Mu 2025, chipwirikiti chozungulira makina obwezeretsanso pulasitiki chimakhazikika pa makina apamwamba kwambiri, luso lotha kusanja zinthu, ndi njira zatsopano zobwezeretsanso mankhwala. Zatsopanozi zimasintha zinyalala kukhala zofunikira. Chaka chino chikuwonetsa kudumpha kwakukulu pakuchita bwino komanso kukhazikika kwamakampani. Akatswiri akupanga padziko lonse lapansimakina obwezeretsanso pulasitikimsika udzafika USD 3.82 biliyoni mu 2025. Msika uwu ukuyembekeza kukula kwakukulu. Amakina opangira pulasitikikumathandiza kuthyola zinthu zazikulu zapulasitiki. Apulasitiki shredderamakonzekeranso zipangizo bwino. Amakina obwezeretsanso pulasitikiamakonza zinyalala kukhala mafomu osinthika. Pomaliza, amakina opangira pulasitikiatha kugwiritsa ntchito mapulasitiki obwezerezedwanso awa.

Zofunika Kwambiri

- Malamulo ndi ndondomeko zatsopano zimapangitsa 2025 kukhala chaka chachikulu chobwezeretsanso. Malamulowa amakakamiza makampani kugwiritsa ntchito makina abwinoko ndikubwezeretsanso pulasitiki yochulukirapo.

- Makina obwezeretsanso pulasitiki ayamba kukhala anzeru. Amagwiritsa ntchito AI kukonza mapulasitiki bwino ndi IoT kutsata momwe makina amagwirira ntchito. Izi zimapangitsa kuti zobwezeretsanso zigwire ntchito bwino.

- Kukonzanso kwamakina kukuyenda bwino. Makina atsopano amasankha mapulasitiki molondola kwambiri. Amatsukanso ndi kung'amba mapulasitiki bwino. Izi zimapanga zida zobwezerezedwanso zapamwamba.

- Kubwezeretsanso mankhwala kukukula. Imaphwanya mapulasitiki kukhala zigawo zofunika kwambiri. Izi zimathandiza kubwezeretsanso mapulasitiki omwe ndi ovuta kuwakonza. Zimapanga zida zatsopano zopangira.

- Makina apamwamba obwezeretsanso amathandiza chilengedwe komanso chuma. Amasandutsa zinyalala kukhala zinthu zatsopano. Izi zimapulumutsa ndalama komanso zimachepetsa kuipitsa.

The 2025 Landscape for Plastic Recycling Machine Innovation

Chifukwa chiyani 2025 ndi Chaka Chofunikira Kwambiri Paukadaulo Wobwezeretsanso

Chaka cha 2025 ndi nthawi yofunika kwambiri paukadaulo wobwezeretsanso. Ndondomeko zatsopano ndi malamulo akuyendetsa kusintha kwakukulu. Mwachitsanzo, mapulogalamu a Extended Producer Responsibility (EPR), amalimbikitsa opanga kugwiritsa ntchito mapulasitiki opangidwanso. Izi mwachindunji kumawonjezera kufunika kwa zipangizo apamwamba granulation. Malamulo okhudza zinyalala zotayira kutayirako ndi zolinga zobwezeretsanso amakakamiza obwezeretsanso makinawo kuti akonze makina awo. Mfundo za chilengedwe zimayang'ana kwambiri mphamvu zamagetsi ndi kuchepetsa mpweya. Ndondomekozi zimakhudza momwe makampani amapangira ndikugwiritsa ntchito makina opangira granulator, zomwe zimapangitsa kuti pakhale ukadaulo wobiriwira. Mabungwe monga EPA amaika miyezo ya zida. Kutsatira mfundozi kumapangitsa kuti makina akwaniritse chitetezo, chilengedwe, komanso magwiridwe antchito. Malamulo aku North America akugogomezera kwambiri kasamalidwe ka zinyalala kokhazikika. Makampani omwe amaika ndalama pamakina omwe amatsatira mfundozi atha kupeza chilimbikitso cha boma ndikupewa zilango. Izi zimawapatsa mwayi wampikisano.

Zofunika Kwambiri Pakukulitsa Makina Obwezeretsanso Pulasitiki

Zinthu zingapo zazikulu zomwe zikupanga kupanga makina obwezeretsanso pulasitiki. Makina osankhidwa a AI ndi chitukuko chachikulu. Makinawa amatha kukwaniritsa chiyero cha 98% mumitsinje ya PET / HDPE. Amachepetsanso kuipitsidwa ndi 40%. Kuyang'anira kothandizidwa ndi IoT kumalola kutsata nthawi yeniyeni yamakina ndikugwiritsa ntchito mphamvu. Izi zimabweretsa kuchepa kwa 25% panthawi yopuma. Malo okhala m'madera akuchulukirachulukira. Mayunitsi ang'onoang'onowa amatha kupanga 500-800 kg / h. Amathandizira kuchepetsa mpweya wamayendedwe padziko lonse lapansi. Malamulo a EU Packaging and Packaging Waste Regulation (PPWR) ndiwoyendetsa wamkulu. Pamafunika 70% recyclability kuti apake pofika 2030. Imafunikanso 10-35% zomwe zakonzedwanso mu mapulasitiki. Kukwaniritsa lamuloli kumafuna umisiri wapamwamba kwambiri wamakina ndi mankhwala obwezeretsanso. Matekinoloje osankhidwa bwino akusintha zobwezeretsanso pulasitiki. Makina ogwiritsa ntchito amagwiritsa ntchito masensa apamwamba, luntha lochita kupanga, komanso kuphunzira pamakina. Amatha kuzindikira ndi kulekanitsa mapulasitiki potengera kapangidwe kake ka mankhwala, mtundu, ndi mawonekedwe awo. Izi zimathandizira bwino komanso kuyera m'mitsinje yobwezeretsanso. Kuwongolera kumeneku kumathandizira kupanga mapulasitiki opangidwanso apamwamba kwambiri.

Advanced Mechanical Plastic Recycling Machine Technologies

Makina obwezeretsanso akadali mwala wapangodya wa kasamalidwe ka zinyalala za pulasitiki. Mu 2025, kupita patsogolo kwatsopano kumapangitsa njirazi kukhala zogwira mtima komanso zogwira mtima. Makinawa tsopano amanyamula mapulasitiki ambiri. Amapanganso zida zapamwamba zobwezerezedwanso.

Makina Osankhira Otsatira a Makina Opangira Mapulasitiki Obwezeretsanso

Kusanja ndiye gawo loyamba lofunikira pakubwezeretsanso makina. Njira zatsopano zosinthira zimagwiritsa ntchito ukadaulo wapamwamba wa sensor, nzeru zamagetsi (AI), komanso kuphunzira pamakina. Zida izi zimathandizira kwambiri kulondola komanso kuthamanga. Mawonekedwe apakompyuta amagwiritsa ntchito makamera apamwamba kwambiri komanso ma algorithms a AI. Amasanthula zinthu zapulasitiki munthawi yeniyeni. Makinawa amazindikiritsa kusiyana kosawoneka bwino kwa mtundu, mawonekedwe, ndi kapangidwe kake kuti agawane bwino. Mitundu yophunzirira pamakina imakulitsa luso lawo lozindikirika mosalekeza.

Ma algorithms ozama ophunzirira amakonza zidziwitso zovuta zowoneka. Amapanga zisankho zogawanika-zachiwiri pakupanga zinthu. Ma algorithms awa amapambana kuzindikira machitidwe ndi mawonekedwe omwe anthu sangathe kuwona. Izi zimabweretsa kusanja mitengo yolondola yopitilira 95%. Near-Infrared (NIR) spectroscopy ndiukadaulo wina wofunikira. Imagwiritsa ntchito kuwala kwa infrared kusanthula kapangidwe ka maselo. Izi zimathandiza kuzindikira mwachangu komanso molondola mitundu yosiyanasiyana ya pulasitiki ngati PET, HDPE, ndi PVC. Imayesa ma signature awo apadera.

Kujambula kwa hyperspectral kumatenga kusanja kowoneka bwino. Zimaphatikiza kujambula kwachikhalidwe ndi spectroscopy. Izi zimajambula deta m'mabwalo mazana ambiri. Limapereka kusanthula kwatsatanetsatane kwazinthu. Izi zimazindikiritsa zoipitsa, zowonjezera, ndi kusiyana kosawoneka bwino kwa kapangidwe ka pulasitiki. Ukadaulo wa Smart gripper umathandizanso. Ma grippers atsopanowa ali ndi masensa komanso kuwongolera kuthamanga kwamphamvu. Amagwiritsa ntchito zipangizo za kukula, maonekedwe, ndi kulemera kosiyanasiyana popanda kuwonongeka. Amathanso kuzindikira zinthu zakuthupi pogwiritsa ntchito mayankho a tactile. Izi zimakulitsa kusanja kulondola ndikuchepetsa kuipitsidwa.

Makina am'badwo wotsatira awa amagwiritsa ntchito makina apamwamba a kamera, masensa, ndi makina ophunzirira makina. Amazindikira mwachangu komanso molondola ndikusankha zinyalala zosiyanasiyana. Amagwiritsa ntchito masensa omwe amazindikira masiginecha apadera kuti adziwe zenizeni komanso kupatukana. Izi ndizothandiza makamaka pakusankha zinyalala zomwe zabwera pambuyo pa ogula. Izi zikuphatikizapo mapulasitiki, galasi, mapepala, ndi zitsulo. Machitidwewa amatha kuchepetsa ndalama zoyendera ndi zotolera zosachepera 50% zikaphatikizidwa ndi makina otolera zinyalala. Amagwiritsa ntchito masensa a NIR kuzindikira mitundu ya polima. Amalekanitsa mapulasitiki otengera mtundu ndi mtundu. Machitidwewa amapereka mphamvu zambiri, nthawi zambiri amakonza matani mazana patsiku. Amachepetsa kuipitsidwa, zomwe zimatsogolera ku zinthu zapamwamba zobwezerezedwanso. Ukadaulo woyerekeza wa Hyperspectral, monga Specim FX17 ndi GX17, umapereka nthawi yeniyeni, kuzindikira kodalirika. Imalekanitsa PET ku zonyansa monga PVC, HDPE, ABS, mapulasitiki ena, ndi zinthu zachilengedwe. Makamera a Hyperspectral amapereka kudalirika kosankha bwino komanso kusinthasintha. Amajambula mawonekedwe athunthu kapena osankhidwa. Izi zimalola kukonzanso nthawi yonse ya moyo wa makina. Makamera olimba amtundu wa hyperspectral amakhala osasamalira kwa zaka zambiri. Alibe magawo osuntha omwe amafunikira kusinthidwa pafupipafupi ndikusinthanso. Makinawa amaphatikiza kujambula kwa hyperspectral ndi makamera a RGB kuti azitha kuzindikira mtundu komanso mawonekedwe. Amagwiritsa ntchito mitundu ya neural network ya AI yomwe ikuyenda pa ma NVIDIA GPU amphamvu kuti asanthule bwino komanso marekodi atsatanetsatane. Amalankhulanso kusanja kwa pulasitiki wakuda pogwiritsa ntchito kamera ya Specim FX50 HSI. Kamera iyi imagwira ntchito pakatikati pa ma wave infrared (MWIR). Imazindikiritsa ndikusankha mapulasitiki akuda potengera zomwe amapanga.

Kuchapira Bwino ndi Kumeta M'makina Obwezeretsanso Pulasitiki

Akasankha, mapulasitiki amatsuka ndi kung'ambika. Njirazi zimakonzekeretsa zinthuzo kuti zipitirire kukonzanso. Makina amakono ochapira ndi ometa amawonetsa kusintha kwakukulu pakugwiritsa ntchito mphamvu zamagetsi. Makina apamwamba obwezeretsanso pulasitiki, makamaka omwe amagwiritsa ntchito ukadaulo wa servo motor, amachepetsa kugwiritsa ntchito mphamvu mpaka 30% poyerekeza ndi mitundu yakale. Izi zimabweretsa kupulumutsa ndalama komanso phindu la chilengedwe. Mwachitsanzo, zomangira zowongoka, zomapawiri zofananira, ndi masikhwala apawiri amapeza mpaka 30% kuchepetsa kugwiritsa ntchito mphamvu.

Zatsopano za zida ndi mapangidwe a shredder blade zimathandizanso kutulutsa komanso kuchepetsa kukonza. Kapangidwe katsopano ka V rotor, yokhala ndi mainchesi 500 mpaka 2,200 mm kutalika, imagwira zoyambira zazikulu, nkhokwe zopanda kanthu, ndi mbali zowala. F yozungulira yolondola yokhala ndi mphero komanso makonzedwe apadera a mpeni ndi abwino kuphwanya zinthu zosinthika monga ulusi ndi mafilimu. Zimatsimikizira kudulidwa kwa geometri. Masamba osinthika osinthika amatha kusinthidwa mwachangu ndikutembenuka kuchokera kunja. Izi zimasunga kusiyana koyenera ngakhale ndi kuvala. Zimabweretsa kuchulukirachulukira kosalekeza komanso moyo wautali wautumiki wa mpeni. Chovala choyang'ana mowolowa manja chimathandizira kukonza bwino komanso mwayi wofikira ma rotor. Izi zimathandiza kuchotsa mosavuta zinthu zakunja ndi ntchito yabwino yokonza.

Makinawa amagwiritsa ntchito zitsulo zolimba pazitsulo zozungulira ziwiri. Masambawa amanyamula mapulasitiki ofewa komanso olimba bwino. Mapangidwe otsika, okwera kwambiri amatsimikizira kuchepetsa kukula kwa tinthu. Amachepetsanso fumbi ndi phokoso. Chipinda chodulira chosinthika chimalola ogwiritsa ntchito kusintha kukula kwake. Zigawo zamagulu a mafakitale ndi zomangamanga zolimba zimatsimikizira kudalirika kwa nthawi yayitali. Amachepetsa zosowa zosamalira ndikuchepetsa nthawi yopuma. Zida zolimbana ndi kuvala zimasunga magwiridwe antchito munthawi yayitali. Njira yosinthira tsamba mwachangu imachepetsa kusokoneza kwa magwiridwe antchito.

Extrusion and Pelletizing for Premium Recycled Plastics

Gawo lomaliza pakubwezeretsanso makina kumaphatikizapo kutulutsa ndi kutulutsa ma pelletizing. Izi amasintha shredded ndi otsukidwa flakes pulasitiki kukhala yunifolomu pellets. Ma pellets awa amakhala okonzeka kupanga zinthu zatsopano. Zida zamakono za pulasitiki zopangira pelletizing zimapereka mphamvu zambiri. Nthawi zambiri imayenda 100-2,500 kg / h. Izi zimakwaniritsa zosowa zazing'ono komanso zazikulu zopanga. Mitundu ina, monga Wintech WT-150, imapanga 500-700 kg / h. Huarui SJ-120 imapanga 100-130 kg / h. Machitidwe akuluakulu, monga PTC185-95, amakwaniritsa 800-1000 kg / h. Pulojekiti yatsopano yokhudzana ndi 5G Double Filtration Compacting Pelletizing Line ili ndi mphamvu yotulutsa 1100 kg / h. Maluso apamwambawa akuwonetsa luso laukadaulo waposachedwa wa pelletizing. Amawonetsetsa kuti mapulasitiki obwezerezedwanso amaperekedwa m'mafakitale osiyanasiyana.

Kukwera kwa Njira zamakina a Chemical Plastic Recycling Machine

Kubwezeretsanso mankhwala kumapereka yankho lamphamvu la mapulasitiki omwe njira zamakina sizingagwire. Njirazi zimaphwanya mapulasitiki kukhala midadada yomangira mankhwala kapena mankhwala ena ofunikira. Izi zimapanga zida zatsopano zopangira. Chemical recycling ikugwirizana ndi makina obwezeretsanso. Zimathandizira kukwaniritsa chuma chozungulira kwambiri pamapulasitiki.

Pyrolysis ndi Gasification Plastic Recycling Machines

Pyrolysis ndi gasification ndi njira ziwiri zazikulu zobwezeretsanso mankhwala. Pyrolysis imatenthetsa zinyalala za pulasitiki popanda mpweya. Izi zimaphwanya maunyolo aatali a polima kukhala mamolekyu ang'onoang'ono. Amapanga mafuta, gasi, ndi char. Gasification imagwiritsa ntchito kutentha kwambiri komwe kumayendetsedwa ndi mpweya kapena nthunzi. Izi zimatembenuza pulasitiki kukhala syngas, wosakaniza wa haidrojeni ndi carbon monoxide. Ma Syngas amatha kukhala mafuta kapena mafuta opangira mankhwala.

Makampani ngati ExxonMobil amagwiritsa ntchito ukadaulo wa coprocessing. Tekinoloje iyi imaphatikiza zinyalala zapulasitiki kukhala mayunitsi a coker. Amapanga zopangira zopanda pake komanso naphtha. Oyeretsa amatha kupititsa patsogolo izi kukhala zakudya zamafuta a petrochemical. Kuphatikizirapo polyethylene kapena polystyrene pakuphatikizana kumathandizira kwambiri zokolola zamadzimadzi. Pakukhazikitsa kwamadzimadzi, kuwonjezera zinyalala zapulasitiki kumakwezanso kuchuluka kwa ma syngas opangidwa. Ukadaulo wapamwamba kwambiri wa microwave-powered pyrolysis umapanga mafuta apamwamba kwambiri a pyrolysis. Mafutawa amakwaniritsa miyezo yoyenga. Izi zikuwonetsa kuthekera kopanga zinthu zamtengo wapatali.

Njira zobwezeretsanso mankhwala amasintha zinyalala za pulasitiki kukhala zothandiza zosiyanasiyana. Pafupifupi 15-20% ya zinyalala zapulasitiki zimakhala propylene ndi ethylene. Izi ndi midadada yomangira mapulasitiki atsopano. 80-85% yotsala ya zinyalala zapulasitiki zimasandulika kukhala mafuta a dizilo, haidrojeni, methane, ndi mankhwala ena. Zotsatirazi zikuwonetsa kusinthasintha kwa pyrolysis ndi gasification.

Depolymerization kwa Mitundu Yodziwika Yapulasitiki

Depolymerization ndi njira yeniyeni yobwezeretsanso mankhwala. Imaphwanya ma polima ena apulasitiki kukhala ma monomers awo oyamba. Monomers ndi mamolekyu ang'onoang'ono omwe amalumikizana kuti apange ma polima. Njirayi imapanga zida zapamwamba kwambiri. Opanga amatha kugwiritsa ntchito zidazi kuti apange mapulasitiki atsopano okhala ndi zinthu ngati namwali.

Depolymerization imangokhala ndi mitundu ina ya mapulasitiki. Izi zimadziwika kuti ma polima a condensation. Zitsanzo zikuphatikizapo nayiloni ndi PET (polyethylene terephthalate). PET ndiyomwe imayang'ana kwambiri pazamalonda za depolymerization. Kukwanira kwake ndi kuchuluka kwake kumapangitsa kuti ikhale chandamale choyenera. Tekinoloje za m'badwo wotsatira wa depolymerization zimayang'ananso zinyalala za acrylic, makamaka PMMA (polymethyl methacrylate).

Kuyera kwa ma monomers omwe adachira kudzera mu depolymerization ndikokwera kwambiri. Izi zimawapangitsa kukhala ofunikira popanga pulasitiki yatsopano. Njira zosiyanasiyana komanso zothandizira zimapeza zokolola zosiyanasiyana.

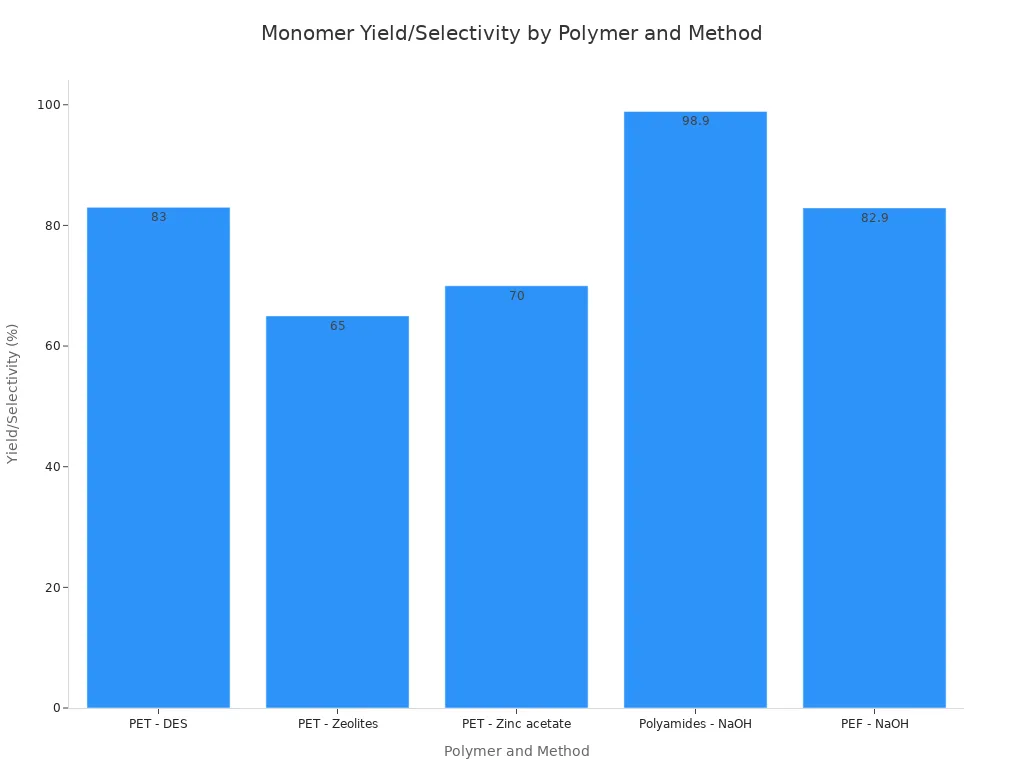

| Polima | Njira/Chothandizira | Zokolola za Monomer / Kusankhidwa |

|---|---|---|

| PET | [urea/ZnCl2] DES | 83% kusankha ku BHET |

| PET | Zeolites | 65% zokolola za BHET |

| PET | Zinc acetate ndi EG | Mpaka 70% zokolola za BHET |

| Polyamides (Kevlar) | Hydrolysis ndi NaOH | 98.9% ya PPD, 95.3% ya PTA |

| PEF | Hydrolysis ndi NaOH | 82.9% zokolola za 2,5-furandicarboxylic acid |

Dimethylethylamine catalysts amalimbikitsa zokolola zambiri za depolymerization. Amagwira ntchito pansi pamikhalidwe yapakati. Izi zimathandizira kutulutsa kofanana kwa monomer. Njira zapamwambazi zimatsimikizira kupezeka kodalirika kwa ma monomers oyera.

Solvolysis ndi Hydrothermal Plastic Recycling Machines

Solvolysis ndi hydrothermal process ndi njira zina zofunika zobwezeretsanso mankhwala. Solvolysis imagwiritsa ntchito zosungunulira kusungunula kapena kuphwanya mapulasitiki. Njira imeneyi nthawi zambiri imagwira ntchito pa kutentha kochepa. Njira za Hydrothermal zimagwiritsa ntchito madzi otentha, opanikizidwa kutembenuza mapulasitiki. Njira zonsezi zimapereka ubwino wapadera kwa mitundu yosiyanasiyana ya pulasitiki.

Mikhalidwe yogwirira ntchito imasiyanasiyana pazochitikazi.

| Mtundu wa Njira | Kutentha (°C) | Pressure Range (MPa) |

|---|---|---|

| Hydrothermal Liquefaction (HTL) | 250-350 | 10-20 |

Njira za Solvolysis zimagwiranso ntchito pazikhalidwe zosiyanasiyana.

| Mtundu wa Njira | Kutentha (°C) | Pressure Range (MPa) |

|---|---|---|

| Solvolysis (LTP) | <200 | Wozungulira |

| Solvolysis (HTP) | Mpaka 450 | 0.3 mpaka 30 |

Zinthu izi zimalola kuti pakhale njira zofananira ndi mitsinje yosiyanasiyana ya zinyalala za pulasitiki.

Kuchiza kwa Hydrothermal (HTT) kumapereka phindu lalikulu la chilengedwe. Itha kukwaniritsa mpaka 80% kuchepetsa kutulutsa kwanyengo. Izi zikufanizidwa ndi kutenthedwa, njira yodziwika yotayira mapulasitiki ovuta kukonzanso. HTT imasunga zinthu mkati mwadongosolo. Izi zimabweretsa kuchepa kwa kagwiritsidwe ntchito ka zinthu zakufa zakale. Choyambitsa chachikulu cha chilengedwe cha HTT ndikugwiritsa ntchito magetsi. Kuchepetsa izi pogwiritsa ntchito mphamvu zamagetsi kapena mphamvu zongowonjezwdwa kutha kupititsa patsogolo ntchito yake zachilengedwe. HTT imapewa kuyaka koyipa kwa zinthu monga ma dioxin ndi char. Njira zobwezeretsanso mankhwala, kuphatikiza HTT, zimagwiritsa ntchito mapulasitiki ochulukirapo osatengera ogula. Izi zimapereka yankho lothandiza pamlingo wachuma chozungulira. Kusintha kwanyengo kwa naphtha komwe kumapangidwa kudzera pa HTT ndikufanana ndi zomwe zikuchitika masiku ano popanga chakudya chamafuta. Izi zimapereka njira zozungulira zopangira mapulasitiki. Matekinoloje apamwamba awa a Plastic Recycling Machine ndiofunikira tsogolo lokhazikika.

Makina Ogwiritsa Ntchito Makina Anzeru a Pulasitiki: AI, IoT, ndi Automation

Ntchito zamakono zobwezeretsanso pulasitiki zimagwiritsa ntchito ukadaulo wapamwamba. Artificial Intelligence (AI), intaneti ya Zinthu (IoT), ndi makina opanga makina amapangitsa njira kukhala zanzeru. Zida zimenezi zimathandiza kuti zinthu ziziwayendera bwino, zimachepetsa ndalama, ndiponso zimawonjezera ubwino wa zinthu zobwezerezedwanso.

Kukonzekera Kukonzekera Kwamakina Obwezeretsanso Pulasitiki

Kukonza zolosera kumapangitsa kuti makina obwezeretsanso pulasitiki aziyenda bwino. Masensa a IoT amasonkhanitsa deta yeniyeni kuchokera ku zipangizo. Amayang'anira kugwedezeka, kutentha, ndi kayendedwe ka galimoto. Ma algorithms a AI amasanthula izi. Amaneneratu nthawi yomwe gawo la makina lingalephereke. Izi zimathandiza kuti zipangizo zisamawonongeke zisanachitike. Zimalepheretsa kutsika kosayembekezereka. Njirayi imapulumutsa ndalama ndikuwonjezera maola ogwira ntchito.

Data Analytics for Optimized Recycling Processes

Kusanthula kwa data kumasintha machitidwe obwezeretsanso. Mapulatifomu apamwamba amasonkhanitsa ndikusanthula mitundu yosiyanasiyana ya data. Amatsata Zizindikiro Zofunikira (KPIs) monga kugwiritsa ntchito mphamvu ndi mpweya wa GHG. Amasonkhanitsanso data ya zinthu, kuphatikiza maperesenti obwezerezedwanso. Deta yogwira ntchito imakhudza momwe makina amagwirira ntchito komanso kutentha kwake. Deta yotsatiridwa imawonetsetsa kuti malowa akwaniritsa zofunikira za m'deralo ndi zomwe zakonzedwanso. Miyezo ya zinyalala imatsata kuchuluka kwa zosonkhanitsira, kusanja zolakwika, ndi kuipitsidwa. Deta ya Traceability imatsimikizira zonena za zinthu zobwezerezedwanso.

Makina osankhira oyendetsedwa ndi AI amagwiritsa ntchito ma spectroscopy a Near-infrared (NIR) ndi ma algorithms a AI. Makinawa amachepetsa kuipitsidwa ndi 50 peresenti. Ofufuza adapanga makina ophunzirira makina omwe amazindikira mitundu ya pulasitiki yolondola mpaka 100%. Kusanja bwino kumeneku kumachepetsa kuipitsidwa. Zimatsogolera ku utomoni wapamwamba kwambiri komanso kutsika kwa ndalama zogwirira ntchito. Ku AdvanTech Plastics, masensa opangidwa ndi AI amayendera zida zowumbidwa munthawi yeniyeni. Izi zimazindikira zolakwika ndikulola kusintha kwachangu. Zimapangitsa kuti zinthu zowonongeka zikhale zochepa, zotsalira zochepa, komanso kuchepetsa kugwiritsa ntchito mphamvu.

Makina Ogwiritsanso Ntchito Pulasitiki Yobwezeretsanso Zinthu

Malo okhala ndi makina akusintha mawonekedwe obwezeretsanso. Maloboti amagwira ntchito zomwe anthu amachita kale. Izi zimachepetsa ndalama zogwirira ntchito ndikuwongolera chitetezo.

| Mbali | Maloboti | Mtundu wa Anthu |

|---|---|---|

| Zosankha pa ola | Mpaka 4,000 | 500-700 (zinthu zolemera) |

| Maola ogwira ntchito | 24/7 | Osati 24/7, imafunikira kupuma |

| Kulemera kwakukulu kwagwiridwa | 66 lbs (30 kg) | Zosatheka / zotetezeka kwa 66 lbs mosalekeza |

Maloboti amatha kutenga zinthu 4,000 pa ola limodzi. Osasankha anthu amagwira zinthu zolemera 500-700 pa ola limodzi. Maloboti amagwira ntchito 24/7 popanda kupuma. Amanyamula mosamala zinthu zolemetsa mpaka 66 lbs. Lundstams Återvinning AB, kampani yaku Sweden, idapulumutsa pafupifupi $22,000 USD pamwezi. Anachepetsa zinyalala zowotchedwa atagwiritsa ntchito maloboti. Maloboti obwezeretsanso amathandizira kupulumutsa kwa nthawi yayitali. Amachepetsa ndalama zogwirira ntchito ndikuchepetsa zolakwika.

Zotsatira ndi Tsogolo Lamakina a 2025 Obwezeretsanso Pulasitiki

Kulankhula ndi Pulasitiki Yosavuta Kubwezeretsanso Ndi Makina Atsopano

Makina atsopano obwezereranso mu 2025 amanyamula mapulasitiki omwe kale ankawoneka kuti sangabwezeretsedwe. Kubwezeretsanso mankhwala kumawononga zinyalala za pulasitiki zoipitsidwa, monga zotengera chakudya kapena mabotolo amafuta agalimoto, mpaka pamlingo wa mamolekyu. Izi zimasefa bwino zowononga. Zinyalala zamapulasitiki zamitundu ingapo, monga kuyika zakudya zosinthika, zimapindulanso ndi kukonzanso kwa maselo. Izi zimathetsa zovuta zomwe zimakumana nazo pakubwezeretsanso makina ndi zida izi. Mayankho apamwamba tsopano akuyang'ana thovu la polystyrene, thovu la polyurethane, ndi mafilimu ndi zikwama za mono-material. Amayang'aniranso zikwama zama multilayer, thermoforms/black rigids, ndi thovu/zolimba zazing'ono. Njira zoyeretsera pakubwezeretsanso kwa maselo amachotsa zowononga kuzinthu zovutazi.

Ubwino Wachuma ndi Zachilengedwe pa Kukonzanso Kwapamwamba

Makina apamwamba obwezeretsanso pulasitiki amapereka zabwino zambiri zachuma komanso zachilengedwe. Amachepetsa ndalama zoyendetsera zinyalala kumatauni ndi mabizinesi. Makampani amapeza ndalama zatsopano posintha zinyalala kukhala zinthu zamtengo wapatali monga zopangira zatsopano kapena zomangira. Izi zimateteza zachilengedwe pochepetsa kufunikira kwa zinthu zopanda pake monga mafuta amafuta. Malinga ndi chilengedwe, matekinolojewa amapanga zinthu zapulasitiki ndi mankhwala zomwe zimatha kuchepetsa kutentha kwa dziko. Amakwaniritsa izi poyerekeza ndi zinthu zopangidwa kuchokera kuzinthu zopanda anamwali. Kubwezeretsanso kwapamwamba kumatha kuchepetsa mpweya wofanana wa CO2 ndi 100% kuyerekeza ndi kutayira ndi kuwononga mphamvu. Ntchito zopitilira 40, zomwe zikuyimira ndalama zopitilira $7 biliyoni, zitha kupatutsa zinyalala zokwana mapaundi 21 biliyoni kuchokera kumalo otayirako nthaka chaka chilichonse.

Zovuta ndi Mwayi Wogwiritsa Ntchito Zamakono Zatsopano

Kugwiritsa ntchito matekinoloje atsopano obwezeretsanso kumabweretsa zovuta komanso mwayi. Kuyika ndalama zambiri zam'tsogolo nthawi zambiri kumakhala kofunikira pamakina apamwamba komanso zomangamanga. Kuphatikiza machitidwe ovutawa m'malo omwe alipo kale kumafunanso kukonzekera mosamala ndi ntchito yaluso. Komabe, matekinolojewa amatsegula zitseko kumisika yatsopano yazinthu zobwezerezedwanso. Amalimbikitsanso luso lazopangapanga zokhazikika. Kuthamangira ku chuma chozungulira kumapangitsa kuti pakhale kufunikira kwakukulu kwa mapulasitiki apamwamba obwezerezedwanso. Izi zimapereka mwayi wokulirapo kwa makampani omwe akulandira izi.

Kupita patsogolo kwaukadaulo wamakina obwezeretsanso pulasitiki mu 2025 kukuwonetsa kusintha kwakukulu. Kusanja mwanzeru komanso njira zotsogola zamakina zikusintha makampani. Zatsopanozi zimatipititsa ku chuma chozungulira. Zinyalala za pulasitiki zikukhala gwero lamtengo wapatali. Izi zimayendetsa kukhazikika komanso kukula kwachuma kwa aliyense.

FAQ

Kodi cholinga chachikulu cha makina obwezeretsanso pulasitiki mu 2025 ndi chiyani?

Makina mu 2025 amayang'ana kwambiri makina apamwamba kwambiri. Amakhalanso ndi luso losankhira zinthu. Njira zatsopano zobwezeretsanso mankhwala ndizofunikira. Umisiriwu umasintha zinyalala kukhala zinthu zamtengo wapatali. Amathandizira kwambiri kuchita bwino komanso kukhazikika. ♻️

Kodi makina osankhira amtundu wotsatira amawongolera bwanji zobwezeretsanso?

Makina osankhira amtundu wotsatira amagwiritsa ntchito AI, kuphunzira pamakina, ndi masensa apamwamba. Amazindikira mapulasitiki potengera mtundu, mawonekedwe, ndi makemikolo. Izi zimakulitsa kusanja kolondola. Amachepetsanso kuipitsidwa. Izi zimatsogolera ku zida zapamwamba zobwezerezedwanso.

Nthawi yotumiza: Oct-25-2025