A plastiki granulatorinoita basa rakakosha mune zvese kudzokorodza uye jekiseni molding zvivakwa. Vashandi vanokoshesa michina inogadzira yunifomu granules, sezvo kuwirirana uku kunowedzera mashandiro ekudzokorora uye inotsigira kugadzirwa kwakatsetseka. Yepamberi granulator michina inobata akawanda marudzi emapurasitiki, achipa kuchinjika kumapurojekiti akasiyana. Maitiro ekuchengetedza magetsi mumakina aya anobatsira kudzikisa mutengo wekushandisa. Mimwe mienzaniso, senge agranule epurasitiki muchinakana aplastic crusher, zvakare kuderedza tsvina nekugadzirisa kushandiswa kwezvinhu. Uhu hunhu hunotsigira kusimba uye kuita kwakavimbika munzvimbo dzemazuva ano dzepurasitiki yekugadzirisa.

Key Takeaways

- Plastic granulators inofanirwa kuburitsa mayunifomu kuti ive nechokwadi chekuenderana kwemhando yechigadzirwa uye kunyatso dzokorora kana kuumba.

- Kusarudza iyo granulator chaiyo zvinoenderana nerudzi rwepurasitiki, vhoriyamu yekugadzirisa, uye zvinodiwa zvekushandisa senge kudzokorodza kanajekiseni kuumba.

- Yepamberi granulator inopa ekuchengetedza simba maficha, kuderedza ruzha, uye nyore kugadzirisa kudzikisa mutengo uye kunatsiridza kuchengetedzwa kwenzvimbo yebasa.

- Akasimba ekuchengetedza maficha, anosanganisira kumira kwechimbichimbi uye kukiya, chengetedza vashandisi uye ubatsire kuzadzisa zviyero zveindasitiri.

- Kuvimbika mushure mekutengesa-rutsigiro uye kugaro gadzirisa kunowedzera hupenyu hwemuchina uye kuchengetedza kugadzirwa kuchifamba zvakanaka.

Plastic Granulator Application Inodiwa

Recycling vs. Injection Molding Zvinodiwa

Kudzokorodza uye jekiseni kuumba nzvimbo yega yega yakasarudzika zvinodiwa paneplastiki granulator. Mukugadzira jekiseni, vashandisi vanowanzo shandisa zvidiki, zvepamusoro-soro granulator padivi pemuchina wekuumba. Michina iyi inobata sprues, runners, uye akaremara zvikamu. Ivo vanotarisa pane compactness uye inobudirira kugadzirisa kwepasi-vhoriyamu zvimedu. Semuyenzaniso, granulator inoshandiswa kuumba jekiseni rePVC inofanira kuputsa zvinhu zvakaoma, zvakaomarara kuita magranules anogona kushandiswa zvakare. Mukupesana, kudzokorodza zvikumbiro kunoda akakura, akasimba magranulator kana shredders. Michina iyi inogadzira tsvina yakakura semabhodhoro, pombi, uye mapepa. Vanoda hukuru hwepamusoro uye kusimba kubata zvakasiyana-siyana zvemhando dzepurasitiki uye saizi. Musiyano muhukuru uye zvimedu mhando inoumba dhizaini uye kushanda kwega yega granulator.

Zvakagovaniswa Zvinodiwa zveMaapplication ari maviri

Zvese kudzokorodza uye kuumba jekiseni zvinotsamira pane zvimwe zvinhu zvakakosha mupurasitiki granulator. Vashandi vanotsvaga michina inogadzira mayunifomu granule saizi, ayo anobatsira kuchengetedza kuenderana kwechigadzirwa. Chengetedzo inoramba iri pamberi pekutanga, saka maficha senge emergency stop mabhatani uye chengetedzo interlocks akakosha. Kuwanikwa kuri nyore kune mablades uye skrini kunobvumira kukurumidza kugadzirisa uye kuchenesa. Zvivakwa zvakawanda zvinosarudza granulator ine yakaderera ruzha mazinga uye nhare dhizaini yekuisa inochinjika. Tafura iri pazasi inoratidza mamwe maitiro akagovaniswa ekushanda:

| Feature | Benefit |

|---|---|

| Uniform granule size | Consistent product quality |

| Safety interlocks | Operator protection |

| Easy kugadzirisa | Yakaderedzwa downtime |

| Low ruzha kushanda | Kuvandudzwa kwenzvimbo yebasa |

| Portability | Flexible kushandiswa munzvimbo dzakasiyana |

Kuongorora Mhando dzeZvinhu uye Kugadzirisa Mavhoriyamu

Zvivako zvinogadzira akawanda marudzi emapurasitiki, anosanganisira sprues, mabhomba, machubhu, mabhodhoro, uye mafirimu. Mamwe mapurasitiki, seaya ane high glass fiber content, anoda akakosha granulator ane nzvimbo yakasimba uye yakakwirira-torque kugaya. Sarudzo yegranulator inobvawo pakugadzirisa vhoriyamu. Mashandiro madiki-diki anoshandisa macompact modhi yezvinhu zvakareruka, nepo nzvimbo huru dzekudzokorora dzichida michina yemaindasitiri inobata matani akati wandei zuva nezuva. Kusarudza iyo granulator chaiyo inogonesa kugadzirisa uye kudzivirira mabhodhoro, ingave chinangwa chiri mukati-mumba kudzokorodza kana kudzikisa marara.

Plastic Granulator Yakakosha Zvimiro

Material Compatibility uye Versatility

Plastiki granulator inofanirwa kubata huwandu hwakawanda hwezvinhu kuti ushumire zvese kudzokorodza uyejekiseni molding applications. Vashandi vanowanzogadzirisa zvinhu zvakadai semabhodhoro akaputirwa, magetsi ekubatanidza, screw pieces, uye extruded profiles. Machina ane akawanda base modhi, seFX 700, FX 1000, uye FX 1600, anobvumira vashandisi kuti vaenzanise granulator kune akasiyana chikamu saizi uye kuburikidza nezvinodiwa. Flexible chamber masisitimu, senge tangential chamber dzezvikamu zvakakura uye offset makamuri ezvikamu zvakakora-madziro, anowedzera kuchinjika.

Ongorora: Customizable hoppers uye madhizaini ekuburitsa anobatsira kukwana granulator mune akasiyana masisitimu masisitimu, zvichiita kuti zvive nyore kusanganisa nemidziyo iripo.

Versatility zvakare zvinoenderana nekugona kugadzirisa mapurasitiki ane akasiyana ekuwedzera kana kuoma mazinga. Magranulator ane nzvimbo isingapfeki uye nyore kugadzirisa kuwana inoderedza nguva yekudzikira uye kuwedzera hupenyu hwemidziyo. Kuwedzeredzwa kwekuchengetedza maficha, anosanganisira redundant interlocks uye solenoid-activated locks, chengetedza vanoshanda panguva yekushandisa. Kudzvinyirirwa kwenzwi kunogadzira ruzha rwakaderera, kuvandudza nzvimbo yebasa. Mamodheru akaita seSL uye G26 akateedzana anomira pachena pakuenderana kwawo kwezvinhu, achitsigira zvese kudzokorodza uye.jekiseni molding maitiro.

Kuburikidza Kukwanisa uye Kubudirira

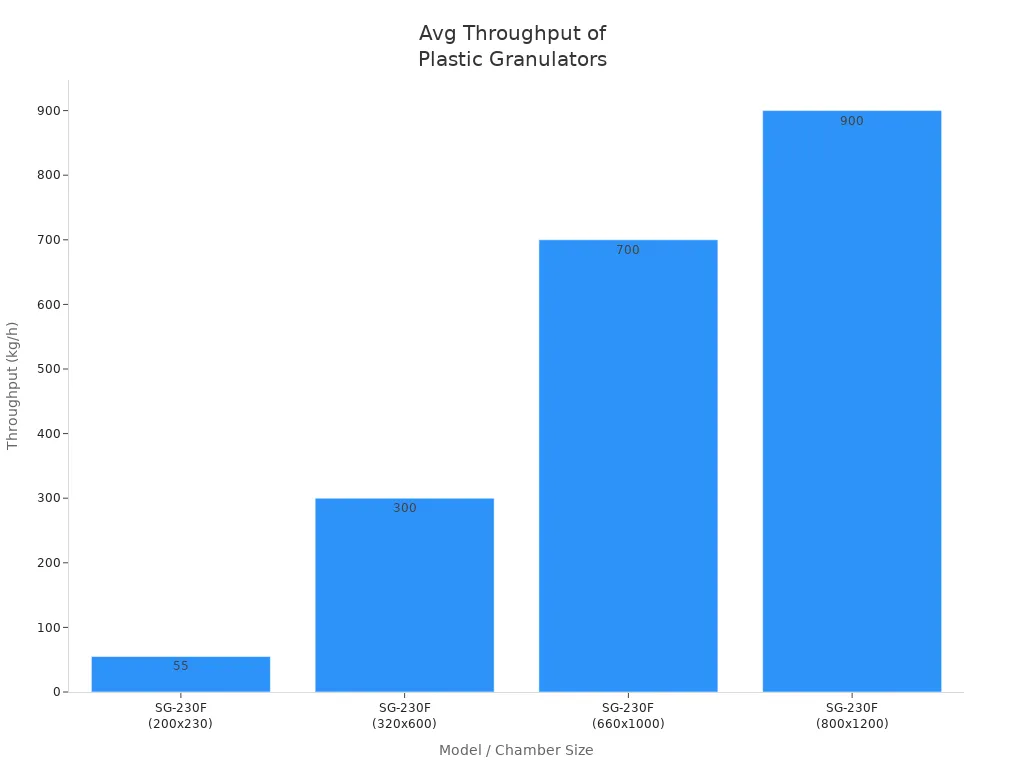

throughput capacity inoyera kuti ingani zvinhu zvinogadzirwa nepurasitiki granulator munguva yakapihwa. Zvishandiso zvinosarudza michina zvichienderana nezvavanoda zuva nezuva kugadzirisa. Makamuri madiki anokodzera kushanda kwakaderera-vhoriyamu, nepo makamuri mahombe anobata kudzokorodza kwakawanda. Tafura iri pazasi inoratidza yakajairika throughput kugona kune akasiyana modhi:

| Muenzaniso / Saizi Yekamuri (mm) | Kukwanisa Kupinza (kg/h) | Motokari Simba (kW) | Notes |

|---|---|---|---|

| SG-230F (200×230) | 50 - 60 | 4 – 45 | Kamuri diki, simba rakaderera |

| SG-230F (320×600) | 250 - 350 | 4 – 45 | Medium chamber |

| SG-230F (660×1000) | 600 - 800 | 4 – 45 | Kamuri hombe |

| SG-230F (800×1200) | 800 - 1,000 | 4 – 45 | Kamuri hombe, kubuda kwepamusoro |

Zvimiro zvepamberi zvinovandudza kushanda uye kunaka kwechigadzirwa. Mapanga anochinjika anotenderera anochengetedza denderedzwa rinogara richicheka mushure mekurodza, iro rinowedzera hupenyu hwebanga uye inova nechokwadi chepamusoro-soro regrind. Madhizaini erotor akadzikama anoderedza maspike emagetsi uye kushandiswa kwesimba, kunyanya kana uchigadzira zvikamu zvakakora. Yakavhurika-rotor dhizaini inosimudzira kuyerera kwemhepo uye kutonhora, izvo zvakakosha kune dzakapfava zvinhu. Hungwaru hwekudyisa masisitimu uye optimized screw uye dhizaini dhizaini inowedzera kuwedzera kuburitsa uye pellet mhando. Magetsi-anoshanda granulator ane akasiyana frequency motors anogona kuchengetedza zviuru zvemadhora mumitengo yemagetsi gore rega rega.

Particle Size Kudzora uye Uniformity

Saizi inopindirana chidimbu yakakosha kune zvese kudzokorodza uye kuumba jekiseni. Inogadziriswa skrini mesh saizi inobvumira vashandisi kudzora granule saizi uye kufanana. High-speed rotors shear mapurasitiki kuita madiki, kunyange zvidimbu. Dust extraction systems inobvisa faindi, uye magineti separators anobata tsvina yesimbi, ichiva nechokwadi chekubuda kwakachena. Smart sensors uye kudzora mapaneru anotarisisa uye gadzirisa kumhanya kwe rotor munguva chaiyo, kuchengetedza particle size inowirirana.

Mazuva ano epurasitiki granulator anoshandisa customizable screen saizi uye inochinjika rotor kumhanya kugadzira yunifomu granules. Kufanana uku kunotsigira kufanofungidzira kuyerera uye kupararira mukuumbwa kwejekiseni, zvichitungamira kumhando yechigadzirwa. Mukudzokorodza, zvimedu zveyunifomu zvinovandudza kuwacha, kunyunguduka, uye kuita pelletizing. Zvishandiso senge vertical color mixers inovimbisa pamusoro pe95% kufanana, kuderedza kuremara uye kunatsiridza mashandiro emuchina.

Zano: Kugarogadzirisa uye smart sensors kunobatsira kuona zvinhu nekukurumidza, kudzivirira kusawirirana kwechikamu chekukura uye kuderedza nguva.

Uniform particle size inobvumirawo kusanganisa kuri nani, kuenderana kwemavara, uye simba remuchina mune zvigadzirwa zvakapedzwa. Machina anopa kukurumidza kuseta shanduko uye otomatiki anochinjika nyore kune akasiyana zvigadzirwa zvinodiwa, kusimudzira kuita kwakasiyana uye kutsigira emhando yepamusoro mhedzisiro mukudzokorodza uye jekiseni kuumba.

Kucheka Technology uye Blade Dhizaini

Kucheka tekinoroji inoumba musimboti weese epurasitiki granulator. Iyo chaiyo blade dhizaini inovimbisa kushanda zvakanaka, emhando yepamusoro granules, uye kushoma kuderera. Mazuva ano granulators anoshandisa akati wandei epamberi kuti asangane nezvinodiwa zvezvese kudzokorodza uye jekiseni kuumba maapplication.

- V-akachekwa rotor mapanga anogadzira yakakwirira-yemhando regrind nemafaindi mashoma, ayo anovandudza kuenderana kwekubuda.

- Mitsara yakawanda yemarotor mapanga, senge 9, 11, kana 13 mitsara, inosimudzira kucheka kugona uye inobvumira muchina kubata mavhoriyamu akakura.

- Inobviswa deflector wedges inoshanda seyechitatu stator blade. Ichi chimiro chinowedzera kucheka hutsinye uye chinobvumira kugadzirisa nekukurumidza panguva yekushanda.

- Oversized rotor bearings uye banga anokwirisa anotsigira anorema-basa recycling mabasa. Izvi zvikamu zvinoramba kupfeka uye kuwedzera hupenyu hwegranulator.

- Pfeka-resistant simbi uye yakaoma-yakatarisana pa rotor uye dzimba dzinodzivirira muchina kubva kune abrasive kana yakasvibiswa zvinhu.

- Kuvakwa kwesimbi kwakasimba kunosimbisa kusimba, kunyangwe munzvimbo dzinoda.

- Heavy-duty outboard bearings, yakaparadzaniswa nekamuri yekucheka, inodzivirira kusvibiswa uye kuderedza dambudziko rekukundikana kusati kwasvika.

Blade dhizaini inokanganisawo kuchengetedza uye granule mhando. Mashizha akagomara kana asina kuparadzaniswa zvakanaka anogona kukonzera asina kufanana, ane guruva granules uye yakaderera throughput. Mablade anochinjika anotenderera anobvumira kurodza kwega, izvo zvinowedzera hupenyu hweblade uye kuchengetedza saizi yegranule yakafanana. Kugara uchiongorora uye kuchengetedza kuchengetedza, sekurodza uye gap kugadzirisa, kubatsira kuderedza nguva.

| Aspect | Pfupiso Yeuchapupu |

|---|---|

| Blade Materials | Tungsten carbide uye high-speed simbi blades inopa yakakwirira kupfeka kuramba uye hupenyu hurefu hwebasa, kuderedza kugadzirisa frequency. |

| Blade Gap | Yakakodzera blade gap (0.1-0.3 mm) inokosha pakucheka kubudirira; gap risiri iro rinokonzeresa mablades akagomara, asina kuenzana granules, uye kuwedzera kuchengetedza. |

| Blade Design | Spiral banga dhizaini inovandudza kucheka mashandiro uye inoderedza kuvharika, inosimudzira granule mhando. |

| Maintenance Practices | Kugara kucheneswa, kudzosa, uye kusimba kuenzanisa kunowedzera hupenyu hweblade uye kuchengetedza granule kufanana. |

| Kukanganisa Kwekugadzira Kwakashata | Mamiriro asina kunaka eblade anotungamira kune guruva, asina-uniform granules uye zvinowanzoitika zvinodikanwa zvekugadzirisa. |

Plastiki granulator ine advanced yekucheka tekinoroji uye yakanyatsogadzirwa blades inopa yakavimbika kuita, emhando yepamusoro granules, uye yakaderera mutengo wekugadzirisa.

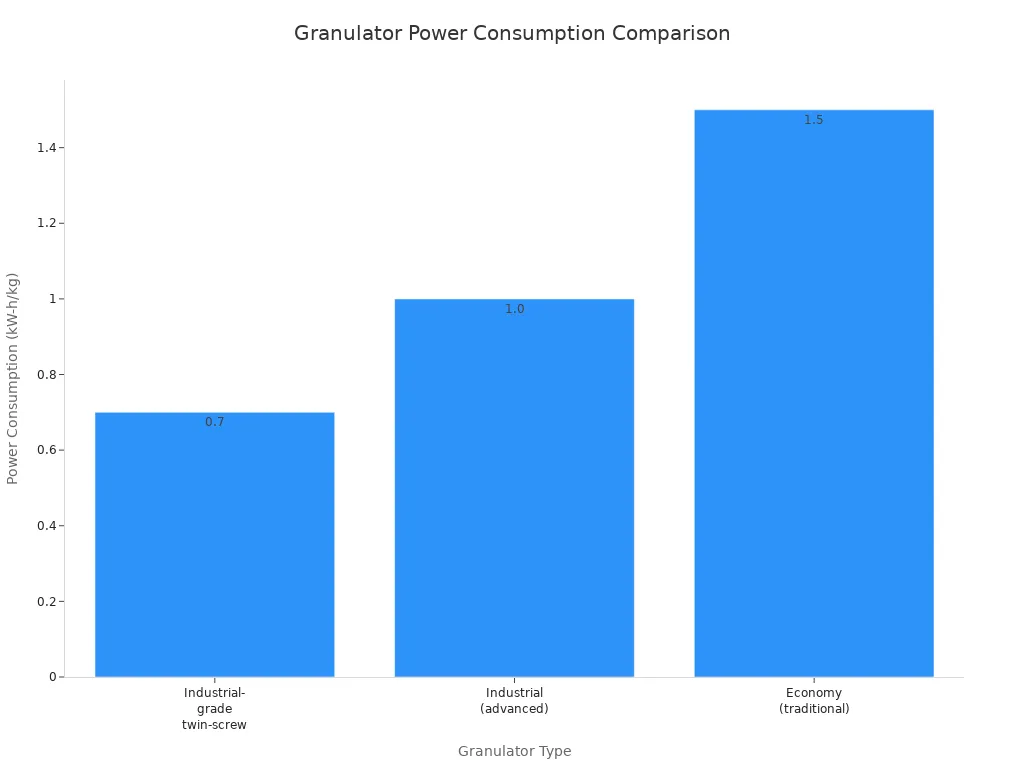

Kushanda Kwesimba uye Kuderedza Ruzha

Kushanda kwemagetsi kwave kunonyanya kukosha mukugadzirwa kwemazuva ano. Yepamberi epurasitiki granulators anoshandisa magetsi-anoshanda mota uye akangwara ekudzora tembiricha masisitimu kuderedza mashandisiro emagetsi. Maindasitiri-giredhi mapatya-screw modhi anogona kushandisa anosvika 40% mashoma simba pane echinyakare ehupfumi mhando. Kuvandudza uku kunoderedza mari yekushandisa uye kunotsigira zvinangwa zvekusimudzira.

Kuderedza ruzha ndechimwe chinhu chinokosha munzvimbo yebasa. Plastic granulators inogona kuita ruzha, asi vanogadzira zvino vanopa mamodheru asina ruzha uye magadzirirwo ekuderedza ruzha. Soundproof casings uye zvizere otomatiki zvinodzora zvinobatsira kudzika mazinga eruzha, zvichiita kuti nzvimbo yebasa ive yakachengeteka uye kugadzikana. Aya maficha anobatsirawo zvivakwa kusangana nemirairo yemheremhere uye kunatsiridza kushanda kwese kushanda zvakanaka.

Zano: Kushandisa kudzivirira nzeve uye kuchengetedza zvipingamupinyi zvinonzwika zvakatenderedza granulator zvinogona kuwedzera kudzikisa kuratidzwa kweruzha kune vanoshanda.

Mapuranga epurasitiki emazuva ano anosanganisa maficha ekuchengetedza simba nematekinoroji ekuderedza ruzha kugadzira nzvimbo yekushandira yakachengeteka, inoshanda zvakanyanya, uye ine hushamwari.

Safety Features uye Kutevedza

Kuchengetedzeka kunoramba kuri kunetseka kwakanyanya mune chero nzvimbo uchishandisa epurasitiki granulator. Machina anofanirwa kusangana akasimba ekuchengetedza zviyero kuchengetedza vashandisi uye kuve nechokwadi chekushanda kwakavimbika.

- ANSI/PLASTICS B151.11-2021 inodonongodza zvinodiwa zvekuchengetedza magranulator, dhizaini yekuvhara, kushanda, kugadzirisa, uye kugadzirisa.

- Mamwe mazinga akakodzera anosanganisira ANSI/PLASTICS B151.1-2017 yemajekiseni ekuumba majekiseni uye ANSI/PLASTICS B151.27-2021 yemarobhoti/jekiseni ekuumba muchina masisitimu.

- Kutevedzera zviyero izvi kwakakosha pakushanda kwakachengeteka mumisika mikuru yekugadzira.

Plastic granulators inoda akati wandei akavakirwa-mukati ekuchengetedza ekudzora:

- Kukiya-kunze/tag-kunze masisitimu anobvisa magetsi asati agadzirisa kana kuchenesa.

- Magadhi uye anovharirana anodzivirira kupinda kwemapanga anofamba.

- Mabhatani ekumisa emergency, maaramu ekuvharisa, uye kuchengetedzwa kwemagetsi maviri zvinopa mhinduro nekukurumidza kune njodzi.

- Vashandi vanofanirwa kupfeka midziyo yekuzvidzivirira, senge magirovhosi, ziso, kumeso, nzeve, uye kudzivirira guruva.

- Kuongororwa nguva dzose uye cheki chekuchengetedza zuva nezuva inochengeta muchina wakachengeteka kushanda.

- Vashandi vanoda kudzidziswa kwakakodzera uye mirayiridzo yakajeka mumutauro wavanonzwisisa.

Cherechedza: Kuchengeta nzvimbo yebasa yakachena uye isina zvipingamupinyi zvinobatsira kudzivirira kutsvedza, nzendo, uye dzimwe tsaona.

Nekutevera aya maitiro ekuchengetedza uye kutevedzera zvinozivikanwa zviyero, zvivakwa zvinogona kuve nekuchengetedza uye kushanda zvakanaka kwemapurasitiki granulators.

Plastic Granulator Kushanda Kufunga

Kudyisa Nzira uye Kurodha Sarudzo

Vashandi vanogona kusarudza kubva kune akati wandei nzira dzekudyisa kana vachibatanidza epurasitiki granulator mumutsara wekugadzira. Kudyisa nemaoko kunoshanda zvakanaka kumabhechi madiki kana kushandiswa pano neapo. Conveyor feeding inotsigira kuenderera mberi kwekushanda uye inoderedza basa remaoko. Roll feeding yakanakira mapepa epurasitiki matete kana mafirimu.Robhoti kudyainowedzera otomatiki uye chengetedzo nekuderedza kubata kwevanhu nezvikamu zvinofamba. Imwe neimwe nzira inokanganisa kushanda kwayo uye kuyerera kwezvinhu nenzira dzakasiyana.

Kuisa ma granulator padivi pemuchina inochengetedza nzvimbo yepasi uye inofambisa mafambiro ebasa. Pamberi pekupinda mapaneru anoita kuti kushanda uye kugadzirisa kuve nyore. Otomatiki yekudyisa sarudzo zvakare inoderedza kubata kwemanyorero, izvo zvinodzikisa njodzi yekukuvara uye inovandudza kukurumidza kwekugadzira.

Tafura iri pazasi inoratidzira zvakakosha zvekushandisa zvekufunga nezvazvo pakusarudza kudyisa uye kurodha sarudzo:

| Operational Factor | Tsanangudzo & Mafungiro |

|---|---|

| Rudzi rwePlastiki Material | Mapurasitiki akaoma anoda mashizha akasimba uye injini; mapurasitiki akapfava anoda kubata zvinyoro. |

| Output Size Zvinodiwa | Anochinjika skrini anobatsira kuwana yaidiwa granule saizi yekudzika kwakadzika maitiro. |

| Kukwanisa Kugadzira | Kuburikidza kunofanirwa kuenderana nekugadzirwa kwezvinodiwa kudzivirira mabhodhoro. |

| Kubatanidzwa Kuenderana | Masisitimu ekudyisa anofanirwa kubatana zvakanaka nemaconveyors, marobhoti, kana imwe otomatiki michina. |

Kugadzirisa uye Kuchenesa Kureruka

Kugaro gadzirisa kunoita kuti girafu repurasitiki rishande zvakanaka uye rinowedzera hupenyu hwayo. Vashandi vanofanirwa kuongorora zuva nezuva mabhaudhi asina kusimba, kuvuza, kana ruzha rusina kujairika. Kuchenesa hopper uye kuongorora kamuri yekucheka mushure mekuchinja kwega kwega kunodzivirira kuvakwa kwezvinhu. Mabasa evhiki nevhiki anosanganisira kutarisa mapanga kuti haana kusimba, kuchenesa masikirini, uye mabheji ekuzora. Mwedzi wega wega kucheneswa kwakadzika uye kugadzirisa kwebanga kunobatsira kuchengetedza kucheka kunyatsoita.

- Zuva nezuva: Ongorora kukuvara, zvakajeka zvipingamupinyi, uye tarisa kuchengetedza maficha.

- Vhiki nevhiki: Ongorora mapanga nezvidzitiro, mabhengi emafuta, uye simbisa zvinosungirira.

- Mwedzi wega wega: Dzimba dzakadzika dzakachena, gadzirisa maburi emapanga, uye ongorora kubatanidza magetsi.

- Semi-Yegore/Yegore: Rodza kana kutsiva mapanga, chinja zvidimbu zvakasakara, uye ita ongororo yakazara.

Kushandisa yepakutanga michina yekugadzira (OEM) zvikamu uye kutevedzera akasimba ekuchengetedza maitiro kunovimbisa kunaka uye kuchengetedzwa kwevashandisi. Kuchengeta nzvimbo yebasa yakachena kunotsigirawo kugadzirisa kwakanaka.

Kugara uye Kuvaka Hunhu

Durability inoita basa rakakosha mukukosha kwenguva refu kwepurasitiki granulator. Michina yakagadzirwa nesimbi inopiswa nekupisa uye mota dzakasimba inoshingirira kushandiswa kwakanyanya uye zvinokurisa. Modular kuvaka inobvumira kukurumidza kutsiva chikamu, kuderedza nguva. Magadzirirwo ari nyore-kuwana anoita shanduko yeblade uye kuchenesa nekukurumidza, izvo zvinobatsira kuchengetedza kupinza uye kushanda nesimba.

Yakakwira yekuvaka mhando inogona kuwedzera hupenyu hwegranulator kusvika kumakore gumi-20. Kuongororwa nguva dzose, kukwizwa kwakakodzera, uye kuchinjwa nenguva kwezvikamu zvakasakara zvinoita kuti muchina wacho uve wakavimbika. Mafuremu akasimba uye zvemhando yepamusoro zvinodzikisira mutengo wekushandisa uye kuderedza kudiwa kwekugadzikiswa.

Kuisa mari mugiyadhi yakasimba inotsigira kuenderera mberi kwekugadzirwa uye kunobatsira zvivakwa kuwana mari yekuchengetedza kwenguva refu.

Mushure-Kutengesa Tsigiro uye Spare Zvikamu

Mushure mekutengesa-rutsigiro inoita basa rakakosha mukubudirira kwenguva refu kwechero purasitiki yekugadzirisa kushanda. Makambani ari mumaindasitiri ekudzokorodza uye majekiseni ekuumba anovimba nebasa rinovimbika kuti midziyo yavo ifambe zvakanaka. Kana muchina wamira kushanda, kugadzirwa kunogona kumira, zvichikonzera kurasikirwa nenguva nemari. Kuvimbika mushure mekutengesa rutsigiro kunobatsira kudzivirira matambudziko aya uye kunovimbisa kupora nekukurumidza kana nyaya dzamuka.

Vazhinji vashandisi vanokoshesa marudzi akati wandei emashure ekutengesa masevhisi. Izvi zvinosanganisira:

- Kuwanikwa kune vane ruzivo rwebasa remumunda vanogona kuongorora nekugadzirisa matambudziko pasaiti.

- Unyanzvi hwekushandisa hunobatsira vashandisi kuwana zvakanyanya kubva kumichina yavo.

- Kutsigira kusingazununguki kubva kumutengesi, izvo zvinovaka kuvimba uye kuvimba.

Zvivako zvekushandisa patsva zvinowanzosangana nematambudziko akasiyana. Vanobatsira kubva:

- Kubvunzana nenyanzvi kwakaenderana nemaitiro avo ekudzokorodza.

- Dzidzo yakakwana yevashandi kuti vashandise uye vachengetedze michina zvakachengeteka.

- Kuenderera mberi rubatsiro rwehunyanzvi kugadzirisa zvinhu zvisingatarisirwe.

Injection molding vashandisi vanotarisawo:

- Kuiswa kwehunyanzvi kuona kuti michina inoshanda nemazvo kubva pakutanga.

- Kudzidziswa kwakakwana kune vese vashandi.

- Rubatsiro rwehunyanzvi rwakavimbika uye kupihwa kwakadzikama kwezvisara.

- Maintenance services anobatsira kuwedzera hupenyu hwemidziyo.

Zviwanikwa zvekutsigira zvinowanika zvinoita mutsauko. Makambani mazhinji anopa:

- Kubvunzana masevhisi kupindura mibvunzo uye kupa nhungamiro.

- Vhidhiyo rutsigiro rwekugadzirisa uye kugadzirisa.

- FAQs dzinobatsira vashandisi kugadzirisa matambudziko akajairika nekukurumidza.

Zano: Kuchengeta stock yeakakosha maspare parts pa-saiti kunogona kuderedza nguva yekudzikira uye kuchengetedza kugadzira kuchifamba.

Iyo yakasimba mushure mekutengesa inotsigira sisitimu inovimbisa kuti michina inogara yakavimbika uye inoshanda. Inopawo vashandisi chivimbo chekubata matambudziko ezuva nezuva uye kuronga kukura mune ramangwana.

Kusarudza Kurudyi Plastic Granulator

Kufananidza Granulator Mhando kune Zvishandiso uye Maitiro

Kusarudza iyo granulator chaiyo kunotanga nekunzwisisa zvinhu uye maitiro ari kushandiswa. Zvimwe zvivakwa zvinogadzira mapurasitiki akaoma seABS kana polycarbonate. Vamwe vanobata zvinhu zvakapfava senge polyethylene firimu. Mhando yega yega yezvinhu inoda chaiyo yekucheka kamuri uye blade dhizaini. Semuyenzaniso, makobvu-amadziro mativi anoda tangential kamuri, nepo matete firimu anoshanda zvakanyanya neakavhurika rotor. Vashandi vanofanirawo kufunga nezvehukuru hwezvimedu uye hukuru hunodiwa hunobuda. Nzvimbo dzepamusoro-soro dzekudzokorora dzinogona kuda mhando dzakakura, dzinorema.Mashopu ekuumba jekisenikazhinji vanosarudza compact, padivi pe-the-press units. Kufananidza rudzi rwegranulator kune zvinhu uye maitiro anovimbisa kushanda kwakanaka uye mhedzisiro yemhando yepamusoro.

Kuenzanisa Mutengo, Kukosha, uye Kushanda Kwenguva Yakareba

Mutengo unobata basa guru mukusarudza michina. Zvisinei, mutengo wakaderera hausi nguva dzose unoreva kukosha kwakanakisisa. Zvivako zvinofanirwa kutarisa mutengo wakazara wevaridzi. Izvi zvinosanganisira kushandiswa kwesimba, kugadzirisa, uye kuwanikwa kwezvisara. Michina ine injini dzinoshanda nesimba uye mablades akasimba kazhinji inochengetedza mari nekufamba kwenguva. Kuvimbika mushure mekutengesa kutsigirwa kunogona kuderedza kuderera uye kugadzirisa mari. Kuisa mari mune yemhando yepamusoro granulator kunobatsira kuchengetedza kugadzirwa kwakafanana uye kunoderedza mari yenguva refu.

Zano: Funga nezvenguva inotarisirwa kurarama uye zvinodiwa kugadzirisa usati watenga. Muchina wakagadzirwa zvakanaka unogona kugara makore mazhinji nekutarisirwa kwakakodzera.

Granulator Sarudzo Yekutarisa

Vashandi vanogona kushandisa chinyorwa kutungamira sarudzo yavo:

- Ziva mhando uye saizi yezvinhu zvepurasitiki zvekugadzirisa.

- Kufungidzira zuva nezuva kana vhiki nevhiki kugadzirisa mavhoriyamu.

- Tarisa kuenderana nezviripo zvekudyisa uye kuburitsa masisitimu.

- Wongorora maficha ekuchengetedza uye kutevedzera zviyero zveindasitiri.

- Ongorora kushandiswa kwesimba uye mazinga eruzha.

- Ongorora kureruka kwekuchengetedza uye kuchenesa.

- Simbisa kuvapo kwezvisara uye rutsigiro rwehunyanzvi.

- Enzanisa mutengo wakakwana wevaridzi, kwete mutengo wekutenga chete.

Kunyatsoongorora kwezvinhu izvi kunobatsira kuona kuti yakasarudzwa yepurasitiki granulator inosangana nezvinodiwa zvazvino uye zveramangwana.

Kusarudza midziyo yakakodzera kunovimbisa kushanda kwakatsetseka mune zvese kudzokorodza uye jekiseni kuumba. Zvishandiso zvinobatsirwa kubva kumakina anopa mutengo unoshanda, anotsigira zvinangwa zvezvakatipoteredza, uye anovandudza kukurumidza kwekugadzira. Mabhenefiti akakosha anosanganisira:

- Mari yepasi mbishi kuburikidza nekudzokorodza.

- Yakaderedzwa tsvina yepurasitiki kuitira nzvimbo yakachena.

- Zviri nyore kubata uye kuchengetedza granulated zvinhu.

- Inopindirana chigadzirwa chemhando neunifomu granules.

- Kugadzirisa kuri nyore uye kwakachengeteka, nzvimbo dzekushandira dzakachena.

Vashandi vanofanira kushandisa rondedzero kutungamira sarudzo yavo uye kuwana budiriro yenguva refu.

FAQ

Ndeapi marudzi emapurasitiki anogona kuita granulator?

Zvizhinjiplastiki granulatorsbata zvinhu zvakajairika senge ABS, PP, PE, PVC, uye PET. Mamwe mamodheru anogadzirisawo mapurasitiki einjiniya kana zvinhu zvine girazi fiber. Gara uchitarisa zvakatemwa nemuchina kuti unoenderana here.

Kangani vafambisi vanofanira kuita gadziriso pagranulator?

Vashandi vanofanira kuongorora granulator zuva nezuva nokuda kwekupfeka kana kukanganisa. Kuchenesa kwevhiki nevhiki nekuzora kunobatsira kuchengetedza kushanda. Mwedzi wega wega kucheneswa kwakadzika uye blade cheki inowedzera hupenyu hwemuchina uye kuona kushanda kwakachengeteka.

Sei yunifomu saizi yakakosha mupurasitiki granulation?

Uniform particle size inovimbisa kudya kwakatsetseka mumajekiseni ekuumba majekiseni. Inovandudzawo kunyunguduka uye kusanganisa panguva yekudzokorora. Consistant granules inobatsira kuchengetedza kunaka kwechigadzirwa uye kuderedza tsvina.

Ko purasitiki granulator inogona kuderedza simba remagetsi?

Ehe. Magetsi anoshandisa magetsi anoshandisa mota dzepamberi uye akangwara kudzora. Izvi zvinoderedza kushandiswa kwemagetsi uye kuderedza mari yekushandisa nekufamba kwenguva.

Ndeapi maficha ekuchengetedza anofanira kusanganisirwa nepurasitiki granulator?

A quality granulator inosanganisira mabhatani ekumisa mbichana, chengetedzo interlocks, uye kukiya-kunze/tag-out masisitimu. Aya maficha anochengetedza vashandisi uye zvivakwa zvekubatsira zvinosangana neindasitiri yekuchengetedza zviyero.

Nguva yekutumira: Jul-17-2025