Kusarudza yakakwanaPlastic Molding Machinekwakakosha pakubudirira kweprojekiti uye kukura kwebhizinesi mune ramangwana. Kuongororwa kwakakwana kwezvido zveprojekiti-chaicho uye kugona kwemuchina kunovimbisa hurongwa hwekudyara. Chimbofunga zvakakoshaJekiseni Molding Machinemusika:

| Market Segment | Kukosha muna 2024 (USD) | Kukosha Kwakarongwa na2030 (USD) | CAGR (2025-2030) |

|---|---|---|---|

| Plastic Blow Molding Machine | 3.1829 bhiriyoni | 4.0477 bhiriyoni | 4.2% |

| Plastiki jekiseni Molding Machine | 11.98 bhiriyoni | 14.78 bhiriyoni | 3.5% |

Musika wepurasitiki wekuumba muchina unotarisira a5.2% CAGR kubva 2024 kusvika 2032, ichikura kubva paUS $ 5.6 bhiriyoni kusvika paUS $ 8.9 bhiriyoni. Uku kukura kunoratidza kudiwa kwesarudzo dzemidziyo yakangwara. Kunzwisisa akakosha tekinoroji maratidziro anovimbisa kuenderana nezvinangwa zvekugadzira. KodzeroJekiseni Molding Machine Plasticyakakosha kuti ishandePlastic jekiseni Molding. Mabhizinesi anofungawoPlastic Recycling Machinespakuronga kwakadzama.

Key Takeaways

- Sarudza chakanakaepurasitiki kuumba muchina mhando. Michina yemagetsi inopa chaiyo uye inochengetedza simba. Hydraulic michina inopa simba rakasimba rezvikamu zvikuru. Hybrid michina inosanganisa ese mabhenefiti.

- Nzwisisa clamping michina. Maviri-plan masisitimu anochengetedza nzvimbo uye anokodzera mold hombe. Toggle masisitimu akanakira kugadzira nekukurumidza. Imwe neimwe sisitimu ine mabhenefiti akasiyana.

- Tarisa kiyi yehunyanzvi ruzivo. Tie-bar spacing inoratidza hombe mold inogona kubata muchina. Simba rekurovera rinomisa plastiki kuti irege kubuda. Platen saizi inoita kuti mold ikwane zvakanaka.

- Matanidza saizi yemuchina nezvikamu zvako. Kurova kwekuvhura uye masikati kunofanirwa kunge kwakakura zvakakwana. Izvi zvinobatsira kuti zvikamu zvibude nyore. Muchina wakashata wesaizi unogona kukonzera matambudziko uye kutambisa.

- Sarudza muchina unoenderana nezvido zvepurojekiti yako. Muchina wakanakisa unobatsira nebasa razvino. Inotsigirawo kukura mune ramangwana. Iyi sarudzo inotungamirira kubudirira kwenguva refu.

Kunzwisisa Yakakosha Plastic Molding Machine Types

Kusarudza iyo chaiyo yepurasitiki yekuumba muchina kunotanga nekuziva iwo emhando mhando. Muchina wega wega unopa akasiyana mabhenefiti kune akasiyana kugadzirwa zvinodiwa. Ngationgororei mapoka makuru.

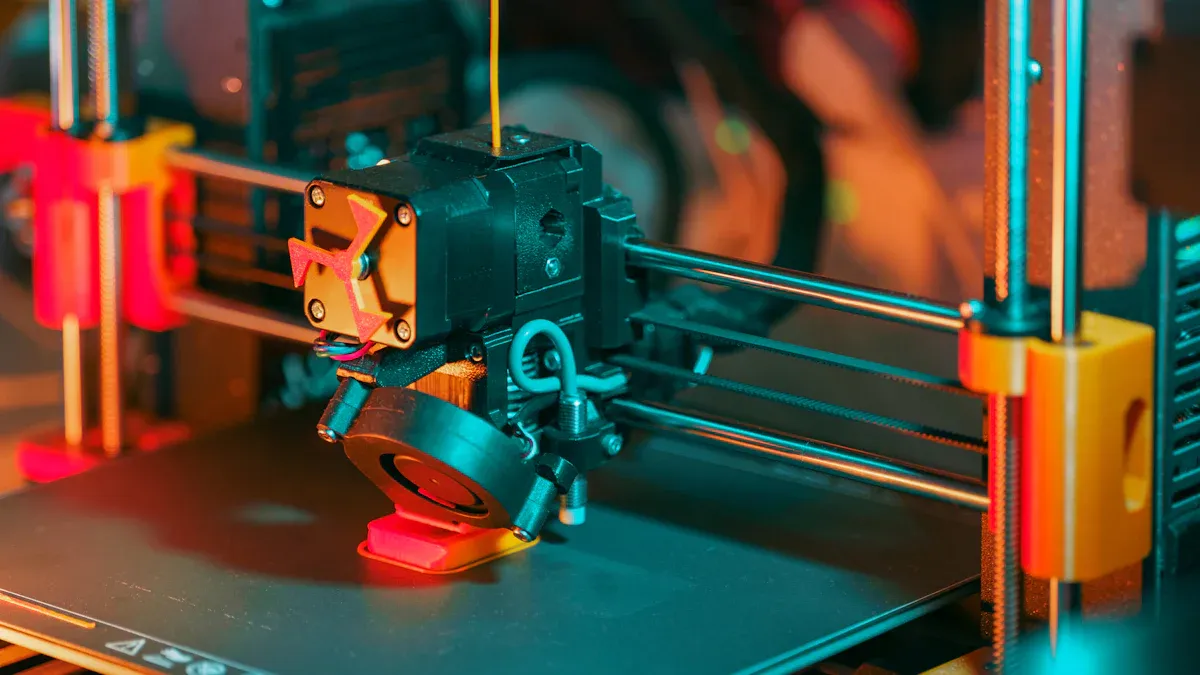

Yemagetsi Plastic Molding Machines

Michina yemagetsi epurasitiki yekuumba ishasha dzekunyatso uye kushanda zvakanaka. Ivoshandisa magetsi servo motors kune ese mafambiro. Iyi dhizaini inoreva kuti vanongoshandisa simba kana vachishingaira kushanda, zvichitungamira kune zvakakosha kuchengetedza simba. Semuenzaniso, michina iyi inogonachengetedza 50% yakawanda simba kana ichienzaniswa neyekare hydraulic masisitimu uye 20-30% kupfuura servo-hydraulics. Yavo madhijitari ekudzora masisitimu anopa zvinoshamisa kurongeka, kuwana chinzvimbo chekudzokorora che ± 0.01 mm. Kunyatsoita uku kunoita kuti ive yakakodzera kune zvidiki, zvakaomarara zvikamu uye maapplication anoda kuenderana kwakanyanya. Funga nezvemidziyo yezvokurapa, zvinhu zvemagetsi, kana lenzi dzemaziso. Michina iyivanokunda munzvimbo dzakachena nekuti havashandise mvura yehydraulic, kudzivirira kusvibiswa.

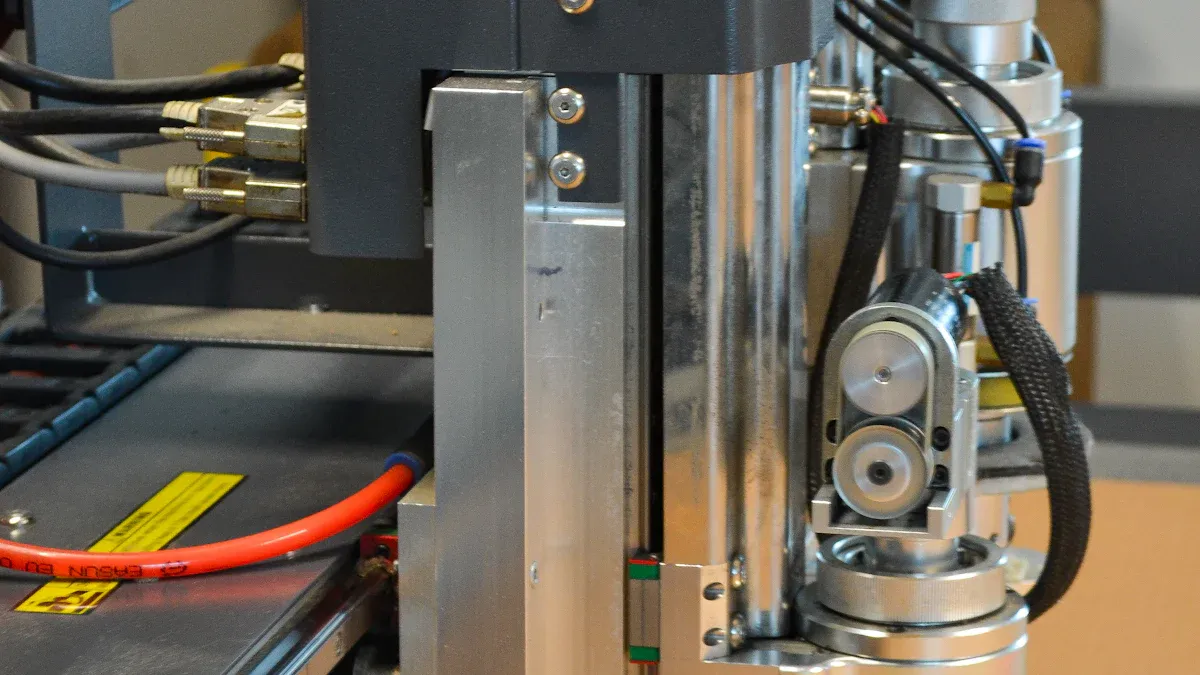

Hydraulic Plastic Molding Machines

Hydraulic plastic molding machines vanozivikanwa nokuda kwavosimba rakasimba uye kusimba. Vanoshandisa hydraulic fluid kugadzira simba, kunyanya kusungirira. Michina iyi yakanakira kushandiswa kwepamusoro-tonnage uye kuumba hombe, zvikamu zvinorema zvine ruzivo rwakaoma. Vanogona kushandahombe clamping simba, zvichiita kuti zvive zvakakwana kune zvinhu zvakadaimabhampa emotokari kana mahombe, akawanda-zvimedu molds. Kunyange zvazvo vangave vanononoka uyehaina kunyatsojeka kupfuura michina yemagetsi nekuda kweiyo fluid dynamics, simba ravo uye kushandiswa kwakasiyana-siyana mukubata zvinhu zvakasiyana-siyana zvinovaita sarudzo inodhurazvikamu zvakakuramumaindasitiri akadaikugadzirwa kwemotokari nemaindasitiri.

Hybrid Plastic Molding Machines

Hybrid epurasitiki yekuumba michina inosanganisa akanakisa maficha eese emagetsi uye hydraulic masisitimu. Ivobatanidza kurongeka kwemagetsi nesimba re hydraulic. Izvi zvinoreva kuti vanopa kugona kwesimba uye kurongeka kwemashini emagetsi, pamwe neakakwira clamping simba uye kusimba kweiyo hydraulic. Mhando dzeHybrid dzakasiyana-siyana. Vanogona kuve nehydraulic clamping ine jekiseni remagetsi, kana vice-versa. Uku kuchinjika kunoita kuti vakwanise kubata hupamhi hwemabasa ekuumba, kubva pazvikamu zvidiki chaizvo kusvika kune zvakakura, zvakaomarara. Semuenzaniso, ivo vanozivikanwa mumitamboindasitiri yemotokari yedashboard mapaneru uye mabumpers, uye mune zvekurapa uye zvekurongedza zvikamunokuda kwekuenzanisa kwavo kwekuita nekushanda. Michina iyi inogona zvakarebata hydraulic mabasa senge musimboti unodhonza usingade yakaparadzana, messy hydraulic unit, inova yakakura kuwedzera kune yakachena nharaunda..

Kuongorora Matanho ekurovera ePlastiki Molding Machines

Kusarudza iyo chaiyo clamping mashini isarudzo hombe kune chero epurasitiki yekuumba muchina. Iyo inokanganisa zvakananga kugadzirwa kwekugadzira uye mhando dzezvikamu zvaunogona kugadzira. Kurumidza Mold Shanduko (QMC) masisitimu, semuenzaniso, akakosha pakucheka nguva yekuchinja mold. Aya masisitimu anogonabvisa nguva yekuzorora kubva maawa kusvika kumaminitsi mashoma. Ivowowedzera kuchengetedzeka nekubvisa kudiwa kwevashandi kuti vabatanidze masimbi mukati memuchina. Izvi zvinorevabasa remaoko shoma uye njodzi shoma.

Maviri-Platin Clamping Systems

Maviri-plan clamping masisitimu anozivikanwa neawo compact dhizaini. Vanoshandisa mahwendefa maviri kuisa simba kune mold. Magadzirirwo ayainobvisa kudiwa kwekumashure clamping platen, kupa muchina adiki zvikuru tsoka. Izvi zvakanakira vagadziri vane nzvimbo shoma yepasi. Aya masisitimu anopawokuchinjika kwezviumbwa zvakakura. Vanopa aane rupo tie bar kure uye kuvhurwa kwemasikati. Izvi zvinobvumira akawanda-cavity maturusi uye yakaoma chikamu geometries. Unogona kuumba zvidimbu zvakakura kana zvidimbu zvidiki zvakawanda panguva imwe chete. Maviri-plan masisitimu zvakare anoderedza kufuratira mold uye anopa nekukurumidza kutenderera nguva.Ivo vanozivikanwa zvakare nekuchengetedza kwavo simba.

Toggle Clamping Systems

Toggle clamping masisitimu anoshandisa mechanical levers uye linkages kugadzira clamping simba. Iwo akanakisa kune yakakwirira-kumhanya jekiseni molding.A toggle unit inosanganisira toggle link, crosshead, uye mudziyo wekutyaira. Iyi gadziriro inobvumirakukurumidza kubatanidzwa uye kusabatanidzwa, zvichiita kuti zvive zvakakwana zvekudzokorora kugadzira. Toggle clamps inopa simba risingachinjiki. Iwo akagadzirirwa "kupfuura-clamp," kukiya munzvimbo pasina kuenderera mberi hydraulic pressure. Izvi zvinobatsira kuchengetedza simba kunyangwe nekugadzira kushivirira nyaya kana vibrations. Iyi systeminotanga nekutsanya, kutama kukuru uye simba rakaderera, yozopedzisa nekunonoka, simba guru.

Zvisinei,zvechinyakare toggle masisitimu anowanzo kuve netsoka yakakura nekuda kwezvikamu zvadzo zvinofamba mukati. Izvi zvinogona kuita kuti mold shanduko isachinjike. Ekunze toggle masisitimu, kune rumwe rutivi, anopa nzvimbo inochengetedza dhizaini uye nyore kuwana mold. Kugadzirisa, toggle clamps inodakuongororwa nguva dzose kwekupfeka uye kukanganisa. Unofaniravachenese nguva zhinji uye shandisa lubricant pazvikamu zvinofamba. Kutsiva zvinhu zvakasakara nekukurumidza kunobatsira kuchengetedza kushanda kwavo uye kuchengeteka. Zvavokusimba kunoenderana nemhando yezvigadzirwa uye kuti iyo yekubatanidza system inovakwa sei.

Yakakosha Tekinoroji Madiro ePlastiki Molding Machine Sarudzo

Kusarudza iyo chaiyo yepurasitiki yekuumba muchina zvinoreva kutarisa zvakanyanya kune ayo ehunyanzvi ruzivo. Aya maratidziro anokuudza izvo muchina unogona kuita uye kana inokodzera chirongwa chako. Kuvanzwisisa kunokubatsira kuita smart investment.

Tie-Bar Spacing yeMold Accommodation

Tie-bar spacing ndiyo chiyero chakakosha. Inokuudza huwandu hwehukuru hwe mold inogona kubata muchina. Fungidzira zvisungo sembiru dzakasimudza chimiro chemuchina. Iyo mold inofanira kukwana pakati pembiru idzi. Kana mold yakakurisa kune nzvimbo iri pakati pe-tie-mbara, haingoshande nemuchina iwoyo.Michina yakajairwa inowanzobata molds kusvika 4 tsoka ne 4 tsoka. Nekudaro, ma mold akakura anoda midziyo yakasarudzika ine yakakura tie-bar spacing.

Heano mamwe mazano ekugadzirisa molds:

- Mold Dimensions:

- Mold width inofanira kuva isingasviki hafu yehorizontal tie-bar spacing.

- Kureba kwe mold kunofanirwa kunge kuri pasi pehafu ye vertical tie-bar spacing.

- Safety Clearance:

- Kune zviumbwa zvidiki, bvumira inokwana 25mm yenzvimbo parutivi rumwe norumwe.

- Kune zviumbwa zvakakura, bvumira inokwana 50mm yenzvimbo kune rumwe rutivi.

- Kukora kweMold: Ukobvu hweforoma hunofanirwa kukwana mukati mehushoma hwemuchina uye huwandu hwehukobvu hwepamusoro.

Vagadziri veMould vanofungawo aya mapoinzi:

- Mold yakafara kana kureba kunofanirwa kunge kuri 1/2 inch (inenge 1.27 cm) yakafara kupfuura saizi yegomba rekusimba.

- Ukobvu hweMoudhi hunofanirwa kuita 2.5 nguva kudzika kwegomba kuti ive nechokwadi chekuvharika kana yakavharwa.

Tonnage Range uye Chikamu Saizi

Clamping force, kana tonnage, isimba rakawanda rinoshandiswa nemuchina kuchengetedza mold halves yakavharwa panguva yejekiseni. Izvi zvinodzivirira plastiki kuti irege kubuda, iyo vanhu vanodana "kupenya."Iyo clamping simba renji yemichina yakaita seTopstar ndeye 90T-2800T. Iwe unoiverenga zvichienderana nechikamu chakafungidzirwa nzvimbo uye ukobvu hwezvinhu zvepurasitiki.

Heino nzira iyo vanhu vanoverengera iyo inodiwa clamping simba:

- Rule of Thumb: Iyi nzira inofungidzira tonnage uchishandisa nzvimbo yechikamu, mhando yepurasitiki, ukobvu hwayo, uyea 'clamp factor' (kazhinji 2 kusvika 8, kana avhareji ye5). Zvisinei, izvi zvinogona kunge zvisina kururama. Kunyanya kusimba kunokonzera matambudziko emhando, uye yakawandisa inowedzera mold mitengo.

- Mold Flow Simulations: Aya mapurogiramu emakomputa anofanotaura iyo chaiyo tonnage inodiwa panguva yekugadzira chikamu.Semuenzaniso, kuenzanisa kwechimwe chikamu kwakafanotaura 509 Matani.

- Theoretical Calculation: Unogona kushandisa formula:Simba rekurovera (T) = Kusunga simba risingaperi (Kp) ✕ Nzvimbo Yakarongwa (S mucm²). Semuyenzaniso, kana PE plastic iine Kp kukosha kwe0.32 uye nzvimbo yakarongwa iri 410 cm², simba rekusunga rinoita 0.32 ✕ 410 = 131.2 T.

- Mold Kuzadza Analysis: Iyi inzira yakanyatsojeka. Iyo inosarudza iyo tonnage factor. Kuwedzera nezve 15 muzana yekuchengetedza chinhu kune izvi zvabuda kunopa chaiyo clamping simba uye kudzivirira kupenya. Kuongorora uku kunoratidzawo kuti zvimwe zvinhu, senhamba yemagedhi (mamwe magedhi anoreva yakaderera tonnage) uye kuyerera kureba (kureba kuyerera kunoda yakakwirira tonnage), kunokanganisa maitiro.

Chii chinoitika kana clamping force isiriyo?

| Aspect | Insufficient Clamping Force | Yakawandisa Clamping Force |

|---|---|---|

| Chikamu Unhu | Flash, symmetry isina kunaka, mapfuti mapfupi, zvimiro zvisina kurongeka, mitsetse yeweld isina simba | Hapana flash, asi overpacking inokonzera kushushikana kwemukati kana sink marks; kutsauka kwe mold, chikamu chinonamira, kana mavanga epamusoro |

| Mold & Machine Impact | Kupfeka mold pamitsara yekuparadzana kubva pakudzokorora kupenya; kusaenzana clamping inokuvadza mapini/bushings | Kukuvadzwa kweforoma isati yasvika (kutsemuka, kupfeka pamapini ekutungamira / maplate); mahwendefa akaremara, akatsemuka anopinza |

| Kugadzira Mari | Zvimwe zvimedu, rework, uye downtime yekuchenesa mold | Yakakwira mari yekuchengetedza uye njodzi yekuputsika kwemuchina |

| Kushanda Kwesimba | Minimal simba tsvina, asi yakakwirira zvisaririra rates | Kushandiswa kwesimba kusingakoshi kubva pamushini wakawandisa |

| Cycle Time | Kureba kutenderera kugadzirisa kukanganisa (sekubvisa flash) | Hapana kuvandudzwa munguva yekutenderera; zvinogona kunonoka kubva mukukuvadzwa kwe mold |

Kusakwana clamping tonnage kunopedza mold nekukurumidza. Kusaenzana clamping kunogona kukanganisa mutungamiri pini uye bushings. Izvi zvinoreva nguva yakawanda yekudzikira uye mari yekuchengetedza yakakwirira. Yakawandisa clamping tonnage inogona kukonzera mavanga ekutsva pazvikamu nekuti mweya haugone kubuda. Iyo inowedzerawo mukati mold pressure, ichiita kuti jekiseni rienderane.

Platen Saizi uye Kurongeka kweMold Fit

Saizi yeplate uye marongero akaita semuchengeti wegedhi rekuenderana nekuumbwa.Iyo mold inofanira kukwana mukati memaplatens emuchina. Upamhi hwayo uye kureba, kusanganisira mahwendefa anosungirirwa, anofanira kunge ari diki pane nzvimbo iri pakati pemasimbi emushini. Kana mold yakapamhama zvishoma, haikwane.Mold yakagadzirirwa muchina muhombe (se500-ton) haigone kukwana kana kushanda pane diki (senge 200-ton).

Funga kuti chikamu dhizaini chinokanganisa sei chimiro chekuumbwa:

- Iyo yakakura preform mutsipa dhayamita inoda imwe nzvimbo pakati pemakomba pane mold plate. Izvi zvinowedzera huwandu hwese mold base.

- Kune yakagadziriswa platen size, 28mm PCO1881 mutsipa (yakajairwa kumabhodhoro emvura) inogona kubvumira 50mm pitch. Izvi zvinogona kureva 8 × 9 marongerwo e72-cavity mold.

- Nekudaro, 38mm Bericap mutsipa (yemuto) ingangoda 70mm pitch yedhayamita yayo yakakura. Izvi zvinogona kuderedza marongerwo kusvika ku6 × 6, zvichikonzera chete 36-cavity mold mukati meiyo nzvimbo yemuviri.

Izvi zvinoratidza kuti yakakura mutsipa saizi inomanikidza hombe mold base yehuwandu hwakafanana hwema cavities. Izvi zvinozoreva huwandu hwakaderera hwemakomba emuchina wakapihwa wepurasitiki wekuumba.

Platen parallelism uye rigidity zvakare zvakakosha. Ivo vanovimbisa kuenderana chikamu chemhando.Intelligent leveling system uye chaiyo platen controlbatsira kuchengeta maplatens akanyatsodzika uye akaenzana. Izvi zvinodzivirira kuremara kubva kune isina kuenzana clamping pressure. Kugaya kwepamusoro kunogadzira nzvimbo dzakati sandara, dzakafanana pamapuleti egasi mukati mekushivirira kwakasimba, kazhinji0.005mm pa100mm yehurefu.

Kuvhura Stroke uye Masikati eEjection Efficiency

Iyo yekuvhura sitiroko uye masikati masheji akakosha kuyero kune chero epurasitiki yekuumba muchina. Ivo vanobata zvakananga kuti zviri nyore uye zvinobudirira chikamu chakaumbwa chinobuda mu mold. Kuvhura kunoreva nhambwe inofambwa neplaten. Kujeka kwemasikati ndiyo nzvimbo yakavhurika yakawanda pakati pehafu mold kana muchina wanyatsovhurika. Ose ari maviri anofanira kunge akakura zvakakwana kuti chikamu chibvise mold pasina nyaya.

Kana nzvimbo yakazaruka, kana kuti masikati, pakati pehalf mold isina kukwana kuti chikamu chibude zvakanaka, zvinogadzira matambudziko akawanda. Vagadziri vangangoda muchina muhombe, unodhura une sitiroko yakakura yekuvhura. Izvi zvinogona kukonzera kusashanda kwakasiyana-siyana:

- Kuparara kwezvinhu kunoitika nekuti plastiki inogara mudhiramu kwenguva refu.

- Kupfeka kwe mold kunowedzera nekuda kwekuwedzera kwekumanikidza.

- Kupenya kwechikamu kunoitika apo maplatens anozununguka nekuti mold diki iri mumushini muhombe.

- Shot inconsistency inoguma kana hombe jekiseni unit yaunza vhoriyamu diki yekupfura.

- Nguva dzekutenderera dzinowedzera nekuti michina mikuru inowanzoshanda zvishoma.

Iyo ejection sitiroko yakakoshawo. Iyi ndiyo chinhambwe icho mapini ejector anosundira chikamu kunze kwe mold. Iyo inodiwa ejection sitiroko inofanirwa kukwana mukati memushini unokwanisa. Zvikamu zvine hudzamu hwakakura hwekudhirowa, senge machubhu kana midziyo yakadzika, inoda mastroke ejection akareba kuti abvise. Iyo ejector cylinder's kureba inosarudza iyo yakawanda inowanikwa ejection stroke. Vagadziri veMould vanogara vachisimbisa izvi kana vasina chokwadi nekukwana kwayo. Ivo vanovimbisa kuti muchina unogona kusundira chikamu kunze zvizere uye zvakachena.

Kusarudza Plastic Molding Machine inzira inoenderera mberi. Inopindirana nezvinodiwa zveprojekiti nemaitiro emuchina. Muchina wepamusoro unowirirana nezvido zvekugadzira zvazvino uye unotsigira kuwedzera kweramangwana. Strategic investimendi yemuchina wekurudyi ndiyo yakakosha pakubudirira kwekushanda kwenguva refu uye kuita pundutso. Izvi zvinosanganisirakugamuchira misimboti yekugadzira yakaonda kutema tsvina uye kushandisa dhijitari kugadzira kwechokwadi-nguva yekutarisa. Makambani zvakare anosiyanisa vatengi vavo uye kuisa mari muvashandi vane hunyanzvi. Aya matanho anovimbisa kukura kwakasimba uye kushanda zvakanaka.

FAQ

Ndeupi musiyano mukuru pakati pemagetsi uye hydraulic epurasitiki yekuumba michina?

Michina yemagetsi inopa kunyatso uye kuchengetedza simba. Vanoshandisa servo motors kune ese mafambiro. Hydraulic michina inopa simba rakasimba rezvikamu zvakakura. Vanoshandisa fluid pressure. Michina yeHybrid inosanganisa ese mabhenefiti, achipa kuita zvakasiyana.

Nei tie-bar spacing yakakosha pakusarudza muchina?

Tie-bar spacing inotaridza huwandu hwehukuru hwe mold inogona kubata muchina. Iyo mold inofanira kukwana pakati pembiru idzi. Kupatsanura kusina kunaka kunoreva kuti mold haishande nemuchina iwoyo. Icho chiyero chakakosha chekugara mold.

Simba rekusunga rinokanganisa sei kunaka kwezvikamu zvakaumbwa?

Clamping force inochengeta mold halves yakavharwa panguva yejekiseni. Simba shoma rinokonzera "kupenya" kana kuti chikamu chisina kunaka. Simba rakawandisa rinogona kukuvadza mold kana kukonzera kukanganisa kwechikamu senge sink marks. Kusunga kwakaringana kunovimbisa mhedzisiro inowirirana.

Ndezvipi zvakanakira maviri-plan clamping system?

Maviri-plan masisitimu anopa compact dhizaini, kuchengetedza nzvimbo yepasi. Ivo vanopa rupo tie-bar kure uye kuvhurika kwemasikati kune hombe mold. Aya masisitimu zvakare anoderedza kutenderera kwe mold uye anogona kutungamira kune nekukurumidza kutenderera nguva.

Bhizinesi rinofanira kufunga riini muchina wakasanganiswa wepurasitiki wekuumba?

Mabhizinesi anofanirwa kufunga michina yakasanganiswa kana ichida zvese nemazvo uye simba. Michina iyi inosanganisa kurongeka kwemagetsi nesimba re hydraulic. Dzinochinja-chinja, dzinobata mabasa akawanda okuumba nounyanzvi.

Nguva yekutumira: Oct-14-2025