A ipulasitiki granulatoridlala indima ebalulekile kukho kokubili izinsiza zokuphinda zigaywe kanye nezijovwe. Ama-opharetha ayazisa imishini ekhiqiza ama-granules afanayo, njengoba lokhu kuvumelana kuthuthukisa ukusebenza kahle kokugaya kabusha futhi kusekela ukukhiqizwa okushelelayo. Imishini ye-granulator ethuthukisiwe iphatha izinhlobo eziningi zamapulasitiki, enikeza ukuguquguquka kwamaphrojekthi ahlukene. Izici ezonga amandla kule mishini zisiza ukwehlisa izindleko zokusebenza. Amanye amamodeli, njenge-aumshini wepulasitiki we-granulenoma ai-plastic crusher, futhi yehlisa imfucuza ngokuthuthukisa ukusetshenziswa kwempahla. Lezi zimfanelo zisekela ukusimama nokusebenza okuthembekile ezindaweni zanamuhla zokucubungula ipulasitiki.

Okuthathwayo Okubalulekile

- Ama-granulator epulasitiki kufanele akhiqize ama-granules afanayo ukuze kuqinisekiswe ikhwalithi yomkhiqizo engaguquki kanye nokugaywa kabusha okusebenzayo noma ukubunjwa.

- Ukukhetha i-granulator efanele kuncike ohlotsheni lwepulasitiki, ivolumu yokucubungula, kanye nezidingo zohlelo lokusebenza njengokugaywa kabusha nomaukubumba umjovo.

- Ama-granulator athuthukisiwe anikezela ngezici zokonga amandla, ukunciphisa umsindo, nokunakekela kalula ukuze kwehlise izindleko nokuthuthukisa ukuphepha kwendawo yokusebenza.

- Izici zokuphepha eziqinile, ezifaka izitobhi eziphuthumayo nezikhiya, zivikela opharetha futhi zisize ukuhlangabezana namazinga omkhakha.

- Ukwesekwa okuthembekile kwangemva kokuthengisa nokunakekelwa okuvamile kwandisa impilo yomshini futhi kugcine ukukhiqiza kusebenza kahle.

Izidingo Zesicelo Se-Granulator Yepulasitiki

Ukugaywa kabusha vs. Izidingo zokubumba umjovo

Ukugaya kabusha nokubumba umjovo indawo ngayinye inezidingo ezihlukile ku-aipulasitiki granulator. Ekubumbeni umjovo, opharetha bavame ukusebenzisa ama-granulator amancane, asebenza kahle kakhulu eduze komshini wokubumba. Le mishini iphatha ama-sprues, ama-runner, nezingxenye ezinesici. Zigxile ekuhlanganisweni nasekucutshungulweni okusebenzayo kwezinsalela zevolumu ephansi. Isibonelo, i-granulator esetshenziselwa ukubumba umjovo we-PVC kufanele yephule izinto eziqinile, eziqinile zibe izingcwecwe ezisebenzisekayo kabusha. Ngokuphambene, izinhlelo zokusebenza zokugaywa kabusha zidinga ama-granulator amakhulu, aqine kakhulu noma ama-shredders. Le mishini igaya imfucuza emikhulu njengamabhodlela, amapayipi, namashidi. Badinga umthamo ophezulu nokuqina ukuze baphathe izinhlobo eziningi zepulasitiki nosayizi. Umehluko esikalini kanye nohlobo lwe-scrap lilolonga idizayini nokusebenza kwegranulator ngayinye.

Izidingo Ezabiwe Zazo Zombili Izicelo

Kokubili ukugaywa kabusha nokubumba komjovo kuncike ezicini ezithile ezibalulekile kugranulator yepulasitiki. Ama-opharetha abheka imishini ekhiqiza amasayizi afanayo we-granule, esiza ukugcina ikhwalithi yomkhiqizo engaguquki. Ukuphepha kuhlala kuyinto ehamba phambili, ngakho izici ezifana nezinkinobho zokumisa izimo eziphuthumayo nezikhiye zokuphepha zibalulekile. Ukufinyelela okulula kuma-blades nezikrini kuvumela ukulungiswa okusheshayo nokuhlanza. Izikhungo eziningi zithanda ama-granulator anamazinga aphansi omsindo kanye nemiklamo yeselula yokubeka okuvumelana nezimo. Ithebula elingezansi ligqamisa izici ezithile zokusebenza okwabelwana ngazo:

| Isici | Zuza |

|---|---|

| Usayizi we-granule olinganayo | Ikhwalithi yomkhiqizo engaguquki |

| Ukuphepha kokuxhumana | Ukuvikelwa komsebenzisi |

| Ukugcinwa okulula | Isikhathi sokuphumula esincishisiwe |

| Ukusebenza komsindo ophansi | Indawo yokusebenza ethuthukisiwe |

| Ukuphatheka | Ukusetshenziswa okuguquguqukayo ezindaweni ezahlukene |

Ukuhlola Izinhlobo Zezinto Zokusebenza kanye Nevolumu Yokucubungula

Izinsiza zicubungula izinhlobo eziningi zamapulasitiki, okuhlanganisa ama-sprues, amagobolondo, amashubhu, amabhodlela, namafilimu. Amanye amapulasitiki, afana nalawo anefayibha yengilazi ephezulu, adinga ama-granulator akhethekile anezindawo ezihlala isikhathi eside kanye nokugaya kwetorque ephezulu. Ukukhethwa kwegranulator nakho kuncike ekucubunguleni ivolumu. Imisebenzi emincane isebenzisa amamodeli ahlangene wezinto ezilula, kuyilapho izikhungo ezinkulu zokugaywa kabusha zidinga imishini yezimboni ephatha amathani amaningana nsuku zonke. Ukukhetha i-granulator efanele kuqinisekisa ukucutshungulwa okusebenzayo futhi kuvimbela izingqinamba, noma ngabe inhloso kuwukugaywa kabusha kwasendlini noma ukunciphisa imfucuza enkulu.

I-Plastic Granulator Izici Ezibalulekile

Ukuhambisana Kwezinto Ezibalulekile kanye Nokuhlukahluka

I-granulator yepulasitiki kufanele iphathe uhla olubanzi lwezinto ukuze isebenze kokubili ukugaywa kabusha kanyeumjovo ekubumbeni izicelo. Ama-opharetha avame ukucubungula izinto ezifana namabhodlela abunjwe ngokushaywa, izixhumi zikagesi, izingcezu zezikulufu, namaphrofayili akhishiwe. Imishini enamamodeli ayisisekelo amaningi, njenge-FX 700, FX 1000, ne-FX 1600, ivumela abasebenzisi ukuthi bafanise isimbudumbudu namasayizi ahlukene wezingxenye nezidingo zokuphuma. Ukucushwa kwekamelo okuguquguqukayo, okufana namakamelo aqinile ezingxenye ezinkulu kanye namakamelo acishe abe yizingxenye ezinezindonga eziwugqinsi, akhuphula ukuguquguquka.

Qaphela: Ama-hopper enziwe ngendlela oyifisayo nemiklamo yokukhipha isiza ukufaka i-granulator ekuhlelweni kwesistimu ehlukahlukene, okwenza kube lula ukuhlanganisa nezisetshenziswa ezikhona.

I-Versatility iphinde incike emandleni okucubungula amapulasitiki anezithasiselo ezahlukene noma amazinga obunzima. Ama-Granulator anezindawo ezingagugi kanye nokufinyelela okulula kokulungisa anciphisa isikhathi sokuphumula futhi andise impilo yesisetshenziswa. Izici zokuphepha ezithuthukisiwe, okuhlanganisa ukukhiya okungafuneki kanye nezingidi ezicushwe i-solenoid, zivikela opharetha ngesikhathi sokusetshenziswa. Ukucindezela umsindo kwakha umsindo ophansi, kuthuthukise indawo yokusebenza. Amamodeli afana nochungechunge lwe-SL kanye ne-G26 agqama ngokuhambisana kwawo okubanzi, asekela kokubili ukugaywa kabusha kanyeizinqubo zokubumba umjovo.

Amandla Wokusebenzisa kanye Nempumelelo

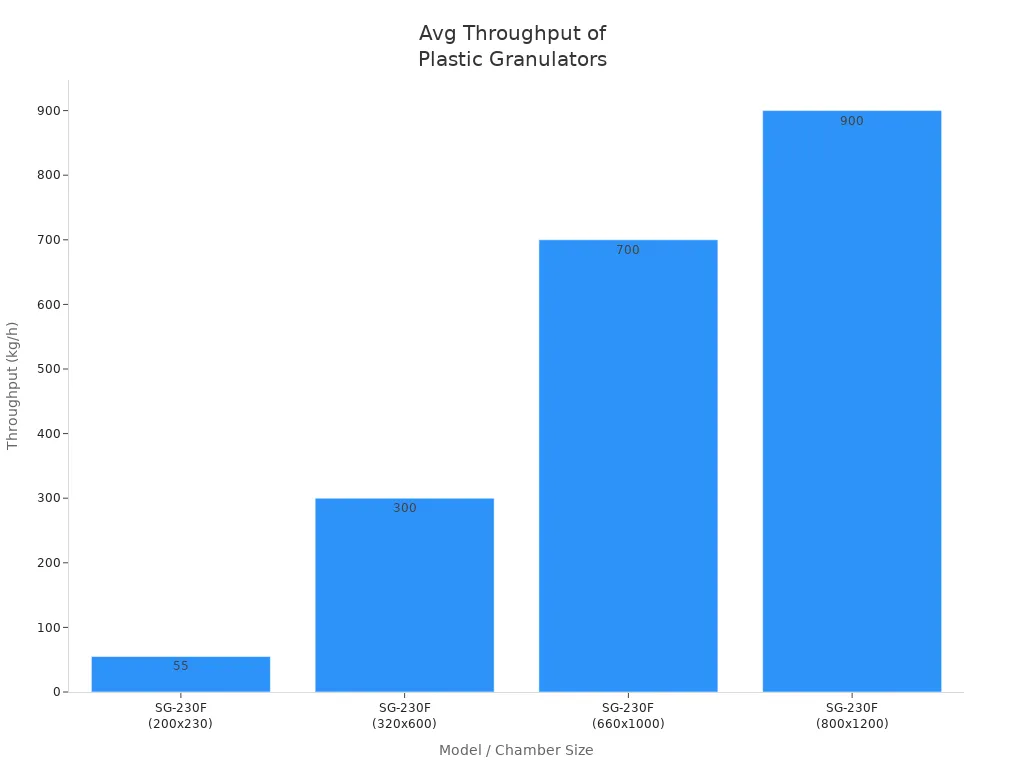

Umthamo wokukhipha ukala ukuthi ingakanani impahla ekwazi ukucutshungulwa imbudumbudu yepulasitiki ngesikhathi esithile. Izikhungo zikhetha imishini ngokuya ngezidingo zabo zansuku zonke zokucubungula. Amakamelo amancane afanele ukusebenza kwevolumu ephansi, kuyilapho amakamelo amakhulu aphatha ukuguqulwa kwenqwaba. Ithebula elingezansi libonisa amandla okuphuma ajwayelekile kumamodeli ahlukene:

| Imodeli / Usayizi Wegumbi (mm) | Amandla okusebenzisa (kg/h) | Amandla Emotor (kW) | Amanothi |

|---|---|---|---|

| I-SG-230F (200×230) | 50 - 60 | 4 – 45 | Igumbi elincane, umthamo ophansi |

| I-SG-230F (320×600) | 250 - 350 | 4 – 45 | Igumbi eliphakathi |

| I-SG-230F (660×1000) | 600 - 800 | 4 – 45 | Igumbi elikhulu |

| SG-230F (800×1200) | 800 - 1,000 | 4 – 45 | Igumbi elikhulu, okukhiphayo okuphezulu |

Izici ezithuthukile zithuthukisa ukusebenza kahle kanye nekhwalithi yomkhiqizo. Imimese eshintshayo eshintshayo igcina indingilizi yokusika engaguquki ngemva kokulola, enweba ukuphila kommese futhi iqinisekise ukugaywa kwekhwalithi ephezulu. Imiklamo yerotha emile inciphisa ama-spikes amandla kanye nokusetshenziswa kwamandla, ikakhulukazi lapho kucutshungulwa izingxenye eziwugqinsi. Imiklamo ye-open-rotor ithuthukisa ukuhamba komoya nokupholisa, okubalulekile ezintweni ezithambile. Amasistimu okuphakelayo ahlakaniphile kanye nemiklamo ethuthukisiwe yesikulufu nemiphongolo kuqhubeza nokwandisa ukuphuma kanye nekhwalithi ye-pellet. Ama-granulator akonga amandla anamamotho ashintshashintshayo angonga izinkulungwane zamadola ezindlekweni zikagesi unyaka ngamunye.

Ukulawula Usayizi Wezinhlayiya Nokufanayo

Usayizi wezinhlayiyana ongaguquguquki ubalulekile kukho kokubili ukugaywa kabusha nokubumba umjovo. Osayizi bemeshi besikrini abalungisekayo bavumela opharetha ukuthi balawule usayizi wegranule nokufana. Ama-rotor anesivinini esikhulu agunda amapulasitiki abe yizicucu ezincane. Amasistimu wokukhipha uthuli asusa izinhlawulo, futhi izihlukanisi kazibuthe zibamba ukungcola kwensimbi, ziqinisekise ukuphuma okuhlanzekile. Izinzwa ezihlakaniphile namaphaneli okulawula aqapha futhi alungise isivinini se-rotor ngesikhathi sangempela, okugcina usayizi wezinhlayiyana ungashintshi.

Ama-granulator epulasitiki esimanje asebenzisa osayizi besikrini ongenziwa ngokwezifiso kanye nesivinini se-rotor esilungisekayo ukukhiqiza ama-granules afanayo. Lokhu kufana kusekela ukugeleza okubikezelwe nokusabalala ekubunjweni komjovo, okuholela kwikhwalithi yomkhiqizo engaguquki. Lapho kugaywa kabusha, izinhlayiya ezifanayo zithuthukisa ukugeza, ukuncibilika, kanye nokusebenza kahle kwe-pelletizing. Izisetshenziswa ezifana nezixube zemibala ezime mpo ziqinisekisa ukufana okungaphezulu kuka-95%, zinciphisa amaphutha futhi zithuthukise ukusebenza kwemishini.

Ithiphu: Ukunakekelwa okuvamile nezinzwa ezihlakaniphile kusiza ekutholeni izinkinga kusenesikhathi, kuvimbele usayizi wezinhlayiyana ongahambisani nokunciphisa isikhathi sokuphumula.

Usayizi wezinhlayiyana ezifanayo futhi uvumela ukuxubana okungcono, ukungaguquguquki kombala, namandla emishini emikhiqizweni eqediwe. Imishini ehlinzeka ngoshintsho olusheshayo lwesethingi kanye nokuzenzakalela kuzivumelanisa kalula nezimfuneko ezihlukene zomkhiqizo, ithuthukisa ukuguquguquka nokusekela imiphumela yekhwalithi ephezulu kukho kokubili ukugaywa kabusha nokubumba komjovo.

Cutting Technology kanye Blade Design

Ubuchwepheshe bokusika bakha umnyombo wawo wonke ama-granulator epulasitiki. Idizayini ye-blade elungile iqinisekisa ukucutshungulwa okusebenzayo, ama-granules ekhwalithi ephezulu, kanye nesikhathi esincane sokuphumula. Ama-granulator esimanje asebenzisa izici ezimbalwa ezithuthukile ukuze ahlangabezane nezidingo zakho zombili izinhlelo zokusebenza zokuphinda zigaywe kabusha nokubumba umjovo.

- Imimese ye-rotor ye-V-cut idala ukugaywa kwekhwalithi ephezulu ngezinhlawulo ezimbalwa, okuthuthukisa ukuvumelana kokuphumayo.

- Imigqa eminingi yemimese yerotor, efana nemigqa engu-9, 11, noma engu-13, ikhulisa umthamo wokusika futhi ivumela umshini ukuthi ubambe amavolumu amakhulu.

- Ama-deflector wedge akhishwayo asebenza njenge-stator blade yesithathu. Lesi sici sikhulisa ulaka lokusika futhi sivumela ukulungiswa okusheshayo ngesikhathi sokusebenza.

- Ama-rotor bearings amakhulu kakhulu kanye nokukhwezwa kommese kusekela imisebenzi esindayo yokuvuselela kabusha. Lezi zingxenye zimelana nokuguga futhi zandise impilo ye-granulator.

- Izinsimbi ezingagqoki futhi ezibheke kanzima kuma-rotor nezindlu zivikela umshini ezintweni ezihugayo noma ezingcolile.

- Ukwakhiwa kwensimbi eshiselwe ngokuqinile kuqinisekisa ukuqina, ngisho nasezimweni ezinzima.

- Ama-bearings asebenza kanzima angaphandle, ahlukaniswe negumbi lokusika, avimbela ukungcola futhi anciphise ingozi yokwehluleka ngaphambi kwesikhathi.

Idizayini ye-blade iphinde ithinte ukugcinwa kanye nekhwalithi ye-granule. Ama-blade abuthuntu noma angahlukani kahle angabangela ama-granules angalingani, anothuli kanye nokuphuma okuncane. Ama-blade ajikelezayo alungisekayo avumela ukucijwa ngakunye, okunweba ukuphila kwe-blade futhi kugcine usayizi wegranule ulingana. Ukuhlola okuvamile nokugcinwa kokuvikela, njengokucija nokulungiswa kwegebe, kusiza ukunciphisa isikhathi sokuphumula.

| Isici | Isifinyezo sobufakazi |

|---|---|

| Blade Materials | I-Tungsten carbide nezinsimbi zensimbi ezinesivinini esikhulu zinikeza ukumelana nokugqoka okuphezulu nempilo ende yesevisi, enciphisa imvamisa yokulungisa. |

| I-Blade Gap | Igebe elifanele le-blade (0.1-0.3 mm) libalulekile ekusebenzeni kahle kokusika; igebe elingalungile lidala ama-blade abuthuntu, ama-granules angalingani, kanye nokugcinwa okwengeziwe. |

| I-Blade Design | Idizayini yommese ovunguzayo ithuthukisa ukusebenza kahle kokusika futhi inciphise ukuvala, ithuthukise ikhwalithi ye-granule. |

| Imikhuba Yesondlo | Ukuhlanza okuvamile, ukuthambisa, nokulinganisa ibhalansi okuguquguqukayo kwandisa ukuphila kwe-blade futhi kugcine ukufana kwe-granule. |

| Umthelela Wedizayini Engalungile | Isimo esingesihle se-blade siholela ekubeni izimbumbulu ezinothuli, ezingalingani kanye nezidingo zokulondolozwa njalo. |

I-granulator yepulasitiki enobuchwepheshe bokusika obusezingeni eliphezulu nama-blade aklanywe kahle iletha ukusebenza okuthembekile, ama-granules ekhwalithi ephezulu, nezindleko zokulungisa eziphansi.

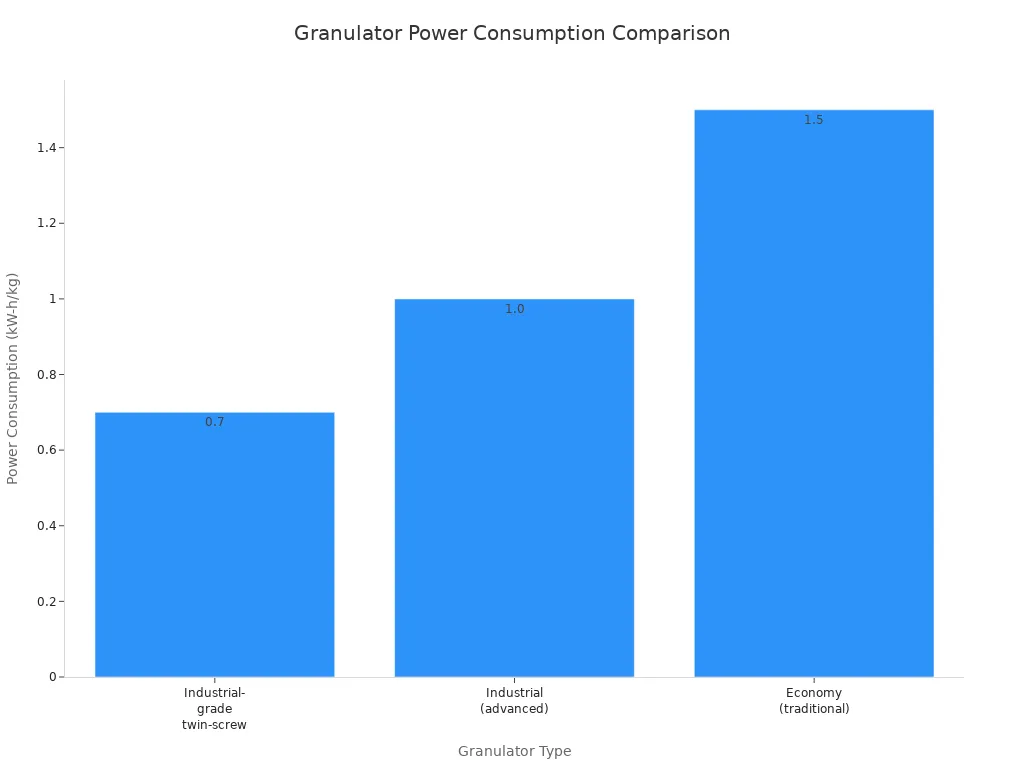

Ukusebenza kahle kwamandla kanye nokuncishiswa komsindo

Ukusebenza kahle kwamandla sekuyinto ehamba phambili ekukhiqizeni kwesimanje. Ama-granulator epulasitiki athuthukisiwe asebenzisa izinjini ezonga amandla kanye nezinhlelo ezihlakaniphile zokulawula izinga lokushisa ukuze kuncishiswe ukusetshenziswa kwamandla. Amamodeli we-twin-screw wezinga lezimboni angasebenzisa amandla afika kwangu-40% angaphansi kunamamodeli wezomnotho wendabuko. Lokhu kuthuthukiswa kwehlisa izindleko zokusebenza futhi kusekela imigomo yokusimama.

Ukunciphisa umsindo kungesinye isici esibalulekile emsebenzini. Ama-granulator epulasitiki angaba nomsindo, kodwa abakhiqizi manje banikeza amamodeli angazwakali kanye nemiklamo enciphisa umsindo. Amakesi angangeni msindo nezilawuli ezizenzakalelayo ngokugcwele zisiza amazinga omsindo aphansi, zenze indawo yokusebenza iphephe futhi inethezeke. Lezi zici futhi zisiza izikhungo ukuthi zihlangabezane nemithetho yomsindo wendawo futhi zithuthukise ukusebenza kahle sekukonke.

Ithiphu: Ukusebenzisa ukuvikela izindlebe nokugcina izithiyo ezingazwakali eduze kwe-granulator kungaqhubeka nokunciphisa ukuchayeka komsindo kuma-opharetha.

Izimbumbulu zepulasitiki zesimanje zihlanganisa izici zokonga amandla nobuchwepheshe bokunciphisa umsindo ukuze zakhe indawo yokusebenza ephephile, esebenza kahle kakhulu, futhi enobungani bemvelo.

Izici Zokuphepha Nokuhambisana

Ukuphepha kuhlala kuwukukhathazeka okubalulekile kunoma yisiphi isikhungo esisebenzisa i-granulator yepulasitiki. Imishini kufanele ihlangabezane nezindinganiso eziqinile zokuphepha ukuze ivikele abaqhubi kanye nokuqinisekisa ukusebenza okuthembekile.

- I-ANSI/PLASTICS B151.11-2021 iveza izidingo zokuphepha zamagranulator, idizayini yokumboza, ukusebenza, ukunakekela, nokulungiswa.

- Amanye amazinga afanelekile ahlanganisa i-ANSI/PLASTICS B151.1-2017 yemishini yokubumba umjovo kanye ne-ANSI/PLASTICS B151.27-2021 yezinhlelo zemishini yokubumba irobhothi/umjovo.

- Ukuhambisana nalawa mazinga kubalulekile ekusebenzeni okuphephile ezimakethe ezinkulu zokukhiqiza.

Ama-granulator epulasitiki adinga izilawuli zokuphepha ezimbalwa ezakhelwe ngaphakathi:

- Amasistimu wokukhiya/aphuma ngaphandle anqamula amandla ngaphambi kokulungiswa noma ukuhlanza.

- Onogada nezingidi zivimbela ukufinyelela emimese enyakazayo.

- Izinkinobho zokumisa izimo eziphuthumayo, ama-alamu okuvimbela, nezokuphepha zikagesi ezimbili zinikeza impendulo esheshayo ezingozini.

- Abasebenzisi kufanele bagqoke izinto zokuzivikela, njengamagilavu, iso, ubuso, indlebe, nokuvikela uthuli.

- Ukuhlola okuvamile nokuhlolwa kokuphepha kwansuku zonke kugcina umshini usesimweni sokusebenza esiphephile.

- Abasebenzisi badinga ukuqeqeshwa okufanele neziyalezo ezicacile ngolimi abaluqondayo.

Qaphela: Ukugcina indawo yokusebenza ihlanzekile futhi ingenazo izithiyo kusiza ukuvimbela ukushelela, uhambo, nezinye izingozi.

Ngokulandela lezi zindlela zokuphepha nokuthobelana namazinga aziwayo, izikhungo zingaqinisekisa ukusebenza okuphephile nokusebenza kahle kwama-granulator azo epulasitiki.

Ukucatshangelwa kokusebenza kwe-Granulator yePlastiki

Izindlela Zokudla kanye Nezinketho Zokulayisha

Ama-opharetha angakhetha ezindleleni ezimbalwa zokuphakela lapho ehlanganisa i-granulator yepulasitiki emugqeni wokukhiqiza. Ukuphakelwa ngezandla kusebenza kahle kumaqoqo amancane noma ukusetshenziswa ngezikhathi ezithile. Ukuphakela amaconveyor kusekela ukusebenza okuqhubekayo futhi kunciphisa umsebenzi wezandla. I-roll feeding ilungele amashidi amancane epulasitiki noma amafilimu.Ukuphakela amarobhothikwandisa okuzenzakalelayo nokuphepha ngokunciphisa ukuthintana kwabantu nezingxenye ezihambayo. Indlela ngayinye ithinta ukusebenza kahle nokugeleza kwezinto ezibonakalayo ngezindlela ezahlukene.

Ukubeka ama-granulator eceleni komshini wokunyathelisa konga indawo yaphansi futhi kuqondise ukuhamba komsebenzi. Amaphaneli okufinyelela ngaphambili enza ukusebenza nokugcinwa kube lula. Izinketho zokuphakela ezizenzakalelayo nazo zinciphisa ukuphatha ngesandla, okwehlisa ingozi yokulimala futhi kuthuthukise isivinini sokukhiqiza.

Ithebula elingezansi ligqamisa izici zokusebenza ezibalulekile okufanele zicatshangelwe lapho kukhethwa izinketho zokuphakela nokulayisha:

| Isici sokuSebenza | Incazelo & Ukucatshangelwa |

|---|---|

| Uhlobo Lwezinto Zepulasitiki | Amapulasitiki aqinile adinga izindwani eziqinile nezinjini; amapulasitiki athambile adinga ukuphathwa ngobumnene. |

| Izidingo Zosayizi Wokukhiphayo | Izikrini ezilungisekayo zisiza ukufeza usayizi wegranule ofunekayo wezinqubo eziya phansi komfula. |

| Amandla Okukhiqiza | Ukukhiqiza kumele kuhambisane nezidingo zokukhiqiza ukuze kugwenywe izingqinamba. |

| Ukuhambisana Ukuhlanganisa | Amasistimu okudla kufanele axhumeke ngokushelelayo namaconveyor, amarobhothi, noma ezinye izisetshenziswa ezishintshayo. |

Isondlo Nokuhlanza Kalula

Ukunakekelwa okuvamile kugcina i-granulator yepulasitiki isebenza kahle futhi kwandisa ubude bayo bempilo. Ama-opharetha kufanele ahlole nsuku zonke amabhawodi axegayo, ukuvuza, noma imisindo engajwayelekile. Ukusula i-hopper nokuhlola igumbi lokusika ngemva kokushintsha ngakunye kuvimbela ukwakheka kwezinto. Imisebenzi yamasonto onke ihlanganisa ukuhlola imimese ukuthi ibuthuntu yini, izikrini zokuhlanza, namabheringi okugcoba. Ukuhlanza okujulile kwanyanga zonke nokulungiswa kwegebe lommese kusiza ekugcineni ukusika ukusebenza kahle.

- Nsuku zonke: Hlola umonakalo, sula izithiyo, futhi uhlole izici zokuphepha.

- Maviki onke: Hlola imimese nezikrini, gcoba amabheringi, futhi uqinise izinto zokubopha.

- Nyanga zonke: Amakamelo ahlanzekile ajulile, lungisa izikhala zommese, futhi uhlole ukuxhunywa kukagesi.

- Ngaphakathi/Ngonyaka: Lola noma shintsha imimese, shintsha izingxenye ezigugile, bese uhlola ngokugcwele.

Ukusebenzisa izingxenye zomkhiqizi wemishini yoqobo (i-OEM) nokulandela izinqubo eziqinile zokuphepha kuqinisekisa ikhwalithi nokuphepha komqhubi. Ukugcina indawo yokusebenza ihlanzekile nakho kusekela ukulungiswa okuphumelelayo.

Ukuqina kanye Nokwakha Ikhwalithi

Ukuqina kudlala indima ebalulekile kunani lesikhathi eside le-granulator yepulasitiki. Imishini eyakhiwe ngezinsimbi ezifakwe ukushisa namamotho aqinile imelana nokusetshenziswa okunzima kanye nezinto eziqhumayo. Ukwakhiwa kwe-modular kuvumela ukushintshwa kwengxenye ngokushesha, ukunciphisa isikhathi sokuphumula. Imiklamo efinyeleleka kalula yenza izinguquko ze-blade nokuhlanza ngokushesha, okusiza ukugcina ukucijile nokusebenza kahle.

Ikhwalithi ephezulu yokwakha inganweba isikhathi sokuphila se-granulator sibe iminyaka eyi-10-20. Ukuhlolwa okuvamile, ukugcotshwa okufanele, nokushintshwa ngesikhathi kwezingxenye ezigugile kugcina umshini uthembekile. Amafreyimu aqinile kanye nezingxenye zekhwalithi kwehlisa izindleko zokusebenza futhi kunciphise isidingo sokulungisa njalo.

Ukutshala imali ku-granulator eqinile kusekela ukukhiqizwa okuqhubekayo futhi kusiza izindawo zithole ukonga izindleko zesikhathi eside.

Ukusekela Ngemva Kokuthengisa Nezingxenye Ezisele

Ukwesekwa ngemuva kokuthengisa kudlala indima ebalulekile empumelelweni yesikhathi eside yanoma yikuphi ukusebenza kokucubungula kwepulasitiki. Izinkampani ezimbonini zokugaywa kabusha nokubumba umjovo zithembele kusevisi ethembekile ukuze zigcine okokusebenza kwazo kusebenza kahle. Lapho umshini uyeka ukusebenza, ukukhiqiza kungama, okuholela ekulahlekeni kwesikhathi nemali. Ukwesekwa okuthembekile kwangemuva kokuthengisa kusiza ukuvimbela lezi zinkinga futhi kuqinisekisa ukutholakala okusheshayo lapho kuphakama izinkinga.

Abasebenzisi abaningi bazisa izinhlobo ezimbalwa zamasevisi angemva kokuthengisa. Lokhu kubandakanya:

- Ukufinyelela kochwepheshe benkonzo yasensimini abanolwazi abakwazi ukuxilonga futhi balungise izinkinga esizeni.

- Ubuchwepheshe bokufaka izicelo obusiza opharetha ukuthi bathole okuningi emishinini yabo.

- Ukwesekwa okungantengantengi okuvela kumphakeli, okwakha ukwethembana nokuzethemba.

Izikhungo zokugaywa kabusha zivame ukubhekana nezinselele ezihlukile. Bazuza kulokhu:

- Ukubonisana nochwepheshe okuhambisana nezinqubo zabo zokugaywa kabusha.

- Ukuqeqeshwa okuphelele kwabasebenzi ukuze basebenzise futhi banakekele izinto zokusebenza ngokuphepha.

- Usizo lobuchwepheshe oluqhubekayo lokuxazulula izinkinga ezingalindelekile.

Abasebenzisi bokubumba umjovo baphinde babheke:

- Ukufakwa kochwepheshe ukuqinisekisa ukuthi imishini isebenza kahle kusukela ekuqaleni.

- Ukuqeqeshwa okuphelele kwabo bonke abasebenzi.

- Usizo lwezobuchwepheshe oluthembekile kanye nokuhlinzekwa okuqhubekayo kwezinsimbi eziyisipele.

- Izinsizakalo zokunakekela ezisiza ukwelula impilo yesisetshenziswa.

Izinsiza zokusekela ezifinyelelekayo zenza umehluko. Izinkampani eziningi zinikeza:

- Amasevisi okubonisana ukuphendula imibuzo nokunikeza isiqondiso.

- Usekelo lwevidiyo lokuxazulula izinkinga nokulungisa.

- Ama-FAQ asiza abasebenzisi ukuxazulula izinkinga ezijwayelekile ngokushesha.

Ithiphu: Ukugcina isitokwe sezingxenye eziyisipele ezibalulekile kusayithi kunganciphisa isikhathi sokuphumula futhi kugcine ukukhiqiza kuqhubeka.

Uhlelo oluqinile lokusekela ngemva kokuthengisa luqinisekisa ukuthi imishini ihlala ithembekile futhi isebenza kahle. Iphinde inikeze abaqhubi ithemba lokusingatha izinselele zansuku zonke futhi bahlele ukukhula kwesikhathi esizayo.

Ukukhetha i-Granulator Elungile yePlastiki

Ukufanisa Izinhlobo Ze-Granulator Ezibalulekile Nezinqubo

Ukukhetha i-granulator efanele kuqala ngokuqonda izinto ezisetshenziswayo nezinqubo ezisetshenziswayo. Ezinye izikhungo zicubungula amapulasitiki aqinile njenge-ABS noma i-polycarbonate. Abanye baphatha izinto ezithambile ezifana nefilimu ye-polyethylene. Uhlobo ngalunye lwezinto ezibonakalayo ludinga igumbi lokusika elithile kanye nomklamo we-blade. Isibonelo, izingxenye ezinezindonga eziwugqinsi zidinga igumbi le-tangential, kuyilapho amafilimu amancane asebenza kangcono ngama-rotor avulekile. Ama-opharetha kufanele futhi acabangele usayizi we-scrap kanye nosayizi odingekayo wokuphumayo. Izikhungo zokugaywa kabusha kwevolumu ephezulu zingadinga amamodeli amakhulu, asindayo.Izitolo zokubumba umjovobavame ukukhetha amayunithi ahlangene, aseceleni komshini. Ukufanisa uhlobo lwe-granulator nokokusebenza nenqubo kuqinisekisa ukusebenza kahle kanye nemiphumela yekhwalithi ephezulu.

Izindleko Zokulinganisa, Ivelu, kanye Nokusebenza Kwesikhathi Eside

Izindleko zidlala indima enkulu ekukhethweni kwemishini. Nokho, intengo ephansi kakhulu ayisho njalo inani elingcono kakhulu. Izinsiza kufanele zibheke izindleko eziphelele zobunikazi. Lokhu kubandakanya ukusetshenziswa kwamandla, ukulungiswa, nokutholakala kwezingxenye ezisele. Imishini enamamotho awonga amandla nezinsimbi eziqinile ngokuvamile yonga imali ngokuhamba kwesikhathi. Ukwesekwa okuthembekile kwangemuva kokuthengisa kunganciphisa isikhathi sokuphumula kanye nezindleko zokulungisa. Ukutshala imali kugranulator yekhwalithi ephezulu kusiza ukugcina ukukhiqizwa okungaguquki futhi kunciphisa izindleko zesikhathi eside.

Ithiphu: Cabangela ubude bempilo obulindelwe kanye nezidingo zokunakekela ngaphambi kokuthenga. Umshini owakhiwe kahle ungahlala iminyaka eminingi ngokunakekelwa okufanele.

Uhlu Lokuhlola Lokukhetha I-Granulator

Abasebenzisi bangasebenzisa uhlu lokuhlola ukuze baqondise isinqumo sabo:

- Khomba izinhlobo nosayizi bezinto zepulasitiki okufanele zicutshungulwe.

- Linganisela amavolumu okucubungula nsuku zonke noma angeviki.

- Hlola ukuhambisana nezinhlelo ezikhona zokuphakela nokukhipha.

- Buyekeza izici zokuphepha nokuhambisana nezindinganiso zomkhakha.

- Linganisa ukusebenza kahle kwamandla kanye namazinga omsindo.

- Hlola kalula ukugcinwa nokuhlanza.

- Qinisekisa ukutholakala kwezingxenye ezisele nosekelo lobuchwepheshe.

- Qhathanisa izindleko eziphelele zobunikazi, hhayi nje inani lokuthenga.

Ukubuyekezwa ngokucophelela kwalezi zici kusiza ukuqinisekisa ukuthi i-granulator yepulasitiki ekhethiwe ihlangabezana nezidingo zamanje nezesikhathi esizayo.

Ukukhetha okokusebenza okufanele kuqinisekisa ukusebenza kahle kukho kokubili ukuvuselela nokubunjwa komjovo. Izinsiza ziyazuza emishinini enikeza ukusebenza kahle kwezindleko, isekela imigomo yemvelo, futhi ithuthukise isivinini sokukhiqiza. Izinzuzo ezibalulekile zifaka:

- Yehlisa izindleko zempahla eluhlaza ngokugaywa kabusha.

- Udoti oncishisiwe wepulasitiki endaweni ehlanzekile.

- Ukuphatha kalula kanye nokugcinwa kwe-granulated material.

- Ikhwalithi yomkhiqizo engaguquki enezinhlamvu ezifanayo.

- Ukunakekelwa okulula kanye nezindawo zokusebenza eziphephile, ezihlanzekile.

Abasebenzisi kufanele basebenzise uhlu lokuhlola ukuze baqondise isinqumo sabo futhi bathole impumelelo yesikhathi eside.

FAQ

Yiziphi izinhlobo zepulasitiki ezingenza inqubo ye-granulator?

Iningiama-granulator epulasitikiphatha izinto ezijwayelekile ezifana ne-ABS, PP, PE, PVC, ne-PET. Amanye amamodeli aphinde acubungule amapulasitiki obunjiniyela noma izinto zokwakha nge-glass fiber. Ngaso sonke isikhathi hlola ukucaciswa komshini ukuthi uyahambisana yini.

Kufanele opharetha benze kangaki ukunakekelwa ku-granulator?

Ama-opharetha kufanele ahlole i-granulator nsuku zonke ngokuguga noma ukulimala. Ukuhlanza nokugcoba kwamasonto onke kusiza ekugcineni ukusebenza. Ukuhlanza okujulile kwanyanga zonke kanye nokuhlolwa kwe-blade kunweba impilo yomshini futhi kuqinisekise ukusebenza okuphephile.

Kungani usayizi wezinhlayiyana ezifanayo ubalulekile ku-granulation yepulasitiki?

Usayizi wezinhlayiyana olinganayo uqinisekisa ukudla okubushelelezi emishinini yokubumba umjovo. Iphinde ithuthukise ukuncibilika kanye nokuxutshwa ngesikhathi sokugaywa kabusha. Ama-granules angaguquguquki asiza ukugcina ikhwalithi yomkhiqizo futhi anciphise ukungcola.

Ingabe i-granulator yepulasitiki inganciphisa izindleko zamandla?

Yebo. Ama-granulator awonga amandla asebenzisa izinjini ezithuthukile nezilawuli ezihlakaniphile. Lezi zici zinciphisa ukusetshenziswa kukagesi futhi zinciphisa izindleko zokusebenza ngokuhamba kwesikhathi.

Yiziphi izici zokuphepha okufanele i-granulator yepulasitiki ihlanganise?

I-granulator yekhwalithi ihlanganisa izinkinobho zokumisa izimo eziphuthumayo, izikhiye zokuphepha, namasistimu wokukhiya/wokukhipha umaka. Lezi zici zivikela opharetha kanye nezinsiza ezisiza ukuhlangabezana namazinga okuphepha embonini.

Isikhathi sokuthumela: Jul-17-2025