In 2025, the buzz around plastic recycling machines centers on advanced automation, enhanced material sorting capabilities, and innovative chemical recycling processes. These innovations transform waste into valuable resources. This year marks a significant leap in efficiency and sustainability for the industry. Experts project the global plastic recycling machine market will reach USD 3.82 billion in 2025. This market anticipates strong growth. A plastic crusher machine helps break down large plastic items. A plastic shredder also prepares materials efficiently. A plastic recycle machine processes waste into reusable forms. Finally, a plastic making machine can utilize these recycled plastics.

Key Takeaways

- New rules and policies make 2025 a big year for recycling. These rules push companies to use better machines and recycle more plastic.

- Plastic recycling machines are getting smarter. They use AI to sort plastics better and IoT to track how machines work. This makes recycling more efficient.

- Mechanical recycling is improving. New machines sort plastics with high accuracy. They also wash and shred plastics better. This makes high-quality recycled materials.

- Chemical recycling is growing. It breaks down plastics into basic parts. This helps recycle plastics that are hard to process. It creates new materials for products.

- Advanced recycling machines help the environment and economy. They turn waste into new products. This saves money and reduces pollution.

The 2025 Landscape for Plastic Recycling Machine Innovation

Why 2025 is a Pivotal Year for Recycling Technology

The year 2025 marks a crucial period for recycling technology. New policies and regulations are driving significant changes. Extended Producer Responsibility (EPR) programs, for example, encourage manufacturers to use recycled plastics. This directly increases the need for high-quality granulation equipment. Regulations on landfill waste and recycling targets also push recyclers to improve their machinery. Environmental policies focus on energy efficiency and reducing emissions. These policies influence how companies design and operate granulator machines, leading to greener technologies. Agencies like the EPA set standards for equipment. Compliance with these standards ensures machines meet safety, environmental, and operational benchmarks. North American regulations increasingly emphasize sustainable waste management. Companies investing in machines that follow these policies can get government incentives and avoid penalties. This gives them a competitive advantage.

Key Trends in Plastic Recycling Machine Development

Several key trends are shaping the development of plastic recycling machines. AI-powered sorting systems are a major advancement. These systems can achieve 98% purity in PET/HDPE streams. They also reduce contamination by 40%. IoT-enabled monitoring allows for real-time tracking of machine performance and energy use. This leads to a 25% reduction in downtime. Decentralized facilities are also becoming more common. These compact units can process 500–800 kg/h. They help reduce transportation emissions globally. The EU’s Packaging and Packaging Waste Regulation (PPWR) is a big driver. It requires 70% recyclability for packaging by 2030. It also demands 10–35% recycled content in plastics. Meeting this rule requires advanced mechanical and chemical recycling technologies. Enhanced sorting technologies are changing plastic recycling. Automated systems use advanced sensors, artificial intelligence, and machine learning. They can identify and separate plastics based on their chemical makeup, color, and shape. This improves efficiency and purity in recycling streams. This improvement helps produce higher-quality recycled plastics.

Advanced Mechanical Plastic Recycling Machine Technologies

Mechanical recycling remains a cornerstone of plastic waste management. In 2025, new advancements make these processes more efficient and effective. These machines now handle a wider range of plastics. They also produce higher quality recycled materials.

Next-Gen Sorting Systems for Plastic Recycling Machines

Sorting is the first critical step in mechanical recycling. New sorting systems use advanced sensor technology, artificial intelligence (AI), and machine learning. These tools greatly improve accuracy and speed. Computer vision systems use high-resolution cameras and AI algorithms. They analyze plastic items in real-time. These systems identify subtle differences in color, shape, and texture for precise classification. Machine learning models continuously improve their recognition capabilities.

Deep learning algorithms process complex visual information. They make split-second decisions about material composition. These algorithms excel at recognizing patterns and features humans cannot see. This leads to sorting accuracy rates exceeding 95%. Near-Infrared (NIR) spectroscopy is another key technology. It uses infrared light to analyze molecular composition. This allows rapid and accurate identification of different plastic types like PET, HDPE, and PVC. It measures their unique spectral signatures.

Hyperspectral imaging takes spectroscopic sorting further. It combines traditional imaging with spectroscopy. This captures data across hundreds of spectral bands. It provides highly detailed material analysis. This identifies contaminants, additives, and subtle variations in plastic composition. Smart gripper technology also helps. These innovative grippers have sensors and adaptive pressure control. They handle materials of varying sizes, shapes, and weights without damage. They can also detect material properties through tactile feedback. This enhances sorting accuracy and reduces contamination.

These next-generation optical sorting systems use advanced camera systems, sensors, and machine learning algorithms. They swiftly and accurately identify and sort various waste materials. They employ sensors that detect unique spectral signatures for precise material identification and separation. This is especially useful for sorting post-consumer waste. This includes plastics, glass, paper, and metal. These systems can reduce transport and collection costs by at least 50% when combined with automated waste collection systems. They use NIR sensors to identify polymer types. They separate plastics based on color and type. These systems offer high throughput capacity, often processing hundreds of tons per day. They reduce contamination, leading to higher-quality recycled materials. Hyperspectral imaging technology, like Specim FX17 and GX17, provides real-time, reliable detection. It separates PET from contaminants such as PVC, HDPE, ABS, other plastics, and organic materials. Hyperspectral cameras offer superior sorting reliability and flexibility. They capture full or selectable spectral ranges. This allows reconfiguration throughout the machine’s lifecycle. Solid-state hyperspectral cameras are maintenance-free for many years. They do not have moving parts that require regular replacement and recalibration. These systems combine hyperspectral imaging with RGB cameras for enhanced color and shape detection. They use AI-based neural network models running on powerful NVIDIA GPUs for more precise sorting and detailed statistical records. They even address black plastic sorting using the Specim FX50 HSI camera. This camera operates in the mid-wave infrared (MWIR) range. It identifies and sorts black plastics based on their chemical composition.

Enhanced Washing and Shredding in Plastic Recycling Machines

After sorting, plastics undergo washing and shredding. These processes prepare the material for further processing. Modern washing and shredding machines show significant improvements in energy efficiency. Advanced plastic recycling machines, especially those using servo motor technology, reduce power consumption by up to 30% compared to older models. This leads to cost savings and environmental benefits. For example, conical twin screw, parallel twin screw, and compound twin screw models achieve up to 30% reduced energy usage.

Innovations in shredder blade materials and designs also improve throughput and reduce maintenance. An innovative V rotor design, with a 500 mm diameter and up to 2,200 mm length, handles large start-up lumps, hollow bins, and voluminous parts. A precise F rotor with milling and a special knife arrangement is ideal for shredding flexible materials like fibers and films. It ensures precise cutting geometries. Adjustable counter blades can be quickly adjusted and turned from the outside. This maintains an optimal cutting gap even with wear. It leads to consistently high throughput and extended knife service life. A generous inspection flap allows convenient maintenance and optimal rotor access. This enables easy removal of foreign matter and comfortable maintenance work.

These machines use hardened steel blades on dual rotating shafts. These blades handle both soft and rigid plastics efficiently. A low-speed, high-torque design ensures consistent particle size reduction. It also minimizes dust and noise. An adjustable cutting chamber allows operators to customize output sizes. Industrial-grade components and robust construction ensure long-term reliability. They reduce maintenance needs and minimize downtime. Wear-resistant components maintain consistent performance over extended operating periods. A quick blade replacement system minimizes operational interruptions.

Extrusion and Pelletizing for Premium Recycled Plastics

The final step in mechanical recycling involves extrusion and pelletizing. This transforms shredded and washed plastic flakes into uniform pellets. These pellets are then ready for manufacturing new products. Modern plastic pelletizing equipment offers a wide capacity range. It typically processes 100–2,500 kg/h. This accommodates both small and large-scale production needs. Some models, like the Wintech WT-150, produce 500–700 kg/h. The Huarui SJ-120 produces 100–130 kg/h. Larger systems, such as the PTC185-95, achieve 800-1000 kg/h. A new project involving a 5G Double Filtration Compacting Pelletizing Line has an output capacity of 1100 kg/h. These high capacities demonstrate the efficiency of current pelletizing technologies. They ensure a steady supply of premium recycled plastics for various industries.

The Rise of Chemical Plastic Recycling Machine Processes

Chemical recycling offers a powerful solution for plastics that mechanical methods cannot handle. These processes break down plastics into their original chemical building blocks or other valuable chemicals. This creates new raw materials for manufacturing. Chemical recycling complements mechanical recycling. It helps achieve a more circular economy for plastics.

Pyrolysis and Gasification Plastic Recycling Machines

Pyrolysis and gasification are two key chemical recycling methods. Pyrolysis heats plastic waste without oxygen. This process breaks down long polymer chains into smaller molecules. It produces oils, gases, and char. Gasification uses high temperatures with a controlled amount of oxygen or steam. This converts plastic into syngas, a mixture of hydrogen and carbon monoxide. Syngas can then become fuel or chemical feedstocks.

Companies like ExxonMobil use coprocessing technology. This technology integrates plastic waste into coker units. It generates synthetic crude and naphtha. Refineries can further process these into petrochemical feedstocks. Including polyethylene or polystyrene in coprocessing significantly boosts the liquid product yield. In a fluidized coking setup, adding plastic waste also raises the amount of syngas produced. An advanced microwave-powered pyrolysis technology produces high-quality pyrolysis oil. This oil meets refinery standards. This shows the potential for creating valuable products.

Chemical recycling processes convert plastic waste into various useful outputs. About 15-20% of plastic waste becomes propylene and ethylene. These are basic building blocks for new plastics. The remaining 80-85% of plastic waste transforms into diesel fuel, hydrogen, methane, and other chemicals. These outputs highlight the versatility of pyrolysis and gasification.

Depolymerization for Specific Plastic Types

Depolymerization is a precise chemical recycling method. It breaks down specific plastic polymers back into their original monomers. Monomers are the small molecules that link together to form polymers. This process creates high-quality raw materials. Manufacturers can use these raw materials to make new plastics with virgin-like properties.

Depolymerization is limited to specific types of plastics. These are known as condensation polymers. Examples include nylon and PET (polyethylene terephthalate). PET is a primary focus for commercialized depolymerization processes. Its suitability and abundance make it an ideal target. Next-generation depolymerization technologies also target acrylic waste, specifically PMMA (polymethyl methacrylate).

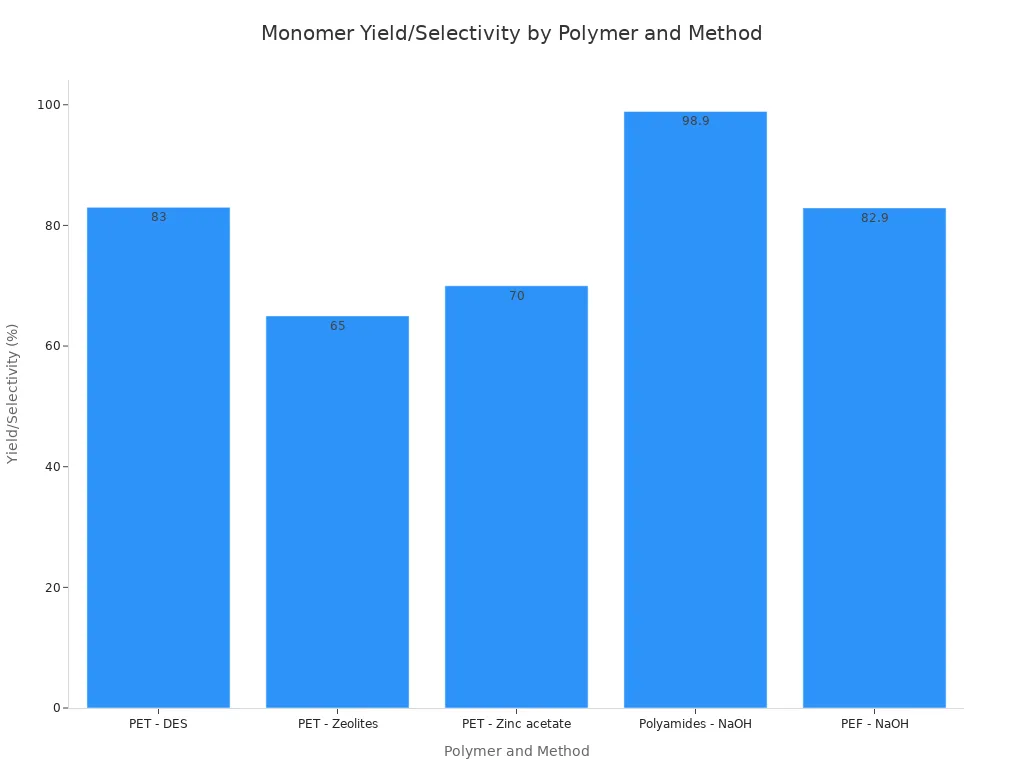

The purity of monomers recovered through depolymerization is very high. This makes them valuable for new plastic production. Different methods and catalysts achieve varying yields.

| Polymer | Method/Catalyst | Monomer Yield/Selectivity |

|---|---|---|

| PET | [urea/ZnCl2] DES | 83% selectivity to BHET |

| PET | Zeolites | 65% yield of BHET |

| PET | Zinc acetate and EG | Up to 70% yield of BHET |

| Polyamides (Kevlar) | Hydrolysis with NaOH | 98.9% for PPD, 95.3% for PTA |

| PEF | Hydrolysis with NaOH | 82.9% yield of 2,5-furandicarboxylic acid |

Dimethylethylamine catalysts promote high depolymerization yields. They work under moderate conditions. This contributes to consistent monomer output. These advanced methods ensure a reliable supply of pure monomers.

Solvolysis and Hydrothermal Plastic Recycling Machines

Solvolysis and hydrothermal processes are other important chemical recycling technologies. Solvolysis uses solvents to dissolve or break down plastics. This process often works at lower temperatures. Hydrothermal processes use hot, pressurized water to convert plastics. Both methods offer unique advantages for different plastic types.

Operational conditions vary for these processes.

| Process Type | Temperature Range (°C) | Pressure Range (MPa) |

|---|---|---|

| Hydrothermal Liquefaction (HTL) | 250–350 | 10–20 |

Solvolysis processes also operate under different conditions.

| Process Type | Temperature Range (°C) | Pressure Range (MPa) |

|---|---|---|

| Solvolysis (LTP) | < 200 | Ambient |

| Solvolysis (HTP) | Up to 450 | 0.3 to 30 |

These conditions allow for tailored approaches to various plastic waste streams.

Hydrothermal Treatment (HTT) offers significant environmental benefits. It can achieve up to an 80% reduction in climate change emissions. This is compared to incineration, a common disposal method for hard-to-recycle plastics. HTT conserves material within the system. This leads to a reduction in the consumption of fossil-based resources. The primary environmental impact of HTT is electricity consumption. Reducing this through energy efficiency or renewable energy sources could further improve its environmental performance. HTT avoids harmful combustion by-products like dioxins and char. Chemical recycling processes, including HTT, handle a wider range of non-homogeneous post-consumer plastics. This offers a practical solution at scale for a circular economy. The climate change impact of naphtha produced via HTT is comparable to current fossil chemical feedstock production processes. This offers circularity options for plastics manufacturing. These advanced chemical Plastic Recycling Machine technologies are crucial for a sustainable future.

Smart Plastic Recycling Machine Operations: AI, IoT, and Automation

Modern plastic recycling operations use advanced technology. Artificial intelligence (AI), the Internet of Things (IoT), and automation make processes smarter. These tools improve efficiency, reduce costs, and increase the quality of recycled materials.

Predictive Maintenance for Plastic Recycling Machines

Predictive maintenance keeps plastic recycling machines running smoothly. IoT sensors collect real-time data from equipment. They monitor vibrations, temperature, and motor performance. AI algorithms analyze this data. They predict when a machine part might fail. This allows facilities to perform maintenance before a breakdown occurs. It prevents unexpected downtime. This approach saves money and increases operational hours.

Data Analytics for Optimized Recycling Processes

Data analytics transforms recycling operations. Advanced platforms collect and analyze various data types. They track Key Performance Indicators (KPIs) like energy use and GHG emissions. They also gather material composition data, including recycled input percentages. Operational data covers machinery performance and processing temperatures. Compliance data ensures facilities meet local mandates and recycled content targets. Waste metrics track collection rates, sorting inaccuracies, and contamination. Traceability data validates claims about recycled products.

AI-powered sorting systems use Near-infrared (NIR) spectroscopy and AI algorithms. These systems reduce contamination rates by up to 50 percent. Researchers developed machine learning models that identify plastic types with up to 100% accuracy. This precision in sorting reduces contamination. It leads to higher-quality recycled resin and lower operational costs. At AdvanTech Plastics, AI-powered sensors inspect molded parts in real-time. This detects imperfections and allows immediate adjustments. It results in fewer defective products, less scrap, and lower energy use.

Fully Automated Plastic Recycling Facilities

Fully automated facilities are changing the recycling landscape. Robots perform tasks once done by humans. This reduces labor costs and improves safety.

| Feature | Robots | Human Sorter |

|---|---|---|

| Picks per hour | Up to 4,000 | 500-700 (heavy objects) |

| Operating hours | 24/7 | Not 24/7, requires breaks |

| Max weight handled | 66 lbs (30 kg) | Not feasible/safe for 66 lbs continuously |

Robots can pick up to 4,000 items per hour. Human sorters handle 500-700 heavy objects per hour. Robots work 24/7 without breaks. They safely handle heavy items up to 66 lbs. Lundstams Återvinning AB, a Swedish company, saved about $22,000 USD monthly. They reduced incinerated waste after using robots. Recycling robots contribute to long-term savings. They reduce labor costs and minimize errors.

Impact and Future Outlook of 2025 Plastic Recycling Machines

Addressing Hard-to-Recycle Plastics with New Machines

New recycling machines in 2025 tackle plastics previously considered unrecyclable. Chemical recycling breaks down contaminated plastic waste, like food packaging or motor oil bottles, to a molecular level. This process filters out contaminants effectively. Multi-layer plastic waste, such as flexible food packaging, also benefits from molecular recycling. This overcomes challenges mechanical recycling faces with these materials. Advanced solutions now target polystyrene foam, polyurethane foam, and mono-material films and bags. They also address multilayer pouches, thermoforms/black rigids, and foam/small rigids. Purification processes in molecular recycling remove contaminants from these complex materials.

Economic and Environmental Benefits of Advanced Recycling

Advanced plastic recycling machines offer significant economic and environmental advantages. They reduce waste management costs for municipalities and businesses. Companies generate new revenue by transforming waste into valuable products like new packaging or construction materials. This protects natural resources by reducing the need for virgin raw materials such as petroleum. Environmentally, these technologies produce plastic and chemical products with reduced global warming potential. They achieve this compared to products made from virgin resources. Advanced recycling can reduce CO2 equivalent emissions by over 100% compared to landfill and waste-to-energy processes. Over 40 projects, representing more than $7 billion in investments, could divert approximately 21 billion pounds of waste from landfills annually.

Challenges and Opportunities for Adopting New Technologies

Adopting new recycling technologies presents both challenges and opportunities. Significant upfront investment is often necessary for advanced machinery and infrastructure. Integrating these complex systems into existing facilities also requires careful planning and skilled labor. However, these technologies open doors to new markets for recycled materials. They also foster innovation in sustainable manufacturing. The drive towards a circular economy creates strong demand for high-quality recycled plastics. This offers substantial growth opportunities for companies embracing these advancements.

The advancements in plastic recycling machine technologies in 2025 represent a fundamental shift. Intelligent sorting and sophisticated chemical processes are transforming the industry. These innovations move us towards a more circular economy. Plastic waste is becoming a valuable resource. This drives sustainability and economic growth for everyone.

FAQ

What is the main focus of plastic recycling machines in 2025?

Machines in 2025 focus on advanced automation. They also feature enhanced material sorting capabilities. Innovative chemical recycling processes are key. These technologies transform waste into valuable resources. They significantly improve efficiency and sustainability. ♻️

How do next-gen sorting systems improve recycling?

Next-gen sorting systems use AI, machine learning, and advanced sensors. They identify plastics by color, shape, and chemical makeup. This improves sorting accuracy. It also reduces contamination. This leads to higher-quality recycled materials.

Post time: Oct-25-2025