A polasetiki ea granulatore bapala karolo ea bohlokoa lits'ebetsong tsa ho e sebelisa hape le ho bopeng ente. Basebelisi ba bohlokoa ba mechini e hlahisang li-granules tse tšoanang, kaha ts'ebetso ena e matlafatsa ts'ebetso ea ts'ebetso hape e ts'ehetsa tlhahiso e boreleli. Mechini e tsoetseng pele ea granulator e sebetsana le mefuta e mengata ea polasetiki, e fanang ka maemo a bonolo bakeng sa merero e fapaneng. Likarolo tsa ho boloka matla mochining ona li thusa ho theola litšenyehelo tsa ts'ebetso. Mehlala e meng, joalo ka amochini oa polasetiki oa granulekapa apolasetiki e silafatsang, hape fokotsa litšila ka ho ntlafatsa tšebeliso ea thepa. Litšobotsi tsena li tšehetsa ts'ebetso e tsitsitseng le e ka tšeptjoang libakeng tsa sejoale-joale tsa polasetiki.

Lintlha tsa bohlokoa

- Li-granulator tsa polasetiki li tlameha ho hlahisa li-granules tse ts'oanang ho netefatsa boleng bo tsitsitseng ba sehlahisoa le ho sebelisoa hantle kapa ho bopa.

- Ho khetha granulator e nepahetseng ho ipapisitse le mofuta oa polasetiki, bophahamo ba molumo, le litlhoko tsa ts'ebeliso joalo ka ho recycle kapaho bopa ka ente.

- Li-granulator tse tsoetseng pele li fana ka likarolo tsa ho boloka matla, phokotso ea lerata, le tlhokomelo e bonolo ho fokotsa litšenyehelo le ho ntlafatsa polokeho ea mosebetsing.

- Likarolo tse matla tsa polokeho, ho kenyeletsoa libaka tsa ho emisa le li-interlock tsa tšohanyetso, li sireletsa basebelisi le ho thusa ho fihlela maemo a indasteri.

- Tšehetso e tšepahalang ka mor'a thekiso le tlhokomelo ea kamehla e atolosa bophelo ba mochine le ho boloka tlhahiso e sebetsa hantle.

Litlhoko tsa kopo ea polasetiki ea Granulator

Recycling vs. Ente Molding Litlhoko

Recycling le ente molding sebaka se seng le se seng litlhoko tse ikhethang tsapolasetiki ea granulator. Ha ho etsoa ente, hangata basebetsi ba sebelisa li-granulator tse nyane tse sebetsang hantle ka thoko ho mochini o bopang. Mechini ena e sebetsana le li-sprues, limathi le likarolo tse nang le bothata. Ba tsepamisitse maikutlo ho compactness le ts'ebetso e sebetsang ea likhechana tsa molumo o tlase. Mohlala, granulator e sebelisetsoang ho etsa ente ea PVC e tlameha ho qhaqha lisebelisoa tse thata, tse thata hore e be granule tse ka sebelisoang hape. Ka lehlakoreng le leng, lisebelisoa tsa ho tsosolosa li hloka li-granulator tse kholoanyane, tse matla haholoanyane kapa li-shredders. Mechini ena e sebetsa litšila tse ngata joalo ka libotlolo, lipeipi le lishiti. Ba hloka bokhoni bo phahameng le ho tšoarella ho sebetsana le mefuta e mengata ea polasetiki le boholo. Phapang ea sekala le mofuta oa scrap e theha moralo le ts'ebetso ea granulator ka 'ngoe.

Litlhoko tse Abelaneng tsa Likopo ka Bobeli

Ka bobeli ho bopeha le ho etsa liente li itšetlehile ka likarolo tse itseng tsa bohlokoa ka har'a granulator ea polasetiki. Basebelisi ba batla mechini e hlahisang boholo ba granule e lekanang, e thusang ho boloka boleng ba sehlahisoa bo sa fetoheng. Tšireletseho e lula e le eona ntho ea bohlokoa ka ho fetisisa, kahoo likarolo tse kang likonopo tsa ho emisa ts'ohanyetso le li-interlock tsa polokeho li bohlokoa. Ho fihlella habonolo li-blades le li-skrini ho lumella ho lokisoa le ho hloekisa kapele. Mehaho e mengata e khetha li-granulator tse nang le maemo a tlase a lerata le meralo ea mehala bakeng sa ho beoa habonolo. Tafole e ka tlase e totobatsa likarolo tse ling tsa ts'ebetso tse arolelanoang:

| Sebopeho | Molemo |

|---|---|

| Saese e tšoanang ea granule | Boleng bo lumellanang ba sehlahisoa |

| Tšireletso interlocks | Tšireletso ea opereishene |

| Tlhokomelo e bonolo | Nako e fokotsehileng |

| Ts'ebetso ea lerata le tlase | Sebaka sa mosebetsi se ntlafetseng |

| Portability | Tšebeliso e bonolo libakeng tse fapaneng |

Ho lekanya Mefuta ea Lisebelisuoa le Mefuta ea Ts'ebetso

Lisebelisoa li sebetsana le mefuta e mengata ea polasetiki, ho kenyeletsoa li-sprues, likhetla, li-tubes, libotlolo le lifilimi. Li-plastiki tse ling, joalo ka tse nang le fiber e ngata ea khalase, li hloka li-granulator tse khethehileng tse nang le libaka tse tšoarellang le ho sila ha torque e phahameng. Khetho ea granulator e boetse e itšetlehile ka ho sebetsa ha molumo. Ts'ebetso e nyane e sebelisa mefuta e kopaneng bakeng sa lisebelisoa tse bobebe, athe litsi tse kholo tsa ho e sebelisa hape li hloka mechini ea indasteri e sebetsanang le lithane tse 'maloa letsatsi le letsatsi. Ho khetha granulator e nepahetseng ho netefatsa ts'ebetso e nepahetseng le ho thibela mathata, ebang sepheo ke ho tsosolosa ka tlung kapa ho fokotsa litšila tse ngata.

Likarolo tsa Bohlokoa tsa Granulator ea polasetiki

Tšebelisano 'moho le Lintho tse fapaneng

Polasetiki granulator lokela ho sebetsana le mefuta e fapaneng ya thepa ho sebeletsa ka bobeli recycled lelisebelisoa tsa ho bopa ka ente. Hangata li-operators li sebetsana le lintho tse kang libotlolo tse entsoeng ka moea o fokang, lihokelo tsa motlakase, likotoana tsa li-screw, le li-profile tse fetisitsoeng. Mechini e nang le mefuta e mengata ea motheo, joalo ka FX 700, FX 1000, le FX 1600, e lumella basebelisi ho bapisa granulator le boholo bo fapaneng ba likarolo le litlhoko tsa ho feta. Litlhophiso tsa kamore e feto-fetohang, joalo ka likamore tse tangential bakeng sa likarolo tse kholo le likamore tsa offset bakeng sa likarolo tse nang le marako a teteaneng, li eketsa ho ikamahanya le maemo.

Tlhokomeliso: Li-hopper tse ka tloahelehang le meralo ea ho lahla li thusa ho kopanya granulator ka har'a litlhophiso tse fapaneng tsa sistimi, ho etsa hore ho be bonolo ho li kopanya le lisebelisoa tse seng li ntse li le teng.

Ho feto-fetoha ha maemo ho boetse ho ipapisitse le bokhoni ba ho sebetsana le li-plastiki tse nang le li-additives tse fapaneng kapa maemo a thata. Li-granulator tse nang le libaka tse sa senyeheng le phihlello e bonolo ea ho lokisoa li fokotsa nako le ho lelefatsa bophelo ba lisebelisoa. Likarolo tse ntlafalitsoeng tsa polokeho, ho kenyeletsoa li-interlock tse sa hlokahaleng le liloko tse kentsoeng ke solenoid, li sireletsa basebelisi nakong ea ts'ebeliso. Ho hatella molumo ho etsa lerata le tlase, ho ntlafatsa tikoloho ea mosebetsi. Mefuta e joalo ka letoto la SL le G26 li hlahella bakeng sa tšebelisano ea tsona e pharalletseng, e ts'ehetsang ho sebelisoa hape lemekhoa ea ho etsa ente.

Bokhoni ba ho Phahamisa le Bokhabane

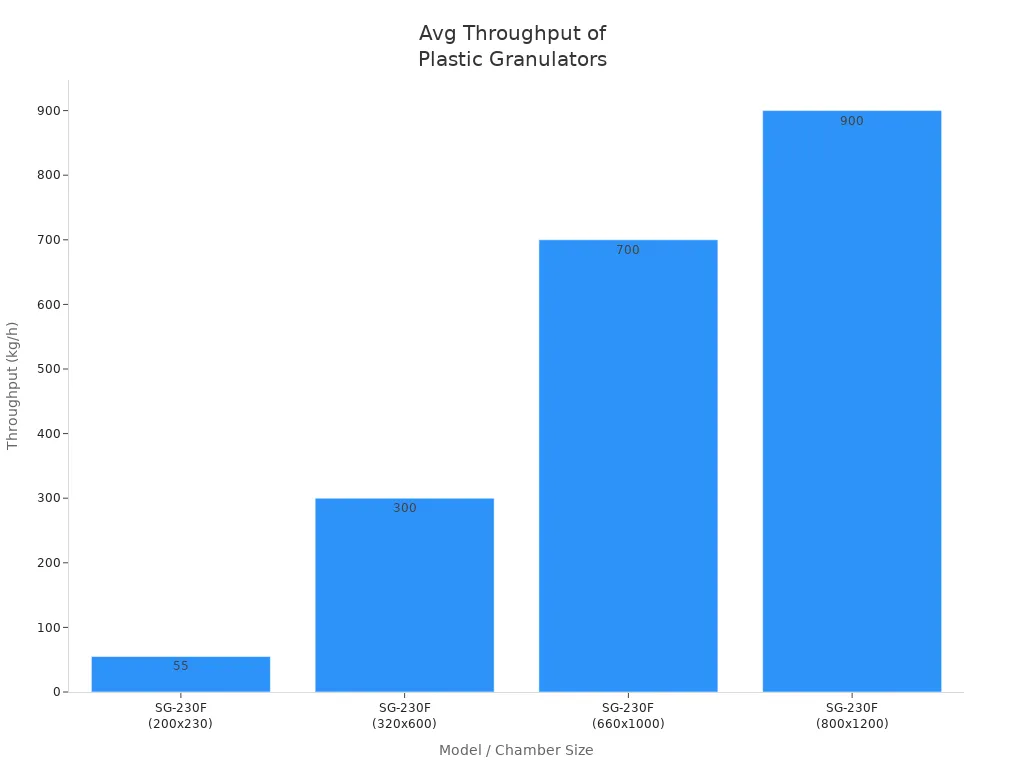

Matla a ho fetisa a lekanya hore na granulator ea polasetiki e ka sebetsa lintho tse kae ka nako e itseng. Lisebelisoa li khetha mechini ho latela litlhoko tsa bona tsa letsatsi le letsatsi. Likamore tse nyane li lumellana le ts'ebetso ea molumo o tlase, ha liphaposi tse kholo li sebetsana le ts'ebetso ea bongata. Tafole e ka tlase e bonts'a bokhoni bo tloaelehileng ba ho sebelisa mefuta e fapaneng:

| Mohlala / Boholo ba Kamore (mm) | Matla a ho fetisa (kg/h) | Matla a Enjene (kW) | Lintlha |

|---|---|---|---|

| SG-230F (200×230) | 50-60 | 4 - 45 | Kamore e nyane, matla a tlase |

| SG-230F (320×600) | 250 - 350 | 4 - 45 | Kamore e mahareng |

| SG-230F (660×1000) | 600-800 | 4 - 45 | Kamore e kholoanyane |

| SG-230F (800×1200) | 800 - 1,000 | 4 - 45 | Kamore e kholo ka ho fetisisa, tlhahiso e phahameng |

Lintlha tse tsoetseng pele li ntlafatsa katleho le boleng ba sehlahisoa. Lithipa tse feto-fetohang li boloka selikalikoe se sa khaotseng ka mor'a ho leotsa, e leng ho lelefatsang bophelo ba thipa le ho netefatsa hore boleng ba boleng bo holimo bo khutla. Meralo ea rotor e tsitsitseng e fokotsa li-spikes tsa matla le ts'ebeliso ea matla, haholo ha ho sebetsa likarolo tse teteaneng. Meetso e bulehileng ea rotor e ntlafatsa phallo ea moea le ho tsidifala, e leng ntho ea bohlokoa bakeng sa lisebelisoa tse bobebe. Lisebelisoa tse bohlale tsa ho fepa le meralo e ntlafalitsoeng ea screw le barrel e eketsa tlhahiso le boleng ba pellet. Li-granulator tse sebetsang hantle tse nang le li-mothara tse feto-fetohang li ka boloka likete tsa lidolara ka litšenyehelo tsa motlakase selemo se seng le se seng.

Taolo ea boholo ba likaroloana le ho ts'oana

Boholo bo sa fetoheng bo bohlokoa bakeng sa ho e sebelisa hape le ho bopeng ente. Boholo bo feto-fetohang ba letlooeng la skrine bo lumella li-opereishene ho laola boholo ba granule le ho tšoana. Li-rotor tse lebelo le phahameng li kuta lipolasetiki hore li be likotoana tse nyane, esita le likhechana. Lisebelisoa tsa ho ntša lerōle li tlosa likotlo, 'me li-separator tsa makenete li tšoara litšila tsa tšepe, li netefatsa hore li hloekile. Li-sensor tse bohlale le liphanele tsa taolo li beha leihlo le ho fetola lebelo la rotor ka nako ea 'nete, li boloka boholo ba karolo bo sa fetohe.

Li-granulator tsa sejoale-joale tsa polasetiki li sebelisa boholo ba skrineng bo ikhethileng le lebelo le feto-fetohang la rotor ho hlahisa li-granules tse tšoanang. Ho tšoana hona ho ts'ehetsa phallo e lebelletsoeng esale pele le ho ata ha ho etsoa ka ente, e lebisang ho boleng bo tsitsitseng ba sehlahisoa. Ha li sebelisoa hape, likaroloana tse tšoanang li ntlafatsa ho hlatsoa, ho qhibiliha le ho hlahisa pelletizing. Lisebelisoa tse kang li-mixer tse otlolohileng tsa mebala li netefatsa ho tšoana ho fetang 95%, ho fokotsa likoli le ho ntlafatsa ts'ebetso ea mochini.

Keletso: Tlhokomelo ea kamehla le li-sensor tse bohlale li thusa ho lemoha mathata pele ho nako, ho thibela boholo bo sa tsitsang ba likaroloana le ho fokotsa nako.

Boholo ba likaroloana bo tšoanang bo boetse bo lumella ho kopanya hantle, ho lumellana ha mebala, le matla a mochine lihlahisoa tse felileng. Mechini e fanang ka liphetoho tse potlakileng tsa litlhophiso le ea othomathike e ikamahanya habonolo le litlhoko tse fapaneng tsa sehlahisoa, e ntlafatsa ho feto-fetoha ha maemo le ho ts'ehetsa liphetho tsa boleng bo holimo molemong oa ho sebelisoa hape le ho bopeng ente.

Theknoloji ea ho Cutting le Blade Design

Theknoloji ea ho itšeha e theha motheo oa granulator e 'ngoe le e' ngoe ea polasetiki. Moralo o nepahetseng oa blade o netefatsa ts'ebetso e nepahetseng, li-granules tsa boleng bo holimo, le nako e fokolang ea ho theoha. Li-granulator tsa sejoale-joale li sebelisa likarolo tse 'maloa tse tsoetseng pele ho fihlela litlhoko tsa ts'ebetso ea ho e sebelisa hape le ea ho etsa ente.

- Lithipa tsa V-cut rotor li theha boleng ba boleng bo holimo ka likotlo tse fokolang, tse ntlafatsang ho tsitsisa ha tlhahiso.

- Mela e mengata ea lithipa tsa rotor, joalo ka mela e 9, 11, kapa 13, e matlafatsa bokhoni ba ho itšeha 'me e lumella mochini ho sebetsana le meqolo e meholo.

- Li-wedge tsa deflector tse tlosoang li sebetsa joalo ka lehare la boraro la stator. Tšobotsi ena e eketsa bohale ba ho itšeha 'me e lumella liphetoho tse potlakileng nakong ea ts'ebetso.

- Li-rotor bearings le lisebelisoa tsa thipa li tšehetsa mesebetsi e boima ea ho tsosolosa. Likarolo tsena li hanela ho roala le ho lelefatsa bophelo ba granulator.

- Litšepe tse sa khoneng ho roala le tse shebaneng ka thata holim'a li-rotor le matlo li sireletsa mochine ho tloha linthong tse senyang kapa tse silafetseng.

- Kaho e matla ea tšepe e cheselitsoeng e tiisa hore e tšoarella, leha e le maemong a boima.

- Li-bearings tse boima tse ka ntle, tse arohaneng le kamore ea ho itšeha, li thibela tšilafalo le ho fokotsa kotsi ea ho hlōleha pele ho nako.

Moralo oa lehare o boetse o ama tlhokomelo le boleng ba granule. Li-blades tse lerootho kapa tse sa arohaneng hantle li ka baka li-granules tse sa tloaheleheng, tse lerōle le phallo e tlase. Li-blade tse feto-fetohang li lumella ho chorisa ka bomong, ho eketsang bophelo ba lehare le ho boloka boholo ba granule bo tsitsitse. Ho hlahloba khafetsa le tlhokomelo e thibelang, joalo ka ho chorisa le ho lokisa lekhalo, ho thusa ho fokotsa nako ea ho theoha.

| Karolo | Kakaretso ea Bopaki |

|---|---|

| Lisebelisoa tsa Blade | Tungsten carbide le li-blades tsa tšepe tse lebelo le phahameng li fana ka khanyetso e phahameng ea ho apara le bophelo bo bolelele ba ts'ebeletso, ho fokotsa khafetsa ea tlhokomelo. |

| Blade Gap | Lekhalo le nepahetseng la lehare (0.1-0.3 mm) le bohlokoa bakeng sa ho itšeha ka katleho; lekhalo le fosahetseng le baka li-blades tse lerootho, li-granules tse sa lekaneng, le tlhokomelo e eketsehileng. |

| Moqapi oa Blade | Moralo oa thipa oa Spiral o ntlafatsa ts'ebetso ea ho itšeha hape o fokotsa ho koala, o ntlafatsa boleng ba granule. |

| Mekhoa ea Tlhokomelo | Ho hloekisa khafetsa, ho tlotsa, le ho leka-lekanya ho leka-lekana ho eketsa bophelo ba lehare le ho boloka ho tšoana ha granule. |

| Tšusumetso ea Moqapi o Fosahetseng | Boemo bo bobe ba lehare bo lebisa ho lerōle, li-granules tse sa tšoaneng le litlhoko tsa tlhokomelo khafetsa. |

Granulator ea polasetiki e nang le theknoloji e tsoetseng pele ea ho itšeha le li-blades tse entsoeng hantle e fana ka ts'ebetso e tšepahalang, li-granules tsa boleng bo holimo le litšenyehelo tse tlase tsa tlhokomelo.

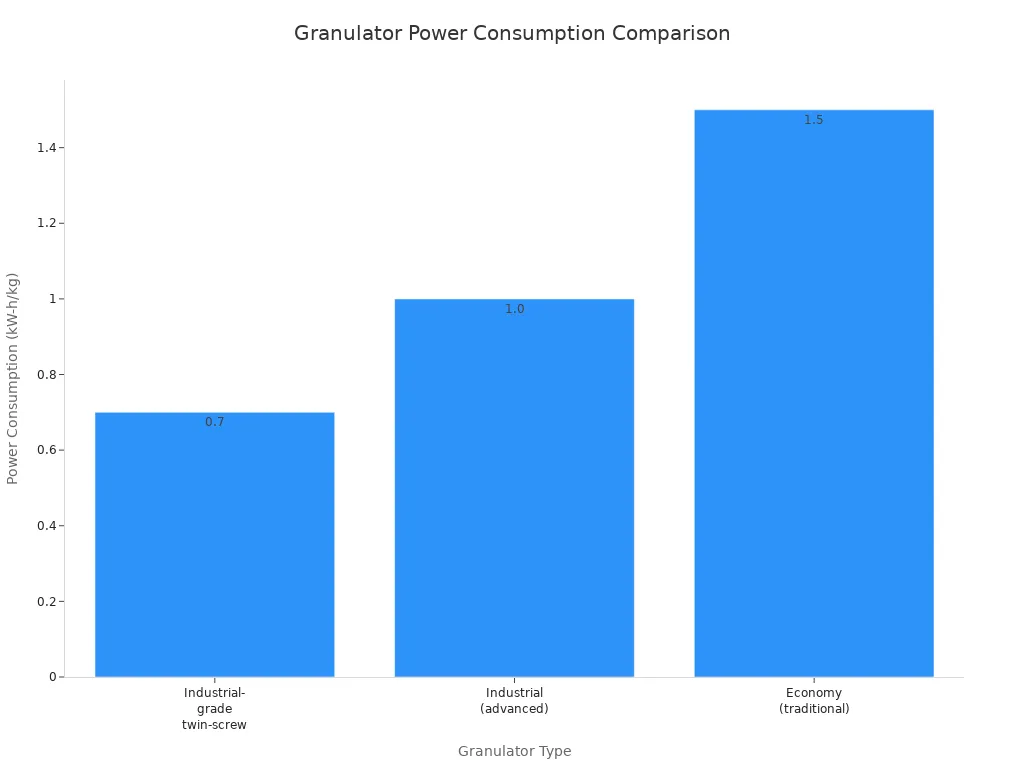

Matla a Matla le Phokotso ea Lerata

Tšebeliso ea matla a matla e fetohile ntho e ka sehloohong ea tlhahiso ea morao-rao. Li-granulator tsa polasetiki tse tsoetseng pele li sebelisa li-motor tse bolokang matla le lisebelisoa tse bohlale tsa ho laola mocheso ho fokotsa tšebeliso ea matla. Meetso ea li-twin-screw tsa boemo ba indasteri e ka sebelisa matla a ka tlase ho 40% ho feta mekhoa ea khale ea moruo. Ntlafatso ena e theola litšenyehelo tsa ts'ebetso mme e ts'ehetsa merero ea ts'ebetso.

Ho fokotsa lerata ke ntlha e ’ngoe ea bohlokoa mosebetsing. Li-granulator tsa polasetiki li ka ba lerata, empa joale bahlahisi ba fana ka mefuta e sa utloahaleng le meralo e fokotsang lerata. Likhase tse sa keneng molumo le litaolo tsa othomathike ka botlalo li thusa maemo a tlase a lerata, ho etsa hore tikoloho ea mosebetsi e bolokehe le ho phutholoha haholoanyane. Likarolo tsena li boetse li thusa lits'ebeletso ho kopana le melaoana ea lerata ea tikoloho le ho ntlafatsa ts'ebetso ea ts'ebetso ka kakaretso.

Keletso: Ho sebelisa ts'ireletso ea litsebe le ho boloka litšitiso tse sa utloeng molumo ho potoloha granulator ho ka fokotsa ho pepeseha ha lerata ho basebelisi.

Li-granulator tsa sejoale-joale tsa polasetiki li kopanya likarolo tsa ho boloka matla le mahlale a phokotso ea lerata ho theha sebaka sa ts'ebetso se sireletsehileng haholoanyane, se sebetsang hantle le se baballang tikoloho.

Likarolo tsa Tšireletseho le Tumellano

Tšireletseho e ntse e le taba ea bohlokoa setsing sefe kapa sefe se sebelisang granulator ea polasetiki. Mechini e tlameha ho fihlela litekanyetso tse tiileng tsa polokeho ho sireletsa basebelisi le ho netefatsa ts'ebetso e tšepahalang.

- ANSI/PLASTICS B151.11-2021 e fana ka litlhoko tsa polokeho bakeng sa li-granulator, moralo o koahelang, ts'ebetso, tlhokomelo le phetoho.

- Litekanyetso tse ling tse amehang li kenyelletsa ANSI/PLASTICS B151.1-2017 bakeng sa mechini ea ho bopa ente le ANSI/PLASTICS B151.27-2021 bakeng sa litsamaiso tsa mochini oa liroboto / ente.

- Ho lumellana le litekanyetso tsena ho bohlokoa bakeng sa ts'ebetso e sireletsehileng limmarakeng tse kholo tsa tlhahiso.

Li-granulator tsa polasetiki li hloka litsamaiso tse 'maloa tsa polokeho tse hahelletsoeng ka hare:

- Lits'ebetso tsa ho notlela / tag-out li hakolla motlakase pele ho tlhokomelo kapa ho hloekisa.

- Balebeli le li- interlocks li thibela ho kena ha lithipa tse tsamaeang.

- Likonopo tsa ho emisa ha ts'ohanyetso, lialamo tse thibelang, le litšireletseho tse peli tsa motlakase li fana ka karabelo ea hang-hang likotsing.

- Basebelisi ba tlameha ho apara lisebelisoa tsa ho itšireletsa, tse kang liatlana, mahlo, sefahleho, litsebe le lerōle.

- Ho hlahlojoa khafetsa le ho hlahloba polokeho ea letsatsi le letsatsi ho boloka mochine o le boemong bo sireletsehileng ba ho sebetsa.

- Basebelisi ba hloka koetliso e nepahetseng le litaelo tse hlakileng ka puo eo ba e utloisisang.

Tlhokomeliso: Ho boloka sebaka sa mosebetsi se hloekile ’me se se na litšitiso ho thusa ho thibela ho thella, maeto le likotsi tse ling.

Ka ho latela mekhoa ena ea polokeho le ho latela litekanyetso tse tsebahalang, lits'ebeletso li ka netefatsa ts'ebetso e bolokehileng le e sebetsang ea li-granulator tsa polasetiki.

Mehopolo ea Ts'ebetso ea Granulator ea polasetiki

Mekhoa ea ho fepa le ho Loading Options

Basebelisi ba ka khetha ho tsoa mekhoeng e mengata ea ho fepa ha ba kopanya granulator ea polasetiki moleng oa tlhahiso. Ho fepa ka letsoho ho sebetsa hantle bakeng sa lihlopha tse nyenyane kapa ho sebelisoa nako le nako. Ho fepa ka conveyor ho ts'ehetsa ts'ebetso e tsoelang pele le ho fokotsa mosebetsi oa matsoho. Ho fepa ka roll ho loketse bakeng sa maqephe a polasetiki a masesaane kapa lifilimi.Ho fepa ka lirobotoe eketsa boits'oaro le polokeho ka ho fokotsa ho kopana ha batho le likarolo tse tsamaeang. Mokhoa o mong le o mong o ama katleho le phallo ea thepa ka litsela tse fapaneng.

Ho beha li-granulator ka thōko ho mochine oa khatiso ho boloka sebaka sa fatše le ho tsamaisa mosebetsi. Liphanele tse ka pele li etsa hore ts'ebetso le tlhokomelo e be bonolo. Likhetho tsa ho fepa ka boiketsetso li boetse li fokotsa ts'ebetso ea matsoho, e fokotsang kotsi ea kotsi le ho ntlafatsa lebelo la tlhahiso.

Tafole e ka tlase e totobatsa lintlha tsa bohlokoa tsa ts'ebetso tse lokelang ho nahanoa ha u khetha likhetho tsa ho fepa le ho kenya:

| Ntlha ea Ts'ebetso | Tlhaloso & Litlhaloso |

|---|---|

| Mofuta oa thepa ea polasetiki | Li-plastiki tse thata li hloka li-blades le li-motors tse matla; polasetiki e bonolo e hloka ho tšoaroa ka bonolo. |

| Litlhoko tsa boholo ba Output | Lits'oants'o tse feto-fetohang li thusa ho fihlela boholo bo lakatsehang ba granule bakeng sa lits'ebetso tse tlase. |

| Bokhoni ba Tlhahiso | Tlhahiso e tlameha ho tsamaisana le litlhoko tsa tlhahiso ho qoba mathata. |

| Kopanelo ya Kopanyo | Sistimi ea phepelo e lokela ho hokahana hantle le li-conveyors, liroboto kapa lisebelisoa tse ling tsa othomathike. |

Tlhokomelo le Tlhoekiso Bonolo

Tlhokomelo ea kamehla e boloka granulator ea polasetiki e sebetsa hantle 'me e lelefatsa bophelo ba eona. Basebelisi ba lokela ho etsa tlhahlobo ea letsatsi le letsatsi bakeng sa liboutu tse hlephileng, ho lutla, kapa lerata le sa tloaelehang. Ho hloekisa hopper le ho hlahloba kamore ea ho itšeha ka mor'a hore ho be le phetoho e 'ngoe le e' ngoe ho thibela ho bokellana ha thepa. Mesebetsi ea beke le beke e kenyelletsa ho hlahloba lithipa hore na ha ho na lerootho, ho hloekisa li-skrini le li-bearings tsa lubricate. Litokiso tsa khoeli le khoeli tse tebileng tsa ho hloekisa le lekhalo la lithipa li thusa ho boloka bokhoni ba ho itšeha.

- Letsatsi le Letsatsi: Lekola tšenyo, hlakola litšitiso, 'me u hlahlobe likarolo tsa polokeho.

- Beke le beke: Hlahloba lithipa le li-skrini, li-bearings tsa lubricate, 'me u hatelle li-fasteners.

- Kgwedi le Kgwedi: Dikamore tse hlwekileng ka botebo, lokisa dikheo tsa dithipa, mme o hlahlobe dikgokelo tsa motlakase.

- Seka-Selemo/Selemo: Rena kapa u fetole lithipa, fetola likarolo tse tsofetseng, 'me u hlahlobe ka botlalo.

Ho sebelisa likarolo tsa moetsi oa lisebelisoa tsa mantlha (OEM) le ho latela mekhoa e tiileng ea polokeho ho netefatsa boleng le polokeho ea opareitara. Ho boloka sebaka sa mosebetsi se hloekile ho boetse ho tšehetsa tlhokomelo e nepahetseng.

Durability le Haha Boleng

Ho tšoarella ho phetha karolo ea bohlokoa molemong oa nako e telele oa granulator ea polasetiki. Mechini e hahiloeng ka litšepe tse kentsoeng mochesong le li-motor tse matla li mamella tšebeliso e matla le lisebelisoa tse chefo. Mohaho oa modular o lumella ho fetoha ha karolo kapele, ho fokotsa nako ea ho theoha. Meralo e fumanehang habonolo e etsa liphetoho tsa blade le ho hloekisa kapele, e thusang ho boloka bohloeki le katleho.

Boleng bo phahameng ba ho haha bo ka eketsa nako ea bophelo ea granulator ho lilemo tse 10-20. Ho hlahlojoa khafetsa, ho tlotsoa ka mokhoa o nepahetseng, le ho nkela likarolo tse tsofetseng sebaka ka nako ho boloka mochine o tšepahala. Liforeimi tse matla le likarolo tsa boleng li theola litšenyehelo tsa ts'ebetso le ho fokotsa tlhoko ea ho lokisoa khafetsa.

Ho tsetela ho granulator e tšoarellang ho ts'ehetsa tlhahiso e tsoelang pele 'me ho thusa lits'ebeletso ho fumana poloko ea nako e telele ea litšenyehelo.

Tšehetso ea Ka mor'a Thekiso le Likarolo tsa Spare

Tšehetso ea ka mor'a ho rekisa e phetha karolo ea bohlokoa katlehong ea nako e telele ea ts'ebetso leha e le efe ea ho lokisa polasetiki. Likhamphani tse liindastering tsa ho bopa le ho etsa liente li itšetlehile ka litšebeletso tse tšepahalang ho boloka lisebelisoa tsa tsona li sebetsa hantle. Ha mochine o emisa ho sebetsa, tlhahiso e ka ema, e lebisang ho lahleheloa ke nako le chelete. Tšehetso e ka tšeptjoang ka mor'a thekiso e thusa ho thibela mathata ana 'me e tiisa ho hlaphoheloa kapele ha mathata a hlaha.

Basebelisi ba bangata ba ananela mefuta e mengata ea litšebeletso tsa morao-rao. Tsena li kenyelletsa:

- Ho fumana litsebi tse nang le phihlelo ea tšebeletso ea tšimo tse ka hlahlobang le ho lokisa mathata setšeng.

- Tsebo ea ts'ebeliso e thusang basebelisi ho fumana molemo ka ho fetisisa mechini ea bona.

- Tšehetso e sa thekeseleng e tsoang ho mofani oa thepa, e hahang tšepo le kholiseho.

Lisebelisoa tsa ho tsosolosa hangata li tobana le mathata a ikhethang. Ba rua molemo ho:

- Therisano ea litsebi e tsamaellanang le mekhoa ea bona ea ho e sebelisa hape.

- Koetliso e felletseng bakeng sa basebetsi ho sebetsa le ho hlokomela lisebelisoa ka polokeho.

- Thuso e tsoelang pele ea tekheniki ho rarolla mathata a sa lebelloang.

Basebelisi ba ho etsa ente ba boetse ba batla:

- Kenyelletso ea litsebi ho netefatsa hore mechini e sebetsa hantle ho tloha qalong.

- Koetliso e phethahetseng bakeng sa basebetsi bohle.

- Thuso e tšepahalang ea botekgeniki le phepelo e tsitsitseng ea likarolo tse ling.

- Litšebeletso tsa tlhokomelo tse thusang ho lelefatsa bophelo ba lisebelisoa.

Lisebelisoa tsa tšehetso tse fumanehang li etsa phapang. Lik'hamphani tse ngata li fana ka:

- Litšebeletso tsa lipuisano ho araba lipotso le ho fana ka tataiso.

- Tšehetso ea video bakeng sa ho rarolla mathata le ho lokisa.

- Lipotso tse thusang basebelisi ho rarolla mathata a tloaelehileng kapele.

Keletso: Ho boloka thepa ea lisebelisoa tsa bohlokoa sebakeng sa marang-rang ho ka fokotsa nako ea ho phomola le ho boloka tlhahiso e ntse e tsoela pele.

Sistimi e matla ea tšehetso kamora thekiso e netefatsa hore mechini e lula e tšepahala ebile e sebetsa hantle. E boetse e fa basebetsi kholiseho ea ho sebetsana le mathata a letsatsi le letsatsi le moralo oa kholo ea nako e tlang.

Ho Khetha Granulator ea Plastiki e nepahetseng

Ho Bapisa Mefuta ea Granulator ho Lisebelisoa le Mekhoa

Ho khetha granulator e nepahetseng ho qala ka ho utloisisa lisebelisoa le lits'ebetso tse sebelisoang. Mehaho e meng e sebetsa lipolasetiki tse thata joalo ka ABS kapa polycarbonate. Tse ling li sebetsana le lisebelisoa tse bonolo tse kang filimi ea polyethylene. Mofuta o mong le o mong oa thepa o hloka kamore e khethehileng ea ho itšeha le moralo oa lehare. Ka mohlala, likarolo tse teteaneng tse nang le marako li hloka kamore ea tangential, ha lifilimi tse tšesaane li sebetsa hantle ka li-rotor tse bulehileng. Basebelisi ba boetse ba lokela ho nahana ka boholo ba sekhechana le boholo bo hlokahalang ba tlhahiso. Libaka tse phahameng tsa ho tsosolosa li ka 'na tsa hloka mefuta e meholo, e boima.Mabenkele a ho bopa ka entehangata ba khetha li-compact, tse ka thoko ho li-unit tsa khatiso. Ho bapisa mofuta oa granulator ho thepa le ts'ebetso ho netefatsa ts'ebetso e sebetsang le liphetho tsa boleng bo holimo.

Litšenyehelo tse leka-lekaneng, Boleng, le Ts'ebetso ea Nako e Telele

Litšenyehelo li phetha karolo e kholo khethong ea lisebelisoa. Leha ho le joalo, theko e tlaase ka ho fetisisa hase kamehla e bolelang boleng bo molemo ka ho fetisisa. Lisebelisoa li lokela ho sheba kakaretso ea litšenyehelo tsa beng. Sena se kenyelletsa tšebeliso ea matla, tlhokomelo, le ho fumaneha ha likarolo tse ling. Mechini e nang le lienjene tse baballang matla le li-blade tse tšoarellang hangata li boloka chelete ha nako e ntse e ea. Tšehetso e ka tšeptjoang ka mor'a thekiso e ka fokotsa litšenyehelo tsa ho theoha le ho lokisa. Ho tsetela ho granulator ea boleng bo holimo ho thusa ho boloka tlhahiso e tsitsitseng le ho fokotsa litšenyehelo tsa nako e telele.

Keletso: Nahana ka nako e lebelletsoeng ea bophelo le litlhoko tsa tlhokomelo pele u reka. Mochine o hahiloeng hantle o ka tšoarella lilemo tse ngata ka tlhokomelo e nepahetseng.

Lethathamo la Khetho ea Granulator

Basebelisi ba ka sebelisa lethathamo ho tataisa liqeto tsa bona:

- Hlalosa mefuta le boholo ba lisebelisoa tsa polasetiki tse lokelang ho sebetsoa.

- Hakanya palo ea ts'ebetso ea letsatsi le letsatsi kapa beke le beke.

- Hlahloba ho lumellana le mekhoa e teng ea ho fepa le ea ho ntša metsi.

- Lekola likarolo tsa polokeho le ho latela maemo a indasteri.

- Hlahloba matla a matla le maemo a lerata.

- Lekola boiketlo ba tlhokomelo le tlhoekiso.

- Netefatsa boteng ba likarolo tse ling le tšehetso ea tekheniki.

- Bapisa kakaretso ea litšenyehelo tsa botho, eseng theko ea theko feela.

Tlhahlobo e hlokolosi ea lintlha tsena e thusa ho netefatsa hore granulator ea polasetiki e khethiloeng e fihlela litlhoko tsa hajoale le tsa nako e tlang.

Ho khetha lisebelisoa tse nepahetseng ho netefatsa ts'ebetso e bonolo ho recycling le molding ea ente. Lisebelisoa li rua molemo ho mechini e fanang ka katleho ea litšenyehelo, e tšehetsang lipakane tsa tikoloho, le ho ntlafatsa lebelo la tlhahiso. Melemo ea bohlokoa e kenyelletsa:

- Litsenyehelo tse tlase tsa thepa e tala ka ho recycle.

- Matlakala a polasetiki a fokotsehileng bakeng sa tikoloho e hlwekileng.

- Ho bonolo ho sebetsana le ho boloka thepa ea granulated.

- Boleng bo lumellanang ba sehlahisoa se nang le li-granules tse tšoanang.

- Tlhokomelo e bonolo le libaka tse sireletsehileng, tse hloekileng tsa mosebetsi.

Basebelisi ba lokela ho sebelisa lenane ho tataisa liqeto tsa bona le ho fumana katleho ea nako e telele.

LBH

Ke mefuta efe ea polasetiki e ka etsang granulator?

Bohololi-granulator tsa polasetikitšoara lisebelisoa tse tloaelehileng tse kang ABS, PP, PE, PVC, le PET. Mefuta e meng e boetse e sebetsa lipolasetiki tsa boenjiniere kapa lisebelisoa tse nang le fiber ea khalase. Kamehla hlahloba lintlha tsa mochini bakeng sa ho lumellana.

Ke hangata hakae basebetsi ba lokelang ho lokisa granulator?

Basebelisi ba lokela ho hlahloba granulator letsatsi le leng le le leng bakeng sa ho senyeha kapa ho senyeha. Ho hloekisa beke le beke le ho tlotsa ho thusa ho boloka ts'ebetso. Ho hloekisa ho tebileng ha khoeli le khoeli le licheke tsa blade li eketsa bophelo ba mochini le ho netefatsa ts'ebetso e bolokehileng.

Ke hobane'ng ha boholo ba likaroloana tse tšoanang bo le bohlokoa ho granulation ea polasetiki?

Saese e tšoanang ea likaroloana e netefatsa phepelo e bonolo mochining oa ho bopa ente. E boetse e ntlafatsa ho qhibiliha le ho kopanya nakong ea ho tsosolosa. Li-granules tse tsitsitseng li thusa ho boloka boleng ba sehlahisoa le ho fokotsa litšila.

Na granulator ea polasetiki e ka fokotsa litšenyehelo tsa matla?

Ee. Li-granulator tse baballang matla li sebelisa li-motor tse tsoetseng pele le li-control tse bohlale. Lintlha tsena li fokotsa tšebeliso ea motlakase le ho fokotsa litšenyehelo tsa ts'ebetso ha nako e ntse e ea.

Ke likarolo life tsa polokeho tse lokelang ho kenyelletsa granulator ea polasetiki?

Granulator ea boleng e kenyelletsa likonopo tsa ho emisa ts'ohanyetso, li-interlock tsa polokeho, le lits'ebetso tsa ho notlela/tag-out. Likarolo tsena li sireletsa basebelisi le lits'ebeletso tsa thuso ho fihlela litekanyetso tsa polokeho ea indasteri.

Nako ea poso: Jul-17-2025