Yese Chiller Machine inoda kutarisirwa nguva dzose kuti ifambe zvakanaka. AnIndustrial Water Chillerinogona kurasikirwa nekubudirira nekukurumidza kana ikafuratirwa. Vanowanzoona tsvina ichivaka, kana kutarisana nenyaya dzemvura.Mvura Inotonhorera Chillervaridzi vanocherechedza kutonhora kuri nani nemacheki akareruka. Kunyange aScrew Chillerinoshanda kwenguva yakareba nekuchenesa uye kutarisa.

Key Takeaways

- Kugara kwezuva nezuva, pamwedzi, uye kwepagore kugadzirisa kunoita kuti michina inotonhora ishande zvakanaka uye inodzivirira kuparara kunodhura.

- Kutevera nhungamiro yevagadziri uye kuchengeta akadzama marekodhi kunodzivirira muchina wako uye kuwedzera hupenyu hwawo.

- Macoil akachena, kurapwa kwemvura kwakakodzera, uye kuongorora mamiriro ekushanda kunochengetedza simba, kunatsiridza kutonhora, uye kuderedza mari yekugadzirisa.

Chiller Machine Maintenance Essentials

Matanho Akakosha eKuchengeta Zuva Nezuva, Mwedzi, uye Negore

Kuchengeta Chiller Machine zvinoreva kuomerera kuhurongwa hwenguva dzose. Zuva rimwe nerimwe, mwedzi, uye gore rinounza gadziriro dzaro rimene dzebasa. Aya matanho anobatsira kuchengetedza muchina uchishanda zvakanaka uye kudzivirira matambudziko makuru gare gare.

Daily Care:

- Nyora nhamba dzakakosha senge kudzvanywa, tembiricha, uye mazinga emvura. Izvi zvinobatsira kuona dambudziko pakutanga.

- Tarisa panopinda mvura kana panobuda mvura.

- Teerera kune ruzha rusinganzwisisike kana vibrations kubva kune compressor.

- Tarisa zviratidzo zvekubuda kwemafuta kana kuchinja kwemazinga emafuta.

Kuchengeta Kwemwedzi uye Kwekota:

- Chenesa uye ongorora mabatiro emagetsi. Tsiva chero chine tsvina kana chakashata mafirita dryer.

- Ongorora mafirita emhepo uye woashandura kana achinge akasviba.

- Tarisa mazinga efiriji uye tsvaga inodonha.

- Chenesa machubhu ekuchiisa mwedzi mishoma yega yega kuti umise ngura nekuyera.

Kuchengeta Kwegore:

- Yakadzika yakachena kupisa exchanger uye tubing kuchengetedza kupisa kwakasimba.

- Bata condenser zvishwe zvemvura kuti ubvise tsvina uye uchengetedze system inoshanda.

- Ongorora compressor mafuta uye chinja kana zvichidikanwa.

- Ita ongororo izere yezvikamu zvese, kusanganisira kuchengetedza kudzora uye zvimiro zvinotsigira.

Zano:Muzhizha, chenesa coils kakawanda uye tarisa fan kunyatsoshanda. Munguva yechando, chengetedza glycol mazinga uye tarisa kuvharika kwemhepo.

Chimiro chenguva dzose seizvi chinoita kuti Chiller Machine irambe iri muchimiro chepamusoro uye inobatsira kudzivirira kugadzirisa kunodhura.

Kutevera Manufacture Recommendations

Vagadziri vanoziva michina yavo zvakanyanya. Vanopa matanho akajeka ekuchengeta imwe neimwe Chiller Machine ichishanda nemazvo. Kutevera nhungamiro idzi kunodzivirira muchina uye kuchengetedza waranti inoshanda.

- Chengeta marekodhi akadzama ebasa rose rekugadzirisa. Izvi zvinobatsira newaranti zvichemo uye zvinoita shuwa kuti hapana chinopotsa.

- Shandisa matanho ekuedza emugadziri kuseta hwaro hwemashandisirwo aunofanira kuita muchina.

- Chenesa makoiri econdenser ane dzvinyiriro chaiyo uye makemikari akachengeteka, sezvinoratidzwa nebhuku.

- Nguva dzose shandisa mvura yakasefa uye yakacheneswa mugadziriro yekutonhodza. Izvi zvinomisa chikero, ngura, uye kukura kwebiological.

- Chenesa zvikamu zvese, kusanganisira mafirita emhepo uye mafeni econdenser, pachirongwa chenguva dzose.

- Nyora cheki yega yega uye kuchenesa. Kana chimwe chinhu chikatadza, marekodhi aya anobatsira kuratidza kuti muchina waitarisirwa.

Vagadziri vanokurudzirawo kugara uchiongorora kemikari yemafuta uye refrigerant. Izvi zvinobatsira kuona matambudziko asati awedzera. Nekunamatira kumatanho aya, varidzi vanogona kuchengeta yavo Chiller Machine ichimhanya zvakanaka kwemakore.

Nei Chiller Machine Maintenance uye Yekuchenesa Matter

Performance uye Efficiency Benefits

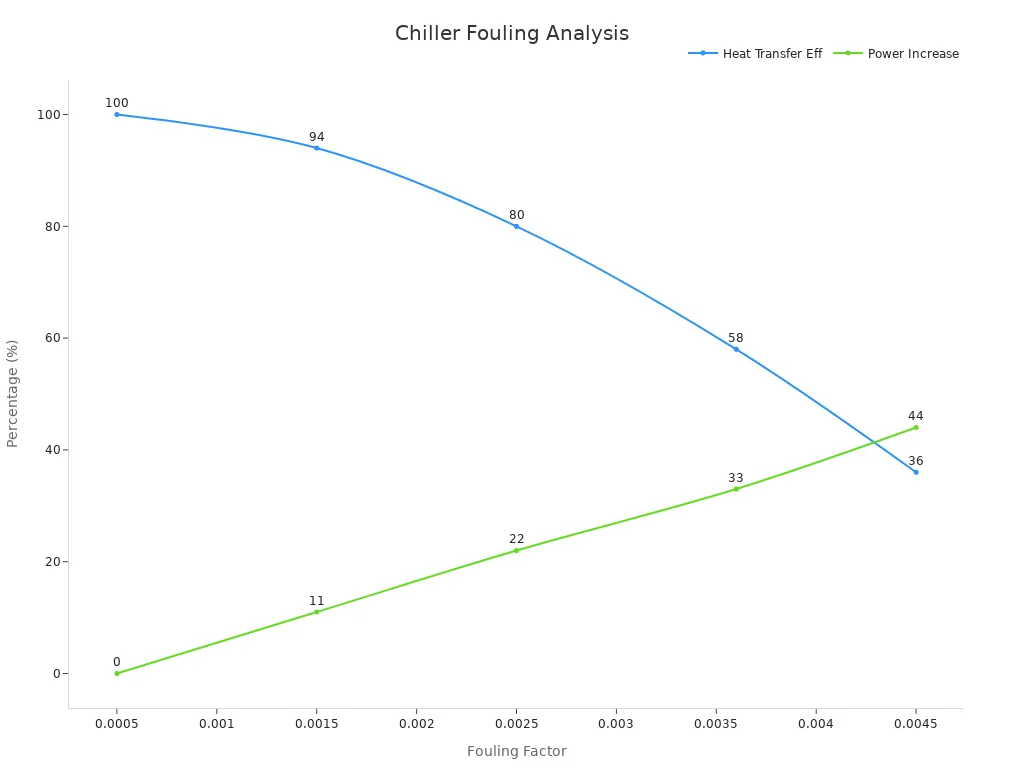

Kugara uchigadzirisa uye kucheneswa kunobatsira Chiller Machine kushanda zvakanyanya. Kana machubhu achigara akachena uye mazinga efiriji anoramba akamira, sisitimu inotonhora nekukurumidza uye inoshandisa simba shoma. Zvidzidzo zvinoratidza kuti mabasa akareruka senge kuchenesa makoiri uye kutarisa madhiraivha anogona kuwedzera kuyerera kwemhepokusvika ku46% uye cheka kushandiswa kwesimba re fan nekusvika 60%.

Heino kukurumidza kutarisa manhamba:

| Metric | Range / Mhedzisiro |

|---|---|

| Fan Energy Savings | 41% kusvika 60% kuderedza |

| Kuvandudza Kuyerera Kwemhepo | 10% kusvika 46% kuwedzera |

Zvikoro zvinotevera chirongwa chekuchengetedza zvakaona mabhiri emagetsi achidonha nehafu. Yakachena masisitimu zvakarekubatsira zvakatipoteredza nekudzikisa carbon emissions. Kana Chiller Machine ichimhanya zvakanaka, munhu wese anochengetedza mari nesimba.

Kudzivirira Kuparara Kunodhura

Hapana anofarira kugadzirisa kunoshamisa. Cheki dzenguva dzose dzinobata matambudziko madiki asati ashanduka kuita makuru. Semuyenzaniso, kutarisa kuti pane kuvuza here, kuchenesa makoiri, uye mota dzekuyedza zvinogona kumisa kuputsika uko kunodhura zvakawanda kugadzirisa. Zvikoro zvakawanda nemabhizinesi vakaona kuti kugadzirisa nguva dzose kunoreva kushomeka kwekukurumidzira uye kushomeka nguva.

Kukurumidza kuona nyaya kunoita kuti sisitimu ishande uye inodzivirira kugadzirisa kunodhura.

Kuwedzera Equipment Lifespan

Kuchengeta Chiller Machine kunobatsira kuti igare kwenguva refu. Kugara uchichenesa, kuchinja oiri, uye kuongorora kunoita kuti zvikamu zvese zvishande zvakanaka. Vanamazvikokota vanotarisa sisitimu gore rega rega vanogona kuona kupfeka uye kubvaruka zvisati zvakonzera dambudziko. Izvi zvinoreva kuti muchina unogara wakavimbika kwemakore mazhinji, uye varidzi havafanirwe kutenga michina mitsva kazhinji.

Iyo inochengetedzwa zvakanaka system ndeye smart investimendi kune chero bhizinesi.

Daily Chiller Machine Maintenance

Kuongorora Kwekuona uye Kubviswa kwemarara

Kuongorora kwezuva nezuva kunobatsira kuona matambudziko asati awedzera. Vanamazvikokota vanotarisa panobuda mvura, nhengo dzisina kusimba, uye zviratidzo zvekuora. Vanobvisawo chero tsvina kana marara anogona kuvhara mhepo kana kuyerera kwemvura. Heano mamwe matanho akakosha:

- Ongorora midziyo yese kuona kuti inoshanda uye maficha ekuchengetedza aripo.

- Tarisa kuti pombi hadzibvisi here uye tsvaga mafuta, refrigerant, kana kurasika kwemvura.

- Teerera maungira asinganzwisisike kana kudedera.

- Simbisa chero mabhaudhi asina kusununguka kana zvisungo.

- Tsvaga ngura, kunyanya pamapombi nemakoiri.

- Tarisa kune tsvina kana kuvaka pane chiller parts.

- Ongorora zvikamu zvemagetsi semarelay uye waya.

- Edza kuchengetedza zvishandiso.

- Tarisa mafirita, mavharuvhu, uye midziyo yekumanikidza.

- Ona kana mafuta, firiji, kana mvura ichida kuchinjwa.

Aya matanho anobatsira kuchengetedza Chiller Machine yakachena uye yakachengeteka. Kubvisa marara uye kutarisa kukuvara kunogona kumisa matambudziko makuru kuti asaitike.

Monitoring Operating Parameters uye Logs

Kutariswa kwemazuva ese kwenhamba dzekushanda kunopa mufananidzo wakajeka wekuti system inoshanda sei. Technicians anorekodha tembiricha, kumanikidzwa, uye mazinga efiriji. Ruzivo urwu runobatsira kuchinja kwemavara nekukurumidza. Makambani mazhinji anoshandisa maturusi akangwara kuteedzera nhamba idzi zuva rese. Kuchengeta logi kunobatsira kuwana mafambiro uye kuratidza kana chimwe chinhu chikatanga kushata. Inobatsirawo kusangana nemitemo yekuchengetedza uye inochengeta munhu wese akatendeseka nezvekuchengetedza. Apo zvikwata zvinochengeta zvinyorwa zvakanaka, zvinogona kugadzirisa zviduku zvisati zvachinja kuva kugadzirisa kukuru.

Kutarisa Kusina Kujairika Noise kana Vibrations

Ruzha runoshamisa kana kudedera zvinowanzoreva dambudziko. Apo nyanzvi dzinonzwa ruzha rusinganzwisisike, dzinoita nokukurumidza. Mune imwe nzvimbo yedata, kugadzirisa matambudziko eruzha kwakachengetedza kudarika £100,000 uye kuchengetedza kutonhora kwakasimba. Chimwe chivakwa chakashandisa akakosha madhiraivha ekucheka ruzha ne95% uye akaita kuti sisitimu ishande. Kurumidza kuita paruzha uye kudedera kunoita kuti Chiller Machine irambe ichimhanya zvakanaka uye inodzivirira kugadzirisa kunodhura. Kuteerera zuva nezuva kunobatsira kubata matambudziko nekukurumidza.

Monthly Chiller Machine Kuchenesa uye Macheki

Kuchenesa Condenser uye Evaporator Coils

Mwedzi wega wega coil kuchenesa kunoita kuti sisitimu ishande zvakanaka. Tsvina, madhaka, uye algae zvinogona kuungana pamakoiri, zvichiita kuti zviomere muchina wacho kuburitsa kupisa. Kana makoiri achigara akasviba, sisitimu inoshanda zvakanyanya uye inoshandisa simba rakawanda. Zvidzidzo zvinoratidza kuti kuchenesa coil nguva dzose kunogona kuvandudza kushanda kwesimba ne10-15%. Zvimwe zvivako zvakachengeta zviuru zvemadhora gore negore nokungochengeta makoiri akachena. Koiri yakachena inobatsirawo kuti sisitimu igare kwenguva yakareba uye inoita kuti mhepo irambe yakachena.

Zano: Shandisa maturusi ekuchenesa akakodzera uye tevera mirairo yemugadziri kuti uwane mibairo yakanaka.

| Dambudziko kubva kune Dirty Coils | Impact paSystem |

|---|---|

| Kutonhora kwesimba kunodonha | Kusvikira ku40% kushoma kutonhora |

| Compressor simba rinowedzera | Kusvika ku70% mamwe simba rinoshandiswa |

| Kupisa kwemhepo kunokwira | Zvinenge 5°F kukwira |

Kuongorora uye Kutsiva Mhepo Mafirita

Masefa emhepo anobata huruva nemarara asati asvika pamakoiri. Nekufamba kwenguva, mafirita anovharika uye anovharira kuyerera kwemhepo. Cheki dzepamwedzi dzinobatsira kuona masefa ane tsvina kare. Kuvatsiva kunoita kuti hurongwa hwekufema huve nyore uye hunomisa tsvina kuti isasvike kune dzimwe nzvimbo. Masefa akachena anobatsirawo kuchengetedza mweya uri mukati mechivako uine hutano.

Ongorora: Maka zuva kana uchichinja mafirita kuti uchengete hurongwa hwakanaka.

Kutarisa Refrigerant Levels uye Leaks

Refrigerant inochengetedza sisitimu inotonhorera. Kana iyo nhanho inodonha kana kubuda kunze, iyo system inorasikirwa nekubudirira uye inoshandisa simba rakawanda. Macheki epamwedzi anobatsira nzvimbo dzinobuda dzisati dzakonzera matambudziko makuru. Technicians anotarisa kudzvanywa kuverenga uye tembiricha kuti ive nechokwadi chekuti zvese zvinogara muchikamu chakakodzera. Tsvagiridzo inoratidza kuti kunyangwe kudonha kudiki kunogona kukwidza mutengo wesimba uye kukuvadza sisitimu.

- Kuongorora nguva dzose kunobatsira kubata mvura inobuda kare.

- Yakagadzika firiji mazinga anoreva kutonhora kuri nani uye kudzikisa mabhiri.

Kuongorora Magetsi Zvikamu

Zvikamu zvemagetsi zvinoda kutarisirwa, zvakare. Waya, maswichi, uye zvidhiraivho zvinogona kupera kana kupera. Kuongorora kwemwedzi kunobatsira kuwana matambudziko asati akonzera kuparara. Kusimbisa kubatanidza uye zvikamu zvekuchenesa zvinochengeta zvese zvakachengeteka uye zvakanaka. Aya macheki anobatsirawo kusangana nemitemo yekuchengetedza uye kuchengetedza sisitimu ichimhanya kwenguva refu.

- Kuongorora kunodzivirira kupisa uye kupera simba.

- Marekodhi akanaka anobatsira nezvikumbiro zvewaranti uye kuronda hutano hwehurongwa.

Yegore Chiller Machine Maintenance Procedus

Kuchenesa Kwakadzika kweKupisa Kupisa uye Tubing

Kuchenesa kwakadzika zvinopisa zvinopisa uye tubing zvinoita kuti sisitimu ishande yakasimba. Nokufamba kwenguva, tsvina uye chiyero zvinovaka mukati memachubhu. Ichi chivakwa chinovharira kutamisa kupisa uye chinoita kuti muchina ushande nesimba. PaHapuna Beach Prince Hotel muHawaii, otomatiki chubhu yekuchenesa sisitimu inobvisa kusvibisa maawa mashoma ega ega. Ihotera yakaona kuchengetedza kwesimba pakati pe10% ne35%, uye sisitimu yakazvibhadharira mukati isingasviki gore.

Kusarudza nzira yekuchenesa yakakodzera. Semuenzaniso, rotary chubhu yekuchenesa inoshanda nemazvo pachiyero chakaoma, nepo online masisitimu akachena achienderera asi anodhura zvakanyanya pakutanga. Mhando yechubhu uye dhipoziti inotungamira chishandiso chakanakisa chebasa racho.

Kutsvaira uye Kurapa Mvura Systems

Hunhu hwemvura hunokanganisa mashandiro anoita chiller. Kana mvura iine zvicherwa kana tsvina, inogona kusiya madhipoziti mukati mehurongwa. Aya madhipoziti anosimudza tembiricha uye anomanikidza muchina kushandisa simba rakawanda. Kugara uchitsvaira uye kurapwa kwemakemikari kunobvisa chiyero uye kumisa algae kuti isakure. Nyanzvi dzakawanda dzinokurudzira kuedza mvura mwedzi mishoma yega yega uye kugadzirisa kurapwa sezvinodiwa. Mvura yakachena inobatsira sisitimu kugara kwenguva refu uye kutonhorera zviri nani.

Mafuta Anofambisa Zvikamu

Zvikamu zvinofamba zvakaita semabhengi nemamotor zvinoda kugara uchizora mafuta. Kuzora kunoderedza kukweshana uye kunoita kuti nhengo dzisasakara nekukurumidza. Kana nyanzvi dzichichengeta zvikamu izvi zvakazodzwa mafuta, sisitimu inomhanya zvakanaka uye inoshandisa simba shoma. Lubrication inoderedzawo mukana wekuparara kamwe kamwe. Nekutarisa nekuisa mafuta ekuzora sekukurudzira kwazvinoita mugadziri, zvikwata zvinobatsira kuti michina igare kwenguva refu.

Comprehensive System Inspection

Kuongorora kwakazara kunotarisa chikamu chese chehurongwa. Technicians anotarisa pafiriji nemafuta mazinga, bvunzo yekudzora, uye kuyera tembiricha uye kumanikidza. Ivo zvakare vanotarisa kana kuvuza, teerera kune isinganzwisisike ruzha, uye iva nechokwadi chekuti zvese zvekuchengetedza zvinoshanda.

Kuongorora kwakadzama kunobatsira kuona matambudziko madiki asati akura.

Iyi nzira inochengetedza sisitimu yakachengeteka uye inoshanda. Zvinobatsirawo zvikwata kuronga kugadzirisa zvinhu zvisati zvaitika.

Chiller Machine Mvura Yehutano Management

Kukosha Kwemvura Kurapa uye Glycol Musanganiswa

Hunhu hwemvura hunoita basa guru pakuti akutonhora systemanoshanda. Kana mvura iine zvicherwa zvakawandisa senge calcium kana magnesium, inogona kusiya madhipoziti akaomarara. Aya madhipoziti, anonzi chikero, anovharira kuyerera kwemvura uye anoita kuti muchina ushande nesimba. Kana mvura yakanyanya kupfava, inogona kuita kuti simbi dziite ngura. Iyo pH level inokosha, zvakare. Mvura yakanyanyisa kana kuti yakanyanya kuwanda inogona kukuvadza mapaipi nezvimwe zvikamu. Utachiona huri mumvura hunogonawo kukonzera matambudziko. Vanogona kuumba slime, iyo inovhara machubhu uye inoderedza kushanda zvakanaka.

Chirongwa chakanaka chekuchenesa mvura chinochengetedza matambudziko aya kure. Mazhinji masisitimu anoshandisa musanganiswa wemvura uye glycol. Glycol inobatsira kudzivirira kutonhora uye inodzivirira kubva pakuora. Kugara uchiyedzwa mvura yezvicherwa, pH, uye hutachiona hunobatsira kuti zvese zvifambe zvakanaka. Mvura yakachena inoreva kutonhora kuri nani, mabhiri emagetsi mashoma, uye hupenyu hwakareba hwemidziyo.

Kutariswa kweChikero, Kuora, uye Kukura Kwezvipenyu

Kuchengeta ziso pachikero, ngura, uye kukura kwebiological kwakakosha kune chero kutonhora system. Chikero mafomu apo zvicherwa zvinovaka mukati mepombi nemachubhu. Kuvaka uku kunoita kuti zviome kuti sisitimu ifambise kupisa, saka inoshandisa simba rakawanda. Ngura inoitika kana mvura yadya zvikamu zvesimbi. Izvi zvinogona kukonzera kuvuza uye kunyangwe kutadza kwehurongwa. Kukura kwehutachiona, senge algae kana bhakitiriya, inogona kugadzira slime inovhara kuyerera kwemvura.

Nyanzvi dzinokurudzira matanho mashoma ari nyore:

- Chengetedza chinyorwa chezuva nezuva chekushisa, kumanikidzika, uye kuyerera kwemvura. Izvi zvinobatsira kuchinja kwemavara kare.

- Chenesa condenser uye evaporator machubhu kazhinji kumisa kusvibisa kubva pachiyero kana hutachiona.

- Watchkumhanya kwemvura. Kuyerera pakati pe3 uye 11 tsoka pasekondi kunobatsira kudzivirira kuvaka.

- Shandisa makemikari akakodzera kuchenesa mvura. Izvi zvinomisa chikero, ngura, uye kukura kwebiological.

Zano: Kugara uchiongorora uye kurapwa kwemvura kunoita kuti sisitimu ishande uye inobatsira kudzivirira kugadzirisa kunodhura.

Troubleshooting Chiller Machine Issues

Kugadzirisa Kuchinja Kwematembiricha

Kuchinja kwekushisa kunogona kuratidza matambudziko akadzama. Vashandisi vanowanzotanga nekutarisa kana sisitimu ichimhanya nenzira kwayo. Tsvagiridzo inoratidza kuti kudzoreredza kwakaringana chiller kutevedzana uye kushandisa yakanakisa dhizaini kune akawanda chiller anogonakuderedza kushandiswa kwesimba nepamusoro pe26%. Zvikwata zvakawanda zvinoshandisa variable-speed drives (VFDs) kudzora compressor uye fan kumhanya. Izvi zvinobatsira sisitimu kujaira kuchinja mitoro uye kuchengetedza tembiricha yakatsiga.

Heino kukurumidza kutarisa zvimwenzira dzinobatsira:

| Nzira/Technique | Tsanangudzo | Impact/Benefit |

|---|---|---|

| VFDs yemacompressor uye mafeni | Rongedza kumhanya kuti unyatso kutonhora | Zvirinani kushanda zvakanaka, kugadzikana temps |

| Optimized setpoint controls | Shandura zvigadziriso zvichibva pane chaiyo-nguva data | Kuderedza simba rekushandisa, kupindura nokukurumidza |

| Data-inofambiswa mienzaniso | Shandisa maturusi akangwara kufanotaura nekugadzirisa nyaya | Zvishoma zvinoshamisa, kutonga kwakawanda |

Vashandi vanoshandisawo mhando dzepamusoro izvosanganisa ruzivo rwepasirese nekudzidza muchina. Zvishandiso izvi zvinobatsira kuona matambudziko nekukurumidza uye kuchengetedza sisitimu ichishanda zvakanaka.

Kuita Noise Zvisina Kujairika

Kunzwika kunoshamisa kunowanzoreva dambudziko. Vashandi vanoteerera vachirira, kuridza muridzo, kana kugaya. Mheremhere iyi inogona kunongedza kunyaya dzemagetsi, kutadza kwepombi, kana zvivharo zvekuyerera kwemhepo. Kuongorora kunobatsira kubata matambudziko aya asati anyanya kuipa. Zvikwata zvakawanda zvinoshandisa Computerized Maintenance Management Systems (CMMS) kuronda nekuronga macheki.

Zano: Zvishandiso zveCMMS zvinopa zvigadziriso zvenguva chaiyo uye zvinobatsira zvikwata kugadzirisa nyaya nekukurumidza.

Kana nyanzvi ikanzwa ruzha rutsva, inotarisa kuti haina zvidimbu here, mabhengi akasakara, kana kuti mafeni akavharika. Kuita nekukurumidza kunochengetedza sisitimu uye inodzivirira kugadzirisa kwakakura.

Kugadzirisa Kushanda Kwakaderera

Kusashanda zvakanaka kunoparadza simba nemari. Zvidzidzo zvenyaya zvinoratidza kuti data analytics inogona kuona iyo mudzi chikonzero. Semuenzaniso, chimwe chikwata chakawana a40% kunyatsoshanda gappakati pechillers maviri. Vakagadzirisa chikamu chakaputsika uye vakadzorera kushanda. Rimwe boka rakashandisaParticle Swarm Optimizationkuenzanisa mitoro uye kuchengetedza simba.

Zvinowanzogadziriswa zvinosanganisira:

- Kutarisa kune yakaderera refrigerant kana kukanganisa zvinodzora

- Kugadzirisa akatyoka actuators kana mabhodhi

- Kushandisa smart algorithms kukwidziridza kugovera mitoro

Routine data wongororo uye kushanda pamwe chete kunobatsira kuchengetedza kushanda kwakakwirira. Nzira dzepamusoro dzekugadzirisa, seGenetic Algorithms uye Ruva Pollination Algorithm, dzakacheka kushandiswa kwesimba kusvika ku27%. Zvishandiso izvi zvinobatsira vashandisi kuwana zvakanyanya kubva mumidziyo yavo.

Chiller Machine Preventive Maintenance Checklist

Zvinhu Zvikuru Zvokuongorora Nguva Dzose

Rondedzero yakanaka yekudzivirira yekudzivirira inobatsira zvikwata kubata matambudziko nekukurumidza uye kuchengetedza sisitimu ichishanda zvakanaka. Nyanzvi dzakawanda dzinokurudzira kuongorora zvinhu izvi nguva dzose:

- Ita vibration ongororo pamamotor uye compressors. Iyi nhanho inobatsira kuona mechanic nyaya dzisati dzanyanya kuipa.

- Edza masisitimu ese ekuchengetedza, kusanganisira maalarm uye makiyi. Macheki aya anodzivirira mamiriro asina kuchengeteka.

- Chengetedza matanda ekugadzirisa akadzama. Rekodha kuyerera kwemazinga, tembiricha, kudzvanywa, uye mazinga emvura mazuva ese.

- Shandisa maremote ekutarisa masisitimu kune chaiyo-nguva zvigadziriso uye otomatiki mishumo.

- Chenesa condenser uye evaporator coils kuchengetedza kupisa kwakasimba.

- Zora zvinhu zvinofamba zvakaita semabheya uye mafeni kuti uderedze kupokana.

- Tarisa uye chengetedza mazinga efiriji kuitira kutonhora kwakanyanya.

- Ongorora zvinhu zvemagetsi, zvidzori, uye masensa kudzivirira kutadza.

- Edzai mhando yemvura uye wedzera mishonga yemakemikari kumisa chiyero uye ngura.

- Calibrate tembiricha uye kudzvanywa kudzora mwaka wega wega.

- Ongorora insulation uye zvisimbiso kudzivirira kudonha uye kurasikirwa nekupisa.

- Ongorora compressor mafuta kuti uwane kusvibiswa uye kuronga oiri kuchinja.

Zano: Zvikwata zvinotevera iyi yekutarisa zvinoona kushomeka kushoma uye hupenyu hurefu hwemidziyo.

Kuronga Kuongorora Kwenyanzvi

Kuongorora kwehunyanzvi kunowedzera imwe nhanho yekuchengetedza. Vanamazvikokota vakadzidziswa vanoshandisa maturusi akakosha kutarisa matambudziko akavanzika. Vanowanzowana nyaya dzinogona kupotsa zuva nezuva. Nyanzvi zhinji dzinokurudzira kuronga kuongorora kwakazara kanenge kamwe chete pagore. Zvimwe zvivakwa zvinosarudza kuita izvi mwaka wekutonhora usati wanyanya. Nyanzvi inogona zvakare kubatsira kugadzirisa zvidzoreso, kuyedza mhando yemvura, uye kuongorora matanda ekugadzirisa. Kuongororwa nguva dzose kunochengetedza sisitimu yakachengeteka, inoshanda, uye yakagadzirira chero dambudziko.

Kugadzirisa nguva dzose kunoita kuti michina ishande zvakanaka uye inochengetedza mari. Matimu anotevera matanho aya anoona kushomeka kushoma uye kuita zvirinani. Unoda mhinduro dzakanakisa? Vanofanirwa kufonera nyanzvi yemabasa akaomarara kana kugadzirwa kwehunyanzvi. Kugara pamusoro pekutarisira kunobatsira munhu wese kuwana zvakanyanya kubva kune yavo yekutonhodza system.

FAQ

Kangani munhu anofanirwa kuchenesa muchina wekutonhora?

Nyanzvi dzakawanda dzinotikuchenesa makoiri nemasefamwedzi woga woga. Gore negore kucheneswa kwakadzika kunoita kuti sisitimu ishande zvakanaka. Cheki dzezuva nezuva dzinobatsira kuona matambudziko nekukurumidza.

Ndezvipi zviratidzo zvinoratidza chiller inoda kugadziriswa?

Ruzha rusina kujairika, mabhiri emagetsi epamusoro, kana kutonhora kusina simba kunowanzoreva dambudziko. Kubvinza kana kunhuwa kusinganzwisisike kunoratidzawo kudiwa kwekuongororwa.

Pane munhu angaite chiller maintenance, kana kuti nyanzvi iite?

Basic mabasa akadaikuchenesa mafiritazviri nyore kuvanhu vazhinji. Pakugadzirisa hunyanzvi kana kuongororwa, nyanzvi yakadzidziswa inofanirwa kubata basa racho.

Nguva yekutumira: Jun-19-2025