A igranulator yeplastikiidlala indima ebalulekileyo kuzo zombini iifasilithi zokuphinda zisetyenziswe kunye nezitofu. Abasebenzi baxabisa oomatshini abavelisa iigranuli ezifanayo, njengoko oku kuhambelana kukhulisa ukusebenza kakuhle kokurisayikilisha kwaye kuxhasa imveliso egudileyo. Oomatshini begranulator abaphezulu baphatha iintlobo ezininzi zeeplastiki, ezinikezela ngokuguquguquka kwiiprojekthi ezahlukeneyo. Iimpawu zokonga amandla kwaba matshini zinceda ukuthoba iindleko zokusebenza. Ezinye iimodeli, njengeumatshini weplastiki yegranuleokanye aiplastiki yokutyumza, kwakhona ukunciphisa inkunkuma ngokulungiselela ukusetyenziswa kwezinto eziphathekayo. Ezi mpawu zixhasa ukuzinza kunye nokusebenza okuthembekileyo kwiindawo zokulungisa iplastiki yanamhlanje.

Izinto eziphambili zokuThatha

- Iigranulator zePlastiki kufuneka zivelise iigranule ezifanayo ukuqinisekisa umgangatho wemveliso ongaguqukiyo kunye nokuhlaziywa okusebenzayo okanye ukubumba.

- Ukukhetha igranulator elungileyo kuxhomekeke kuhlobo lweplastiki, umthamo wokulungisa, kunye neemfuno zesicelo njengokurisayikilishwa okanyeisitofu sokubumba.

- Iigranulator ezikumgangatho ophezulu zibonelela ngezinto zokonga amandla, ukunciphisa ingxolo, kunye nokugcinwa lula ukuthoba iindleko nokuphucula ukhuseleko emsebenzini.

- Iimpawu zokhuseleko olomeleleyo, kubandakanywa iindawo zokumisa ezingxamisekileyo kunye ne-interlocks, zikhusela abaqhubi kunye nokunceda ukuhlangabezana nemigangatho yoshishino.

- Inkxaso ethembekileyo emva kokuthengisa kunye nokugcinwa rhoqo kwandisa ubomi bomatshini kunye nokugcina imveliso isebenza kakuhle.

Iimfuno zeSicelo seGranulator yePlastiki

Ukurisayikilisha vs. IiMfuno zokuBunjwa kwesitofu

Ukurisayikilishwa kunye nokubumba indawo nganye kwiimfuno ezizodwaigranulator yeplastiki. Ekubumbeni inaliti, abaqhubi bahlala besebenzisa iigranulator ezincinci, ezisebenza kakhulu ecaleni komatshini wokubumba. Aba matshini baphatha i-sprues, iimbaleki, kunye namalungu anesiphene. Bajolise ekubambeni nasekuqhubeni kakuhle i-scrap yomthamo ophantsi. Umzekelo, igranulator esetyenziselwa ukubumba inaliti yePVC kufuneka yaphule izinto ezomeleleyo, ezomeleleyo zibe ziigranuli ezinokuphinda zisetyenziswe. Ngokwahlukileyo, usetyenziso lokurisayikilisha lufuna iigranulator ezinkulu, ezomeleleyo okanye iishredders. Aba matshini benza inkunkuma eninzi njengeebhotile, imibhobho, kunye namashiti. Bafuna umthamo ophezulu kunye nokuqina ukuze baphathe uluhlu olubanzi lweentlobo zeplastiki kunye nobukhulu. Umahluko kwisikali kunye nohlobo lwe-scrap lubumba uyilo kunye nokusebenza kwegranulator nganye.

Iimfuno ekwabelwana ngazo kuzo zozibini izicelo

Zombini ukurisayikilishwa kunye nokubumba isitofu kuxhomekeke kwizinto ezithile eziphambili kwigranulator yeplastiki. Abaqhubi bajonga oomatshini abavelisa ubungakanani obufanayo begranule, obunceda ukugcina umgangatho wemveliso ongaguqukiyo. Ukhuseleko luhlala lungundoqo, ngoko ke iimpawu ezifana namaqhosha okumisa unxunguphalo kunye nezitshixo zokhuseleko zibalulekile. Ukufikelela ngokulula kwiiblades kunye nezikrini zivumela ukugcinwa ngokukhawuleza kunye nokucoca. Amaziko amaninzi akhetha iigranulator ezinamazinga aphantsi engxolo kunye noyilo oluphathwayo lokubekwa okuguquguqukayo. Itheyibhile engezantsi ibonisa ezinye iimpawu zokusebenza ekwabelwana ngazo:

| Uphawu | Inzuzo |

|---|---|

| Ubungakanani obufanayo begranule | Umgangatho wemveliso ohambelanayo |

| Ukhuseleko lonxibelelwano | Ukhuseleko lomsebenzisi |

| Ukugcinwa lula | Ixesha lokuphumla elincitshisiweyo |

| Ukusebenza kwengxolo ephantsi | Ukuphuculwa kwendawo yokusebenza |

| Ukuphatheka | Ukusetyenziswa okuguquguqukayo kwiindawo ezahlukeneyo |

Ukuphonononga iintlobo zeMathiriyeli kunye neMithamo yokuLungiselela

Amaziko aqhuba iintlobo ezininzi zeplastiki, kubandakanya i-sprues, amaqokobhe, iityhubhu, iibhotile kunye neefilimu. Ezinye iiplastiki, ezifana nezo zinefiber ephezulu yeglasi, zifuna iigranulator ezikhethekileyo ezinomgangatho oqinileyo kunye nokusila okuphezulu. Ukukhethwa kwegranulator kwakhona kuxhomekeke kumthamo wokucubungula. Imisebenzi emincinci isebenzisa iimodeli ezixineneyo kwizinto ezikhanyayo, ngelixa amaziko amakhulu okurisayikilisha afuna oomatshini boshishino abaphatha iitoni ezininzi mihla le. Ukukhetha i-granulator efanelekileyo iqinisekisa ukucubungula ngokufanelekileyo kunye nokuthintela iibhotile, nokuba injongo kukuhlaziywa kwendlu okanye ukunciphisa inkunkuma enkulu.

Iplastiki yeGranulator Iimpawu ezibalulekileyo

Ukuhambelana kweMathiriyeli kunye noKuguquguquka

Igranulator yeplastiki kufuneka iphathe uluhlu olubanzi lwemathiriyeli ukuze isebenze zombini ukurisayikilishwa kunyeizicelo zokubumba isitofu. Abaqhubi bahlala belungisa izinto ezinjengeebhotile ezibunjiweyo, iziqhagamshelo zombane, iziqwenga zescrew, kunye neeprofayili ezikhutshiweyo. Oomatshini abaneemodeli ezisisiseko ezininzi, njengeFX 700, FX 1000, kunye neFX 1600, bavumela abasebenzisi ukuba batshatise igranulator kubungakanani bamacandelo ahlukeneyo kunye neemfuno zokuphuma. Ulungelelwaniso lwegumbi eliguquguqukayo, elinje ngamagumbi e-tangential kumalungu amakhulu kunye namagumbi okulinganisa amacandelo anodonga olungqingqwa, anyusa ukuguquguquka.

Qaphela: Iihopper ezinokwenziwa ngokwezifiso kunye noyilo lokukhutshwa lunceda ukufaka igranulator kwiindlela ezahlukeneyo zoyilo lwenkqubo, ikwenza kube lula ukudityaniswa nezixhobo ezikhoyo.

Ukuguquguquka kwakhona kuxhomekeke kwisakhono sokwenza iiplastiki ezinezongezo ezahlukeneyo okanye amanqanaba obunzima. Iigranulator ezinomgangatho ongagugiyo kunye nofikelelo olulula kulondolozo zinciphisa ixesha lokuphumla kwaye zandise ubomi besixhobo. Iimpawu eziphuculweyo zokhuseleko, kubandakanywa ukuvala okungafunekiyo kunye ne-solenoid-activated locks, ukukhusela abaqhubi ngexesha lokusetyenziswa. Ukunciphisa isandi kuyila ingxolo ephantsi, ukuphucula indawo yokusebenza. Iimodeli ezifana ne-SL kunye ne-G26 series zibalasele ngokuhambelana kwazo kwempahla ebanzi, ezixhasa zombini ukurisayikilisha kunyeiinkqubo zokubumba isitofu.

Amandla oMsebenzi kunye noGcitho

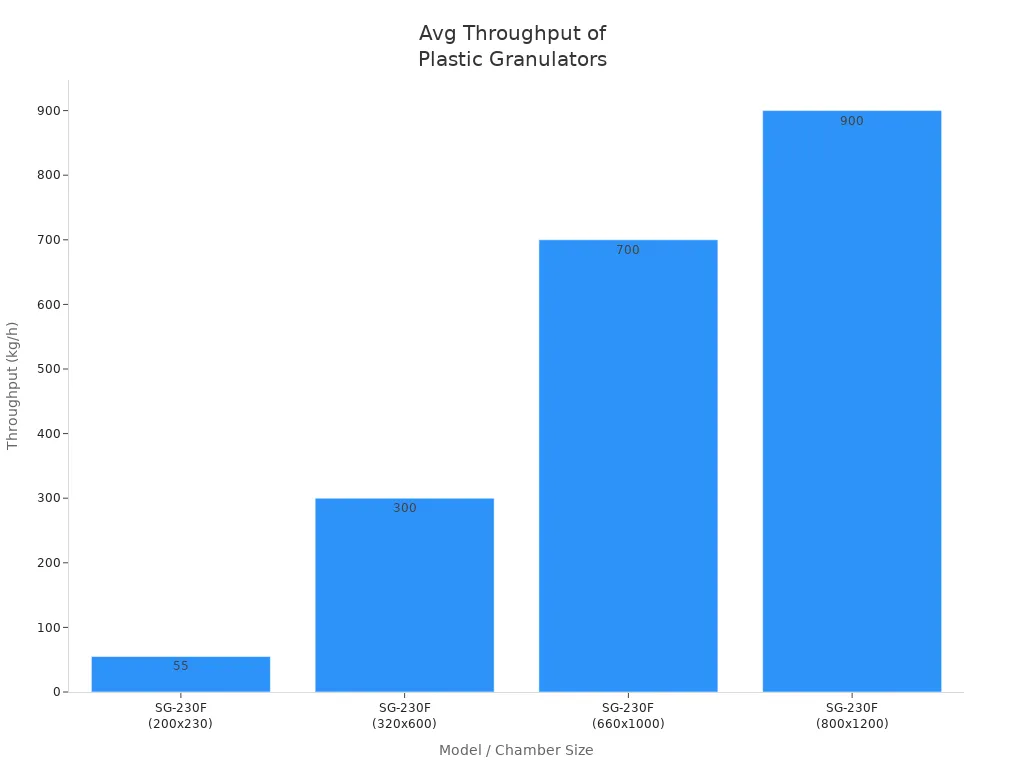

Umthamo womsebenzi ulinganisa ukuba ingakanani imathiriyeli enokwenziwa yigranulator yeplastiki ngexesha elinikiweyo. Izibonelelo zikhetha oomatshini ngokusekelwe kwiimfuno zabo zemihla ngemihla. Amagumbi amancinci afanele ukusebenza kwevolyum ephantsi, ngelixa amagumbi amakhulu esebenza ngokuphindaphindiweyo. Itheyibhile engezantsi ibonisa amandla okuphumelela aqhelekileyo kwiimodeli ezahlukeneyo:

| Imodeli / Ubungakanani beGumbi (mm) | Umthamo wokugqiba (kg/h) | Amandla eMoto (kW) | Amanqaku |

|---|---|---|---|

| SG-230F (200×230) | 50 – 60 | 4 – 45 | Igumbi elincinci, umthamo ophantsi |

| SG-230F (320×600) | 250 – 350 | 4 – 45 | Igumbi eliphakathi |

| SG-230F (660×1000) | 600 - 800 | 4 – 45 | Igumbi elikhulu |

| SG-230F (800×1200) | 800 - 1,000 | 4 – 45 | Igumbi elikhulu, imveliso ephezulu |

Iimpawu eziphezulu ziphucula ukusebenza kakuhle kunye nomgangatho wemveliso. Iimela eziguqukayo eziguqukayo zigcina isangqa sokusika rhoqo emva kokulola, okokwandisa ubomi bemela kunye nokuqinisekisa ukubuyisela umgangatho ophezulu. Uyilo lwe-rotor oluguquguqukayo lunciphisa izikhonkwane zamandla kunye nokusetyenziswa kwamandla, ngakumbi xa kusetyenzwa iindawo ezishinyeneyo. Uyilo lwe-rotor evulekileyo luphucula ukuhamba komoya kunye nokupholisa, okubalulekileyo kwizinto ezibuthathaka. Iinkqubo zokutyisa ezikrelekrele kunye noyilo olulungisiweyo lwesikrufu kunye nemigqomo yonyusa imveliso kunye nomgangatho wepellet. Igranulators ezonga amandla kunye neemotor frequency frequency zingagcina amawaka eedola kwiindleko zombane ngonyaka ngamnye.

Ulawulo lobungakanani beNcam kunye noKufana

Ubungakanani besuntswana elingaguqukiyo bubalulekile ekusetyenzisweni ngokutsha kunye nokubumba inaliti. Ubungakanani bemesh yesikrini ehlengahlengiswayo buvumela abaqhubi ukuba balawule ubungakanani begranule kunye nokufana. Iirotha ezinesantya esiphezulu zicheba iiplastiki zibe zincinci, nokuba ngamaqhekeza. Iinkqubo zokutsalwa kothuli zisusa izohlwayo, kunye nezahluli zemagnethi zibamba izinto ezingcolisa isinyithi, ziqinisekisa ukuphuma okucocekileyo. I-Smart sensors kunye neepaneli zokulawula zibeke iliso kwaye zilungelelanise isantya se-rotor ngexesha langempela, ukugcina ubungakanani be-particle buhambelana.

Iigranulator zeplastiki zanamhlanje zisebenzisa ubungakanani besikrini obunokwenzeka kunye nezantya eziguquguqukayo zerotor ukuvelisa iigranuli ezifanayo. Oku kufana kuxhasa ukuhamba okuqikelelwayo kunye nokusabalalisa kwi-injection yokubumba, ekhokelela kumgangatho wemveliso ongaguqukiyo. Kwi-recycling, amasuntswana afanayo aphucula ukuhlamba, ukunyibilika, kunye nokusebenza kakuhle kwepelletizing. Izixhobo ezifana nabaxube bemibala ethe nkqo ziqinisekisa ngaphezulu kwe-95% ukufana, ukunciphisa iziphene kunye nokuphucula ukusebenza koomatshini.

Icebiso: Ukugcinwa rhoqo kunye neenzwa ezihlakaniphile kunceda ukufumanisa imiba kwangaphambili, ukuthintela ubungakanani besuntswana elingahambelaniyo kunye nokunciphisa ixesha lokuphumla.

Ubungakanani besuntswana obufanayo bukwavumela ukuxubana okungcono, ukuhambelana kombala, kunye namandla oomatshini kwiimveliso ezigqityiweyo. Oomatshini ababonelela ngotshintsho olukhawulezayo lwesetingi kunye nokuzenzekela baziqhelanisa ngokulula neemfuno ezahlukeneyo zemveliso, ukomeleza ukuguquguquka kunye nokuxhasa iziphumo ezikumgangatho ophezulu kuzo zombini ukuhlaziya kunye nokubumba inaliti.

Itekhnoloji yokusika kunye noYilo lweBlade

Itekhnoloji yokusika yenza isiseko sayo yonke igranulator yeplastiki. Uyilo oluchanekileyo lweblade luqinisekisa ukusetyenzwa okusebenzayo, iigranule ezikumgangatho ophezulu, kunye nexesha elincinci lokuphumla. Iigranulator zale mihla zisebenzisa izinto ezininzi eziphambili ukuhlangabezana neemfuno zokuphinda zisetyenziswe kunye nokubumba iinaliti.

- I-V-cut rotor knives yenza umgangatho ophezulu we-regrind kunye neentlawulo ezincinci, eziphucula ukuhambelana kwemveliso.

- Imiqolo emininzi yee-rotor knives, njenge-9, 11, okanye i-13 imigqa, iphakamisa umthamo wokusika kwaye ivumele umatshini ukuba aphathe imiqulu emikhulu.

- Iincam ezishenxisekayo eziphambukisayo zisebenza njengeblade yestator yesithathu. Olu phawu longeza ubundlongondlongo bokusika kwaye luvumela uhlengahlengiso olukhawulezayo ngexesha lokusebenza.

- Iibheringi zerotor ezinkulu kunye nokunyuswa kweemela zixhasa imisebenzi enzima yokurisayikilisha. Ezi nxalenye zichasene nokugqoka kunye nokwandisa ubomi begranulator.

- Iintsimbi ezikwaziyo ukunxiba kunye nobuso obunzima kwi-rotors kunye nezindlu zikhusela umatshini kwizinto ezinqabileyo okanye ezingcolileyo.

- Ulwakhiwo oluqinileyo lwentsimbi oludityanisiweyo luqinisekisa ukuqina, nakwiindawo ezifunayo.

- Iibheringi zebhodi zangaphandle ezinzima, ezihlukaniswe kwigumbi lokusika, zithintela ukungcola kunye nokunciphisa umngcipheko wokungaphumeleli kwangaphambi kwexesha.

Uyilo lwe-blade luchaphazela ukugcinwa kunye nomgangatho wegranule. Iincakuba ezibuthuntu okanye ezingakhekanga kakuhle zinokubangela iigranuli ezingalinganiyo, ezinothuli kunye nokuphuma okuphantsi. Amagqabi ajikelezayo ahlengahlengiswayo avumela ukulolwa komntu ngamnye, okwandisa ubomi beblade kwaye igcine ubungakanani begranule buhambelana. Ukuhlolwa rhoqo kunye nokugcinwa kokukhusela, okufana nokulola kunye nokulungiswa kwe-gap, kunceda ukunciphisa ixesha lokunciphisa.

| Umba | Isishwankathelo sobungqina |

|---|---|

| Blade Materials | I-Tungsten carbide kunye ne-high-speed steel blades zinika ukuxhathisa okuphezulu kunye nobomi obude benkonzo, ukunciphisa ukugcinwa rhoqo. |

| I-Blade Gap | I-gap efanelekileyo ye-blade (0.1-0.3 mm) ibaluleke kakhulu ekunciphiseni ukusebenza kakuhle; Umsantsa ongachanekanga ubangela iincakuba ezibuthuntu, iigranuli ezingalinganiyo, kunye nokwanda kokulondolozwa. |

| I-Blade Design | Uyilo lwe-Spiral knife luphucula ukusebenza kakuhle kokusika kwaye lunciphisa ukuvala, luphucula umgangatho wegranule. |

| Iindlela Zokugcina Isondlo | Ukucoca rhoqo, ukuthambisa, kunye nokulinganisa ukulinganisa okuguquguqukayo kwandisa ubomi be-blade kunye nokugcina ukufana kwegranule. |

| Impembelelo yoyilo olungalunganga | Imeko yeblade engalunganga ikhokelela kuthuli, iigranuli ezingafaniyo kunye neemfuno zokulondolozwa rhoqo. |

Igranulator yeplastiki enetekhnoloji yokusika ephucukileyo kunye neeblade eziyilwe kakuhle zibonelela ngokusebenza okuthembekileyo, iigranule ezikumgangatho ophezulu, kunye neendleko zokugcinwa okuphantsi.

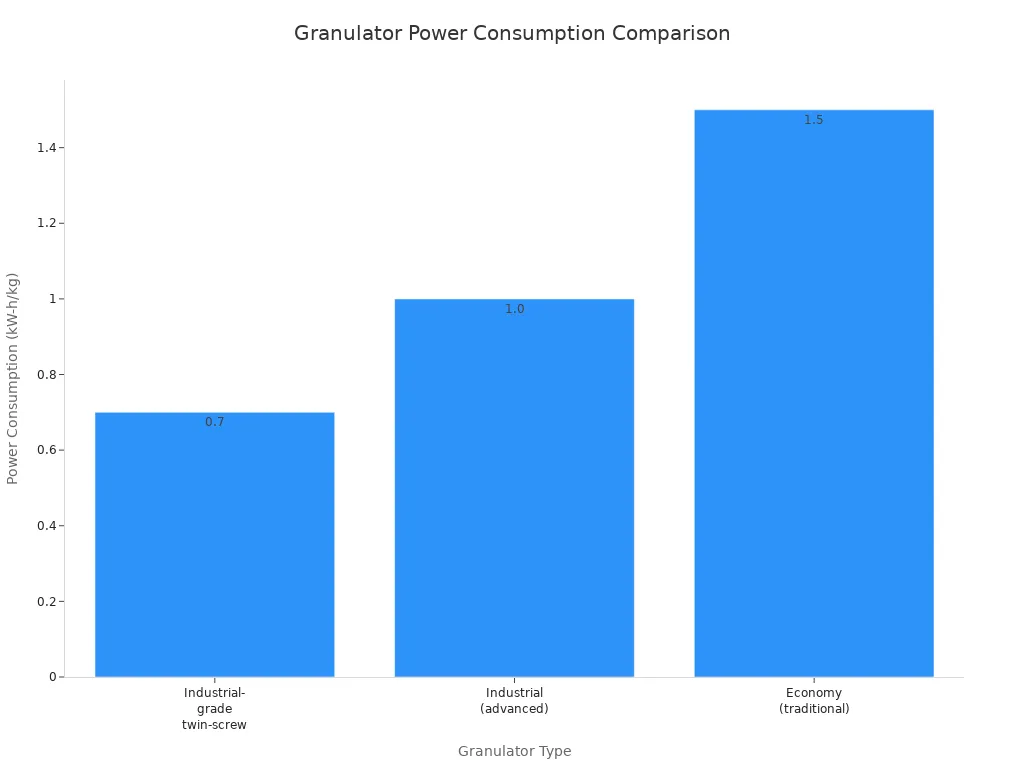

Ukusebenza kakuhle kwamandla kunye nokuNcitshiswa kwengxolo

Ukusebenza kakuhle kwamandla kuye kwaba yinto ephambili kwimveliso yanamhlanje. Iigranulator zeplastiki eziphucukileyo zisebenzisa iimotor ezonga amandla kunye neenkqubo ezikrelekrele zokulawula ubushushu ukunciphisa ukusetyenziswa kwamandla. Imifuziselo ye-Industrial-grade twin-screw ingasebenzisa ukuya kuma-40% amandla angaphantsi kuneemodeli zoqoqosho eziqhelekileyo. Olu phuculo luthoba iindleko zokusebenza kwaye luxhasa iinjongo zozinzo.

Ukunciphisa ingxolo yenye into ebalulekileyo emsebenzini. Iigranulator zePlastiki zinokuba nengxolo, kodwa abavelisi ngoku babonelela ngeemodeli ezingenakuvakala kunye noyilo lokunciphisa ingxolo. Iicasings ezikhusela isandi kunye nolawulo oluzenzekelayo ngokupheleleyo lunceda amanqanaba engxolo asezantsi, okwenza indawo yokusebenza ikhuseleke kwaye ikhululeke ngakumbi. Ezi mpawu zikwanceda amaziko ukuhlangabezana nemithetho yengxolo yokusingqongileyo kunye nokuphucula ukusebenza kakuhle ngokupheleleyo.

Ingcebiso: Ukusebenzisa ukukhuselwa kweendlebe kunye nokugcina izithintelo zesandi ezijikeleze igranulator kunokunciphisa ngakumbi ukubonakaliswa kwengxolo kubaqhubi.

Iigranulator zeplastiki zanamhlanje zidibanisa iimpawu zokonga umbane kunye nobuchwepheshe bokunciphisa ingxolo ukudala indawo yokusebenza ekhuselekileyo, esebenza kakuhle, kunye neyokusingqongileyo.

Iimpawu zoKhuseleko kunye nokuThotyelwa

Ukhuseleko luhlala luyinkxalabo ebalulekileyo kuyo nayiphi na indawo esebenzisa igranulator yeplastiki. Oomatshini kufuneka bahlangabezane nemigangatho engqongqo yokhuseleko ukukhusela abaqhubi kunye nokuqinisekisa ukusebenza okuthembekileyo.

- I-ANSI/PLASTICS B151.11-2021 ichaza iimfuno zokhuseleko kwiigranulator, ukuyila okugqumayo, ukusebenza, ukugcinwa kunye nokuguqulwa.

- Eminye imigangatho efanelekileyo ibandakanya i-ANSI / PLASTICS B151.1-2017 kumatshini wokubumba inaliti kunye ne-ANSI / PLASTICS B151.27-2021 yerobhothi / i-injection molding systems systems.

- Ukuthobela le migangatho kubalulekile ekusebenzeni ngokukhuselekileyo kwiimarike ezinkulu zemveliso.

Iigranulator zePlastiki zifuna ulawulo oluninzi olwakhelwe ngaphakathi lokhuseleko:

- Iisistim zokutshixa/zokukhupha umbane ziqhawula umbane phambi kokugcinwa okanye ukucoca.

- Abalindi kunye nee-interlocks zithintela ukufikelela kwiimela ezihambayo.

- Amaqhosha okumisa okungxamisekileyo, ii-alam zokuthintela, kunye nezikhuselo zombane ezimbini zibonelela ngokusabela ngokukhawuleza kwiingozi.

- Abanini-zithuthi kufuneka banxibe izixhobo zokuzikhusela, ezinje ngeeglavu, iliso, ubuso, indlebe nothuli.

- Ukuhlolwa rhoqo kunye nokutshekishwa kokhuseleko lwemihla ngemihla kugcina umatshini kwindawo ekhuselekileyo yokusebenza.

- Abaqhubi bafuna uqeqesho olufanelekileyo kunye nemiyalelo ecacileyo ngolwimi abaluqondayo.

Qaphela: Ukugcina indawo ekusetyenzwa kuyo icocekile kwaye ingenamiqobo kunceda ukuthintela ukutyibilika, iihambo, nezinye iingozi.

Ngokulandela ezi ndlela zokhuseleko kunye nokuthobela imigangatho eyaziwayo, amaziko anokuqinisekisa ukusebenza ngokukhuselekileyo nangokufanelekileyo kweegranulator zabo zeplastiki.

Iingqwalasela zePlastiki zeGranulator yokuSebenza

Iindlela zokutyisa kunye neeKhetho zokuLayisha

Abaqhubi banokukhetha kwiindlela ezininzi zokutya xa bedibanisa igranulator yeplastiki kumgca wemveliso. Ukutya ngezandla kusebenza kakuhle kwiibhetshi ezincinci okanye ukusetyenziswa ngamaxesha athile. Ukutya kwee-Conveyor kuxhasa umsebenzi oqhubekayo kwaye kunciphisa umsebenzi wezandla. I-Roll feeding ilungile kumaphepha eplastiki amancinci okanye iifilimu.Ukutyisa iirobhothikwandisa i-automation kunye nokhuseleko ngokunciphisa ukudibanisa komntu kunye neendawo ezihambayo. Indlela nganye ichaphazela ukusebenza kakuhle kunye nokuhamba kwezinto ngeendlela ezahlukeneyo.

Ukubeka iigranulator ecaleni koshicilelo konga indawo yomgangatho kwaye ulungelelanisa ukuhamba komsebenzi. Iiphaneli zokufikelela ngaphambili zenza ukusebenza kunye nokugcinwa kube lula. Izinketho zokondla ngokuzenzekelayo nazo zinciphisa ukuphathwa ngesandla, okunciphisa umngcipheko wokulimala kunye nokuphucula isantya sokuvelisa.

Itheyibhile engezantsi igxininisa imiba yokusebenza ephambili ekufuneka iqwalaselwe xa ukhetha iindlela zokutyisa kunye nokulayisha:

| Umba wokuSebenza | Inkcazo kunye neNgqwalasela |

|---|---|

| Uhlobo lweMathiriyeli yePlastiki | Iiplastiki eziqinileyo zifuna iincakuba ezinamandla kunye neenjini; iiplastiki ezithambileyo zifuna ukuphathwa kakuhle. |

| Iimfuno zobungakanani bemveliso | Izikrini ezilungelelanisiweyo zinceda ukufezekisa ubungakanani obufunekayo begranule kwiinkqubo ezisezantsi. |

| Isakhono seMveliso | Imveliso kufuneka ihambelane neemfuno zemveliso ukuthintela imiqobo. |

| Ukuhambelana kokudibanisa | Iinkqubo zokutya kufuneka ziqhagamshelane ngokutyibilikayo kunye nezixhobo zokuhambisa, iirobhothi, okanye ezinye izixhobo ezizenzekelayo. |

ULondolozo kunye nokuCoca lula

Ukugcinwa rhoqo kugcina igranulator yeplastiki isebenza kakuhle kwaye yandisa ubomi bayo. Abanini-zithuthi kufuneka bajonge yonke imihla iibholiti ezixekileyo, ukuvuza, okanye ingxolo engaqhelekanga. Ukucoca i-hopper kunye nokuhlola igumbi lokusika emva kokutshintsha ngalunye kuthintela ukwakhiwa kwezinto. Imisebenzi yeveki iquka ukujonga iimela ukuba buthuntu, izikrini zokucoca, kunye neebheringi zokuthambisa. Ukucocwa okunzulu kwenyanga kunye nohlengahlengiso lwesikhewu somese kunceda ukugcina ukusebenza kakuhle kokusika.

- Mihla le: Hlola umonakalo, cacisa imiqobo, kwaye ujonge iimpawu zokhuseleko.

- Rhoqo ngeveki: Hlola iimela kunye nezikrini, iibheringi zokuthambisa, kwaye uqinise izibophelelo.

- Ngenyanga: Amagumbi acocekileyo acocekileyo, lungisa izikhewu zeemela, kwaye uhlole uqhagamshelo lombane.

- Ngesiqingatha soNyaka/Ngonyaka: Lola okanye utshintshe iimela, buyisela iindawo ezigugileyo, kwaye wenze uhlolo olupheleleyo.

Ukusebenzisa izixhobo zomvelisi (OEM) iinxalenye kunye nokulandela iinkqubo ezingqongqo zokhuseleko kuqinisekisa umgangatho kunye nokhuseleko lomsebenzisi. Ukugcina indawo ekusetyenzwa kuyo icocekile nako kuxhasa ugcino olusebenzayo.

Ukuqina kunye noKwakha uMgangatho

Ukuqina kudlala indima ephambili kwixabiso lexesha elide legranulator yeplastiki. Oomatshini abakhiwe ngamacangci entsimbi aphethwe bubushushu kunye neenjini ezomeleleyo zimelana nokusetyenziswa kakhulu kunye nezinto ezirhabaxa. Ukwakhiwa kweemodyuli kuvumela ukutshintshwa kwenxalenye ekhawulezayo, ukunciphisa ixesha lokuphumla. Uyilo lokufikelela ngokulula lwenza utshintsho lwe-blade kunye nokucoca ngokukhawuleza, olunceda ukugcina ubukhali kunye nokusebenza kakuhle.

Umgangatho wokwakha ophezulu unokwandisa ixesha lokuphila kwe-granulator ukuya kwi-10-20 iminyaka. Ukuhlolwa rhoqo, ukuthambisa okufanelekileyo, kunye nokutshintshwa kwangethuba kwamalungu agugileyo kugcina umatshini uthembekile. Izakhelo ezinamandla kunye namacandelo asemgangathweni athoba iindleko zokusebenza kunye nokunciphisa imfuno yokulungiswa rhoqo.

Utyalo-mali kwigranulator ehlala ixesha elide ixhasa imveliso eqhubekayo kwaye inceda izibonelelo zifezekise ukonga iindleko zexesha elide.

Emva koThengiso lweNkxaso kunye neeNdawo eziSpare

Inkxaso yokuthengisa emva kokuthengisa idlala indima ebalulekileyo kwimpumelelo yexesha elide kuyo nayiphi na imisebenzi yeplastiki. Iinkampani kwimizi-mveliso yokuhlaziya kunye nenaliti yokubumba ixhomekeke kwinkonzo ethembekileyo ukugcina izixhobo zabo zisebenza kakuhle. Xa umatshini uyeka ukusebenza, imveliso inokuma, nto leyo ekhokelela ekuphulukaneni nexesha nemali. Inkxaso ethembekileyo emva kokuthengisa inceda ukukhusela ezi ngxaki kwaye iqinisekise ukubuyiswa ngokukhawuleza xa kuvela imiba.

Abasebenzisi abaninzi baxabisa iintlobo ezininzi zeenkonzo emva kokuthengisa. Ezi ziquka:

- Ukufikelela kwiingcali zenkonzo yasentsimini ezinamava ezinokuxilonga zize zilungise iingxaki esizeni.

- Ubuchwephesha besicelo obunceda abaqhubi ukuba bafumane okuninzi koomatshini babo.

- Inkxaso engagungqiyo evela kumthengisi, eyakha ukuthembana nokuzithemba.

Izibonelelo zokurisayikilisha zihlala zijongene nemingeni eyodwa. Baxhamla kwi:

- Uthethwano lweengcali olulungiselelwe iinkqubo zabo zokurisayikilishwa.

- Uqeqesho olubanzi lwabasebenzi ukuze basebenzise kwaye bagcine izixhobo ngokukhuselekileyo.

- Uncedo lobugcisa oluqhubekayo ukusombulula imiba engalindelekanga.

Abasebenzisi bokubumba isitofu nabo bajonge:

- Ufakelo lobungcali ukuqinisekisa ukuba oomatshini basebenza ngokuchanekileyo kwasekuqaleni.

- Uqeqesho olugqibeleleyo kubo bonke abasebenzi.

- Uncedo lobuchwephesha oluthembekileyo kunye nobonelelo oluzinzileyo lweendawo ezisecaleni.

- Iinkonzo zogcino ezinceda ukwandisa ubomi besixhobo.

Izibonelelo zenkxaso ezifikelelekayo zenza umahluko. Iinkampani ezininzi zibonelela:

- Iinkonzo zothethwano ukuphendula imibuzo kunye nokubonelela ngesikhokelo.

- Inkxaso yevidiyo yokulungisa ingxaki kunye nokulungiswa.

- Ii-FAQ ezinceda abasebenzisi ukusombulula iingxaki eziqhelekileyo ngokukhawuleza.

Ingcebiso: Ukugcina isitokhwe seendawo eziyimfuneko kwindawo kunokunciphisa ixesha lokuphumla kwaye ugcine imveliso ihamba.

Inkqubo yokuxhasa eyomeleleyo emva kokuthengisa iqinisekisa ukuba oomatshini bahlala bethembekile kwaye besebenza kakuhle. Ikwanika abaqhubi ukuzithemba kokusingatha imingeni yemihla ngemihla kunye nesicwangciso sokukhula kwexesha elizayo.

Ukukhetha iGranulator yePlastiki eLungileyo

Ukuthelekisa iiNdidi zeGranulator kwiiMathiriyeli kunye neeNkqubo

Ukukhetha igranulator efanelekileyo kuqala ngokuqonda izinto kunye neenkqubo ezisetyenziswayo. Amanye amaziko enza iiplastiki eziqinileyo ezifana ne-ABS okanye i-polycarbonate. Abanye baphatha izinto ezithambileyo ezifana nefilimu yepolyethylene. Uhlobo ngalunye lwezinto eziphathekayo ludinga igumbi elithile lokusika kunye noyilo lwe-blade. Umzekelo, iinxalenye ezinodonga olungqingqwa zifuna igumbi le-tangential, ngelixa iifilimu ezincinci zisebenza kakuhle ngeerotors ezivulekileyo. Abaqhubi kufuneka baqwalasele ubungakanani be-scrap kunye nobungakanani obufunekayo bemveliso. Amaziko okurisayikilisha omthamo ophezulu angafuna imifuziselo emikhulu, enzima.Iivenkile zokubumba izitofubahlala bekhetha iiyunithi ezixineneyo, ezisecaleni kweendaba. Ukufanisa uhlobo lwegranulator kwizinto eziphathekayo kunye nenkqubo iqinisekisa ukusebenza ngokufanelekileyo kunye neziphumo eziphezulu.

Iindleko zokulinganisa, iXabiso, kunye nokuSebenza kwexesha elide

Iindleko zidlala indima enkulu ekukhetheni izixhobo. Nangona kunjalo, ixabiso eliphantsi alisoloko lithetha ixabiso elingcono. Amaziko kufuneka ajonge ixabiso lilonke lobunini. Oku kubandakanya ukusetyenziswa kwamandla, ukugcinwa, kunye nokufumaneka kweendawo ezisecaleni. Oomatshini abaneenjini ezonga amandla kunye neencakuba ezomeleleyo bahlala begcina imali ngokuhamba kwexesha. Inkxaso ethembekileyo emva kokuthengisa inokunciphisa ixesha lokuphumla kunye neendleko zokulungisa. Utyalo-mali kwigranulator ekumgangatho ophezulu inceda ukugcina imveliso engaguqukiyo kunye nokunciphisa iindleko zexesha elide.

Ingcebiso: Qwalasela ubomi obulindelekileyo kunye neemfuno zokulondolozwa phambi kokuba uthenge. Umatshini owakhiwe kakuhle unokuhlala iminyaka emininzi ngononophelo olufanelekileyo.

Uluhlu lokuKhetha iGranulator

Abasebenzisi banokusebenzisa uluhlu lokutshekisha ukukhokela isigqibo sabo:

- Ukuchonga iintlobo kunye nobukhulu bezinto zeplastiki eziza kuqhutyelwa phambili.

- Qikelela umthamo wemihla ngemihla okanye ngeveki.

- Jonga ukuhambelana neenkqubo zokutyisa ezikhoyo kunye nokukhupha.

- Ukuphonononga iimpawu zokhuseleko kunye nokuthotyelwa kwemigangatho yoshishino.

- Ukuvavanya ukusebenza kakuhle kwamandla kunye namanqanaba engxolo.

- Vavanya lula ukugcinwa nokucoca.

- Qinisekisa ubukho beendawo ezisecaleni kunye nenkxaso yobugcisa.

- Thelekisa iindleko zizonke zobunini, hayi nje ixabiso lokuthenga.

Ukuphononongwa ngononophelo kwezi zinto kunceda ukuqinisekisa ukuba igranulator yeplastiki ekhethiweyo ihlangabezana neemfuno zangoku nezexesha elizayo.

Ukukhetha izixhobo ezichanekileyo kuqinisekisa imisebenzi egudileyo kwi-recycling kunye nesitofu sokubumba. Izibonelelo zixhamla koomatshini ababonelela ngeendleko ezifanelekileyo, ukuxhasa iinjongo zokusingqongileyo, kunye nokuphucula isantya semveliso. Iinzuzo eziphambili ziquka:

- Iindleko ezisezantsi zemathiriyeli ekrwada ngokurisayikilishwa.

- Ukunciphisa inkunkuma yeplastiki kwindawo ecocekileyo.

- Ukuphathwa lula kunye nokugcinwa kwemathiriyeli granulated.

- Umgangatho wemveliso ohambelanayo kunye neegranule ezifanayo.

- Ukugcinwa okulula kunye neendawo zokusebenza ezikhuselekileyo, ezicocekileyo.

Abanini-zithuthi kufuneka basebenzise uluhlu lokutshekisha ukukhokela kwisigqibo sabo kunye nokuzuza impumelelo yexesha elide.

FAQ

Ziziphi iintlobo zeeplastiki ezinokuthi inkqubo yegranulator?

Uninziiigranulator zeplastikiukuphatha izinto eziqhelekileyo ezifana ne-ABS, PP, PE, PVC, kunye ne-PET. Ezinye iimodeli zikwasebenza iiplastiki zobunjineli okanye izinto ezinefiber yeglasi. Soloko ujonga iinkcukacha zomatshini ukuhambelana.

Kufuneka abaqhubi benze kangaphi ulondolozo kwigranulator?

Abaqhubi kufuneka bahlole i-granulator yonke imihla ngokunxiba okanye ukonakala. Ukucoca rhoqo ngeveki kunye nokuthambisa kunceda ukugcina ukusebenza. Ukucocwa okunzulu kwenyanga kunye nokuhlolwa kwe-blade kwandisa ubomi bomatshini kunye nokuqinisekisa ukusebenza ngokukhuselekileyo.

Kutheni le nto ubungakanani bamasuntswana afanayo bubalulekile kwigranulation yeplastiki?

Ubungakanani besuntswana obufanayo buqinisekisa ukondla okugudileyo koomatshini bokubumba inaliti. Ikwaphucula ukunyibilika kunye nokuxuba ngexesha lokurisayikilishwa. Iigranule ezihambelanayo zinceda ukugcina umgangatho wemveliso kunye nokunciphisa inkunkuma.

Ngaba igranulator yeplastiki inganciphisa iindleko zamandla?

Ewe. Iigranulator ezonga amandla zisebenzisa iimotor eziphambili kunye nolawulo olukrelekrele. Ezi mpawu zinciphisa ukusetyenziswa kombane kwaye zinciphisa iindleko zokusebenza ekuhambeni kwexesha.

Ziziphi iimpawu zokhuseleko ekufuneka i-granulator yeplastiki ibandakanye?

Igranulator esemgangathweni ibandakanya amaqhosha okumisa okungxamisekileyo, ukhuseleko lokungena, kunye neenkqubo zokutshixa/ukuphuma. Ezi mpawu zikhusela abaqhubi kunye nezibonelelo zoncedo ukuhlangabezana nemigangatho yokhuseleko lweshishini.

Ixesha lokuposa: Jul-17-2025