Cov tshuab tshiab PAC-E tsom rau kev ua haujlwm siab, ua rau lawv zoo tagnrho rau cov chaw tsim khoom ceev ceev. Tsis tas li ntawd, Demag integrates advanced automation solutions, txhim kho tag nrho cov txheej txheem efficiency. Cov kws tshaj lij kuj txaus siab rau qhov ruaj khov thiab qhov tseeb uas muaj los ntawm cov neeg hlau sab saum toj nkag, uas muab cov kev daws teeb meem tsis muaj kev txi.

Zuag qhia tag nrho, Demag txhaj tshuaj molding tshuab sawv tawm rau lawv cov thev naus laus zis siab, kev ntseeg siab, thiab cov neeg siv kev txaus siab, ua rau lawv muaj kev xaiv zoo rau cov tuam txhab.

SWOT Analysis

Thaum ntsuam xyuas Demag txhaj tshuaj molding tshuab, SWOT tsom xam qhia lawv lub zog, tsis muaj zog, lub cib fim, thiab kev hem thawj. Qhov kev tshuaj ntsuam no pab cov tuam txhab nkag siab tias cov tshuab no haum rau lawv cov kev xav tau li cas.

Lub zog

- Kev Tsim Kho Tshuab: Demag machines feature advanced technology uas txhim khu kev ua tau zoo thiab precision.

- Kev ntseeg tau: Cov neeg siv feem ntau qhuas txog kev ua haujlwm ntev ntawm Demag cov cav tov, uas ua rau txo tus nqi kho.

- Zog Efficiency: Ntau tus qauv tuaj nrog cov yam ntxwv txuag hluav taws xob, pab cov tuam txhab txo nqi ua haujlwm.

Tsis muaj zog

- Tus nqi pib siab dua: Kev nqis peev ua ntej rau Demag cov cav tov tuaj yeem ua tau ntau dua li qee tus neeg sib tw, uas tuaj yeem cuam tshuam cov neeg yuav khoom siv nyiaj.

- Cov yam ntxwv nyuaj: Qee qhov kev ua haujlwm siab heev yuav xav tau kev cob qhia ntxiv rau cov neeg ua haujlwm, ua rau muaj peev xwm kawm nkhaus.

Muaj cib fim

- Kev loj hlob xav tau rau Automation: Raws li kev lag luam nce kev siv automation, Demag cov kev daws teeb meem tshiab ua rau lawv zoo los tuav lub khw no.

- Sustainability Trends: Nrog rau kev tsom mus rau kev siv hluav taws xob, Demag tuaj yeem nyiam cov tuam txhab nrhiav kom txo lawv cov kev cuam tshuam ib puag ncig.

Kev hem

- Kev sib tw khaus: Kev txhaj tshuaj molding tshuab kev lag luam yog cov neeg coob coob, nrog ntau lub npe muab cov yam ntxwv zoo sib xws ntawm cov nqi sib tw.

- Kev hloov pauv nyiaj txiag: Kev lag luam poob qis tuaj yeem cuam tshuam cov peev txheej tsim khoom, ua rau txo kev nqis peev hauv cov tshuab tshiab.

Sib piv kev tshuaj ntsuam ntawm Txhaj Molding Machine

Thaum nws los txog rau kev xaiv lub tshuab txhaj tshuaj molding zoo, kev tshuaj xyuas kev sib piv tuaj yeem pab cov tuam txhab txiav txim siab. Tshooj lus no muab faib ua peb yam tseem ceeb: kev ua tau zoo, tus nqi rau nyiaj, thiab kev ntseeg siab.

Kev sib piv

Kev ntsuas kev ua tau zoo ua lub luag haujlwm tseem ceeb hauv kev ntsuas cov tshuab txhaj tshuaj molding. Nov yog qee qhovcov cim qhia ua haujlwm tseem ceebxav txog:

- Tus nqi tsis zoo

- Kev txaus siab ntawm cov neeg siv khoom (raws li kev soj ntsuam tau qhab nia)

- Cov nyiaj tau los tag nrho

- Net profit

- Ua haujlwm raws li feem pua ntawm kev muag khoom

- Raws sij hawm xa tuaj feem pua

- Tus neeg ua haujlwm efficiency

- Qhwv feem pua

- Kev siv tshuab

Cov kev ntsuas no pab cov tuam txhab ntsuas seb lub tshuab ua haujlwm zoo li cas hauv cov ntawv thov tiag tiag. Piv txwv li, lub tshuab uas khav theeb cov neeg ua haujlwm siab ua haujlwm thiab cov nqi qis qis tuaj yeem txhim kho cov khoom tsim tawm thiab txo cov nqi.

Tsis tas li ntawd, kev teeb tsa lub sijhawm thiab tus nqi ntawm cov khoom poob thaum lub sijhawm ua haujlwm yog qhov tseem ceeb heev. Lub tshuab uas txo cov sij hawm teeb tsa thiab cov resin poob tuaj yeem ua rau muaj txiaj ntsig zoo dua thiab muaj txiaj ntsig zoo.

Tus nqi rau Nyiaj

Tus nqi rau cov nyiaj yog lwm qhov tseem ceeb rau kev txiav txim siab thaum xaiv lub tshuab txhaj tshuaj molding. Cov neeg tsim khoom yuav tsum ntsuas qhov kev nqis peev thawj zaug tiv thaiv lub tshuab cov txiaj ntsig mus ntev. Nov yog qee yam uas yuav tsum xav txog:

- Warranty Terms: Ntau manufacturers muab ib12-lub hlis warranty rau txhua yam, hydraulic, thiab hluav taws xob qhov chaw, tsis suav nrog cov ntsia hlau thiab lub thoob. Kev lav 6 lub hlis rau cov ntsia hlau thiab lub thoob yog ntau, tab sis qhov no yuav tsis siv rau cov khoom siv rov ua dua tshiab. Cov lus lees paub meej qhia tias cov chaw tsim khoom muaj kev ntseeg siab hauv lawv cov khoom.

- Kev them nyiaj yug tom qab muag: Saib rau cov tuam txhab uas muab kev teeb tsa thiab kev txhawb nqa, kev cob qhia tus neeg ua haujlwm, thiab kev pabcuam saib xyuas tsis tu ncua. Kev xa khoom ceev ceev ntawm cov khoom seem kuj tseem ceeb heev rau kev txo qis qis.

- Tus nqi ntawm cov tswv cuab: Xav txog tag nrho cov nqi ntawm cov tswv, uas suav nrog kev saib xyuas, kev siv hluav taws xob, thiab lub sijhawm poob qis. Lub tshuab uas kim dua me ntsis ua ntej tab sis muaj cov nqi qis dua tuaj yeem muab tus nqi zoo dua nyob rau lub sijhawm.

Reliability thiab Durability

Kev ntseeg tau thiab kav ntev yog qhov tseem ceeb thaum nqis peev hauv lub tshuab txhaj tshuaj molding. Lub tshuab txhim khu kev qha minimizes kev npaj txhij txog kev tawg thiab cov nqi tu. Nov yog qee yam uas yuav tsum xav txog:

- Ua kom zoo: Cov cav tov nrog cov qauv tsim muaj zog yuav siv sij hawm ntev dua thiab yuav tsum muaj kev saib xyuas tsawg dua. Nrhiav cov npe uas paub txog lawv txoj kev tsim kho.

- Cov lus qhia siv: Kev tshuaj xyuas cov neeg siv khoom feem ntau qhia txog kev ntseeg tau ntawm cov qauv tshwj xeeb. Cov tshuab uas tsis tu ncua tau txais kev ntsuas siab rau kev ua haujlwm ntev yog feem ntau yog qhov kev nyab xeeb thawj koom ruam.

- Chaw tsim tshuaj paus Reputation: Tsim cov hom lag luam feem ntau muaj cov ntaub ntawv teev tseg ntawm kev tsim cov tshuab txhim khu kev qha. Tshawb nrhiav cov chaw tsim khoom keeb kwm tuaj yeem muab kev nkag siab txog lawv txoj kev ntseeg siab.

Hauv cov ntsiab lus, ntau lub npe nrov tshaj plaws hauv kev lag luam txhaj tshuaj molding tshuab, suav nrog Engel, Husky, KraussMaffei, thiab Arburg. Txhua lub npe muaj cov yam ntxwv tshwj xeeb uas ua raws li cov kev xav tau ntau lawm.

Cov kws tshaj lij pom zooxav txog cov hauv qab no thaum xaiv lub tshuab txhaj tshuaj molding:

- Txhais koj qhov project xav tau.

- Xaiv hom tshuab zoo.

- Txiav txim siab qhov tsim nyog clamp tonnage.

- Muab cov tshuaj txhaj rau qhov project specifications.

- Xyuas pwm compatibility.

- Ua ntej siv zog ua haujlwm.

- Nrhiav precision thiab tswj nta.

- Ua kom ntseeg tau kev txhawb nqa tom qab muag.

- Ua ib qho kev ntsuam xyuas tus nqi-cov txiaj ntsig.

- Ntsuas cov khoom lag luam lub koob npe nrov thiab kev txawj ntse.

Teem koj xaiv nrog cov kev xav tau tshwj xeeb, xws li cov khoom siv thiab ntim ntau lawm, ua kom pom kev ua haujlwm zoo. Kev nkag siab txog cov xwm txheej no yuav pab cov tuam txhab tsim cov kev txiav txim siab uas txhim khu kev ua tau zoo thiab cov khoom zoo.

FAQ

Kev txhaj tshuaj molding yog dab tsi?

Kev txhaj tshuaj molding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj molten rau hauv pwm los tsim cov khoom. Txoj kev no yog siv dav rau kev tsim cov khoom yas hauv ntau qhov kev lag luam, suav nrog tsheb, kev kho mob, thiab cov khoom siv.

Kuv yuav xaiv txoj cai txhaj tshuaj molding tshuab li cas?

Txhawm rau xaiv lub tshuab zoo, xav txog yam xws li ntim ntau lawm, hom khoom, thiab qhov nyuaj. Ntsuas cov kev qhia tshwj xeeb xws li clamping quab yuam, kev txhaj tshuaj muaj peev xwm, thiab lub zog ua haujlwm kom nrhiav tau lub tshuab ua tau raws li koj cov kev xav tau tshwj xeeb.

Dab tsi yog cov txiaj ntsig ntawm tag nrho cov hluav taws xob txhaj tshuaj molding tshuab?

Txhua-hluav taws xob txhaj tshuaj molding tshuab muaj ntau yam zoo, nrog rau kev siv hluav taws xob qis, txo kev txij nkawm, thiab txhim kho precision. Lawv kuj muab lub sijhawm voj voog nrawm dua thiab ua haujlwm ntsiag to, ua rau lawv zoo tagnrho rau cov chaw tsim khoom siab ceev.

Kuv tuaj yeem txhim kho qhov ua tau zoo ntawm kuv txoj kev txhaj tshuaj molding li cas?

Koj tuaj yeem txhim kho kev ua tau zoo los ntawm kev ua kom zoo ntawm lub tshuab teeb tsa, txo lub sijhawm voj voog, thiab txo qis cov nqi seem. Kev saib xyuas tsis tu ncua thiab kev nqis peev hauv automation tuaj yeem txhim kho kev tsim khoom thiab txo qis sijhawm.

Kuv yuav tsum xav txog dab tsi rau kev txhawb nqa tom qab muag?

Thaum ntsuaskev txhawb nqa tom qab muag, nrhiav cov lus lav, muaj cov khoom seem, thiab kev cob qhia rau cov neeg ua haujlwm. Kev ntseeg siab rau cov neeg siv khoom thiab kev txhawb nqa yog qhov tseem ceeb rau kev txo qis qis thiab ua kom muaj kev ua haujlwm zoo.

Lub sij hawm xa tuaj: Sep-30-2025