Ngo-2025, umsindo omayelana nemishini yokugaywa kabusha kwepulasitiki ugxila ekuzenzekeleni okuthuthukisiwe, amakhono athuthukisiwe okuhlunga, kanye nezinqubo ezintsha zokugaywa kabusha kwamakhemikhali. Lezi zindlela ezintsha ziguqula imfucuza ibe yizinsiza ezibalulekile. Lo nyaka ukhombisa ukweqa okukhulu ekusebenzeni kahle nasekusimameni kwemboni. Ochwepheshe bakhiqiza umhlaba wonkeumshini wokugaywa kabusha wepulasitikiimakethe izofinyelela ku-USD 3.82 billion ngo-2025. Le makethe ilindele ukukhula okuqinile. Aumshini we-plastic crusherisiza ukudiliza izinto ezinkulu zepulasitiki. Aipulastiki shredderfuthi ulungiselela izinto zokwakha kahle. Aumshini wokuphinda usebenzise ipulasitikiicubungula imfucuza ibe amafomu angasetshenziswa kabusha. Ekugcineni, aumshini wokwenza ipulasitikibangasebenzisa la mapulasitiki agaywe kabusha.

Okuthathwayo Okubalulekile

- Imithetho emisha nezinqubomgomo zenza unyaka ka-2025 ube unyaka omkhulu wokugaywa kabusha. Le mithetho icindezela izinkampani ukuthi zisebenzise imishini engcono futhi zigaye kabusha amapulasitiki amaningi.

- Imishini yokugaywa kabusha kwepulasitiki iya ngobuhlakani. Basebenzisa i-AI ukuhlunga amapulasitiki kangcono kanye ne-IoT ukulandelela ukuthi imishini isebenza kanjani. Lokhu kwenza ukugaywa kabusha kusebenze kahle.

- Ukugaywa kabusha kwemishini kuyathuthuka. Imishini emisha ihlunga amapulasitiki ngokunemba okuphezulu. Baphinde bawashe futhi bahlephule amapulasitiki kangcono. Lokhu kwenza izinto ezigaywe kabusha zekhwalithi ephezulu.

- Ukugaywa kabusha kwamakhemikhali kuyakhula. Idiliza amapulasitiki abe izingxenye eziyisisekelo. Lokhu kusiza ukubuyisela kabusha amapulasitiki okunzima ukuwacubungula. Idala izinto ezintsha zemikhiqizo.

- Imishini esezingeni eliphezulu yokubuyisela kabusha isiza imvelo nomnotho. Baphendula imfucuza ibe yimikhiqizo emisha. Lokhu konga imali futhi kunciphisa ukungcola.

I-Landscape yango-2025 Yomshini Wokugaywa Kabusha Womshini Wepulasitiki

Kungani u-2025 Kungunyaka Obalulekile Wobuchwepheshe Bokugaywa kabusha

Unyaka wezi-2025 uphawula isikhathi esibalulekile sokwenza kabusha ubuchwepheshe. Izinqubomgomo nemithetho emisha idala izinguquko ezibalulekile. Izinhlelo Zesibopho Esandisiwe Somkhiqizi (EPR), ngokwesibonelo, zikhuthaza abakhiqizi ukuthi basebenzise amapulasitiki agaywe kabusha. Lokhu kwandisa ngokuqondile isidingo semishini yekhwalithi ephezulu ye-granulation. Imithetho mayelana nokulahlwa kukadoti kanye nezinhloso zokugaywa kabusha kuphinde kuphushe abagayli kabusha ukuthi bathuthukise imishini yabo. Izinqubomgomo zemvelo zigxile ekusebenzeni kahle kwamandla kanye nokunciphisa ukukhishwa kwegesi. Lezi zinqubomgomo zinethonya endleleni izinkampani eziklama futhi zisebenzise ngayo imishini ye-granulator, okuholela kubuchwepheshe obuluhlaza. Ama-ejensi afana ne-EPA abeka izindinganiso zemishini. Ukuthobelana nalawa mazinga kuqinisekisa ukuthi imishini ihlangabezana nezokuphepha, imvelo, kanye nezilinganiso zokusebenza. Imithetho yaseNyakatho Melika iya ngokuya igcizelela ukuphathwa kwemfucuza okusimeme. Izinkampani ezitshala imali emishinini elandela lezi zinqubomgomo zingathola imihlomulo kahulumeni futhi zigweme izinhlawulo. Lokhu kubanika inzuzo yokuncintisana.

Amathrendi Abalulekile Ekuthuthukisweni Komshini Wokugaywa Kabusha Kwepulasitiki

Amathrendi amaningana abalulekile abumba ukuthuthukiswa kwemishini yokugaywa kabusha kwepulasitiki. Amasistimu wokuhlela anamandla e-AI ayintuthuko enkulu. Lezi zinhlelo zingafinyelela ubumsulwa obungu-98% ekusakazweni kwe-PET/HDPE. Ziphinde zehlise ukusuleleka ngo-40%. Ukuqapha okunikwe amandla i-IoT kuvumela ukulandelela ngesikhathi sangempela sokusebenza komshini nokusetshenziswa kwamandla. Lokhu kuholela ekuncipheni ngo-25% esikhathini sokuphumula. Izikhungo ezihlukaniselwe izifundazwe nazo ziyanda. Lawa mayunithi ahlangene angakwazi ukucubungula 500-800 kg/h. Basiza ukunciphisa ukukhishwa kwezinto zokuhamba emhlabeni jikelele. I-EU's Packaging and Packaging Waste Regulation (PPWR) ingumshayeli omkhulu. Idinga u-70% wokuphinda ugaywe kabusha ukuze upakishwe ngo-2030. Iphinde ifune u-10-35% wokuqukethwe okugaywe kabusha kumapulasitiki. Ukuhlangabezana nalo mthetho kudinga ubuchwepheshe obuthuthukisiwe bokugaywa kabusha kwemishini namakhemikhali. Ubuchwepheshe bokuhlunga obuthuthukisiwe bushintsha ukugaywa kabusha kwepulasitiki. Amasistimu azenzakalelayo asebenzisa izinzwa ezithuthukisiwe, ubuhlakani bokwenziwa, nokufunda komshini. Bangakwazi ukukhomba futhi bahlukanise amapulasitiki ngokusekelwe ekwakhekeni kwamakhemikhali, umbala, nokuma kwawo. Lokhu kuthuthukisa ukusebenza kahle nobumsulwa ekusakazweni kokugaya kabusha. Lokhu kuthuthukiswa kusiza ukukhiqiza amapulasitiki agaywe kabusha ekhwalithi ephezulu.

Ubuchwepheshe Bomshini Wokugcwalisa Kabusha Wepulasitiki Wemishini Ethuthukisiwe

Ukugaywa kabusha kwemishini kuseyinsika yokulawulwa kwemfucuza yepulasitiki. Ngo-2025, intuthuko entsha yenza lezi zinqubo zisebenze kahle futhi ziphumelele. Le mishini manje isingatha uhla olubanzi lwamapulasitiki. Baphinde bakhiqize izinto ezigaywe kabusha ezisezingeni eliphezulu.

I-Next-Gen Sorting Systems Yemishini Yokugaywa Kabusha Kwepulasitiki

Ukuhlunga kuyisinyathelo sokuqala esibalulekile ekugayweni kabusha kwemishini. Amasistimu amasha okuhlunga asebenzisa ubuchwepheshe bezinzwa obuthuthukisiwe, ubuhlakani bokwenziwa (AI), nokufunda komshini. Lawa mathuluzi athuthukisa kakhulu ukunemba nesivinini. Amasistimu okubona ngekhompyutha asebenzisa amakhamera anokulungiswa okuphezulu kanye nama-algorithms e-AI. Bahlaziya izinto zepulasitiki ngesikhathi sangempela. Lawa masistimu ahlonza umehluko ocashile ngombala, umumo, nokuthungwa ukuze kuhlukaniswe ngokunembile. Amamodeli okufunda omshini aqhubeka ethuthukisa amakhono awo okuqashelwa.

Ama-algorithms wokufunda okujulile acubungula ulwazi oluyinkimbinkimbi olubonakalayo. Benza izinqumo ezihlukanisa isibili mayelana nokwakheka kwezinto. Lawa ma-algorithms ahamba phambili ekuboneni amaphethini nezici abantu abangakwazi ukuzibona. Lokhu kuholela emazingeni okunemba okuhlunga angaphezu kwama-95%. I-Near-Infrared (NIR) spectroscopy obunye ubuchwepheshe obubalulekile. Isebenzisa ukukhanya kwe-infrared ukuhlaziya ukwakheka kwamangqamuzana. Lokhu kuvumela ukuhlonza okusheshayo nokunembile kwezinhlobo ezahlukene zepulasitiki njenge-PET, i-HDPE, ne-PVC. Ikala amasiginesha abo ahlukile we-spectral.

I-hyperspectral imaging ithatha ukuhlelwa kwe-spectroscopic ngokuqhubekayo. Ihlanganisa izithombe zendabuko ne-spectroscopy. Lokhu kuthatha idatha kumakhulu amabhendi we-spectral. Inikeza ukuhlaziywa kwezinto ezinemininingwane eminingi. Lokhu kukhomba ukungcola, izithasiselo, kanye nokwehluka okucashile ekubunjweni kwepulasitiki. Ubuchwepheshe be-Smart gripper nabo bayasiza. Lezi zibamba ezintsha zinezinzwa nokulawula ingcindezi eguquguqukayo. Baphatha izinto zobukhulu obuhlukahlukene, izimo, nezisindo ngaphandle kokulimala. Bangakwazi futhi ukubona izici ezibonakalayo ngempendulo ethintekayo. Lokhu kuthuthukisa ukunemba kokuhlunga futhi kunciphisa ukungcoliswa.

Lezi zinhlelo zesizukulwane esilandelayo zokuhlela zisebenzisa amasistimu ekhamera athuthukile, izinzwa, nama-algorithms okufunda komshini. Bahlonza ngokushesha nangokunembile futhi bahlunge izinto ezilahlwayo ezihlukahlukene. Basebenzisa izinzwa ezithola amasiginesha e-spectral ahlukile ngokuhlonza okunembayo nokuhlukaniswa. Lokhu kuwusizo ikakhulukazi ekuhleleni udoti wangemva komthengi. Lokhu kuhlanganisa amapulasitiki, ingilazi, iphepha, nensimbi. Lezi zinhlelo zinganciphisa izindleko zokuthutha nokuqoqwa okungenani ngama-50% uma zihlanganiswa nezinhlelo zokuqoqwa kwemfucuza ezizenzakalelayo. Basebenzisa izinzwa ze-NIR ukuhlonza izinhlobo ze-polymer. Bahlukanisa amapulasitiki ngokusekelwe kumbala nohlobo. Lezi zinhlelo zinikeza umthamo ophezulu wokuphuma, ngokuvamile ukucubungula amakhulu amathani ngosuku. Anciphisa ukungcola, okuholela ezintweni ezigaywe kabusha zekhwalithi ephezulu. Ubuchwepheshe bezithombe ze-hyperspectral, njenge-Specim FX17 ne-GX17, buhlinzeka ngesikhathi sangempela, ukutholwa okuthembekile. Ihlukanisa i-PET kokungcola okufana ne-PVC, i-HDPE, i-ABS, amanye amapulasitiki, nezinto eziphilayo. Amakhamera we-Hyperspectral anikeza ukuthembeka okuphezulu kokuhlunga nokuguquguquka. Bathwebula ububanzi obugcwele noma obukhethekayo be-spectral. Lokhu kuvumela ukulungiswa kabusha kuwo wonke umjikelezo wokuphila womshini. Amakhamera we-Solid-state hyperspectral awanakekelwa iminyaka eminingi. Azinazo izingxenye ezinyakazayo ezidinga ukushintshwa okujwayelekile nokulungiswa kabusha. Lezi zinhlelo zihlanganisa izithombe ze-hyperspectral namakhamera e-RGB ukuze kutholakale umbala othuthukisiwe nokuma. Basebenzisa amamodeli enethiwekhi ye-neural asekelwe ku-AI asebenza kuma-NVIDIA GPU anamandla ukuze bathole ukuhlunga okunembe kakhudlwana namarekhodi ezibalo anemininingwane. Baze bakhulume nokuhlelwa kwepulasitiki emnyama kusetshenziswa ikhamera ye-Specim FX50 HSI. Le khamera isebenza kububanzi be-mid-wave infrared (MWIR). Ihlonza futhi ihlukanise amapulasitiki amnyama ngokusekelwe ekwakhekeni kwawo kwamakhemikhali.

Ukuwasha Okuthuthukisiwe Nokusihlinza Emishinini Yokugaywa Kabusha Kwepulasitiki

Ngemuva kokuhlunga, amapulasitiki ayawashwa futhi ahlukaniswe. Lezi zinqubo zilungiselela okokusebenza ukuze kuqhutshekwe nokucubungula. Imishini yesimanje yokuwasha neyokucucuza ikhombisa ukuthuthuka okukhulu ekusebenzeni kahle kwamandla. Imishini ethuthukisiwe yokugaywa kabusha kwepulasitiki, ikakhulukazi leyo esebenzisa ubuchwepheshe bezimoto ze-servo, inciphisa ukusetshenziswa kwamandla kufika ku-30% uma kuqhathaniswa namamodeli amadala. Lokhu kuholela ekongeni izindleko kanye nezinzuzo zemvelo. Isibonelo, isikulufu esingamawele esiyikhoni, isikulufu samawele ahambisanayo, namamodeli angamawele ahlanganisiwe afinyelela kufikela kokungu-30% ukusetshenziswa kwamandla okwehlisiwe.

Ukuqanjwa kwezinto ezintsha ze-shredder blade kanye nemiklamo nakho kuyathuthukisa ukusebenza futhi kunciphise ukulungiswa. Idizayini entsha ye-rotor engu-V, enobubanzi obungu-500 mm nobude obufika ku-2,200 mm, ibamba izigaxa ezinkulu zokuqalisa, imigqomo engenalutho, nezingxenye ezinamandla. Irotha engu-F enembile enokugaya kanye nokuhlelwa kommese okukhethekile ilungele ukusika izinto eziguqukayo ezifana namafayibha namafilimu. Iqinisekisa ukusika okunembile kwejometri. Ama-counter blades alungisekayo angalungiswa ngokushesha futhi ajike ngaphandle. Lokhu kugcina igebe elilungile lokusika ngisho nokuguga. Kuholela ekusebenzeni okuphezulu okungaguquki kanye nempilo yesevisi yommese eyandisiwe. I-flap yokuhlola evulekile ivumela ukulungiswa okulula kanye nokufinyelela okuqondile kwe-rotor. Lokhu kwenza kube lula ukususwa kwezinto zangaphandle kanye nomsebenzi wokulungisa onethezekile.

Le mishini isebenzisa izindwani zensimbi eziqinile emiphini ezungezayo ekabili. Lawa ma-blades aphatha kahle amapulasitiki athambile futhi aqinile. Idizayini enesivinini esiphansi, yetorque ephezulu iqinisekisa ukuncishiswa kosayizi wezinhlayiyana okungaguquki. Iphinde inciphise uthuli nomsindo. Igumbi lokusika elilungisekayo livumela opharetha ukuthi benze ngokwezifiso osayizi bokuphumayo. Izingxenye zebanga lezimboni kanye nokwakhiwa okuqinile kuqinisekisa ukwethembeka kwesikhathi eside. Banciphisa izidingo zokunakekelwa futhi banciphise isikhathi sokuphumula. Izingxenye ezimelana nokugqokwa zigcina ukusebenza okungaguquki phakathi nezikhathi zokusebenza ezinwetshiwe. Isistimu yokushintsha i-blade esheshayo inciphisa ukuphazamiseka kokusebenza.

I-Extrusion and Pelletizing for Premium Recycled Plastics

Isinyathelo sokugcina sokugaywa kabusha ngomshini sifaka i-extrusion kanye ne-pelletizing. Lokhu kuguqula ama-flakes epulasitiki aqoshiwe futhi ahlanjululwe abe ama-pellets afanayo. Lawa ma-pellets asuke eselungele ukukhiqiza imikhiqizo emisha. Imishini yesimanje ye-plastic pelletizing inikeza ububanzi obubanzi bomthamo. Ivamise ukwenza u-100-2,500 kg/h. Lokhu kuvumelana nezidingo zokukhiqiza ezincane nezinkulu. Amanye amamodeli, njengeWintech WT-150, akhiqiza u-500-700 kg/h. I-Huarui SJ-120 ikhiqiza i-100-130 kg/h. Amasistimu amakhulu, njenge-PTC185-95, afinyelela ku-800-1000 kg/h. Iphrojekthi entsha ehlanganisa i-5G Double Filtration Compacting Pelletizing Line inamandla okukhipha angu-1100 kg/h. Lawa makhono aphezulu akhombisa ukusebenza kahle kobuchwepheshe bamanje be-pelletizing. Baqinisekisa ukuhlinzekwa okuqhubekayo kwamapulasitiki asetshenziswe kabusha e-premium ezimbonini ezihlukahlukene.

Ukunyuka Kwezinqubo Zomshini Wokugaywa Kabusha Wamakhemikhali Wepulasitiki

Ukugaywa kabusha kwamakhemikhali kunikeza isisombululo esinamandla samapulasitiki izindlela zemishini ezingakwazi ukusiphatha. Lezi zinqubo zephula amapulasitiki abe yizingqimba zawo zokwakha zamakhemikhali zangempela noma amanye amakhemikhali abalulekile. Lokhu kudala izinto ezintsha zokukhiqiza. Ukugaywa kabusha kwamakhemikhali kuhambisana nokugaywa kabusha kwemishini. Kuyasiza ukuzuza umnotho oyindilinga kakhudlwana kumapulasitiki.

Pyrolysis kanye Gasification Plastic Recycling Machines

I-Pyrolysis kanye ne-gasification yizindlela ezimbili ezibalulekile zokuvuselela amakhemikhali. I-Pyrolysis ishisa imfucuza yepulasitiki ngaphandle kwe-oxygen. Le nqubo idiliza amaketanga e-polymer amade abe ama-molecule amancane. Ikhiqiza amafutha, amagesi, ne-char. I-gasification isebenzisa amazinga okushisa aphezulu anenani elilawulwayo le-oxygen noma isitimu. Lokhu kuguqula ipulasitiki ibe yi-syngas, ingxube ye-hydrogen ne-carbon monoxide. I-Syngas ingaba isitokwe samafutha noma samakhemikhali.

Izinkampani ezifana ne-ExxonMobil zisebenzisa ubuchwepheshe be-coprocessing. Lobu buchwepheshe buhlanganisa imfucuza yepulasitiki ibe amayunithi e-coker. Ikhiqiza i-synthetic crude ne-naphtha. Izihlungi zingaqhubeka zicubungula lezi zibe yi-petrochemical feedstocks. Ukufaka i-polyethylene noma i-polystyrene ekuhlanganiseni kukhulisa kakhulu isivuno somkhiqizo owuketshezi. Kusethaphu ye-coking enoketshezi, ukwengeza imfucuza yepulasitiki nakho kuphakamisa inani lama-syngas akhiqizwayo. Ubuchwepheshe be-pyrolysis obuthuthukisiwe obusebenzisa i-microwave bukhiqiza uwoyela we-pyrolysis wezinga eliphezulu. La mafutha ahlangabezana nezindinganiso zokuhluzwa. Lokhu kubonisa amandla okudala imikhiqizo ebalulekile.

Izinqubo zokugaywa kabusha kwamakhemikhali ziguqula imfucuza yepulasitiki ibe yimiphumela ehlukahlukene ewusizo. Cishe i-15-20% yemfucuza yepulasitiki iba yi-propylene ne-ethylene. Lawa amabhulokhi okwakha ayisisekelo amapulasitiki amasha. I-80-85% esele yemfucuza yepulasitiki ishintsha ibe uphethiloli we-diesel, i-hydrogen, i-methane, namanye amakhemikhali. Le miphumela igqamisa ukuguquguquka kwe-pyrolysis kanye ne-gasification.

I-Depolymerization yezinhlobo ezithile zePlastiki

I-Depolymerization iyindlela enembile yokubuyisela kabusha amakhemikhali. Idiliza ama-polymer epulasitiki athile abuyele kuma-monomer awo asekuqaleni. Ama-monomers ama-molecule amancane ahlangana ndawonye ukuze akhe ama-polymer. Le nqubo idala izinto ezingavuthiwe zekhwalithi ephezulu. Abakhiqizi bangasebenzisa lezi zinto zokusetshenziswa ukwenza amapulasitiki amasha anezakhiwo ezinjengama-virgin.

I-Depolymerization ikhawulelwe ezinhlotsheni ezithile zamapulasitiki. Lezi zaziwa ngokuthi ama-polymers e-condensation. Izibonelo zifaka inayiloni ne-PET (i-polyethylene terephthalate). I-PET igxile kakhulu ezinqubweni ze-depolymerization ezenzelwe ukuhweba. Ukufaneleka kwayo nokuchichima kwayo kuyenza ibe inhloso ekahle. Ubuchwepheshe besizukulwane esilandelayo be-depolymerization buphinde buqondise udoti we-acrylic, ikakhulukazi i-PMMA (i-polymethyl methacrylate).

Ukuhlanzeka kwama-monomers atholwe nge-depolymerization kuphezulu kakhulu. Lokhu kubenza babe yigugu ekukhiqizeni okusha kwepulasitiki. Izindlela ezihlukene kanye nama-catalysts athola isivuno esihlukile.

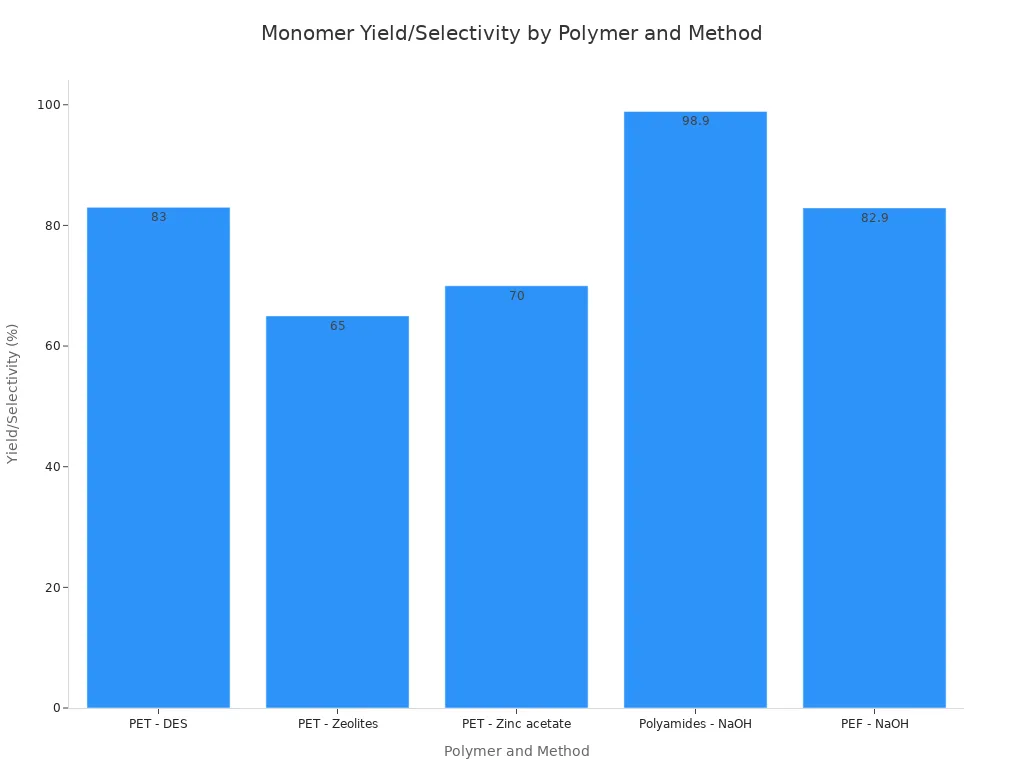

| I-polymer | Indlela/I-Catalyst | I-Monomer Yield/Ukukhetha |

|---|---|---|

| I-PET | [urea/ZnCl2] DES | 83% ukukhetha ku-BHET |

| I-PET | AmaZeolite | 65% isivuno seBHET |

| I-PET | I-Zinc acetate ne-EG | Kufika ku-70% isivuno se-BHET |

| I-Polyamides (Kevlar) | I-Hydrolysis nge-NaOH | U-98.9% we-PPD, u-95.3% we-PTA |

| I-PEF | I-Hydrolysis nge-NaOH | I-82.9% isivuno se-2,5-furandicarboxylic acid |

I-Dimethylethylamine catalysts ikhuthaza isivuno esiphezulu se-depolymerization. Basebenza ngaphansi kwezimo ezimaphakathi. Lokhu kunomthelela ekukhishweni kwe-monomer okungaguquki. Lezi zindlela ezithuthukisiwe ziqinisekisa ukunikezwa okuthembekile kwama-monomers ahlanzekile.

I-Solvolysis kanye ne-Hydrothermal Plastic Recycling Machines

Izinqubo ze-Solvolysis kanye ne-hydrothermal zingobunye ubuchwepheshe obubalulekile bokugaywa kabusha kwamakhemikhali. I-Solvolysis isebenzisa izincibilikisi ukuncibilikisa noma ukudiliza amapulasitiki. Le nqubo ivame ukusebenza emazingeni okushisa aphansi. Izinqubo ze-Hydrothermal zisebenzisa amanzi ashisayo, acindezelwe ukuguqula amapulasitiki. Zombili izindlela zinikeza izinzuzo eziyingqayizivele zezinhlobo ezahlukene zepulasitiki.

Izimo zokusebenza ziyahlukahluka kulezi zinqubo.

| Uhlobo Lwenqubo | Ibanga Lezinga lokushisa (°C) | I-Pressure Range (MPa) |

|---|---|---|

| I-Hydrothermal Liquefaction (HTL) | 250–350 | 10–20 |

Izinqubo ze-Solvolysis nazo zisebenza ngaphansi kwezimo ezahlukene.

| Uhlobo Lwenqubo | Ibanga Lezinga lokushisa (°C) | I-Pressure Range (MPa) |

|---|---|---|

| I-Solvolysis (LTP) | <200 | I-ambient |

| I-Solvolysis (HTP) | Kufika ku-450 | 0.3 kuya ku-30 |

Lezi zimo zivumela izindlela ezilungiselelwe emifudlaneni ehlukahlukene yemfucuza yepulasitiki.

IHydrothermal Treatment (HTT) inikeza izinzuzo ezibalulekile zemvelo. Ingafinyelela ekuncipheni okungama-80% kokukhishwa kwesimo sezulu. Lokhu kuqhathaniswa nokushiswa, indlela evamile yokulahla amapulasitiki okunzima ukuwasebenzisa kabusha. I-HTT ilondoloza impahla ngaphakathi kwesistimu. Lokhu kuholela ekuncipheni kokusetshenziswa kwemithombo yezinto ezimbiwa phansi. Umthelela oyinhloko wemvelo we-HTT ukusetshenziswa kukagesi. Ukunciphisa lokhu ngokusebenzisa ukonga kwamandla noma imithombo yamandla avuselelekayo kungase kuthuthukise ukusebenza kwayo kwemvelo. I-HTT igwema ukuvutha okuyingozi kwemikhiqizo efana nama-dioxin ne-char. Izinqubo zokugaywa kabusha kwamakhemikhali, okuhlanganisa i-HTT, zisingatha uhla olubanzi lwamapulasitiki angewona ama-homogeneous post-consumer. Lokhu kunikeza isixazululo esisebenzayo esikalini somnotho oyindilinga. Umthelela wokuguquguquka kwesimo sezulu we-naphtha okhiqizwa nge-HTT ufaniswa nezinqubo zamanje zokukhiqiza ukudla kwamakhemikhali ezinsalela. Lokhu kunikeza izinketho zokujikeleza zokukhiqiza amapulasitiki. Lobu buchwepheshe obuthuthukisiwe bomshini Wokugaywa Kabusha Wamakhemikhali Wamakhemikhali bubalulekile ekusaseni elisimeme.

I-Smart Plastic Recycling Machine Operations: AI, IoT, kanye ne-Automation

Imisebenzi yesimanje yokugaywa kabusha kwepulasitiki isebenzisa ubuchwepheshe obuphambili. I-Artificial intelligence (AI), i-Inthanethi Yezinto (IoT), kanye ne-automation kwenza izinqubo zibe nobuhlakani. Lawa mathuluzi athuthukisa ukusebenza kahle, ehlisa izindleko, futhi andise ikhwalithi yezinto ezigaywe kabusha.

Ukulungiswa Okuqagelayo Kwemishini Yokugaywa Kabusha Kwepulasitiki

Ukulungiswa kokuqagela kugcina imishini yokuvuselela ipulasitiki isebenza kahle. Izinzwa ze-IoT ziqoqa idatha yesikhathi sangempela emishinini. Baqapha ukudlidliza, izinga lokushisa, nokusebenza kwemoto. Ama-algorithms e-AI ahlaziya le datha. Babikezela ukuthi ingxenye yomshini ingase yehlule nini. Lokhu kuvumela izikhungo ukuthi zenze ukulungiswa ngaphambi kokuthi kwenzeke ukuwohloka. Ivimbela isikhathi sokuphumula esingalindelekile. Le ndlela yonga imali futhi inyusa amahora okusebenza.

Izibalo Zedatha Yezinqubo Ezithuthukisiwe Zokugaywa kabusha

Ukuhlaziywa kwedatha kuguqula imisebenzi yokuvuselela kabusha. Izinkundla ezithuthukile ziqoqa futhi zihlaziye izinhlobo ezahlukene zedatha. Balandelela Izinkomba Zokusebenza Okubalulekile (KPIs) njengokusetshenziswa kwamandla kanye nokukhishwa kwe-GHG. Baphinde baqoqe idatha yokwakheka kwezinto, okuhlanganisa namaphesenti okokufaka agaywe kabusha. Idatha yokusebenza ihlanganisa ukusebenza kwemishini kanye namazinga okushisa okucubungula. Idatha yokuthobela iqinisekisa ukuthi izikhungo zihlangabezana nemiyalelo yendawo kanye nokuhlosiwe kokuqukethwe okugaywe kabusha. Izilinganiso zokuqoqwa kwama-Metrics kadoti, ukunemba kokuhlunga, nokungcoliswa. Idatha yokulandeleka iqinisekisa izimangalo mayelana nemikhiqizo egaywe kabusha.

Amasistimu okuhlela anamandla e-AI asebenzisa i-spectroscopy ye-Near-infrared (NIR) kanye ne-AI algorithms. Lezi zinhlelo zehlisa izinga lokungcola ngamaphesenti angama-50. Abacwaningi bathuthukise amamodeli okufunda emishini akhomba izinhlobo zepulasitiki ngokunemba okungafika ku-100%. Lokhu kunemba ekuhlungeni kunciphisa ukungcoliswa. Kuholela ku-resin egaywe kabusha yekhwalithi ephezulu kanye nezindleko eziphansi zokusebenza. Kwa-AdvanTech Plastics, izinzwa ezisebenza nge-AI zihlola izingxenye ezibunjiwe ngesikhathi sangempela. Lokhu kuthola ukungapheleli futhi kuvumela ukulungiswa ngokushesha. Kuholela emikhiqizweni embalwa enesici, ukuchithwa okuncane, nokusebenzisa amandla aphansi.

I-Automated Plastic Recycling Izinsiza Ngokugcwele

Izinsiza ezisebenza ngokuzenzakalelayo zishintsha isimo sokugaywa kabusha. Amarobhothi enza imisebenzi eyake yenziwa abantu. Lokhu kunciphisa izindleko zabasebenzi futhi kuthuthukisa ukuphepha.

| Isici | Amarobhothi | IHluli Lomuntu |

|---|---|---|

| Ukukhetha ngehora | Kufika ku-4,000 | 500-700 (izinto ezinzima) |

| Amahora okusebenza | 24/7 | Hhayi 24/7, kudinga amakhefu |

| Isisindo esiphezulu esibanjiwe | 66 lbs (30 kg) | Akwenzeki/kuphephile ngo-66 lbs ngokuqhubekayo |

Amarobhothi angakwazi ukuthatha izinto ezingafika kwezi-4,000 ngehora. Abahluzi babantu baphatha izinto ezisindayo ezingama-500-700 ngehora. Amarobhothi asebenza 24/7 ngaphandle kwekhefu. Baphatha ngokuphepha izinto ezisindayo ezifika ku-66 lbs. I-Lundstams Återvinning AB, inkampani yase-Swedish, yonge cishe u-$22,000 USD nyanga zonke. Banciphisa imfucuza eshisiwe ngemva kokusebenzisa amarobhothi. Amarobhothi agaywa kabusha afaka isandla ekongeni isikhathi eside. Banciphisa izindleko zabasebenzi futhi banciphise amaphutha.

Umthelela kanye Nekusasa Lemishini Ka-2025 Yokugaywa Kabusha Kwepulasitiki

Ukubhekana Nepulasitiki Okunzima Uku-Recycle Nemishini Emisha

Imishini emisha yokugaywa kabusha ngo-2025 ibhekana namapulasitiki phambilini ayethathwa njengangaphinde asetshenziswe. Ukugaywa kabusha kwamakhemikhali kwephula imfucumfucu yepulasitiki engcolile, njengokupakishwa kokudla noma amabhodlela kawoyela emoto, ifike ezingeni lamangqamuzana. Le nqubo ihlunga ukungcola ngempumelelo. Imfucumfucu yepulasitiki enezingqimba eziningi, njengokupakishwa kokudla okuguquguqukayo, nakho kuyazuza ekugayweni kabusha kwamangqamuzana. Lokhu kunqoba izinselele zokugaywa kabusha kwemishini ngalezi zinto. Izixazululo ezithuthukisiwe manje ziqondise igwebu le-polystyrene, igwebu le-polyurethane, namafilimu nezikhwama ze-mono-material. Baphinde babhekane nezikhwama zama-multilayer, ama-thermoforms/ama-rigids amnyama, kanye nama-foam/ama-rigids amancane. Izinqubo zokuhlanza ekugayweni kabusha kwamangqamuzana zisusa ukungcola kulezi zinto eziyinkimbinkimbi.

Izinzuzo Zezomnotho Nezemvelo Zokugaywa kabusha Okuthuthukile

Imishini eseqophelweni eliphezulu yokugaywa kabusha kwepulasitiki inikeza izinzuzo ezibalulekile zezomnotho nezemvelo. Banciphisa izindleko zokulawulwa kwemfucuza komasipala namabhizinisi. Izinkampani zenza imali entsha ngokuguqula imfucuza ibe yimikhiqizo ebalulekile efana nokupakishwa okusha noma izinto zokwakha. Lokhu kuvikela imithombo yemvelo ngokunciphisa isidingo sezinto ezingavuthiwe ezifana ne-petroleum. Ngokwemvelo, lobu buchwepheshe bukhiqiza imikhiqizo yepulasitiki neyamakhemikhali enamandla ancishisiwe okufudumala komhlaba. Bafinyelela lokhu uma kuqhathaniswa nemikhiqizo eyenziwe ngezinsiza ezimsulwa. Ukugaywa kabusha okuthuthukisiwe kunganciphisa ukukhishwa kwe-CO2 okulinganayo ngaphezu kuka-100% uma kuqhathaniswa nezinqubo zokulahla imfucuza kanye nezinqubo zokulahla udoti ukuya kumandla. Amaphrojekthi angaphezu kuka-40, amele imali engaphezu kwezigidigidi ezingu-7 zamaRandi, angaphambukisa cishe amaphawundi ayizigidi eziyizinkulungwane ezingu-21 wemfucuza ezindaweni zokulahla imfucumfucu minyaka yonke.

Izinselelo Namathuba Okwamukela Ubuchwepheshe Obusha

Ukwamukela ubuchwepheshe obusha bokugaywa kabusha kuveza kokubili izinselele namathuba. Ukutshalwa kwezimali okubalulekile kwangaphambi kwesikhathi kuvame ukudingeka emishinini ethuthukisiwe nengqalasizinda. Ukuhlanganisa lezi zinhlelo eziyinkimbinkimbi ezindaweni ezikhona nakho kudinga ukuhlela ngokucophelela kanye nomsebenzi onamakhono. Nokho, lobu buchwepheshe buvula iminyango ezimakethe ezintsha zezinto ezigaywe kabusha. Baphinde bakhuthaze ukusungulwa kokukhiqiza okusimeme. Umkhankaso obheke emnothweni oyindilinga udala isidingo esinamandla samapulasitiki agaywe kabusha asezingeni eliphezulu. Lokhu kunikeza amathuba okukhula amakhulu ezinkampanini ezamukela lezi ntuthuko.

Intuthuko kubuchwepheshe bomshini wokugaya kabusha wepulasitiki ngo-2025 imele ushintsho olubalulekile. Ukuhlunga okuhlakaniphile kanye nezinqubo zamakhemikhali eziyinkimbinkimbi ziguqula imboni. Lezi zindlela ezintsha zisiqhubela emnothweni oyindilinga. Imfucumfucu yepulasitiki iba insiza ebalulekile. Lokhu kugqugquzela ukusimama nokukhula komnotho wawo wonke umuntu.

FAQ

Ikuphi okugxilwe kakhulu kwemishini yokugaywa kabusha kwepulasitiki ngo-2025?

Imishini ngo-2025 igxila ekuzenzekeleni okuthuthukisiwe. Ziphinde zibe namakhono okuhlunga athuthukisiwe. Izinqubo ezintsha zokugaywa kabusha kwamakhemikhali zibalulekile. Lobu buchwepheshe buguqula imfucuza ibe yizinsiza ezibalulekile. Bathuthukisa kakhulu ukusebenza kahle nokusimama. ♻️

Ingabe amasistimu okuhlunga esizukulwane esilandelayo akuthuthukisa kanjani ukugaywa kabusha?

Amasistimu okuhlunga esizukulwane esilandelayo asebenzisa i-AI, ukufunda ngomshini, nezinzwa ezithuthukile. Bahlonza amapulasitiki ngombala, umumo, nangokwakheka kwamakhemikhali. Lokhu kuthuthukisa ukunemba kokuhlunga. Futhi kunciphisa ukungcoliswa. Lokhu kuholela ezintweni ezigaywe kabusha zekhwalithi ephezulu.

Isikhathi sokuthumela: Oct-25-2025