A granulatorifite uruhare runini haba mu gutunganya no gutera inshinge. Abakoresha baha agaciro imashini zitanga granules imwe, kuko uku guhora kuzamura imbaraga zo gutunganya neza kandi bigashyigikira umusaruro mwiza. Imashini za granulator zigezweho zikoresha ubwoko bwinshi bwa plastiki, zitanga imiterere yimishinga itandukanye. Ibikoresho bizigama ingufu muriyi mashini bifasha kugabanya ibiciro byakazi. Ingero zimwe, nka aimashini ya plastikecyangwa ayamashanyarazi, kandi kugabanya imyanda mugukoresha neza ibikoresho. Izi mico zishyigikira kuramba no gukora neza muburyo bugezweho bwo gutunganya plastiki.

Ibyingenzi

- Imashini ya plastike igomba kubyara granules imwe kugirango ireme neza ibicuruzwa neza kandi bisubirwe neza.

- Guhitamo granulator ibereye biterwa nubwoko bwa plastiki, ingano yo gutunganya, hamwe nibisabwa bikenewe nka recycling cyangwagushushanya inshinge.

- Imashini ziteye imbere zitanga uburyo bwo kuzigama ingufu, kugabanya urusaku, no kubungabunga byoroshye kugabanya ibiciro no kuzamura umutekano wakazi.

- Ibintu bikomeye biranga umutekano, harimo guhagarara byihutirwa no guhuza, kurinda abakora no gufasha kubahiriza ibipimo byinganda.

- Inkunga yizewe nyuma yo kugurisha no kuyitaho byongera ubuzima bwimashini kandi igakomeza umusaruro neza.

Gukoresha Plastike ya Granulator

Gusubiramo hamwe no gutera inshinge Ibisabwa

Gusubiramo no gutera inshinge buri mwanya udasanzwe kuri agranulator. Mugushushanya inshinge, abakoresha akenshi bakoresha ntoya, ikora cyane ya granulators kuruhande rwimashini ibumba. Izi mashini zitwara amasoko, abiruka, nibice bifite inenge. Bibanda ku guhuzagurika no gutunganya neza amajwi make. Kurugero, granulator ikoreshwa mugutera inshinge za PVC igomba gusenya ibikoresho bikomeye, bikomeye muri granules zikoreshwa. Ibinyuranyo, gusubiramo ibicuruzwa bisaba binini, binini cyane bya granulators cyangwa shredders. Izi mashini zitunganya imyanda nini nk'amacupa, imiyoboro, n'amabati. Bakeneye ubushobozi buhanitse kandi burambye kugirango bakemure ubwoko butandukanye bwa plastike nubunini. Itandukaniro mubipimo no gusiba byerekana imiterere nigikorwa cya buri granulator.

Basangiye Ibisabwa Kuri Byombi Porogaramu

Byombi gutunganya no gutera inshinge bishingiye kubintu bimwe na bimwe byingenzi biri muri granulike. Abakoresha bashakisha imashini zitanga ingano ya granule imwe, ifasha kugumana ubuziranenge bwibicuruzwa. Umutekano ukomeje kuba uwambere, kubwibyo biranga ibintu byihutirwa byo guhagarika byihutirwa no guhuza umutekano ni ngombwa. Kubona byoroshye kuri blade na ecran bituma habaho kubungabunga no gukora isuku byihuse. Ibikoresho byinshi bikunda granulators ifite urusaku ruke hamwe nigishushanyo mbonera kigendanwa. Imbonerahamwe ikurikira irerekana bimwe mubikorwa bisangiwe:

| Ikiranga | Inyungu |

|---|---|

| Ingano ya granule imwe | Ubwiza bwibicuruzwa bihoraho |

| Guhuza umutekano | Kurinda abakoresha |

| Kubungabunga byoroshye | Kugabanya igihe |

| Gukoresha urusaku ruke | Kunoza akazi |

| Birashoboka | Gukoresha byoroshye ahantu hatandukanye |

Gusuzuma Ubwoko bwibikoresho hamwe nubunini bwo gutunganya

Ibikoresho bitunganya ubwoko bwinshi bwa plastiki, harimo amasoko, ibishishwa, imiyoboro, amacupa, na firime. Plastiki zimwe, nkibifite ibirahuri byinshi byikirahure, bisaba granulator zidasanzwe zifite ubuso burambye hamwe no gusya cyane. Guhitamo granulator nayo biterwa nubunini bwo gutunganya. Ibikorwa bito bikoresha imashini yoroheje kubikoresho byoroheje, mugihe ibigo binini bitunganya ibicuruzwa bikenera imashini zinganda zitwara toni nyinshi kumunsi. Guhitamo granulatrice ibereye itunganya neza kandi ikarinda icyuho, niba intego ari murugo gutunganya cyangwa kugabanya imyanda minini.

Ibikoresho bya plasitiki byingenzi

Guhuza Ibikoresho no Guhinduka

Imashini ya pulasitike igomba gufata ibikoresho byinshi kugirango ikoreshwe kandigushiramo inshinge. Abakoresha akenshi batunganya ibintu nkamacupa yacuzwe, umuhuza wamashanyarazi, ibice bya screw, hamwe na profili zasohotse. Imashini zifite moderi nyinshi zifatizo, nka FX 700, FX 1000, na FX 1600, zemerera abakoresha guhuza granulator kubice bitandukanye byingana nibikenewe byinjira. Ibikoresho byoroshye bya chambre, nkibyumba bifatika byibyumba binini hamwe nicyumba cya offset kubice bikikijwe n'inkuta, byongera guhuza n'imihindagurikire.

Icyitonderwa: Guhindura ibyiringiro no gusohora ibishushanyo bifasha guhuza granulator muburyo butandukanye bwa sisitemu, byoroshye guhuza nibikoresho bihari.

Guhinduranya kandi biterwa nubushobozi bwo gutunganya plastike hamwe ninyongera zitandukanye cyangwa urwego rukomeye. Granulator ifite isura idashobora kwihanganira no kuyitaho byoroshye igabanya igihe kandi ikongerera ibikoresho ubuzima. Kongera umutekano biranga umutekano, harimo gufunga birenze urugero no gufunga solenoid, kurinda abakoresha mugihe cyo gukoresha. Guhagarika amajwi byerekana urusaku rwo hasi, kunoza akazi. Moderi nka SL na G26 ikurikirana igaragara kubintu byinshi bihuza, bigashyigikira byombi kandiuburyo bwo guterwa inshinge.

Ubushobozi bwo kwinjiza no gukora neza

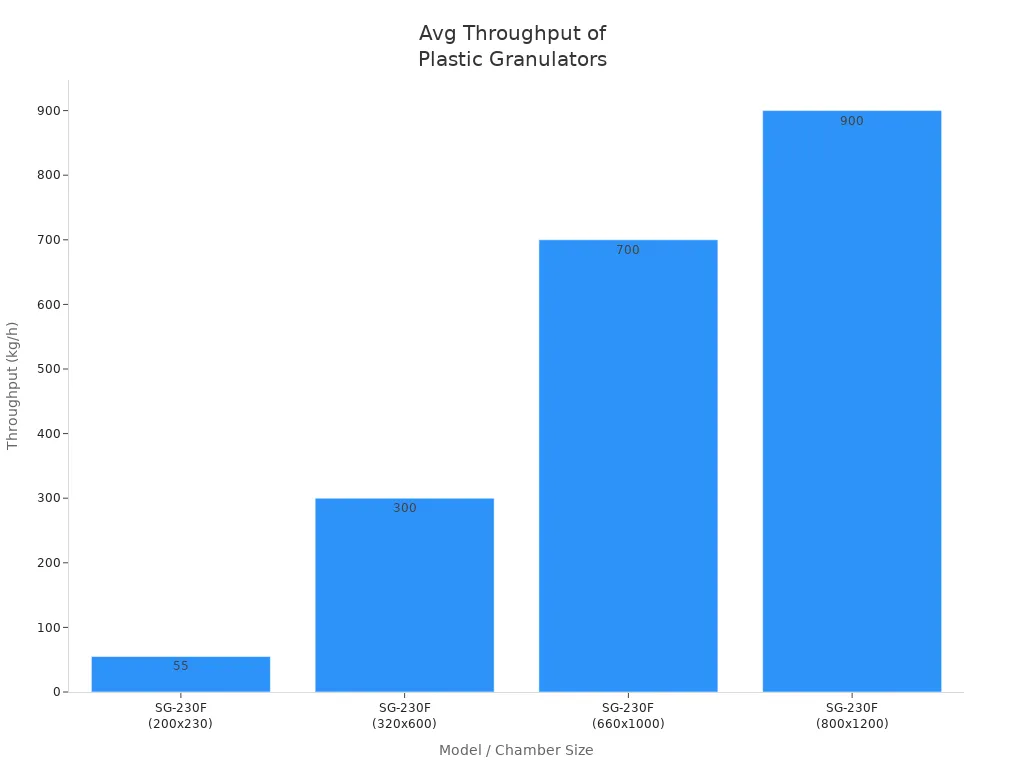

Ubushobozi bwinjiza bupima umubare wibikoresho bya plasitiki ishobora gutunganya mugihe runaka. Ibikoresho bihitamo imashini ukurikije ibyo bakeneye buri munsi. Ibyumba bito bikwiranye nubushobozi buke, mugihe ibyumba binini bikora ibintu byinshi. Imbonerahamwe ikurikira irerekana ubushobozi busanzwe bwo kwinjiza ibintu bitandukanye:

| Icyitegererezo / Ingano y'Urugereko (mm) | Ubushobozi bwo kwinjiza (kg / h) | Imbaraga za moteri (kW) | Inyandiko |

|---|---|---|---|

| SG-230F (200 × 230) | 50 - 60 | 4 - 45 | Icyumba gito, ubushobozi buke |

| SG-230F (320 × 600) | 250 - 350 | 4 - 45 | Icyumba giciriritse |

| SG-230F (660 × 1000) | 600 - 800 | 4 - 45 | Icyumba kinini |

| SG-230F (800 × 1200) | 800 - 1.000 | 4 - 45 | Icyumba kinini, gisohoka cyane |

Ibiranga iterambere bitezimbere imikorere nubuziranenge bwibicuruzwa. Guhindura ibyuma bizunguruka bikomeza uruziga ruhoraho nyuma yo gukarisha, byongerera ubuzima icyuma kandi bigahindura neza. Ibishushanyo mbonera bya rotor bigabanya imbaraga zingufu no gukoresha ingufu, cyane cyane mugutunganya ibice byimbitse. Gufungura-rotor ibishushanyo byongera umwuka no gukonjesha, nibyingenzi kubikoresho byoroshye. Sisitemu yo kugaburira ubwenge hamwe nuburyo bwiza bwa screw na barrel bishushanya kongera umusaruro nubwiza bwa pellet. Imashini ikoresha ingufu hamwe na moteri ihindagurika irashobora kuzigama ibihumbi byamadorari mugiciro cyamashanyarazi buri mwaka.

Ingano yubunini Igenzura nuburinganire

Ingano ihoraho ningirakamaro muburyo bwo gutunganya no gutera inshinge. Ingano ya ecran ya mesh yemerera abashoramari kugenzura ingano ya granule hamwe nuburinganire. Rotor yihuta cyane yogosha plastike mubice bito, ndetse nibice. Sisitemu yo gukuramo ivumbi ikuraho amande, kandi itandukanya magneti ifata ibyuma byangiza, bigatuma umusaruro usohoka. Ibyuma byubwenge hamwe nububiko bugenzura bikurikirana kandi bigahindura umuvuduko wa rotor mugihe nyacyo, bikomeza ubunini buke.

Ibikoresho bya kijyambere bya pulasitiki bifashisha ubunini bwa ecran hamwe na rotor yihuta kugirango bibyare granules imwe. Uku guhuza gushigikira gutembera no gukwirakwizwa muburyo bwo gutera inshinge, biganisha ku bwiza bwibicuruzwa bihoraho. Mu gutunganya ibintu, ibice bimwe biteza imbere gukaraba, gushonga, no gukora neza. Ibikoresho nkibivanze byamabara bihagaritse byemeza hejuru ya 95%, kugabanya inenge no kunoza imikorere yubukanishi.

Impanuro: Kubungabunga buri gihe hamwe na sensor yubwenge bifasha gutahura ibibazo hakiri kare, kurinda ingano yingingo zidahuye no kugabanya igihe.

Ingano imwe yingirakamaro nayo itanga kuvanga neza, guhuza amabara, nimbaraga za mashini mubicuruzwa byarangiye. Imashini zitanga igenamigambi ryihuse hamwe na automatike ihuza byoroshye nibisabwa kubicuruzwa bitandukanye, byongera byinshi kandi bigashyigikira ibisubizo byujuje ubuziranenge haba mu gutunganya no gutera inshinge.

Gukata Ikoranabuhanga hamwe nigishushanyo mbonera

Gukata tekinoroji ikora intandaro ya granateri yose. Igishushanyo cyiburyo cyerekana neza gutunganya neza, granules nziza, hamwe nigihe gito. Imashini zigezweho zikoresha ibintu byinshi byateye imbere kugirango zihuze ibikenewe byombi byongera gukoreshwa no gutera inshinge.

- V-gukata rotor ibyuma birema ubuziranenge bwo kugarura hamwe nibihano bike, bitezimbere guhuza ibisohoka.

- Imirongo myinshi yicyuma cya rotor, nka 9, 11, cyangwa 13, byongera ubushobozi bwo gukata kandi bituma imashini ikora amajwi manini.

- Gukuraho deflector wedges ikora nkicyuma cya gatatu cya stator. Iyi mikorere yongera guca ubukana kandi itanga ihinduka ryihuse mugihe cyo gukora.

- Kurenza urugero rotor hamwe nicyuma gishyigikira imirimo iremereye yo gutunganya. Ibi bice birwanya kwambara no kwagura ubuzima bwa granulator.

- Kwambara ibyuma bidashobora kwangirika no kureba cyane kuri rotor no munzu birinda imashini ibikoresho byangiza cyangwa byanduye.

- Ubwubatsi bukomeye bwo gusudira bwubaka butuma buramba, ndetse no mubidukikije bisaba.

- Ibikoresho biremereye byo hanze, bitandukanijwe nicyumba gikata, birinda kwanduza no kugabanya ibyago byo gutsindwa imburagihe.

Igishushanyo mbonera nacyo kigira ingaruka kubibungabunga hamwe nubwiza bwa granule. Icyuma cyijimye cyangwa kidafite umwanya muto gishobora gutera ibinyampeke, ivumbi hamwe ninjiza yo hasi. Guhinduranya ibyuma bizemerera gukarisha kugiti cye, byongerera ubuzima icyuma kandi bikomeza ubunini bwa granule. Kugenzura buri gihe no kubungabunga ibidukikije, nko gukarisha no guhindura icyuho, bifasha kugabanya igihe cyo gutaha.

| Icyerekezo | Incamake y'ibimenyetso |

|---|---|

| Ibikoresho | Tungsten karbide hamwe nicyuma cyihuta cyicyuma gitanga imbaraga zo kwihanganira kwambara no kuramba kumurimo muremure, kugabanya inshuro zo kubungabunga. |

| Icyuho | Icyuho gikwiye (0.1-0.3 mm) ningirakamaro mugukata neza; icyuho kitari cyo gitera ibyuma bidasobanutse, granules zingana, hamwe no kongera kubungabunga. |

| Igishushanyo | Igishushanyo mbonera cya spiral gitezimbere gukata neza kandi kigabanya gufunga, kuzamura ubwiza bwa granule. |

| Imyitozo yo Kubungabunga | Gukora isuku buri gihe, gusiga amavuta, hamwe no kuringaniza kuringaniza imbaraga byongera ubuzima bwicyuma kandi bikagumana uburinganire bwa granule. |

| Ingaruka zuburyo bubi | Imiterere idahwitse iganisha ku mukungugu, udahuje granules hamwe nibikenewe cyane kubungabungwa. |

Imashini ya pulasitike ifite tekinoroji yo gukata igezweho kandi ikozwe neza itanga imikorere yizewe, granules nziza, hamwe nigiciro cyo kubungabunga.

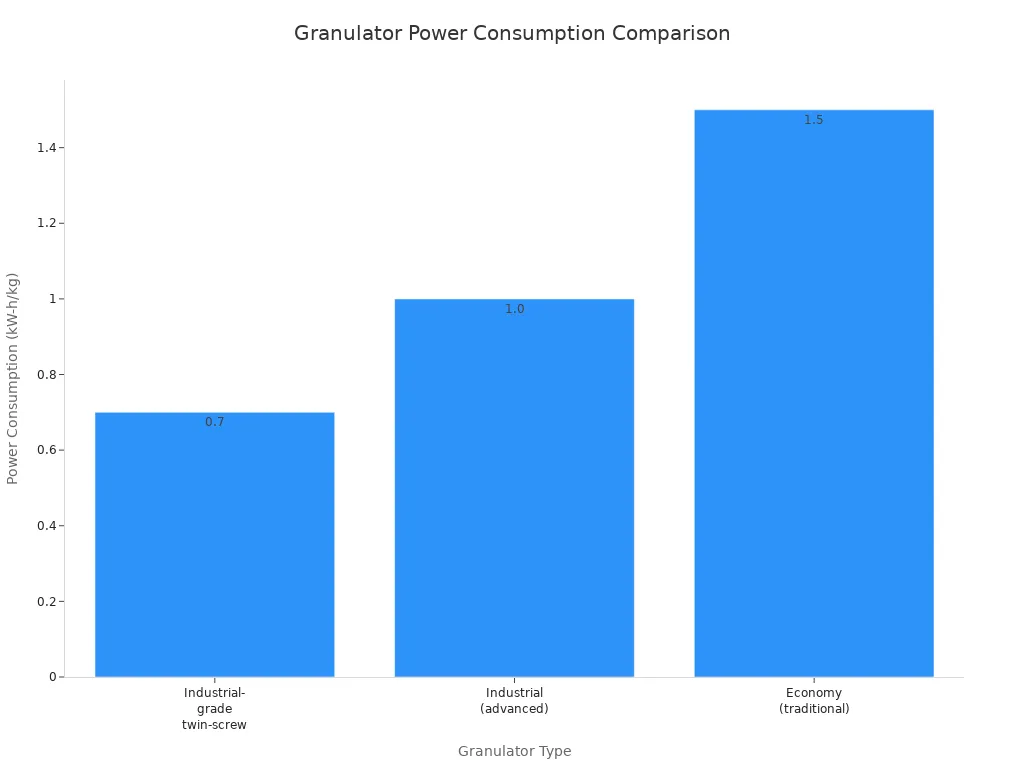

Gukoresha ingufu no kugabanya urusaku

Ingufu zingufu zabaye ikintu cyambere mubikorwa byubu. Imashini ya pulasitike igezweho ikoresha moteri ikoresha ingufu hamwe na sisitemu yo kugenzura ubushyuhe bwubwenge kugirango igabanye gukoresha ingufu. Inganda zo mu rwego rwa nganda zirashobora gukoresha ingufu zingana na 40% ugereranije nubukungu gakondo. Iri terambere rigabanya ibiciro byo gukora kandi rishyigikira intego zirambye.

Kugabanya urusaku ni ikindi kintu cyingenzi mu kazi. Imashini ya plastike irashobora kuba urusaku, ariko abayikora ubu batanga imiterere idakoresha amajwi n'ibishushanyo bigabanya urusaku. Amajwi adafite amajwi hamwe nubushakashatsi bwikora byuzuye bifasha kugabanya urusaku, bigatuma akazi gakorwa neza kandi neza. Ibi biranga kandi bifasha ibikoresho kubahiriza amabwiriza y urusaku rwibidukikije no kunoza imikorere muri rusange.

Impanuro: Gukoresha uburinzi bwamatwi no gukomeza inzitizi zitagira amajwi zikikije granulator birashobora kurushaho kugabanya urusaku kubakoresha.

Ibikoresho bya kijyambere bya pulasitiki bihuza uburyo bwo kuzigama ingufu hamwe n’ikoranabuhanga rigabanya urusaku kugira ngo habeho ahantu hizewe, hakorwa neza, kandi hangiza ibidukikije.

Ibiranga umutekano no kubahiriza

Umutekano ukomeje kuba ikibazo gikomeye mubikoresho byose ukoresheje granatike ya plastike. Imashini zigomba kuba zujuje ubuziranenge bwumutekano kurinda abashoramari no gukora neza.

- ANSI / PLASTICS B151.11-2021 yerekana ibisabwa byumutekano kuri granulator, ikubiyemo igishushanyo, imikorere, kubungabunga, no guhindura.

- Ibindi bipimo bifatika birimo ANSI / PLASTICS B151.1-2017 kumashini ibumba inshinge na ANSI / PLASTICS B151.27-2021 kuri sisitemu ya mashini ya robot / inshinge.

- Kubahiriza ibipimo ngenderwaho nibyingenzi kugirango bikore neza mumasoko akomeye yinganda.

Imashini ya plasitike isaba ibintu byinshi byubatswe mu gucunga umutekano:

- Sisitemu yo gufunga / tag-out sisitemu ihagarika ingufu mbere yo kubungabunga cyangwa gukora isuku.

- Kurinda no gufatanya birinda kugera ku byuma byimuka.

- Guhagarika byihutirwa buto, gutabaza, hamwe nuburyo bubiri bwamashanyarazi bitanga igisubizo cyihuse kubibazo.

- Abakoresha bagomba kwambara ibikoresho birinda umuntu, nk'uturindantoki, ijisho, isura, ugutwi, no gukingira umukungugu.

- Kugenzura buri gihe no kugenzura umutekano wa buri munsi bituma imashini ikora neza.

- Abakoresha bakeneye amahugurwa akwiye n'amabwiriza asobanutse mururimi bumva.

Icyitonderwa: Kugira isuku aho ukorera kandi nta mbogamizi bifasha kwirinda kunyerera, ingendo, nizindi mpanuka.

Mugukurikiza ibyo bikorwa byumutekano no kubahiriza ibipimo byemewe, ibikoresho birashobora gukora neza kandi neza imikorere ya granulatrice.

Ibitekerezo bya Plastike Granulator

Kugaburira Uburyo no Gutwara Amahitamo

Abakoresha barashobora guhitamo muburyo butandukanye bwo kugaburira mugihe bahuza granulike ya plastike mumurongo wo gukora. Kugaburira intoki bikora neza kubice bito cyangwa gukoresha rimwe na rimwe. Kugaburira convoyeur bishyigikira imikorere ikomeza kandi bigabanya imirimo yintoki. Kugaburira kuzunguruka nibyiza kumpapuro za plastike zoroshye.Kugaburira robotbyongera automatike n'umutekano mugabanya imikoranire yabantu nibice byimuka. Buri buryo bugira ingaruka kumikorere no gutembera mubintu muburyo butandukanye.

Gushyira granulators kuruhande rwikinyamakuru bizigama umwanya kandi bikoroshya akazi. Imbere yo kwinjira imbere ituma imikorere no kuyitaho byoroha. Uburyo bwo kugaburira bwikora nabwo bugabanya gukoresha intoki, bigabanya ibyago byo gukomeretsa no kongera umuvuduko wumusaruro.

Imbonerahamwe ikurikira irerekana ibintu byingenzi byingenzi ugomba gusuzuma muguhitamo kugaburira no gupakira:

| Ibikorwa | Ibisobanuro & Ibitekerezo |

|---|---|

| Ubwoko bwibikoresho bya plastiki | Plastiki ikomeye ikenera ibyuma na moteri; plastike yoroshye isaba gufata neza. |

| Ibisohoka Ingano Ibisabwa | Guhindura ibice bifasha kugera kubunini bwa granule yifuzwa kubikorwa byo hasi. |

| Ubushobozi bw'umusaruro | Ibicuruzwa bigomba guhuza umusaruro ukeneye kwirinda icyuho. |

| Kwishyira hamwe | Sisitemu yo kugaburira igomba guhuza neza na convoyeur, robot, cyangwa ibindi bikoresho byikora. |

Kubungabunga no Gusukura Byoroshye

Kubungabunga buri gihe bituma granulatrice ikora neza kandi ikongerera igihe cyayo. Abakoresha bagomba gukora igenzura rya buri munsi kugirango bahindurwe, bitemba, cyangwa urusaku rudasanzwe. Kuraho hopper no kugenzura icyumba gikata nyuma ya buri mwanya birinda kubaka ibintu. Imirimo ya buri cyumweru ikubiyemo kugenzura ibyuma bituje, gusukura ecran, hamwe no gusiga amavuta. Buri kwezi gusukura byimbitse no gutandukanya icyuma bifasha gukomeza kugabanya neza.

- Buri munsi: Kugenzura ibyangiritse, inzitizi zisobanutse, no kugenzura ibiranga umutekano.

- Icyumweru: Suzuma ibyuma na ecran, gusiga amavuta, no gukomera.

- Ukwezi: Ibyumba byera bisukuye, uhindure icyuho, kandi ugenzure amashanyarazi.

- Semi-Annual / Annual: Kongera cyangwa gusimbuza ibyuma, gusimbuza ibice byambarwa, no gukora igenzura ryuzuye.

Gukoresha ibikoresho byumwimerere ukora ibikoresho (OEM) no gukurikiza inzira zumutekano zikomeye byemeza umutekano numutekano. Kugira isuku yumurimo nabyo bifasha kubungabunga neza.

Kuramba no kubaka ubuziranenge

Kuramba bigira uruhare runini mugaciro kigihe kirekire cya granulike ya plastike. Imashini zubatswe nicyuma gikoreshwa nubushyuhe hamwe na moteri ikomeye irwanya ikoreshwa ryinshi nibikoresho byangiza. Ubwubatsi bwubusa butuma igice cyihuta gisimburwa, kugabanya igihe. Ibishushanyo-byoroshye byoroshye gukora blade no gukora isuku byihuse, bifasha kugumana ubukana no gukora neza.

Ubwubatsi buhanitse burashobora kwongerera igihe cya granulator kugeza kumyaka 10-20. Kugenzura buri gihe, gusiga neza, no gusimbuza mugihe cyibice byashaje bituma imashini yizewe. Amakadiri akomeye nibigize ubuziranenge bigabanya ibiciro byakazi kandi bigabanya ibikenewe gusanwa kenshi.

Gushora imari muri granulator iramba ishyigikira umusaruro uhoraho kandi ifasha ibikoresho kugera kubitsa igihe kirekire.

Nyuma yo kugurisha Inkunga hamwe nibice

Inkunga nyuma yo kugurisha igira uruhare runini mugutsindira igihe kirekire ibikorwa byose byo gutunganya plastike. Ibigo mu nganda zongera gutunganya no gutera inshinge zishingiye kuri serivisi zizewe kugirango ibikoresho byazo bigende neza. Iyo imashini ihagaritse gukora, umusaruro urashobora guhagarara, biganisha ku gutakaza igihe n'amafaranga. Inkunga yizewe nyuma yo kugurisha ifasha gukumira ibyo bibazo kandi itanga gukira vuba mugihe ibibazo bivutse.

Abakoresha benshi baha agaciro ubwoko butandukanye bwa serivisi nyuma yo kugurisha. Muri byo harimo:

- Kugera kubanyamwuga ba serivise babishoboye bashobora gusuzuma no gukemura ibibazo kurubuga.

- Ubuhanga bwo gusaba bufasha abakoresha kubona byinshi mumashini zabo.

- Inkunga itajegajega itangwa nuwabitanze, byubaka ikizere nicyizere.

Ibikoresho byo gutunganya ibintu bikunze guhura nibibazo bidasanzwe. Bungukirwa na:

- Impuguke zinzobere zijyanye nuburyo bwihariye bwo gutunganya.

- Amahugurwa yuzuye kubakozi gukora no kubungabunga ibikoresho neza.

- Imfashanyo ya tekiniki ikomeje kugirango ikemure ibibazo bitunguranye.

Abakoresha inshinge bashiraho nabo bareba:

- Kwishyiriraho umwuga kugirango imashini zikore neza guhera.

- Amahugurwa yuzuye kubakozi bose.

- Ubufasha bwizewe bwa tekiniki hamwe no gutanga ibikoresho bihoraho.

- Serivise zo gufata neza zifasha kongera ubuzima bwibikoresho.

Ibikoresho byingirakamaro bigufasha gukora itandukaniro. Ibigo byinshi bitanga:

- Serivisi zo kugisha inama gusubiza ibibazo no gutanga ubuyobozi.

- Inkunga ya videwo yo gukemura no gusana.

- Ibibazo bifasha abakoresha gukemura ibibazo bisanzwe.

Impanuro: Kubika ububiko bwibikoresho byingenzi bikenewe kurubuga birashobora kugabanya igihe cyo gukora kandi bigatuma umusaruro ugenda.

Sisitemu ikomeye nyuma yo kugurisha yemeza ko imashini ziguma zizewe kandi neza. Iha kandi abashoramari ikizere cyo gukemura ibibazo bya buri munsi no gutegura iterambere ryigihe kizaza.

Guhitamo Iburyo bwa Plastike

Guhuza Ubwoko bwa Granulator kubintu nibikoresho

Guhitamo granulator ibereye bitangirana no gusobanukirwa ibikoresho nibikorwa mukoresha. Ibikoresho bimwe bitunganya plastiki zikomeye nka ABS cyangwa polyakarubone. Abandi bakora ibikoresho byoroshye nka polyethylene. Buri bwoko bwibikoresho bukenera icyumba cyo gukata no gushushanya. Kurugero, ibice bikikijwe n'inkuta bisaba icyumba gifatika, mugihe firime yoroheje ikora neza hamwe na rotor ifunguye. Abakoresha bagomba gutekereza ku bunini bwibisakuzo hamwe nubunini busohoka. Ibicuruzwa byinshi byo gutunganya ibicuruzwa birashobora gukenera moderi nini, ziremereye.Amaduka atera inshingeakenshi bikunda guhuzagurika, kuruhande-rw-ibice. Guhuza ubwoko bwa granulator kubintu nibikoresho bigenda neza bikora neza kandi nibisubizo byiza.

Kuringaniza Igiciro, Agaciro, nigihe kirekire

Igiciro kigira uruhare runini muguhitamo ibikoresho. Ariko, igiciro cyo hasi ntabwo buri gihe gisobanura agaciro keza. Ibikoresho bigomba kureba igiciro cyose cya nyirubwite. Ibi birimo gukoresha ingufu, kubungabunga, hamwe nibice byaboneka. Imashini zifite moteri ikoresha ingufu hamwe nicyuma kiramba akenshi bizigama amafaranga mugihe. Inkunga yizewe nyuma yo kugurisha irashobora kugabanya igihe cyo gusana no gusana ibiciro. Gushora imari murwego rwohejuru bifasha gukomeza umusaruro uhoraho kandi bigabanya amafaranga yigihe kirekire.

Impanuro: Reba igihe giteganijwe cyo kubaho no kubungabunga ibikenewe mbere yo kugura. Imashini yubatswe neza irashobora kumara imyaka myinshi witonze.

Urutonde rwa Granulator

Abakoresha barashobora gukoresha urutonde kugirango bayobore icyemezo cyabo:

- Menya ubwoko nubunini bwibikoresho bya pulasitike kugirango bitunganyirizwe.

- Gereranya buri munsi cyangwa icyumweru cyo gutunganya.

- Reba guhuza na sisitemu yo kugaburira no gusohora.

- Subiramo ibiranga umutekano no kubahiriza amahame yinganda.

- Suzuma ingufu zingufu nurwego rwurusaku.

- Suzuma byoroshye kubungabunga no gukora isuku.

- Emeza ko haboneka ibice byabigenewe hamwe ninkunga ya tekiniki.

- Gereranya igiciro cyose cya nyirubwite, ntabwo igiciro cyubuguzi gusa.

Gusubiramo witonze kuri ibi bintu bifasha kwemeza ko granulator yatoranijwe yujuje ibyifuzo byubu nibizaza.

Guhitamo ibikoresho bikwiye bituma imikorere igenda neza haba mu gutunganya no gutera inshinge. Ibikoresho byungukira kumashini zitanga umusaruro ushimishije, zunganira intego zibidukikije, no kuzamura umuvuduko. Ibyiza byingenzi birimo:

- Kugabanuka kubikoresho fatizo binyuze mu gutunganya ibicuruzwa.

- Kugabanya imyanda ya plastike kubidukikije bisukuye.

- Gukoresha byoroshye no kubika ibikoresho byasunitswe.

- Ubwiza bwibicuruzwa bihoraho hamwe na granules imwe.

- Kubungabunga byoroshye kandi bifite umutekano, ahantu hasukuye.

Abakoresha bagomba gukoresha urutonde kugirango bayobore ibyemezo byabo kandi bagere ku ntsinzi ndende.

Ibibazo

Ni ubuhe bwoko bwa plastiki bushobora gutunganya granulator?

Benshigranulatorskora ibikoresho bisanzwe nka ABS, PP, PE, PVC, na PET. Moderi zimwe na zimwe zitunganya plastike yubuhanga cyangwa ibikoresho bifite fibre fibre. Buri gihe ugenzure imashini yihariye kugirango ihuze.

Ni kangahe abashoramari bagomba gufata neza kuri granulator?

Abakoresha bagomba kugenzura granulator buri munsi kugirango bambara cyangwa byangiritse. Buri cyumweru gusukura no gusiga bifasha gukomeza imikorere. Buri kwezi gusukura byimbitse no kugenzura ibyuma byongera ubuzima bwimashini kandi bigakora neza.

Ni ukubera iki ingano nini yingirakamaro muri granulation?

Ingano imwe yingirakamaro ituma kugaburira neza mumashini itera inshinge. Itezimbere kandi gushonga no kuvanga mugihe cyo gutunganya. Ibinyampeke bihoraho bifasha kubungabunga ubuziranenge bwibicuruzwa no kugabanya imyanda.

Imashini ya plastike irashobora kugabanya ibiciro byingufu?

Yego. Ingufu zikoresha ingufu zikoresha moteri igezweho hamwe nubugenzuzi bwubwenge. Ibi biranga kugabanya amashanyarazi no kugabanya amafaranga yo gukora mugihe runaka.

Ni ibihe bintu biranga umutekano bigomba gushiramo granulator?

Granulator nziza irimo buto yo guhagarika byihutirwa, guhuza umutekano, hamwe na sisitemu yo gufunga / tag-out. Ibiranga kurinda abashoramari no gufasha ibikoresho byujuje ubuziranenge bwinganda.

Igihe cyo kohereza: Nyakanga-17-2025