A yas granulatorplays lub luag haujlwm tseem ceeb hauv kev rov ua dua tshiab thiab txhaj tshuaj molding chaw. Cov neeg ua haujlwm muaj nuj nqis rau cov tshuab uas tsim cov granules sib xws, vim tias qhov sib xws no txhawb nqa cov khoom siv rov ua dua tshiab thiab txhawb kev tsim khoom. Advanced granulator tshuab tuav ntau hom yas, muab kev yooj yim rau ntau qhov haujlwm. Cov yam ntxwv txuag hluav taws xob hauv cov tshuab no pab txo cov nqi ua haujlwm. Qee cov qauv, zoo li agranule yas tshuablos yog ayas crusher, kuj txo cov pov tseg los ntawm kev siv cov khoom siv kom zoo. Cov khoom zoo no txhawb kev ruaj khov thiab txhim khu kev qha hauv cov khoom siv yas niaj hnub.

Ntsiab Cai

- Yas granulators yuav tsum tsim cov granules zoo ib yam los xyuas kom meej cov khoom zoo thiab siv tau zoo los yog molding.

- Xaiv cov granulator txoj cai yog nyob ntawm hom yas, ntim ntim, thiab daim ntawv thov xav tau xws li rov ua dua lossistxhaj tshuaj molding.

- Advanced granulators muaj cov yam ntxwv txuag hluav taws xob, txo suab nrov, thiab kev saib xyuas yooj yim kom txo tus nqi thiab txhim kho kev nyab xeeb ntawm chaw ua haujlwm.

- Cov yam ntxwv muaj kev nyab xeeb muaj zog, suav nrog kev nres thaum muaj xwm txheej ceev thiab kev cuam tshuam, tiv thaiv cov neeg ua haujlwm thiab pab ua kom tau raws li cov qauv kev lag luam.

- Txhim khu kev txhawb nqa tom qab muag thiab kev saib xyuas tsis tu ncua txuas lub tshuab lub neej thiab ua kom cov khoom ua haujlwm zoo.

Yas Granulator Daim Ntawv Thov Xav Tau

Recycling vs. Txhaj Moulding Requirements

Recycling thiab txhaj tshuaj molding txhua qhov chaw tshwj xeeb xav tau ntawm ayas granulator. Hauv kev txhaj tshuaj molding, cov neeg ua haujlwm feem ntau siv me me, ua haujlwm siab granulators ib sab ntawm lub tshuab molding. Cov tshuab no tuav cov sprues, khiav, thiab cov khoom puas. Lawv tsom mus rau compactness thiab ua tau zoo ntawm cov khoom qis qis. Piv txwv li, lub granulator siv rau PVC txhaj tshuaj molding yuav tsum zom cov ntaub ntawv tawv, nruj rau hauv reusable granules. Hauv qhov sib piv, daim ntawv thov rov ua dua yuav tsum muaj cov khoom loj dua, muaj zog dua granulators lossis shredders. Cov tshuab no ua cov khib nyiab loj xws li lub raj mis, kav dej, thiab ntawv. Lawv xav tau lub peev xwm siab dua thiab ua haujlwm ntev los tswj ntau hom yas thiab qhov ntau thiab tsawg. Qhov sib txawv ntawm nplai thiab cov khoom seem tsim cov qauv tsim thiab kev ua haujlwm ntawm txhua granulator.

Kev thov sib koom rau ob daim ntawv thov

Ob qho tib si rov ua dua thiab txhaj tshuaj molding cia siab rau qee yam tseem ceeb hauv cov yas granulator. Cov neeg ua haujlwm saib xyuas cov cav tov uas tsim cov granule sib xws, uas pab tswj cov khoom zoo ib yam. Kev nyab xeeb tseem yog qhov tseem ceeb tshaj plaws, yog li cov yam ntxwv zoo li cov khawm nres thaum muaj xwm ceev thiab kev cuam tshuam kev nyab xeeb yog qhov tseem ceeb. Kev nkag tau yooj yim rau cov hniav thiab cov ntxaij vab tshaus tso cai rau kev tu thiab tu sai. Ntau qhov chaw nyiam granulators uas tsis tshua muaj suab nrov thiab cov qauv siv mobile rau qhov chaw yooj yim. Cov lus hauv qab no qhia txog qee qhov kev sib koom ua haujlwm:

| Feature | Tau txais txiaj ntsig |

|---|---|

| Uniform granule loj | Cov khoom zoo ib yam |

| Kev ruaj ntseg interlocks | Kev tiv thaiv tus neeg ua haujlwm |

| Kev saib xyuas yooj yim | Txo downtime |

| Tsawg suab nrov ua haujlwm | Txhim kho ib puag ncig ua haujlwm |

| Portability | Kev siv tau yooj yim hauv qhov chaw sib txawv |

Kev ntsuas cov khoom siv thiab cov ntim ua haujlwm

Cov chaw ua haujlwm ntau hom yas, suav nrog sprues, plhaub, raj, raj mis, thiab zaj duab xis. Qee cov yas, zoo li cov iav fiber ntau cov ntsiab lus, yuav tsum tau tshwj xeeb granulators nrog cov chaw ruaj khov thiab sib tsoo siab. Kev xaiv ntawm granulator kuj nyob ntawm kev ntim khoom. Kev ua haujlwm me me siv cov qauv compact rau cov khoom siv lub teeb, thaum cov chaw ua haujlwm loj loj xav tau cov tshuab ua haujlwm uas ua haujlwm ntau tons txhua hnub. Xaiv cov granulator txoj cai ua kom muaj txiaj ntsig zoo thiab tiv thaiv kev tsis sib haum xeeb, txawm tias lub hom phiaj yog kev rov ua dua tshiab hauv tsev lossis txo cov khib nyiab loj.

Yas Granulator Qhov tseem ceeb nta

Material Compatibility thiab Versatility

Ib lub yas granulator yuav tsum ua ntau yam khoom siv los ua haujlwm rau ob qho tib si rov ua dua thiabkev txhaj tshuaj molding. Cov neeg ua haujlwm feem ntau ua cov khoom xws li lub raj mis molded, cov khoom siv hluav taws xob, cov ntsia hlau, thiab cov ntawv extruded. Cov cav tov nrog ntau lub hauv paus qauv, zoo li FX 700, FX 1000, thiab FX 1600, tso cai rau cov neeg siv kom phim cov granulator rau qhov sib txawv qhov ntau thiab tsawg thiab cov kev xav tau. Saj zawg zog chamber configurations, xws li tangential chambers rau loj qhov chaw thiab offset chambers rau tuab-walled Cheebtsam, nce adaptability.

Nco tseg: Customizable hoppers thiab tso tawm tsim pab kom haum lub granulator rau hauv ntau qhov system layouts, ua kom yooj yim rau kev koom ua ke nrog cov khoom uas twb muaj lawm.

Versatility kuj nyob ntawm lub peev xwm los ua cov yas nrog cov additives sib txawv los yog qib hardness. Granulators nrog hnav-resistant nto thiab kev saib xyuas yooj yim kom txo tau lub sij hawm poob thiab ua rau lub neej ntev. Txhim kho kev nyab xeeb nta, suav nrog kev sib cuam tshuam tsis tu ncua thiab solenoid-activated locks, tiv thaiv cov neeg ua haujlwm thaum siv. Lub suab txwv tsim suab nrov qis, txhim kho qhov chaw ua haujlwm. Cov qauv zoo li SL thiab G26 series sawv tawm rau lawv cov khoom siv dav dav, txhawb nqa ob qho tib si rov ua dua thiabtxhaj tshuaj molding txheej txheem.

Peev Xwm thiab Efficiency

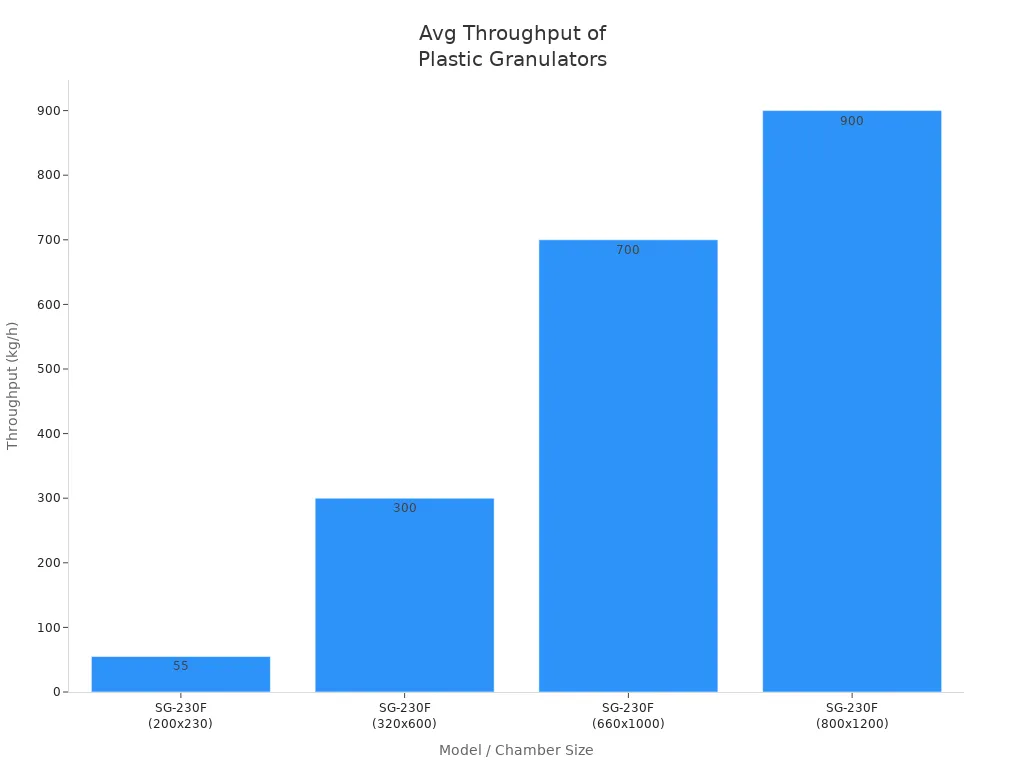

Peev peev xwm ntsuas ntau npaum li cas cov khoom siv yas granulator tuaj yeem ua tiav hauv lub sijhawm. Cov chaw xaiv cov tshuab raws li lawv cov kev xav tau ua txhua hnub. Cov chav me me haum rau kev ua haujlwm qis, thaum cov chav loj tuav cov khoom siv rov ua dua tshiab. Cov lus hauv qab no qhia txog cov peev txheej dhau los ntawm cov qauv sib txawv:

| Qauv / Chamber Loj (mm) | Peev Xwm (kg / h) | Lub cev muaj zog (kW) | Sau ntawv |

|---|---|---|---|

| SG-230F (200 × 230) | 50-60 | 4–45 : kuv | Chamber me me, muaj peev xwm qis dua |

| SG-230F (320 × 600) | 250-350 Nws | 4–45 : kuv | Nruab nrab chamber |

| SG-230F (660 × 1000) | 600-800 Nws | 4–45 : kuv | Loj dua |

| SG-230F (800 × 1200) | 800-1,000 Nws | 4–45 : kuv | Loj tshaj plaws chamber, siab tso zis |

Advanced nta txhim kho efficiency thiab cov khoom zoo. Adjustable rotating riam tuav lub voj voog txiav tas li tom qab sharpening, uas txuas ntxiv riam lub neej thiab ua kom zoo zoo regrind. Staggered rotor designs txo lub zog spikes thiab siv zog, tshwj xeeb tshaj yog thaum ua cov khoom tuab. Open-rotor designs txhim khu airflow thiab txias, uas yog ib qho tseem ceeb rau cov ntaub ntawv mos. Kev txawj ntse noj tshuab thiab optimized ntsia hlau thiab chim tsim ntxiv nce cov zis thiab pellet zoo. Lub zog-npaum granulators nrog lub cev muaj zog sib txawv tuaj yeem txuag tau ntau txhiab nyiaj hauv cov nqi hluav taws xob txhua xyoo.

Particle Size Control thiab Uniformity

Qhov loj me me yog qhov tseem ceeb rau kev rov ua dua tshiab thiab txhaj tshuaj molding. Adjustable screen mesh qhov ntau thiab tsawg tso cai rau cov tswv lag luam los tswj cov granule loj thiab sib xws. High-speed rotors shear plastics rau hauv me me, txawm tias tawg. Cov tshuab nqus plua plav tshem tawm cov nplua nplua, thiab cov khoom sib nqus sib nqus ntes cov hlau tsis huv, ua kom cov khoom tawm huv. Ntse sensors thiab tswj vaj huam sib luag saib xyuas thiab kho rotor ceev hauv lub sijhawm tiag tiag, ua kom cov khoom me me zoo ib yam.

Niaj hnub nimno yas granulators siv customizable npo qhov ntau thiab tsawg thiab adjustable rotor speeds los tsim cov granules. Qhov kev sib txuam no txhawb kev kwv yees tau txaus thiab nthuav dav hauv kev txhaj tshuaj molding, ua rau cov khoom zoo ib yam. Hauv kev rov ua dua tshiab, cov khoom tsis sib xws txhim kho kev ntxuav, yaj, thiab pelletizing efficiency. Cov khoom siv zoo li cov xim ntsug sib xyaw ua kom ntseeg tau ntau dua 95% kev sib txuam, txo qhov tsis xws luag thiab txhim kho kev ua haujlwm zoo.

Tswv yim: Kev saib xyuas tsis tu ncua thiab ntse sensors pab tshawb xyuas cov teeb meem ntxov, tiv thaiv qhov tsis sib xws ntawm qhov loj me thiab txo qis sijhawm.

Uniform particle loj kuj tso cai rau kev sib xyaw zoo dua, xim sib xws, thiab lub zog txhua yam hauv cov khoom tiav. Cov tshuab uas muaj kev hloov pauv sai thiab automation hloov tau yooj yim rau cov khoom siv sib txawv, ua kom muaj ntau yam thiab txhawb nqa cov txiaj ntsig zoo hauv ob qho tib si rov ua dua thiab txhaj tshuaj molding.

Txiav Technology thiab Hniav Tsim

Txiav tshuab tsim cov tub ntxhais ntawm txhua cov yas granulator. Kev tsim cov hniav zoo ua kom muaj kev ua haujlwm zoo, zoo granules, thiab tsawg kawg downtime. Niaj hnub nimno granulators siv ntau yam kev ua haujlwm siab kom ua tau raws li cov kev xav tau ntawm ob qho tib si rov siv dua thiab kev txhaj tshuaj molding.

- V-txiav rotor riam tsim cov khoom zoo zoo nrog cov nplua tsawg, uas txhim kho qhov sib xws ntawm cov zis.

- Ntau kab ntawm rotor riam, xws li 9, 11, lossis 13 kab, txhawb kev txiav lub peev xwm thiab tso cai rau lub tshuab ua cov ntim loj.

- Tshem tau deflector wedges ua raws li qhov thib peb stator hniav. Cov yam ntxwv no ua rau kom muaj kev txhoj puab heev thiab tso cai rau kev hloov kho sai thaum lub sijhawm ua haujlwm.

- Loj rotor bearings thiab riam mounts txhawb nqa hnyav ua haujlwm rov ua dua tshiab. Cov khoom no tiv taus hnav thiab txuas lub neej ntawm granulator.

- Hnav-resistant steels thiab nyuaj-ntsig ntawm rotors thiab vaj tse tiv thaiv lub tshuab los ntawm abrasive los yog cov khoom tsis huv.

- Muaj zog welded steel kev tsim kho kom ruaj khov, txawm tias nyob rau hauv ib puag ncig xav tau.

- Heavy-duty outboard bearings, sib cais los ntawm kev txiav chamber, tiv thaiv kev sib kis thiab txo kev pheej hmoo ntawm kev ua tsis tiav ntxov.

Hniav tsim kuj muaj feem xyuam rau kev tu thiab granule zoo. Cov hniav tsis zoo los yog tsis zoo tuaj yeem ua rau tsis sib xws, plua plav granules thiab qis dua. Adjustable rotating hniav tso cai rau ib tug neeg sharpening, uas extends hniav lub neej thiab ua rau granule loj zoo ib yam. Kev tshuaj xyuas tsis tu ncua thiab kev tiv thaiv kev saib xyuas, xws li kev ua kom pom tseeb thiab kho qhov sib txawv, pab txo qis qis qis.

| Yam | Cov ntaub ntawv pov thawj |

|---|---|

| Cov ntaub ntawv hniav | Tungsten carbide thiab high-speed steel hniav muab siab hnav tsis kam thiab kev pab cuam lub neej ntev, txo kev tu ntau zaus. |

| Hniav Gap | Cov hniav sib txawv (0.1-0.3 hli) yog qhov tseem ceeb rau kev txiav kev ua haujlwm; Qhov sib txawv tsis raug ua rau cov hniav tsis zoo, cov granules tsis sib xws, thiab kev saib xyuas ntau ntxiv. |

| Blade Design | Kauv riam tsim txhim kho kev txiav thiab txo qhov txhaws, txhim kho granule zoo. |

| Cov kev coj ua | Tsis tu ncua tu, lubrication, thiab dynamic tshuav nyiaj li cas calibration txuas hniav lub neej thiab tuav granule uniformity. |

| Kev cuam tshuam ntawm kev tsim tsis zoo | Cov hniav tsis zoo ua rau muaj plua plav, tsis zoo li cov granules thiab xav tau kev saib xyuas ntau zaus. |

Yas granulator nrog cov cuab yeej txiav siab siab thiab cov hniav tsim tau zoo muab cov kev ua tau zoo, cov granules zoo, thiab cov nqi kho mob qis dua.

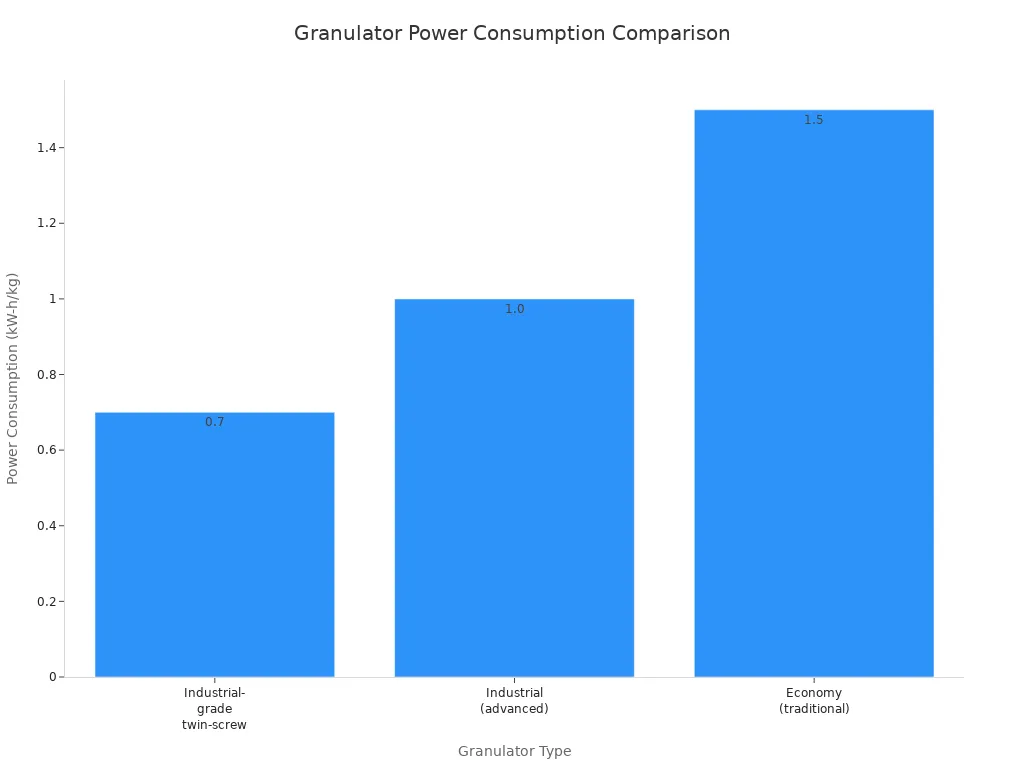

Zog Efficiency thiab suab nrov txo

Lub zog efficiency tau dhau los ua qhov tseem ceeb tshaj plaws hauv kev tsim khoom niaj hnub no. Advanced yas granulators siv lub zog-npaum lub cev muaj zog thiab ntse tswj qhov ntsuas kub kom txo tau lub zog noj. Cov qauv kev lag luam-qib ntxaib-ntsia hlau tuaj yeem siv txog li 40% tsawg zog dua li cov qauv kev lag luam ib txwm muaj. Qhov kev txhim kho no txo qis cov nqi khiav lag luam thiab txhawb nqa cov hom phiaj sustainability.

Kev txo suab nrov yog lwm qhov tseem ceeb hauv chaw ua haujlwm. Yas granulators tuaj yeem ua suab nrov, tab sis cov tuam txhab tam sim no muab cov qauv ua suab nrov thiab cov qauv tsim kom muaj suab nrov. Soundproof casings thiab tag nrho tsis siv neeg tswj pab txo cov suab nrov, ua rau lub chaw ua hauj lwm muaj kev nyab xeeb thiab xis dua. Cov yam ntxwv no tseem pab cov chaw ua kom tau raws li cov cai ntawm ib puag ncig suab nrov thiab txhim kho kev ua haujlwm tag nrho.

Tswv yim: Siv lub pob ntseg tiv thaiv thiab tswj cov suab tsis muaj suab nrov nyob ib ncig ntawm lub granulator tuaj yeem txo qis suab nrov rau cov neeg ua haujlwm.

Niaj hnub nimno yas granulators muab lub zog-txuag nta nrog lub suab nrov txo cov thev naus laus zis los tsim kom muaj kev nyab xeeb dua, muaj txiaj ntsig zoo, thiab ua haujlwm zoo ib puag ncig.

Cov yam ntxwv ntawm kev nyab xeeb thiab kev ua raws cai

Kev nyab xeeb tseem yog ib qho kev txhawj xeeb tseem ceeb hauv txhua qhov chaw siv yas granulator. Cov tshuab yuav tsum ua raws li cov qauv kev nyab xeeb nruj heev los tiv thaiv cov neeg ua haujlwm thiab ua kom ntseeg tau tias kev ua haujlwm ruaj khov.

- ANSI/PLASTICS B151.11-2021 qhia txog kev nyab xeeb rau cov granulators, suav nrog kev tsim, kev ua haujlwm, kev saib xyuas, thiab kev hloov kho.

- Lwm cov qauv tsim muaj xws li ANSI/PLASTICS B151.1-2017 rau kev txhaj tshuaj molding tshuab thiab ANSI/PLASTICS B151.27-2021 rau cov neeg hlau / txhaj tshuaj molding tshuab.

- Ua raws li cov qauv no yog qhov tseem ceeb rau kev ua haujlwm nyab xeeb hauv kev lag luam loj.

Yas granulators xav tau ntau yam kev tswj hwm kev nyab xeeb:

- Lock-out/tag-out systems disconnect fais fab ua ntej tu lossis tu.

- Cov neeg saib xyuas thiab kev cuam tshuam tiv thaiv kev nkag mus rau cov riam txav.

- Cov nyees khawm nres thaum muaj xwm ceev, ceeb toom kev cuam tshuam, thiab kev ruaj ntseg hluav taws xob dual muab cov lus teb tam sim rau kev phom sij.

- Cov neeg ua haujlwm yuav tsum hnav cov khoom tiv thaiv tus kheej, xws li hnab looj tes, qhov muag, ntsej muag, pob ntseg, thiab tiv thaiv plua plav.

- Kev tshuaj xyuas tsis tu ncua thiab kev kuaj xyuas kev nyab xeeb txhua hnub kom lub tshuab ua haujlwm zoo.

- Cov neeg ua haujlwm xav tau kev cob qhia kom raug thiab cov lus qhia meej hauv hom lus lawv nkag siab.

Nco tseg: Khaws thaj chaw ua haujlwm kom huv si thiab tsis muaj kev cuam tshuam yuav pab tiv thaiv kev hla dhau, kev mus ncig, thiab lwm yam xwm txheej.

Los ntawm kev ua raws li cov kev coj ua kev nyab xeeb no thiab ua raws li cov qauv kev lees paub, cov chaw tuaj yeem ua kom muaj kev nyab xeeb thiab ua haujlwm zoo ntawm lawv cov yas granulators.

Yas Granulator Kev txiav txim siab ua haujlwm

Kev pub mis thiab kev xaiv thauj khoom

Cov neeg ua haujlwm tuaj yeem xaiv los ntawm ntau txoj kev pub mis thaum muab cov yas granulator rau hauv cov kab ntau lawm. Kev pub mis los ntawm tes ua haujlwm zoo rau cov khoom me me lossis siv qee zaus. Conveyor feeding txhawb kev ua haujlwm tas mus li thiab txo qis kev ua haujlwm ntawm tes. Yob noj yog zoo tagnrho rau nyias cov ntawv yas los yog zaj duab xis.Neeg hlau pubnce automation thiab kev nyab xeeb los ntawm kev txo tib neeg kev sib cuag nrog cov khoom txav. Txhua txoj kev cuam tshuam rau kev ua tau zoo thiab cov khoom ntws hauv ntau txoj hauv kev.

Muab cov granulators ntawm ib sab ntawm cov xovxwm txuag chaw hauv pem teb thiab ua kom yooj yim rau kev ua haujlwm. Pem hauv ntej nkag panels ua rau kev khiav hauj lwm thiab txij nkawm yooj yim dua. Kev xaiv pub mis tsis siv neeg kuj tseem txo qis kev tuav tuav, uas txo qis kev pheej hmoo ntawm kev raug mob thiab txhim kho kev ua haujlwm ceev.

Cov lus hauv qab no qhia txog cov haujlwm tseem ceeb uas yuav tsum xav txog thaum xaiv cov khoom noj thiab kev thauj khoom:

| Kev ua haujlwm Factor | Kev piav qhia & Kev xav |

|---|---|

| Hom Cov Khoom Siv Yas | Cov yas tawv tawv xav tau cov hniav zoo nkauj thiab lub cev muaj zog; soft plastics yuav tsum tau tuav maj mam. |

| Cov kev xav tau loj | Adjustable cov ntxaij vab tshaus pab ua kom tiav qhov xav tau granule loj rau cov txheej txheem hauv qab. |

| Muaj Peev Xwm Ntau Lawm | Kev xa tawm yuav tsum ua kom haum cov kev xav tau ntau lawm kom tsis txhob muaj qhov khoob. |

| Integration Compatibility | Cov tshuab pub mis yuav tsum txuas nrog cov khoom siv, cov neeg hlau, lossis lwm yam khoom siv automation. |

Kev tu thiab tu yooj yim

Kev saib xyuas tsis tu ncua ua kom cov yas granulator ua haujlwm zoo thiab txuas ntxiv nws txoj sia. Cov neeg khiav dej num yuav tsum tau ua txhua hnub rau cov bolts xoob, xau, lossis suab nrov txawv. Clearing lub hopper thiab tshuaj xyuas lub txiav chamber tom qab txhua qhov kev ua haujlwm tiv thaiv cov khoom tsim. Cov dej num txhua lub limtiam suav nrog xyuas cov riam kom dullness, ntxuav cov ntxaij vab tshaus, thiab lubricating bearings. Txhua hli sib sib zog nqus ntxuav thiab riam qhov sib txawv ntawm kev hloov kho pab tswj kev txiav.

- Txhua Hnub: Tshawb xyuas qhov kev puas tsuaj, tshem tawm cov kev cuam tshuam, thiab xyuas cov yam ntxwv ntawm kev nyab xeeb.

- Txhua lub lim tiam: Tshuaj xyuas cov riam thiab cov ntxaij vab tshaus, lubricate bearings, thiab ceev cov fasteners.

- Txhua hli: Siv cov khoom sib sib zog nqus, kho cov riam hlais, thiab tshuaj xyuas kev sib txuas hluav taws xob.

- Semi-Annual/Annual: Ntxig lossis hloov cov riam, hloov cov khoom hnav, thiab ua qhov kev tshuaj xyuas tag nrho.

Siv cov khoom tsim khoom qub (OEM) qhov chaw thiab ua raws li cov txheej txheem kev nyab xeeb nruj kom ntseeg tau tias muaj kev nyab xeeb thiab tus neeg teb xov tooj. Ua kom thaj chaw ua haujlwm huv si kuj txhawb kev tu kom zoo.

Durability thiab tsim kom zoo

Durability plays lub luag haujlwm tseem ceeb hauv cov nqi mus sij hawm ntev ntawm cov yas granulator. Cov cav tov ua los ntawm cov cua kub-kho steel hniav thiab lub cev muaj zog muaj zog tiv taus kev siv hnyav thiab cov khoom siv abrasive. Kev tsim kho Modular tso cai rau kev hloov pauv sai, txo qis sijhawm. Cov qauv tsim yooj yim ua rau cov hniav hloov pauv thiab ntxuav sai dua, uas pab tswj kev ua kom zoo thiab ua haujlwm zoo.

Kev tsim kom zoo tuaj yeem txuas ntxiv lub neej ntawm granulator mus rau 10-20 xyoo. Kev tshuaj xyuas tsis tu ncua, lubrication kom raug, thiab hloov sijhawm ntawm cov khoom hnav kom lub tshuab txhim khu kev qha. Cov thav duab muaj zog thiab cov khoom ua tau zoo txo qis cov nqi khiav lag luam thiab txo qhov xav tau kev kho ntau zaus.

Kev nqis peev hauv cov granulator ruaj khov txhawb kev tsim khoom tas mus li thiab pab cov chaw ua kom tau txais kev txuag nyiaj mus sij hawm ntev.

Kev them nyiaj yug tom qab muag thiab Spare Parts

Kev txhawb nqa tom qab muag ua lub luag haujlwm tseem ceeb hauv kev ua tiav ntev ntawm kev ua haujlwm ntawm cov yas. Cov tuam txhab lag luam hauv kev rov ua dua tshiab thiab kev txhaj tshuaj molding kev lag luam vam khom cov kev pabcuam kom lawv cov cuab yeej ua haujlwm zoo. Thaum lub tshuab tsis ua haujlwm, kev tsim khoom tuaj yeem nres, ua rau poob sijhawm thiab nyiaj txiag. Txhim khu kev txhawb nqa tom qab muag pab tiv thaiv cov teeb meem no thiab ua kom rov zoo sai thaum muaj teeb meem tshwm sim.

Ntau tus neeg siv khoom muaj nqis rau ntau hom kev pabcuam tomqab muag. Cov no suav nrog:

- Nkag mus rau cov kws tshaj lij kev pabcuam uas muaj peev xwm kuaj xyuas thiab kho cov teeb meem ntawm qhov chaw.

- Daim ntawv thov kev txawj ntse uas pab cov neeg ua haujlwm tau txais txiaj ntsig zoo tshaj plaws ntawm lawv lub tshuab.

- Unwavering kev txhawb nqa los ntawm tus neeg xa khoom, uas ua rau muaj kev ntseeg siab thiab kev ntseeg siab.

Cov khoom siv rov ua dua tshiab feem ntau ntsib cov teeb meem tshwj xeeb. Lawv tau txais txiaj ntsig los ntawm:

- Cov kws tshaj lij kev sib tham tau tsim kho rau lawv cov txheej txheem kev rov ua dua tshiab.

- Kev cob qhia dav rau cov neeg ua haujlwm ua haujlwm thiab tswj cov cuab yeej siv tau zoo.

- Kev pab tsis tu ncua los daws cov teeb meem npaj txhij txog.

Cov neeg siv txhaj tshuaj molding kuj tseem saib rau:

- Kev tshaj lij kev teeb tsa kom ntseeg tau tias cov tshuab ua haujlwm raug txij thaum pib.

- Kev cob qhia zoo rau txhua tus neeg ua haujlwm.

- Txhim khu kev qha kev pab thiab kev ruaj khov ntawm cov khoom seem.

- Cov kev pabcuam tu uas pab txhawb nqa lub neej ntawm cov khoom siv.

Cov peev txheej txhawb nqa siv tau ua qhov sib txawv. Ntau lub tuam txhab muab:

- Kev pab sab laj los teb cov lus nug thiab muab kev taw qhia.

- Kev them nyiaj yug Video rau kev daws teeb meem thiab kho.

- FAQs uas pab cov neeg siv daws cov teeb meem tshwm sim sai.

Tswv yim: Khaws cov khoom lag luam tseem ceeb ntawm qhov chaw tuaj yeem txo qis sijhawm thiab ua kom cov khoom txav mus.

Kev txhawb nqa tom qab muag muaj zog ua kom cov tshuab nyob ruaj khov thiab ua haujlwm tau zoo. Nws tseem ua rau cov neeg ua haujlwm muaj kev ntseeg siab los daws cov teeb meem niaj hnub thiab npaj rau kev loj hlob yav tom ntej.

Xaiv txoj cai yas Granulator

Sib piv Granulator hom rau cov khoom thiab cov txheej txheem

Xaiv qhov zoo granulator pib nrog kev nkag siab txog cov ntaub ntawv thiab cov txheej txheem hauv kev siv. Qee qhov chaw ua cov yas tawv zoo li ABS lossis polycarbonate. Lwm tus tuav cov ntaub ntawv softer xws li polyethylene zaj duab xis. Txhua yam ntaub ntawv xav tau ib tug tshwj xeeb txiav chamber thiab hniav tsim. Piv txwv li, tuab-walled qhov chaw yuav tsum tau ib tug tangential chamber, thaum nyias films ua hauj lwm zoo tshaj plaws nrog qhib rotors. Cov neeg ua haujlwm yuav tsum xav txog qhov loj ntawm cov khoom seem thiab qhov yuav tsum tau tso zis loj. Cov chaw ntim khoom ntim khoom siv ntau yuav xav tau cov qauv loj, hnyav hnyav.Txhaj tshuaj molding khwfeem ntau nyiam compact, ib sab-tus-xovxwm units. Sib piv hom granulator rau cov khoom siv thiab cov txheej txheem ua kom muaj kev ua haujlwm tau zoo thiab cov txiaj ntsig zoo.

Ntsuas tus nqi, tus nqi, thiab kev ua haujlwm ntev

Tus nqi plays lub luag haujlwm tseem ceeb hauv kev xaiv cov khoom siv. Txawm li cas los xij, tus nqi qis tshaj tsis yog ib txwm txhais tau tias tus nqi zoo tshaj plaws. Cov chaw yuav tsum saib tag nrho cov nqi ntawm cov tswv cuab. Qhov no suav nrog kev siv lub zog, kev saib xyuas, thiab cov khoom seem muaj. Cov cav tov nrog lub zog txuag lub cev muaj zog thiab cov hniav ruaj khov feem ntau txuag nyiaj dhau sijhawm. Txhim khu kev txhawb nqa tom qab muag tuaj yeem txo qis sijhawm thiab kho tus nqi. Kev nqis peev hauv cov granulator zoo pab tswj kev tsim khoom zoo ib yam thiab txo cov nqi mus sij hawm ntev.

Tswv yim: Xav txog qhov kev cia siab ntawm lub neej thiab kev tu ncua ua ntej yuav khoom. Lub tshuab ua kom zoo tuaj yeem siv tau ntau xyoo nrog kev saib xyuas kom zoo.

Granulator Selection Checklist

Cov neeg ua haujlwm tuaj yeem siv daim ntawv txheeb xyuas los qhia lawv qhov kev txiav txim siab:

- Txheeb xyuas hom thiab qhov ntau thiab tsawg ntawm cov ntaub ntawv yas los ua.

- Kwv yees cov khoom ntim txhua hnub lossis txhua lub limtiam.

- Tshawb xyuas kev sib raug zoo nrog cov khoom noj uas twb muaj lawm thiab tso tawm.

- Tshawb xyuas cov yam ntxwv kev nyab xeeb thiab ua raws li cov qauv kev lag luam.

- Ntsuas lub zog efficiency thiab suab nrov.

- Ntsuas qhov yooj yim ntawm kev tu thiab tu.

- Paub meej tias muaj cov khoom seem thiab kev txhawb nqa.

- Sib piv tag nrho cov nqi ntawm cov tswv cuab, tsis yog tus nqi yuav khoom xwb.

Kev tshuaj xyuas kom zoo ntawm cov xwm txheej no pab ua kom cov yas granulator tau xaiv raws li qhov xav tau tam sim no thiab yav tom ntej.

Kev xaiv cov cuab yeej tsim nyog ua kom muaj kev ua haujlwm zoo hauv ob qho tib si rov ua dua thiab txhaj tshuaj molding. Cov khoom siv tau txais txiaj ntsig los ntawm cov tshuab uas muab cov nqi ua haujlwm zoo, txhawb nqa ib puag ncig cov hom phiaj, thiab txhim kho kev tsim khoom ceev. Cov txiaj ntsig tseem ceeb muaj xws li:

- Txo cov nqi raw khoom los ntawm kev rov ua dua tshiab.

- Txo cov pov tseg yas kom huv si.

- Yooj yim tuav thiab khaws cov khoom granulated.

- Cov khoom zoo ib yam nrog cov granules sib xws.

- Kev saib xyuas yooj yim thiab muaj kev nyab xeeb dua, huv si ua haujlwm.

Cov neeg ua haujlwm yuav tsum siv daim ntawv txheeb xyuas los coj lawv cov kev txiav txim siab thiab ua tiav kev ua tiav mus ntev.

FAQ

Dab tsi ntawm cov yas tuaj yeem ua cov txheej txheem granulator?

Feem ntauyas granulatorskov cov khoom siv xws li ABS, PP, PE, PVC, thiab PET. Qee cov qauv kuj ua cov yas yas lossis cov khoom siv iav fiber ntau. Nco ntsoov xyuas lub tshuab specifications rau compatibility.

Ntau npaum li cas cov neeg ua haujlwm yuav tsum ua kev saib xyuas ntawm lub granulator?

Cov neeg ua haujlwm yuav tsum tshuaj xyuas lub granulator txhua hnub rau kev hnav lossis kev puas tsuaj. Kev tu txhua lub lim tiam thiab lubrication pab tswj kev ua haujlwm. Txhua hli sib sib zog nqus ntxuav thiab cov hniav kuaj xyuas lub neej ntawm lub tshuab thiab xyuas kom muaj kev nyab xeeb.

Vim li cas cov khoom me me tseem ceeb hauv cov yas granulation?

Uniform particle loj ua kom muaj kev noj qab nyob zoo hauv kev txhaj tshuaj molding tshuab. Nws kuj tseem txhim kho melting thiab sib tov thaum rov ua dua. Cov granules zoo ib yam pab tswj cov khoom zoo thiab txo cov khoom pov tseg.

Cov yas granulator puas tuaj yeem txo cov nqi hluav taws xob?

Yog lawm. Lub zog-npaum granulators siv cov motors siab heev thiab kev tswj ntse. Cov yam ntxwv no txo qis kev siv hluav taws xob thiab txo cov nqi khiav lag luam dhau sijhawm.

Yam kev nyab xeeb dab tsi yuav tsum muaj cov yas granulator suav nrog?

Lub granulator zoo suav nrog cov khawm nres thaum muaj xwm txheej ceev, kev cuam tshuam kev nyab xeeb, thiab kaw-tawm / tag-tawm tshuab. Cov yam ntxwv no tiv thaiv cov neeg ua haujlwm thiab pab cov chaw ua tau raws li cov qauv kev nyab xeeb hauv kev lag luam.

Post lub sij hawm: Lub Xya hli ntuj-17-2025