A pulasitiki granulatorzimagwira ntchito yofunikira pakubwezeretsanso ndi kuumba jekeseni. Ogwira ntchito amayamikira makina omwe amapanga ma granules ofanana, chifukwa kusasinthasintha kumeneku kumapangitsa kuti ntchito yobwezeretsanso ikhale yabwino komanso imathandizira kupanga bwino. Makina apamwamba a granulator amagwira mitundu yambiri ya mapulasitiki, omwe amapereka kusinthasintha kwama projekiti osiyanasiyana. Zinthu zopulumutsa mphamvu zamakinawa zimathandizira kuchepetsa ndalama zogwirira ntchito. Zitsanzo zina, monga amakina apulasitiki a granulekapena apulasitiki crusher, komanso kuchepetsa zinyalala mwa kukhathamiritsa ntchito zinthu. Makhalidwe amenewa amathandiza kukhazikika ndi ntchito yodalirika m'madera amakono a pulasitiki.

Zofunika Kwambiri

- Ma granulators apulasitiki amayenera kupanga ma granules ofanana kuti awonetsetse kuti zinthu sizikuyenda bwino komanso kukonzanso bwino kapena kuumba.

- Kusankha granulator yoyenera zimatengera mtundu wa pulasitiki, kuchuluka kwa ntchito, ndi zosowa zamagwiritsidwe ntchito monga kukonzanso kapenajekeseni akamaumba.

- Ma granulator apamwamba amapereka zinthu zopulumutsa mphamvu, kuchepetsa phokoso, komanso kukonza kosavuta kuti achepetse ndalama komanso kukonza chitetezo chapantchito.

- Chitetezo champhamvu, kuphatikiza kuyimitsidwa mwadzidzidzi ndi zotsekera, zimateteza ogwira ntchito ndikuthandizira kukwaniritsa miyezo yamakampani.

- Thandizo lodalirika pambuyo pogulitsa ndikukonza pafupipafupi kumakulitsa moyo wa makina ndikupangitsa kuti kupanga kuyende bwino.

Pulasitiki Granulator Ntchito Zofunikira

Kubwezeretsanso motsutsana ndi Zofunikira pakuumba jekeseni

Kubwezeretsanso ndi kuumba jekeseni malo aliwonse amafunikira pa apulasitiki granulator. Popanga jakisoni, ogwiritsira ntchito nthawi zambiri amagwiritsa ntchito ma granulator ang'onoang'ono, ochita bwino kwambiri pambali pa makina omangira. Makinawa amanyamula ma sprues, othamanga, ndi zida zolakwika. Amayang'ana kwambiri kuphatikizika komanso kukonza bwino kwa zidutswa zotsika kwambiri. Mwachitsanzo, granulator yomwe imagwiritsidwa ntchito popanga jakisoni wa PVC iyenera kuphwanya zida zolimba, zolimba kuti zikhale zomangiranso. Mosiyana ndi izi, ntchito zobwezeretsanso zimafunikira ma granulator okulirapo, olimba kwambiri kapena ma shredders. Makinawa amachotsa zinyalala zazikulu monga mabotolo, mapaipi, ndi mapepala. Amafunikira mphamvu zapamwamba komanso kulimba kuti athe kuthana ndi mitundu yosiyanasiyana ya pulasitiki ndi kukula kwake. Kusiyana kwa sikelo ndi mtundu wa zidutswa zimapanga mapangidwe ndi magwiridwe antchito a granulator iliyonse.

Zofuna Zogawana Pamapulogalamu Onse awiri

Kukonzanso ndi kuumba jekeseni kumadalira mbali zina zazikulu mu granulator ya pulasitiki. Ogwira ntchito amayang'ana makina omwe amapanga makulidwe ofanana a granule, omwe amathandiza kuti zinthu ziziyenda bwino. Chitetezo chimakhalabe chofunikira kwambiri, chifukwa chake zinthu monga mabatani oyimitsa mwadzidzidzi ndi zotchingira chitetezo ndizofunikira. Kufikira mosavuta pamasamba ndi zowonera kumathandizira kukonza ndikuyeretsa mwachangu. Malo ambiri amakonda ma granulator okhala ndi phokoso lochepa komanso mapangidwe amafoni kuti aziyika mosavuta. Tebulo ili m'munsiyi ikuwonetsa zina zomwe zimagawidwa:

| Mbali | Pindulani |

|---|---|

| Uniform granule kukula | Khalidwe losasinthika lazinthu |

| chitetezo interlocks | Chitetezo cha opareshoni |

| Kukonza kosavuta | Kuchepetsa nthawi yopuma |

| Opaleshoni yotsika phokoso | Malo ogwirira ntchito bwino |

| Kunyamula | Kugwiritsa ntchito mosinthika m'malo osiyanasiyana |

Kuunikira Mitundu Yazinthu ndi Kuchulukira Kwamagawo

Malo amakonza mitundu yambiri ya mapulasitiki, kuphatikizapo sprues, zipolopolo, machubu, mabotolo, ndi mafilimu. Mapulasitiki ena, monga omwe ali ndi magalasi apamwamba kwambiri, amafunikira ma granulator apadera okhala ndi malo olimba komanso akupera kwambiri. Kusankhidwa kwa granulator kumadaliranso pokonza voliyumu. Ntchito zazing'ono zimagwiritsa ntchito mitundu yophatikizika ya zida zopepuka, pomwe malo akulu obwezeretsanso amafunikira makina am'mafakitale omwe amagwira matani angapo tsiku lililonse. Kusankha granulator yoyenera kumapangitsa kuti ntchitoyo ikhale yogwira ntchito bwino komanso imalepheretsa kutsekereza mabotolo, kaya cholinga chake ndikubwezeretsanso m'nyumba kapena kuchepetsa zinyalala zazikulu.

Pulasitiki Granulator Zofunikira

Kugwirizana Kwazinthu ndi Zosiyanasiyana

Granulator ya pulasitiki iyenera kugwira ntchito zosiyanasiyana kuti igwiritse ntchito pokonzanso komansojekeseni akamaumba ntchito. Ogwira ntchito nthawi zambiri amakonza zinthu monga mabotolo owumbidwa ndi mphepo, zolumikizira zamagetsi, zidutswa zomangira, ndi ma profiles otuluka. Makina okhala ndi mitundu ingapo yoyambira, monga FX 700, FX 1000, ndi FX 1600, amalola ogwiritsa ntchito kuti agwirizane ndi granulator ndi magawo osiyanasiyana ndi zosowa zawo. Kusintha kwa zipinda zosinthika, monga zipinda zowoneka bwino za magawo akulu ndi zipinda zosinthira pazigawo zolimba, zimakulitsa kusinthika.

Zindikirani: Ma hopper osinthika ndi mapangidwe otulutsa amathandizira kuyika granulator mumitundu yosiyanasiyana yamakina, kupangitsa kuti ikhale yosavuta kuphatikiza ndi zida zomwe zilipo.

Kusinthasintha kumadaliranso luso lokonza mapulasitiki okhala ndi zowonjezera zosiyanasiyana kapena kuuma. Ma granulator okhala ndi malo osagwira ntchito komanso njira zosavuta zowongolera amachepetsa nthawi yocheperako ndikuwonjezera moyo wa zida. Zida zowonjezera chitetezo, kuphatikiza zotsekera zosafunikira komanso zotsekera za solenoid, zimateteza ogwiritsa ntchito panthawi yomwe akugwiritsa ntchito. Kupondereza kwa mawu kumapangitsa kuti phokoso likhale lochepa, kuwongolera malo ogwirira ntchito. Zitsanzo monga SL ndi G26 mndandanda zimadziwikiratu chifukwa chogwirizana ndi zinthu zambiri, zomwe zimathandizira kukonzanso ndi kukonzanso.jekeseni akamaumba njira.

Kuthekera kwa Ntchito ndi Kuchita Bwino

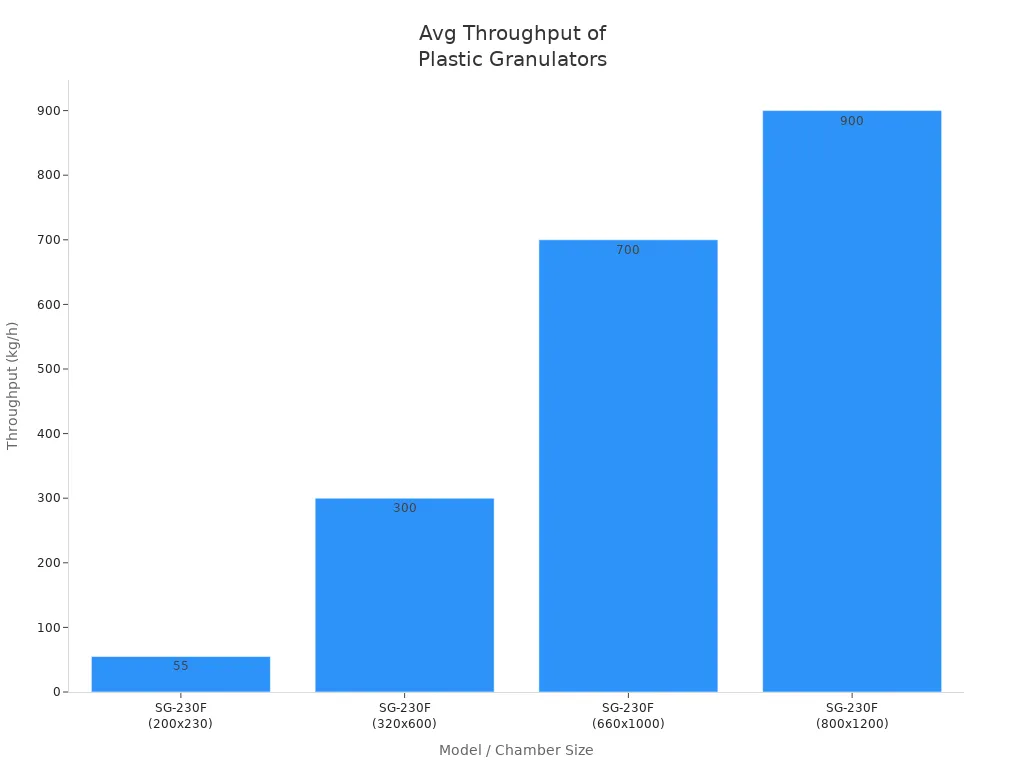

Mphamvu yotulutsa imayesa kuchuluka kwa zinthu zomwe granulator ya pulasitiki imatha kupanga munthawi yake. Maofesi amasankha makina kutengera zosowa zawo zatsiku ndi tsiku. Zipinda zing'onozing'ono zimagwirizana ndi ntchito zochepa, pamene zipinda zazikulu zimagwira ntchito yobwezeretsanso zambiri. Tebulo ili m'munsiyi likuwonetsa kuthekera kwanthawi zonse kwamitundu yosiyanasiyana:

| Chitsanzo / Kukula kwa Chipinda (mm) | Kuthekera (kg/h) | Mphamvu Yamagetsi (kW) | Zolemba |

|---|---|---|---|

| SG-230F (200×230) | 50-60 | 4-45 | Chipinda chaching'ono, chochepa mphamvu |

| SG-230F (320×600) | 250-350 | 4-45 | Chipinda chapakati |

| SG-230F (660×1000) | 600-800 | 4-45 | Chipinda chachikulu |

| SG-230F (800×1200) | 800 - 1,000 | 4-45 | Chipinda chachikulu kwambiri, chotulutsa kwambiri |

Zapamwamba zimathandizira kuti zinthu ziziyenda bwino komanso kuti zikhale zabwino. Mipeni yosinthika yosinthika imasunga bwalo lodulira mosalekeza pambuyo pakunola, zomwe zimatalikitsa moyo wa mpeni ndikuwonetsetsa kubwereza kwapamwamba. Mapangidwe ozungulira ozungulira amachepetsa ma spikes amphamvu komanso kugwiritsa ntchito mphamvu, makamaka pokonza magawo okhuthala. Mapangidwe otsegula amathandizira kuti mpweya uziyenda komanso kuziziritsa, zomwe ndizofunikira pazida zosalimba. Njira zodyetsera zanzeru komanso zokongoletsedwa bwino zopangira mbiya zimawonjezera kutulutsa komanso mtundu wa pellet. Ma granulator osagwiritsa ntchito mphamvu okhala ndi ma motor frequency mosiyanasiyana amatha kupulumutsa masauzande a madola pamitengo yamagetsi chaka chilichonse.

Kukula kwa Particle ndi Kufanana

Kufanana kwa tinthu ting'onoting'ono n'kofunikira pokonzanso ndi kuumba jekeseni. Kukula kwa mesh yosinthika kumalola ogwiritsa ntchito kuwongolera kukula kwa granule ndi kufanana. Ma rotor othamanga kwambiri amameta mapulasitiki kukhala ang'onoang'ono, ngakhale tizidutswa. Makina ochotsa fumbi amachotsa chindapusa, ndipo zolekanitsa maginito zimagwira zitsulo zoyipitsidwa, kuwonetsetsa kutulutsa koyera. Masensa anzeru ndi mapanelo owongolera amawunika ndikusintha kuthamanga kwa rotor munthawi yeniyeni, kusunga kukula kwa tinthu kosasintha.

Ma granulator amakono apulasitiki amagwiritsa ntchito makulidwe a skrini omwe mungasinthike komanso kuthamanga kwa rotor kuti apange ma granules ofanana. Kufanana kumeneku kumathandizira kuthamangitsidwa kodziwikiratu komanso kufalikira pakuumba jekeseni, zomwe zimapangitsa kuti zinthu zikhale bwino. Pobwezeretsanso, tinthu tating'onoting'ono timawonjezera kutsuka, kusungunuka, ndi kutulutsa bwino. Zida ngati zosakaniza zamitundu yoyima zimatsimikizira kupitilira 95%, kuchepetsa zolakwika ndikuwongolera magwiridwe antchito amakina.

Langizo: Kusamalira pafupipafupi komanso masensa anzeru kumathandiza kuzindikira zinthu msanga, kupewa kukula kwa tinthu kosagwirizana komanso kuchepetsa nthawi yopuma.

Kukula kwa tinthu ting'onoting'ono kumathandizanso kusakanikirana bwino, kusasinthika kwamtundu, komanso mphamvu zamakina pazomalizidwa. Makina omwe amapereka masinthidwe ofulumira komanso makina odzipangira okha amasintha mosavuta kuzinthu zosiyanasiyana, kupititsa patsogolo kusinthasintha komanso kuthandizira zotsatira zapamwamba pakukonzanso ndi kuumba jakisoni.

Kudula Technology ndi Blade Design

Tekinoloje yodula imapanga maziko a granulator iliyonse yapulasitiki. Mapangidwe oyenera a tsamba amatsimikizira kukonza bwino, ma granules apamwamba kwambiri, komanso kutsika kochepa. Ma granulator amakono amagwiritsa ntchito zinthu zingapo zapamwamba kuti akwaniritse zofunikira pakubwezeretsanso komanso kuumba jekeseni.

- Mipeni ya V-cut rotor imapanga regrind yapamwamba yokhala ndi chindapusa chocheperako, chomwe chimapangitsa kusasinthika kwa zotulutsa.

- Mizere ingapo ya mipeni yozungulira, monga mizere 9, 11, kapena 13, imakulitsa mphamvu yodulira ndikulola makinawo kugwira ma voliyumu akulu.

- Ma deflector wedges ochotsedwa amakhala ngati tsamba lachitatu la stator. Izi zimawonjezera kuuma mwamphamvu ndikulola kusintha mwachangu panthawi yogwira ntchito.

- Zonyamula ma rotor mokulirapo ndi zoyika mipeni zimathandizira ntchito zolemetsa zobwezeretsanso. Zigawo izi zimakana kuvala ndikukulitsa moyo wa granulator.

- Zitsulo zosamva kuvala komanso zowoneka molimba pa ma rotor ndi nyumba zimateteza makina kuzinthu zowononga kapena zoipitsidwa.

- Kumanga kwachitsulo cholimba kumatsimikizira kulimba, ngakhale m'malo ovuta.

- Ma bere olemetsa akunja, olekanitsidwa ndi chipinda chodulira, amapewa kuipitsidwa ndi kuchepetsa chiopsezo cha kulephera msanga.

Mapangidwe a blade amakhudzanso kukonza ndi khalidwe la granule. Masamba osawoneka bwino kapena osatalikirana bwino amatha kuyambitsa ma granules osafanana, afumbi komanso kutsika pang'ono. Masamba osinthika osinthika amalola kunoledwa payekhapayekha, komwe kumatalikitsa moyo wa tsamba ndikusunga kukula kwa granule. Kuwunika pafupipafupi komanso kukonza zodzitetezera, monga kunola ndi kusintha mipata, kumathandiza kuchepetsa nthawi yopuma.

| Mbali | Chidule cha Umboni |

|---|---|

| Zida za Blade | Tungsten carbide ndi masamba achitsulo othamanga kwambiri amapereka kukana kuvala kwambiri komanso moyo wautali wautumiki, kuchepetsa kukonzanso pafupipafupi. |

| Blade Gap | Kusiyana kwa tsamba loyenera (0.1-0.3 mm) ndikofunikira pakudula bwino; kusiyana kolakwika kumayambitsa masamba osokonekera, ma granules osagwirizana, ndikuwonjezera kukonza. |

| Blade Design | Mapangidwe a mipeni ya Spiral amathandizira kudula bwino ndikuchepetsa kutsekeka, kumapangitsa kuti granule ikhale yabwino. |

| Njira Zosamalira | Kuyeretsa nthawi zonse, kuthira mafuta, ndi kuwongolera moyenera kumakulitsa moyo wa tsamba ndikusunga mawonekedwe a granule. |

| Zotsatira Zapangidwe Koyipa | Kusayenda bwino kwa tsamba kumabweretsa fumbi, ma granules osafanana komanso zofunika kukonza pafupipafupi. |

Granulator ya pulasitiki yokhala ndi ukadaulo wapamwamba wodula komanso masamba opangidwa mwaluso imapereka magwiridwe antchito odalirika, ma granules apamwamba kwambiri, komanso kutsika mtengo wokonza.

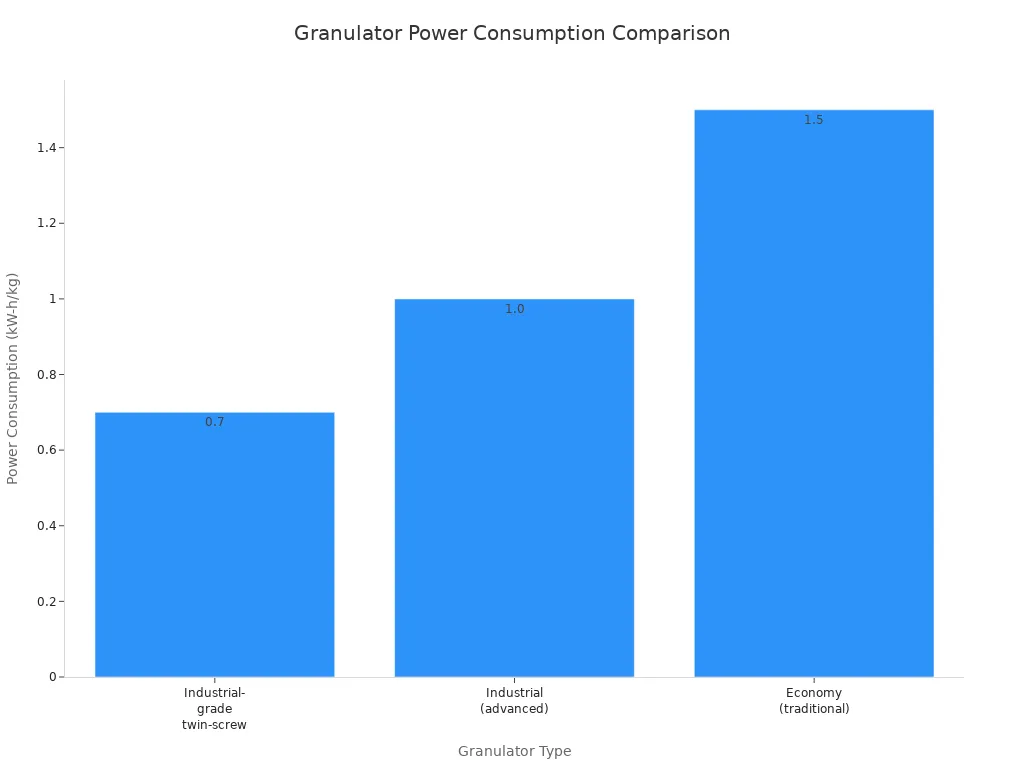

Kugwiritsa Ntchito Mphamvu Mwachangu ndi Kuchepetsa Phokoso

Kugwiritsa ntchito mphamvu zamagetsi kwakhala chinthu chofunikira kwambiri pakupanga zamakono. Ma granulator apamwamba apulasitiki amagwiritsa ntchito ma motors osapatsa mphamvu komanso machitidwe anzeru owongolera kutentha kuti achepetse kugwiritsa ntchito mphamvu. Zitsanzo zamapasa awiri zamafakitale zimatha kugwiritsa ntchito mphamvu zochepera 40% poyerekeza ndi mitundu yakale yazachuma. Kuwongolera uku kumachepetsa mtengo wogwirira ntchito komanso kumathandizira zolinga zokhazikika.

Kuchepetsa phokoso ndi chinthu china chofunika kwambiri kuntchito. Ma granulators apulasitiki amatha kukhala phokoso, koma opanga tsopano amapereka zitsanzo zosamveka komanso zochepetsera phokoso. Zosungira zomveka bwino komanso zowongolera zokha zimathandizira kutsitsa phokoso, kupangitsa malo ogwirira ntchito kukhala otetezeka komanso omasuka. Zinthuzi zimathandizanso kuti malowa akwaniritse malamulo a phokoso la chilengedwe komanso kuwongolera magwiridwe antchito.

Langizo: Kugwiritsa ntchito kuteteza makutu ndi kusunga zotchinga zosamveka mozungulira granulator kungathenso kuchepetsa kuwonekera kwa phokoso kwa ogwira ntchito.

Ma granulator amakono apulasitiki amaphatikiza zinthu zopulumutsa mphamvu ndi matekinoloje ochepetsera phokoso kuti apange malo ogwirira ntchito otetezeka, ogwira ntchito bwino, komanso osakonda chilengedwe.

Mawonekedwe a Chitetezo ndi Kutsata

Chitetezo chimakhalabe chodetsa nkhawa pachinthu chilichonse chogwiritsa ntchito pulasitiki granulator. Makina amayenera kukwaniritsa miyezo yotetezedwa kuti ateteze ogwira ntchito ndikuwonetsetsa kuti akugwira ntchito yodalirika.

- ANSI/PLASTICS B151.11-2021 imafotokoza zofunikira zachitetezo cha granulator, kapangidwe kake, kagwiritsidwe ntchito, kukonza, ndi kusinthidwa.

- Miyezo ina yoyenera ikuphatikiza ANSI/PLASTICS B151.1-2017 yamakina opangira jakisoni ndi ANSI/PLASTICS B151.27-2021 pamakina opangira makina opangira ma robot / jakisoni.

- Kutsatiridwa ndi miyezo imeneyi ndikofunikira kuti mugwire bwino ntchito m'misika yayikulu yopanga zinthu.

Ma granulators apulasitiki amafunikira zowongolera zingapo zomangidwa mkati:

- Makina otsekera / otuluka amadula magetsi musanakonze kapena kuyeretsa.

- Alonda ndi zotchinga zimalepheretsa mipeni yosuntha.

- Mabatani oyimitsa mwadzidzidzi, ma alarm otsekereza, ndi chitetezo chamagetsi apawiri amapereka yankho lachangu kungozi.

- Ogwira ntchito ayenera kuvala zida zodzitetezera, monga magolovesi, maso, nkhope, makutu, ndi chitetezo cha fumbi.

- Kuwunika pafupipafupi komanso kuwunika chitetezo chatsiku ndi tsiku kumapangitsa makinawo kukhala otetezeka.

- Othandizira amafunika kuphunzitsidwa bwino ndi malangizo omveka bwino m'chinenero chomwe amachidziwa.

Zindikirani: Kusunga malo ogwirira ntchito paukhondo komanso opanda zopinga kumathandiza kupewa ngozi, maulendo, ndi ngozi zina.

Potsatira njira zotetezerazi ndikutsata miyezo yodziwika, malo amatha kuonetsetsa kuti ma granulator awo apulasitiki akugwira ntchito motetezeka komanso moyenera.

Pulasitiki Granulator Ntchito Zoganizira

Njira Zodyetsera ndi Zosankha Zotsitsa

Ogwiritsa ntchito amatha kusankha kuchokera ku njira zingapo zodyetsera akaphatikiza pulasitiki granulator mumzere wopanga. Kudyetsa pamanja kumagwira ntchito bwino pamagulu ang'onoang'ono kapena kugwiritsidwa ntchito mwa apo ndi apo. Kudyetsa ma conveyor kumathandizira kugwira ntchito mosalekeza komanso kumachepetsa ntchito yamanja. Kudyetsa mpukutu ndikwabwino pamapepala opyapyala apulasitiki kapena mafilimu.Kudyetsa kwa robotkumawonjezera zodzichitira ndi chitetezo pochepetsa kukhudzana kwa anthu ndi magawo osuntha. Njira iliyonse imakhudza kuyendetsa bwino komanso kuyenda kwazinthu m'njira zosiyanasiyana.

Kuyika ma granulator pafupi ndi makina osindikizira kumapulumutsa malo pansi ndikuwongolera kayendetsedwe ka ntchito. Makanema olowera kutsogolo amapangitsa kuti ntchito ndi kukonza zikhale zosavuta. Zosankha zodyetsera zokha zimachepetsanso kugwira ntchito pamanja, zomwe zimachepetsa chiopsezo cha kuvulala ndikuwonjezera liwiro la kupanga.

Tebulo ili m'munsiyi ikuwonetsa zinthu zofunika kuziganizira posankha njira zodyetsera ndi kukweza:

| Operation Factor | Kufotokozera & Malingaliro |

|---|---|

| Mtundu wa Zinthu Zapulasitiki | Mapulasitiki olimba amafunikira masamba amphamvu ndi ma mota; mapulasitiki ofewa amafunikira kugwiridwa mofatsa. |

| Linanena bungwe Kukula Zofunika | Zowonetsera zosinthika zimathandizira kukwaniritsa kukula kwa granule pamachitidwe akumunsi. |

| Mphamvu Zopanga | Kupititsa patsogolo kuyenera kugwirizana ndi zofunikira za kupanga kuti zisawonongeke. |

| Kuphatikiza Kugwirizana | Njira zodyera ziyenera kulumikizidwa bwino ndi ma conveyor, maloboti, kapena zida zina zodzichitira. |

Kukonza ndi Kuyeretsa Kusavuta

Kusamalira nthawi zonse kumapangitsa kuti granulator ya pulasitiki ikuyenda bwino komanso imatalikitsa moyo wake. Ogwira ntchito amayenera kuyang'ana tsiku ndi tsiku kuti aone ngati pali mabawuti otayirira, kutayikira, kapena phokoso lachilendo. Kuyeretsa hopper ndikuyang'ana chipinda chodulira pambuyo pa kusintha kulikonse kumalepheretsa kuti zinthu zisamangidwe. Ntchito zamlungu ndi mlungu zimaphatikizirapo kuyang'ana mipeni ngati ilibechabechabe, kuyeretsa zotchinga, ndi mayendedwe opaka mafuta. Kuyeretsa mozama pamwezi ndi kusintha kwa mipeni kumathandizira kuti kudulako kukhale kothandiza.

- Tsiku ndi Tsiku: Yang'anani zowonongeka, yeretsani zopinga, ndikuwona mbali zachitetezo.

- Mlungu uliwonse: Yang'anani mipeni ndi zowonetsera, zonyamulira mafuta, ndi kumangitsa zomangira.

- Mwezi uliwonse: Zipinda zoyera kwambiri, sinthani mipata ya mpeni, ndipo fufuzani momwe magetsi amalumikizirana.

- Semi-pachaka/Chaka: Kunola kapena kusintha mipeni, sinthani mbali zotha, ndi kuyendera kwathunthu.

Kugwiritsa ntchito zida zopangira zida zoyambira (OEM) ndikutsata njira zotetezedwa kumawonetsetsa kuti chitetezo cha opareshoni ndi chapamwamba. Kusunga malo ogwirira ntchito kukhala aukhondo kumathandizanso kukonza bwino.

Kukhalitsa ndi Kumanga Ubwino

Kukhalitsa kumagwira ntchito yofunika kwambiri pamtengo wanthawi yayitali wa granulator ya pulasitiki. Makina opangidwa ndi zitsulo zotenthedwa ndi kutentha komanso ma mota amphamvu amapirira kugwiritsa ntchito kwambiri komanso zinthu zowononga. Kupanga kwa modular kumathandizira kusinthidwa mwachangu, kuchepetsa nthawi yopumira. Mapangidwe ofikira mosavuta amapangitsa kusintha kwa tsamba ndikuyeretsa mwachangu, zomwe zimathandizira kukhala akuthwa komanso kuchita bwino.

Kumanga kwapamwamba kumatha kukulitsa moyo wa granulator mpaka zaka 10-20. Kuyendera nthawi zonse, kudzoza koyenera, ndi kusintha kwa nthawi yake ziwalo zotha kumapangitsa makinawo kukhala odalirika. Mafelemu amphamvu ndi zigawo zabwino zimachepetsa ndalama zogwirira ntchito ndikuchepetsa kufunika kokonzanso pafupipafupi.

Kuyika ndalama mu granulator yokhazikika kumathandizira kupanga kosalekeza komanso kumathandiza kuti malowa azitha kupulumutsa nthawi yayitali.

Thandizo Pambuyo-Kugulitsa ndi Zida Zopangira

Thandizo pambuyo pa malonda limagwira ntchito yofunika kwambiri pakuchita bwino kwanthawi yayitali kwa ntchito iliyonse yokonza pulasitiki. Makampani omwe ali m'mafakitole obwezeretsanso ndi kuumba jekeseni amadalira ntchito zodalirika kuti zida zawo ziziyenda bwino. Makina akasiya kugwira ntchito, kupanga kumatha kuyima, zomwe zimapangitsa kutaya nthawi ndi ndalama. Thandizo lodalirika pambuyo pogulitsa limathandizira kupewa mavutowa ndikuwonetsetsa kuchira msanga pakabuka mavuto.

Ogwiritsa ntchito ambiri amayamikira mitundu ingapo ya ntchito zotsatsa pambuyo pake. Izi zikuphatikizapo:

- Kupeza akatswiri odziwa bwino ntchito yakumunda omwe amatha kuzindikira ndi kukonza zovuta pamalowo.

- Ukadaulo wogwiritsa ntchito womwe umathandizira ogwiritsa ntchito kuti apindule kwambiri ndi makina awo.

- Thandizo losagwedezeka kuchokera kwa wothandizira, zomwe zimamanga chidaliro ndi chidaliro.

Malo obwezeretsanso nthawi zambiri amakumana ndi zovuta zapadera. Amapindula ndi:

- Kukambitsirana ndi akatswiri kumagwirizana ndi njira zawo zobwezeretseranso.

- Maphunziro athunthu kwa ogwira ntchito kuti agwiritse ntchito ndikusamalira zida mosamala.

- Thandizo lopitilira laukadaulo kuthana ndi zovuta zosayembekezereka.

Ogwiritsa ntchito jekeseni amayang'ananso:

- Kukhazikitsa kwaukadaulo kuonetsetsa kuti makina akugwira ntchito moyenera kuyambira pachiyambi.

- Maphunziro abwino kwa ogwira ntchito onse.

- Thandizo lodalirika laukadaulo komanso kupezeka kwa zida zosinthira.

- Ntchito zosamalira zomwe zimathandizira kuwonjezera moyo wa zida.

Zothandizira zopezeka zimapanga kusiyana. Makampani ambiri amapereka:

- Mautumiki ofunsira kuyankha mafunso ndikupereka chitsogozo.

- Thandizo lamavidiyo pazovuta ndi kukonza.

- Ma FAQ omwe amathandiza ogwiritsa ntchito kuthetsa mavuto omwe amapezeka nthawi zambiri.

Langizo: Kusunga zida zosinthira zofunika patsamba kumatha kuchepetsa nthawi yopuma ndikupangitsa kuti zinthu ziziyenda.

Dongosolo lamphamvu lothandizira pambuyo pogulitsa limatsimikizira kuti makina azikhala odalirika komanso ogwira mtima. Zimapatsanso ogwira ntchito chidaliro chothana ndi zovuta za tsiku ndi tsiku ndikukonzekera kukula kwamtsogolo.

Kusankha Pulasitiki Yoyenera Granulator

Kufananiza Mitundu ya Granulator ku Zida ndi Njira

Kusankha granulator yoyenera kumayamba ndikumvetsetsa zida ndi njira zomwe zimagwiritsidwa ntchito. Malo ena amakonza mapulasitiki olimba monga ABS kapena polycarbonate. Ena amagwira zinthu zofewa monga filimu ya polyethylene. Mtundu uliwonse wazinthu umafunikira chipinda chodulira komanso kapangidwe ka tsamba. Mwachitsanzo, mbali zolimba-mipanda zimafunikira chipinda cholumikizira, pomwe makanema owonda amagwira ntchito bwino ndi ma rotor otseguka. Oyendetsa ayeneranso kuganizira kukula kwa zidutswa ndi kukula kofunikira. Malo obwezeretsanso kwambiri angafunike zitsanzo zazikulu, zolemetsa.Mashopu opangira jekeseninthawi zambiri amakonda mayunitsi ang'onoang'ono, pafupi ndi atolankhani. Kufananiza mtundu wa granulator ndi zinthu ndi ndondomeko zimatsimikizira kugwira ntchito bwino ndi zotsatira zapamwamba.

Kulinganiza Mtengo, Mtengo, ndi Kuchita Kwanthawi Yaitali

Mtengo umagwira ntchito yayikulu pakusankha zida. Komabe, mtengo wotsikitsitsa sutanthauza mtengo wabwino koposa. Malo ayenera kuyang'ana mtengo wonse wa umwini. Izi zikuphatikiza kugwiritsa ntchito mphamvu, kukonza, komanso kupezeka kwa zida zosinthira. Makina okhala ndi ma mota osapatsa mphamvu komanso masamba olimba nthawi zambiri amasunga ndalama pakapita nthawi. Thandizo lodalirika pambuyo pa malonda lingathe kuchepetsa nthawi yopuma ndi kukonza ndalama. Kuyika ndalama mu granulator yapamwamba kwambiri kumathandizira kuti pakhale kupanga kosasintha komanso kuchepetsa ndalama zomwe zimatenga nthawi yayitali.

Langizo: Ganizirani za nthawi yomwe mukuyembekezeka kukhala ndi moyo komanso zofunika kuzikonza musanagule. Makina opangidwa bwino amatha zaka zambiri ndi chisamaliro choyenera.

Mndandanda Wosankha Granulator

Othandizira atha kugwiritsa ntchito mndandanda wazidziwitso kuti awongolere zomwe akufuna:

- Dziwani mitundu ndi kukula kwa zida zapulasitiki zomwe zikuyenera kukonzedwa.

- Yerekezerani kuchuluka kwa tsiku lililonse kapena sabata iliyonse.

- Yang'anani kuyanjana ndi machitidwe omwe alipo kale odyetsa ndi kutulutsa.

- Unikaninso zachitetezo ndikutsata miyezo yamakampani.

- Unikani mphamvu zogwiritsa ntchito mphamvu ndi kuchuluka kwa phokoso.

- Unikani mosavuta kukonza ndi kuyeretsa.

- Tsimikizirani kupezeka kwa zida zosinthira ndi chithandizo chaukadaulo.

- Yerekezerani mtengo wonse wa umwini, osati mtengo wogulira.

Kuwunika mosamala zinthu izi kumathandiza kuonetsetsa kuti granulator ya pulasitiki yosankhidwa ikukwaniritsa zosowa zapano komanso zamtsogolo.

Kusankha zida zoyenera kumapangitsa kuti ntchito ziziyenda bwino pakubwezeretsanso komanso kuumba jekeseni. Zida zimapindula ndi makina omwe amapereka ndalama zogulira, amathandizira zolinga zachilengedwe, komanso kupititsa patsogolo liwiro la kupanga. Ubwino waukulu ndi:

- M'munsi zopangira ndalama kudzera yobwezeretsanso.

- Kuchepetsa zinyalala zapulasitiki kuti pakhale malo aukhondo.

- Kusamalira mosavuta ndikusunga zinthu za granulated.

- Kusasinthika kwazinthu zopangidwa ndi granules zofananira.

- Kukonza kosavuta ndi kotetezeka, malo ogwirira ntchito oyeretsa.

Ogwira ntchito agwiritse ntchito mndandandawu kuti awongolere zomwe asankha ndikupeza chipambano chanthawi yayitali.

FAQ

Ndi mapulasitiki amtundu wanji omwe amatha kupanga granulator?

Ambiripulasitiki granulatorsGwiritsani ntchito zinthu wamba monga ABS, PP, Pe, PVC, ndi PET. Mitundu ina imapanganso mapulasitiki aumisiri kapena zida zokhala ndi magalasi. Nthawi zonse yang'anani zomwe makinawo amafunikira.

Kodi opareshoni ayenera kukonza kangati pa granulator?

Ogwira ntchito ayenera kuyang'ana granulator tsiku lililonse kuti awonongeke kapena kuwonongeka. Kuyeretsa mlungu ndi mlungu ndi mafuta kumathandiza kuti ntchito ikhale yabwino. Kuyeretsa mozama pamwezi ndi macheke atsamba kumakulitsa moyo wa makina ndikuwonetsetsa kuti ntchito ikuyenda bwino.

Chifukwa chiyani kukula kwa tinthu ting'onoting'ono kuli kofunikira mu granulation ya pulasitiki?

Kukula kwa tinthu ting'onoting'ono kumatsimikizira kudyetsa kosalala mumakina opangira jakisoni. Zimathandizanso kusungunuka ndi kusakaniza panthawi yobwezeretsanso. Ma granules osasinthasintha amathandizira kuti zinthu ziziyenda bwino komanso kuti zichepetse zinyalala.

Kodi granulator ya pulasitiki ingachepetse mtengo wamagetsi?

Inde. Ma granulator osagwiritsa ntchito mphamvu amagwiritsa ntchito ma mota apamwamba komanso zowongolera mwanzeru. Zinthuzi zimachepetsa kugwiritsa ntchito magetsi komanso zimachepetsa ndalama zogwiritsira ntchito pakapita nthawi.

Ndi zinthu ziti zachitetezo zomwe granulator yapulasitiki iyenera kuphatikiza?

Granulator yabwino imaphatikizapo mabatani oyimitsa mwadzidzidzi, zotchingira chitetezo, ndi makina otsekera / otulutsa. Izi zimateteza ogwira ntchito komanso malo othandizira kuti akwaniritse miyezo yachitetezo chamakampani.

Nthawi yotumiza: Jul-17-2025