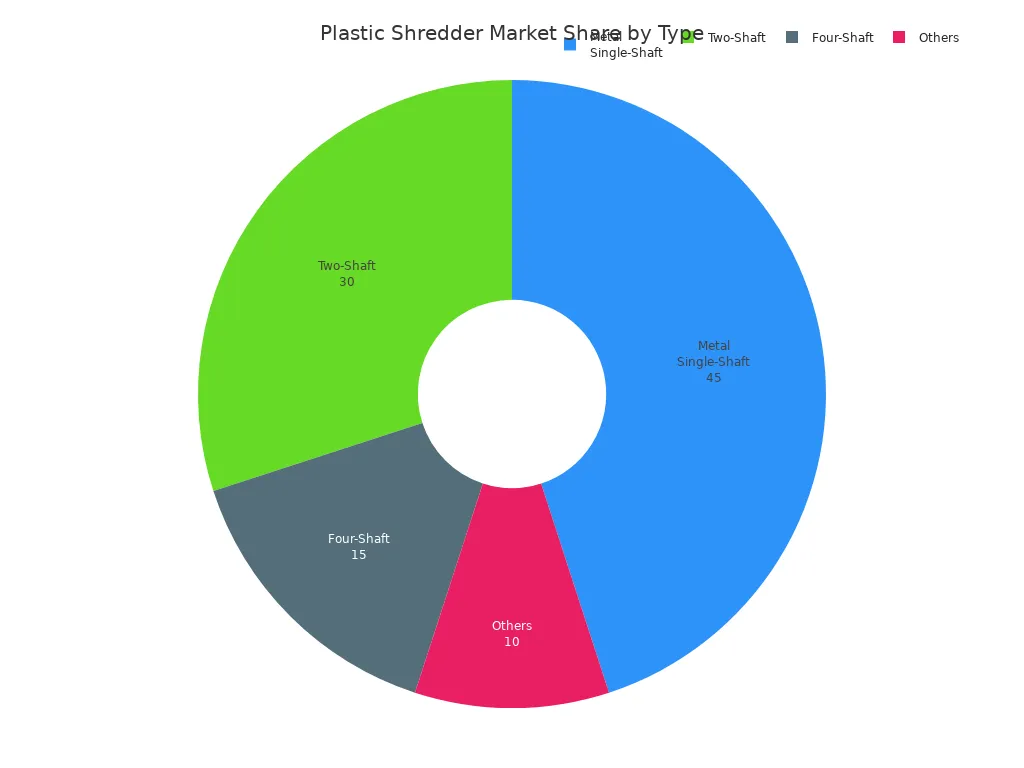

Plastic shredders come in many designs for different materials and tasks. They help process items for recycling, like bottles or packaging. The market reached $1.23 billion in 2023 and keeps growing. Four-shaft models stand out for their efficiency.

People use a plastic crusher machine, plastic granulator, or plastic pelletizing machine for plastic making machine processes.

Key Takeaways

- Single-shaft shredders work best for softer plastics and provide uniform particle sizes with lower energy use and maintenance costs.

- Dual-shaft shredders handle tough, bulky plastics and heavy-duty jobs with high power and durability, ideal for coarse crushing.

- Granulators produce fine, consistent plastic granules perfect for recycling into new products, while mobile shredders offer flexible, on-site processing.

Main Types of Plastic Shredder

Single-Shaft Plastic Shredder

A single-shaft plastic shredder uses one spinning shaft with sharp blades to cut plastic into smaller pieces. This machine works best for softer materials like plastic, rubber, and even wood. It has a special screen that controls the size of the shredded pieces, so the output is usually very uniform. The hydraulic pusher helps feed the material smoothly, making the process efficient and reducing jams.

Here’s a quick look at what makes single-shaft shredders unique:

| Feature | Single-Shaft Plastic Shredder Characteristics |

|---|---|

| Design | One rotating shaft with sharp blades and a sizing screen |

| Shredding Mechanism | Shearing and slicing action |

| Suitable Materials | Softer materials such as plastics, rubber, and wood |

| Particle Size Control | Precise and uniform due to the sizing screen |

| Throughput Efficiency | Moderate, suitable for lighter workloads |

| Energy Consumption | Lower compared to multi-shaft shredders |

| Maintenance | Simple and cost-effective |

| Cost | Lower initial investment |

| Additional Features | Hydraulic pusher system, low vibration, noise, and dust |

| Limitations | Less efficient for hard, bulky, or heavy-duty materials; slower throughput |

Most single-shaft shredders can handle between 500 kg/hr and 10 tons/hr, depending on the model. They are common in recycling centers that process things like PET bottles, PP pipes, and plastic films. The machine’s strong structure and low noise make it a favorite for many plastic recycling jobs.

Tip: Single-shaft shredders are great for getting a consistent particle size, which helps when making new plastic products from recycled material.

Dual-Shaft Plastic Shredder

Dual-shaft plastic shredders use two powerful shafts that rotate together to tear apart tough plastic waste. These machines can handle a wide range of materials, including hard plastics like PE, PP, PVC, PS, PET, ABS, and PC. They are built for heavy-duty jobs and can shred items such as plastic drums, pallets, appliance shells, and even car bumpers.

Some key features of dual-shaft shredders include:

- High-torque motors and strong alloy steel blades for tough jobs

- Claw blade design that grabs and shreds large or bulky items

- Heavy-duty frame for stability and long life

Dual-shaft shredders work well in recycling plants that need to break down mixed or hard plastic waste. They can also process rubber, metals, and even organic waste, making them very versatile.

Note: Dual-shaft shredders are ideal for coarse crushing and size reduction before further processing.

Granulator Plastic Shredder

Granulator plastic shredders focus on making small, uniform plastic pieces. They use sharp blades and a screen to control the final size, which usually ranges from 3 mm to 12 mm. This makes them perfect for recycling plants that need fine, consistent plastic granules for making new products.

Here’s a comparison of granulators and regular shredders:

| Machine Type | Particle Size Output | Particle Shape | Material Suitability | Control over Size |

|---|---|---|---|---|

| Granulator | 3 mm to 12 mm | Small, uniform | Softer materials like plastics, rubber | High (uses screens) |

| Shredder | 20 mm to 100 mm | Larger, irregular | Tougher, denser materials like metals, wood | Low (no screens, irregular size) |

Granulators are used in many industries:

- Plastic recycling plants

- Factories making bottles, pipes, and containers

- Waste management companies

- Automotive and medical manufacturing

They handle many types of plastics, including PET, HDPE, PVC, LDPE, PP, and PS. Granulators help turn plastic waste into valuable raw material for new products.

Mobile Plastic Shredder

Mobile plastic shredders bring flexibility to recycling. These machines can move from site to site, making them perfect for temporary projects, construction sites, or areas with changing waste streams. Their modular design allows for quick setup—sometimes 50–70% faster than traditional shredding plants.

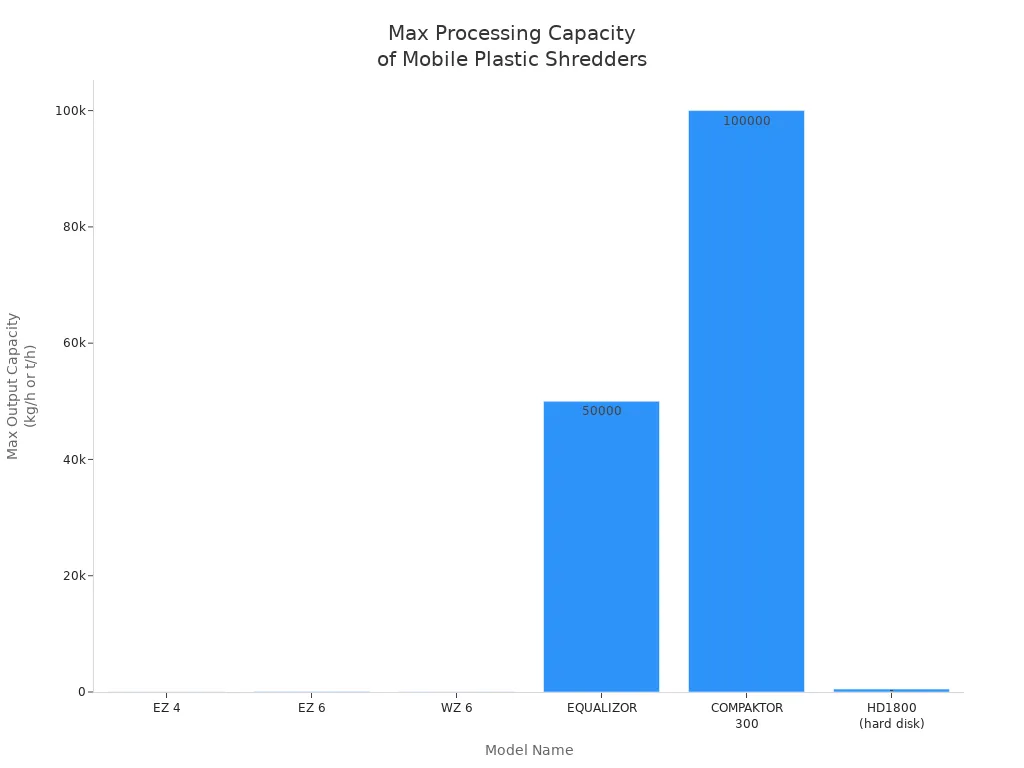

Mobile shredders can process a wide range of materials, including plastic sheets, electronic waste, and even scrap metal. Their working capacity varies by model, from as little as 1 ton per hour up to 20 tons per hour or more.

Some advantages of mobile shredders:

- Easy to relocate as recycling needs change

- Fast deployment for pilot projects or emergencies

- Scalable by adding more modules

- Plug-and-play design for quick adaptation

Tip: Mobile shredders help bring recycling closer to where waste is created, saving time and transportation costs.

Key Differences Between Plastic Shredder Types

Capacity and Throughput

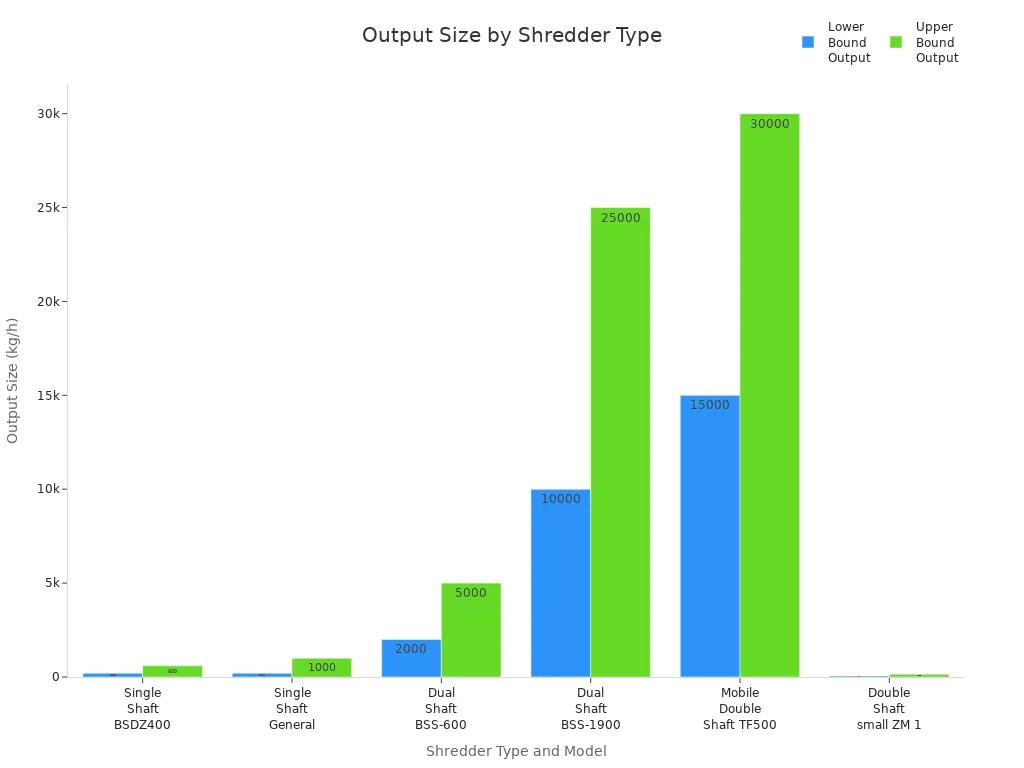

Each plastic shredder type handles different amounts of material. Single-shaft shredders work well for small to medium jobs, with output from 200 kg/h up to 2,000 kg/h. Dual-shaft shredders can tackle much bigger loads, reaching up to 25 tons per hour. Mobile shredders, like the TF500, process even more—up to 30 tons per hour. Granulators focus on smaller batches but create fine, uniform pieces.

Material Compatibility

Some shredders handle a wider range of plastics than others. Dual- and quad-shaft shredders from brands like Shred-Tech can process everything from thin films to large molded parts. Single-shaft shredders, such as those from Wiscon, also show great versatility. They shred thick, rigid plastics and even engineering plastics like PPSU and PES. However, plastics with harsh additives, like carbon fiber, can wear down blades quickly. Blade type and material matter too—tougher blades handle harder plastics but may cost more.

Output Size and Consistency

Granulators and single-shaft shredders produce the most uniform pieces. Granulators make fine granules, perfect for making new plastic products. Dual-shaft shredders create larger, less consistent chunks but work faster. The choice depends on whether the job needs fine, even output or just quick size reduction.

Maintenance and Operating Costs

Single-shaft shredders need regular care for their screens and pushers, but their parts cost less. Dual-shaft shredders have fewer jams and need less frequent maintenance, though their parts can be pricier. Granulators require sharp blades for best results, so blade changes happen often. Mobile shredders may need more upkeep due to frequent moves, but they save on transport costs.

Typical Applications

Single-shaft shredders show up in recycling centers, plastics factories, and even wood shops. Dual-shaft shredders handle tough jobs in scrap yards and waste plants. Granulators work best in plastics processing, turning scrap into reusable granules. Mobile shredders help at construction sites or during cleanup projects, where waste piles up fast.

Choosing the right shredder depends on the type of plastic, how much waste needs processing, and the final particle size. Buyers should list their needs, check machine capacity, and look for safety features. They can avoid common mistakes by matching shredder design to their material and workflow.

FAQ

What safety features do plastic shredders have?

Most shredders use emergency stop buttons, safety covers, and sensors. These features help protect workers from accidents during operation.

How often should someone maintain a plastic shredder?

Manufacturers recommend checking blades and cleaning screens weekly. Regular maintenance keeps the machine running smoothly and extends its life.

Can a plastic shredder handle metal or glass?

No, plastic shredders work best with plastics. Metal or glass can damage the blades and cause costly repairs.

Post time: Aug-21-2025