A Umshini Wokugaywa kabusha wePlastikingo-2025 ihlanganisa izingxenye ezibalulekile ezimbalwa, njengezinhlelo zokuqoqa ezithuthukile, amayunithi okuhlunga, aUmshini we-Granulator, kanye aI-Plastic Shredder. Isigaba ngasinye kule nqubo sibalulekile ekuguquleni udoti ube ama-pellets asebenzisekayo, okwenzaUmshini Wokwenza kabusha Wepulasitikiesebenza kahle kakhulu. Ngokusho kwedatha yemakethe yakamuva,Ukuthengwa kwe-PET scrap kufinyelele cishe kumathani angama-251,000 ngo-2024.

| Isigaba | Incazelo yezibalo / yethrendi |

|---|---|

| I-PET Scrap Imports (2024) | amathani angama-250,961, cishe u-49% wesamba semali esele engenisiwe |

Okuthathwayo Okubalulekile

- Imishini yokugaywa kabusha kwepulasitikisebenzisa inqubo yesinyathelo ngesinyathelo kubandakanya ukuqoqwa, ukuhlunga, ukusika, ukuwasha, ukuhlukanisa, ukukhipha, kanye ne-pelletizing ukuze uguqule imfucuza ibe ngamapulangwe epulasitiki asebenziseka kabusha ngokuphumelelayo.

- Ubuchwepheshe obuhlakaniphile obufana nokuhlunga okushayelwa yi-AI kanye nezinhlelo zokuwasha ezithuthukisiwe zithuthukisa ukunemba kokugaya kabusha, ukunciphisa ukungcola, futhi kukhuphule ikhwalithi yamapulasitiki agaywe kabusha.

- Imishini emisha yokugaywa kabusha yonga amandla futhi inqamule ukukhishwa kwezinto ezikhishwayo, okwenza inqubo yokugaywa kabusha kwepulasitiki iqhubeke futhi ingabizi kakhulu ngekusasa.

Inqubo Yomshini Wokugaywa Kabusha Wepulasitiki Nezingxenye Eziyinhloko

Amasistimu wokuqoqa

Amasistimu wokuqoqa akha isiqalo sanoma yimuphi Umshini Wokugaywa Kabusha Wepulasitiki. Lezi zinhlelo ziqoqa udoti wepulasitiki ezindlini, amabhizinisi, nasezindaweni zomphakathi. Amadolobha amaningi manje asebenzisa imigqomo ehlakaniphile nokulandela ngomkhondo kwedijithali ukuze kukhuliswe amanani okuqoqwa.Amathuluzi edijithali asiza opharetha ukuthi babone idatha yesikhathi sangempela, okusho ukuthi bangaphendula ngokushesha emigqonyeni egcwele noma ezithombeni eziphuthelwe.

Ithiphu: Ukuqeqeshwa kwabaqoqi bemfucuza kanye nezinhlelo zokuklomelisa kungenza ukuqoqwa kusebenze kakhudlwana futhi kugcine udoti wepulasitiki ungangeni ezindaweni zokulahla.

Ezinye izici ezibalulekile ezithuthukisa ukusebenza kahle kwesistimu yokuqoqa zihlanganisa:

- Ukubika kokumosha kwesikhathi sangempela nokuqoqwa kwedatha okuzenzakalelayo.

- Ukuqapha ukusebenza kusetshenziswa izinkomba ezibalulekile njengokusebenzisa isikhathi nesikhathi sokuphumula.

- Ukuqeqeshwa kwabasebenzi ngokusebenza komshini nokuphepha.

- Amasu okonga amandla, njengokusebenzisa amathuluzi asebenzayo kanye nokugcinwa njalo.

Umthetho nawo udlala indima enkulu. Imithetho manje idinga inani elithile lokuqukethwe okugaywe kabusha emikhiqizweni, okuphoqa izinkampani ukuthi ziqoqe amapulasitiki amaningi ukuze agaywe kabusha.

Ukuhlunga amayunithi

Amayunithi okuhlunga ahlukanisa amapulasitiki ngohlobo, umbala, kanye nekhwalithi. Lesi sinyathelo sibalulekile ngoba amapulasitiki ahlukene adinga izinqubo ezihlukene zokugaywa kabusha. Amayunithi okuhlunga esimanje asebenzisa ama-laser ne-AI ukuskena nokuhlunga amapulasitiki ngesivinini esikhulu. Isibonelo, amasistimu wokuhlunga nge-laser angakwaziskena kufika ku-860,000 spectra ngomzuzwana, okwenza kube lula ukuhlunga ngisho namapulasitiki amnyama akhohlisayo. Izitholi ze-FT-NIR manje zihlala amahora afinyelela kwangu-8,000 phakathi kwamaphutha, okusho ukuthi isikhathi sokuphumula sincane kanye nokuhlunga okunembe kakhudlwana.

| Inhlanganisela Yesistimu Yokuhlunga | Imfucumfucu Yepulasitiki Ehlukanisiwe (kg yisakhamuzi ngasinye) |

|---|---|

| Ukuhlukaniswa kokuthunyelwe kuphela | 6.2 |

| Iqoqo le-Curbside kuphela | 5.6 |

| Inhlanganisela yokuhlukaniswa kweposi + i-curbside | 7.6 – 8.0 |

| Iqoqo le-Curbside + letha izindawo | 3.5 |

Amazwe asebenzisa izinqubomgomo eziqinile zokuhlukanisa imithombo, njengeSouth Korea,baphinde basebenzise imfucuza efika ku-70% kamasipala. Amayunithi okuhlunga athuthukisiwe ane-AI kanye nobuchwepheshe be-infrared obuseduze angafinyelela ukunemba okungaphezu kuka-90%, okuthuthukisa ikhwalithi nomkhiqizo wamapulasitiki agaywe kabusha.

Ama-shredders nama-Granulators

Ama-shredders nama-granulator aphula izinto ezinkulu zepulasitiki zibe izingcezu ezincane. Lokhu kwenza kube lula ukuthi Umshini Wokugaywa Kabusha Wepulasitiki ucubungule okokusebenza ngezinyathelo zakamuva. Abasebenzisi kufanele bagcine izindwani zibukhali futhi baphakele umshini ngezinga eliqinile ukuze bagweme ukuminyana. Ukukhipha ukungcola ngaphambi kokusikwa kusiza umshini ukuthi uhlale isikhathi eside.

Ezinye izinqubo ezingcono kakhulu zama-shredders nama-granulator zifaka:

- Ukugcinwa okuvamile nokuhlolwa kwe-blade.

- Izinto zokugeza ngaphambi kokunciphisa ukuguga.

- Ukugcina izinga lokuphakelayo elingaguquki.

- Ukuphatha uthuli nomsindo ngokuphepha.

- Ukuqeqesha ama-opharetha ukubona nokulungisa izinkinga ngokushesha.

Amamethrikhi okusebenza afana nenani lokuphuma, ukusetshenziswa kwamandla, nekhwalithi yokuphuma asiza opharetha ukuthi bagcine le mishini isebenza kahle.

Amasistimu Wokugeza

Imishini yokuwasha ihlanza ipulasitiki ephukile. Basusa ukungcola, amalebula, nokudla okusele noma amakhemikhali. Ipulasitiki ehlanzekile kulula ukuyigaya kabusha futhi yenza imikhiqizo engcono. Ucwaningo lubonisa ukuthi ukugeza ngamanzi abandayo noma ashisayo, ngezinye izikhathi ngama-ejenti okuhlanza, kungasusa ukungcola okuningi. Ngemva kokugeza, ukomisa kuletha umswakama phansi ku-3% noma ngaphansi, okulungele ukuqhubeka nokucubungula.

| Indlela Yokugeza | Ukususa Ukungcola Ngempumelelo | I-Melt Flow Index (MFI) Ukuhlukahluka | Izakhiwo Zemishini (I-Ductility) | Amanothi |

|---|---|---|---|---|

| Okungageziwe (rPPu) | Lutho | Ukuhlukahluka okuphezulu | Ubude obuphansi ngesikhathi sekhefu | Ukungcola kubangela ukuwohloka |

| Ukugeza Amanzi Abandayo (rPPcw) | Okubalulekile | Ukuhlukahluka okwehlisiwe | Ukuthuthukiswa kwe-ductility kancane | Ukonga amandla |

| Ukugeza Amanzi Ashisayo (rPPhw) | Phezulu | Okufana nokugeza okubandayo | Ukuthuthukiswa kwe-ductility kancane | Iqhathaniswa nokugeza okubandayo |

| Amanzi Ashisayo + Ama-ejenti (rPPhwca) | Phezulu | Okufana nokugeza okubandayo | Ukuthuthukiswa kwe-ductility kancane | Iqhathaniswa nokugeza okubandayo |

Izinhlelo zokuwasha ezihlanganisa ukomiswa kwamanzi nomoya zingathuthukisa ikhwalithi nokucutshungulwa kwamapulasitiki agaywe kabusha.

Separation Technologies

Ubuchwepheshe bokuhlukanisa bucwengisa ukusakaza kwepulasitiki nakakhulu. Lawa masistimu asebenzisa izindlela ezifana nokuhlunga kwe-infrared eduze, i-flotation, ngisho nezinqubo zamakhemikhali ukuhlukanisa amapulasitiki ngokuminyana noma ukwakheka kwamakhemikhali.Izinkampani ezifana ne-Dow ne-SABIC zisebenzisa ukuhlunga okuthuthukilekanye nezithasiselo ezihambisanayo zokugcina ikhwalithi yepulasitiki egaywe kabusha iphezulu. Ukuhlunga okuqhutshwa yi-AI kanye nokuhlanzwa okusekelwe ku-solvent nakho kusiza ukususa izinto ezingafuneki.

| Uhlobo Lwereferensi | Incazelo | Igalelo Ekuthembekeni |

|---|---|---|

| Izihloko Zokucwaninga | Izifundo zokuntanta, ukuhlukaniswa komoya, nokuhlukaniswa kokuqina | Nikeza idatha yokuhlola yezindlela zokuhlukanisa |

| Amalungelo obunikazi | Izinqubo zobunikazi zokuhlukaniswa kwepulasitiki | Qinisekisa ukuhlanzwa okusebenzayo |

| Izingxoxo Zenkomfa | Intuthuko ekuhlungeni kwencibilika kanye nokuhlunga okuzenzakalelayo | Thuthukisa ukunemba kokuhlunga kanye nekhwalithi |

| Izindlela Zokuhlonza Spectral | Ukukhishwa okuseduze kwe-infrared kanye ne-laser-induced | Nika amandla ukuhlunga okusheshayo, okuthembekile |

| Imibiko Yezimboni | Ubufakazi obusebenzayo bokuthuthukisa inqubo | Sekela uhlelo lokusebenza lomhlaba wangempela |

Lobu buchwepheshe buqinisekisa kuphela uhlobo olulungile lwepulasitiki oludlulela esinyathelweni esilandelayo, okuwukhiye wokwenza imikhiqizo yekhwalithi ephezulu egaywe kabusha.

Extrusion Units

Amayunithi e-Extrusion ayancibilika futhi amise kabusha ipulasitiki ehlanziwe ibe yifomu elisha. Umshini Wokugaywa Kabusha Wepulasitiki usebenzisa ukushisa nengcindezi ukusunduza ipulasitiki ngesikhunta, udale imicu emide noma amashidi. Ama-extruder amasha asebenza kahle kakhulu kunamamodeli amadala. Ngokwesibonelo, imishini emisha cankhuphula ukukhiqiza ngaphezulu kwama-36%nokusebenzisa ugesi okuphansi, okonga imali namandla.

| Imethrikhi | Ama-Extruders amadala | Ama-Extruders amasha | Ukuthuthukiswa (%) |

|---|---|---|---|

| Ukukhiqiza (amathani/ngosuku) | 11 | 15 | 36.4 |

| Imajini yomnikelo (amayunithi) | 6126.9 | 6881.3 | +754,4 |

Ubuchwepheshe be-extrusion obuthuthukisiwe bugcina ipulasitiki iqinile, ngisho nangemva kwemijikelezo embalwa yokugaywa kabusha. Lokhu kusho ukuthi imikhiqizo egaywe kabusha ingahlala isikhathi eside njengaleyo eyenziwe ngepulasitiki entsha.

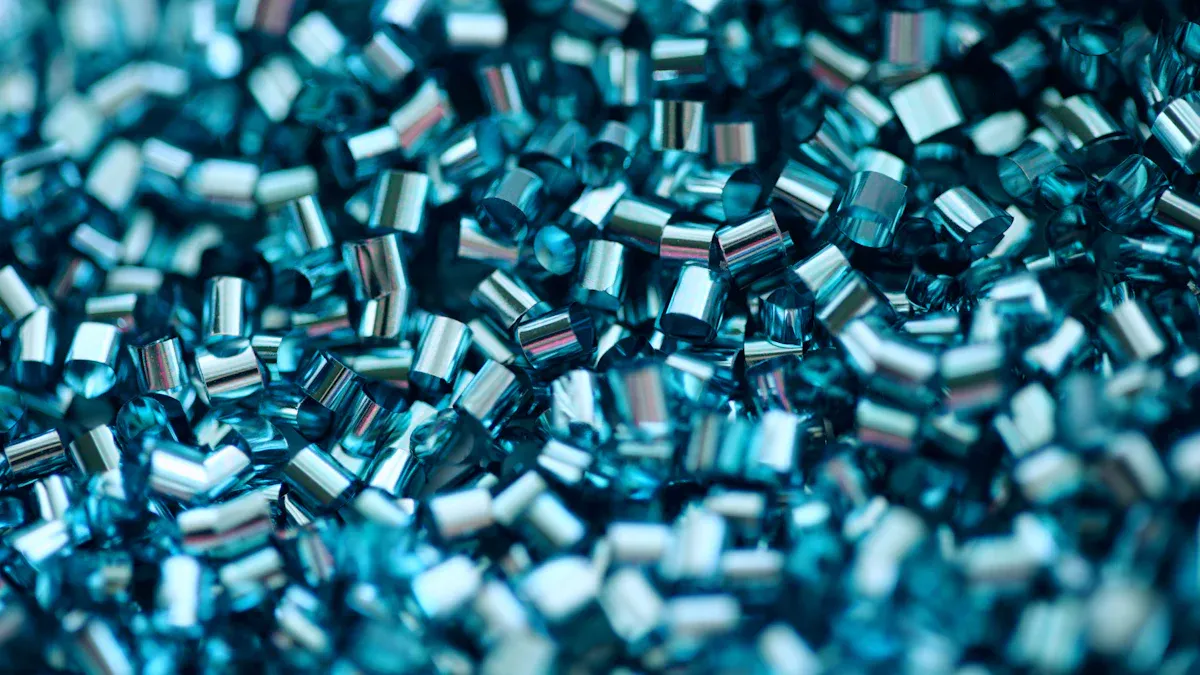

Amayunithi Pelletizing

Amayunithi e-pelletizing asika ipulasitiki ekhishiwe ibe amapellets amancane, afanayo. Lawa ma-pellets kulula ukuthutha futhi asetshenziswe ekwenzeni imikhiqizo emisha.Ukusebenza kahle kwe-Pelletizing kuvame ukufinyelela ngaphezu kwama-90%lapho opharetha belawula umswakama kanye nesivinini somshini.

| Okuphakelayo Isampula | Okuqukethwe Umswakama | I-Die Diameter | Isivinini somshini (rpm) | Ukusebenza Kwe-Pelletizing |

|---|---|---|---|---|

| X1 | 7% | 3 mm | 75 | 94.0% |

| X2 | 7% | 3 mm | 75 | 93.2% |

| X3 | 7% | 3 mm | 75 | 92.1% |

Ama-opharetha angalungisa izilungiselelo ezifana nezinga lokukhiqiza nebanga lommeseukuze uthole ikhwalithi engcono kakhulu ye-pellet. Ukusebenza kahle kwe-pelletizing kusho udoti omncane kanye nezinto ezisetshenziswa kakhulu emikhiqizweni emisha.

Okusungulwe Emishini Yokugaywa Kabusha Kwepulasitiki kwango-2025

I-Smart Sorting kanye ne-AI Integration

Ukuhlunga ngobuhlakani kushintshile ukuthi izindawo zokugaywa kabusha zisebenza kanjani. Izinkampani eziningi manje zisebenzisaumbono wekhompyutha, ukufunda okujulile, kanye ne-hyperspectral imagingezinhlelweni zabo zokuhlunga. Lawa mathuluzi asiza amarobhothi ukuthi abone izinto ezingasetshenziswa kabusha, ahlele ukunyakaza kwawo, futhi ahlele amapulasitiki ngokunemba okuphezulu. Amamodeli okufunda okujulile angabikezela ngisho nezinhlobo zemfucuza futhi asize ngokuhlela.

- Izingalo zerobhothi zisebenzisa i-hyperspectral imaging ukuze zilungise ukubamba kwazo, kwenze ukuhlunga kucace kakhudlwana.

- Amanethiwekhi we-Neural nokufunda komshini kusiza ukubikezela ukukhiqizwa kukadoti, ukuze izindawo zikwazi ukuhlela kangcono.

- Ama-algorithms afana nehlathi elingahleliwe nemishini yokusekela ye-vector athuthukisa ukuhlunga, ngisho namanani amancane edatha.

Izibonelo zomhlaba wangempela zibonisa umthelela. I-HERA yase-Italy isebenze ne-IBM ukwengeza i-AI ohlelweni lwabo lokuhlunga. Lokhu kuholele emazingeni aphezulu okugaywa kabusha kanye nomsebenzi omncane wezandla. E-Japan nase-US, amarobhothi anamandla e-AI ahlunga imfucuza esebenzisa izinzwa namakhamera. Lawa marobhothi abiza phakathi$250,000 futhi $500,000ngayinye, kodwa izikhungo ezinkulu zivame ukubona imbuyiselo eminyakeni emi-5 kuye kweyi-10 ngenxa yokonga kwabasebenzi kanye nokuhlunga okungcono. Imigqomo ehlakaniphile nezinzwa nakho kuyasiza ngokunciphisa ukuthi amaloli adinga kangaki ukuqoqa udoti, onge imali nesikhathi.

I-Advanced Washing and Separation Technologies

Ukugeza nokuhlukanisa izinhlelosebehlakaniphe kakhulu futhi banokwethenjelwa. Kusetshenziswa imishini yokuwasha yesimanjeizinzwa kanye ne-automationukulawula ukuhlanza nokomisa. Lokhu kugcina udoti wepulasitiki uhlanzekile futhi ulungele isinyathelo esilandelayo. Ukuqapha kwesikhathi sangempela kusiza opharetha ukuthi babone izinkinga kusenesikhathi futhi bagcine inqubo isebenza kahle.

- I-Near-infrared spectroscopyihlunga amapulasitiki afana ne-HDPE ngokuhlanzeka okuphezulu.

- Ama-Compatibilizers athuthukisa ikhwalithi yamapulasitiki agaywe kabusha.

- Ukuhlanzwa okusekelwe ku-solvent kususa ukungcola okuqinile namaphunga.

- Ukugaywa kabusha kwamakhemikhali, okufana ne-pyrolysis, kusiza ukuphatha amapulasitiki axubile noma angcolile.

Izindlela zokuhlukanisa amandla adonsela phansi, njenge-sink-float kanye ne-hydrocycloning, zihlukanisa amapulasitiki ngokuminyana. Amasu amasha, njenge-microwave irradiation, enza lezi zindlela zibe ngcono nakakhulu. Izinzwa zamehlo kanye nokubonwa kwesithombe se-AI kuthuthukisa ukunemba kokuhlunga, kusiza izikhungo zifinyelelekuze kufike ku-95% ubumsulwakuma-polymers asetshenziswe kabusha.

Ukusebenza kahle kwamandla kanye nokusimama

Ukusebenza kahle kwamandla manje kuwumgomo ophezulu wawo wonke Umshini Wokugaywa Kabusha Wepulasitiki. Ucwaningo oluvela ku-National Renewable Energy Laboratory lubonisa ukuthi izindlela ezintsha zokugaywa kabusha zisebenzisa amandla amancane futhi zidale amagesi abamba ukushisa ambalwa. Izinto zabo Ezisetshenziswayo Zigeleza Ngethuluzi Lomkhakha lisiza izinkampani zilandelele ukusetshenziswa kwamandla nokukhipha, okwenza kube lula ukuthola izindlela zokonga amandla.

Izinqubo ezihlanganisiwe zokugaywa kabusha manje zifinyelela amazinga okusebenza kahle kwamandla75%. Lokhu kuthuthukiswa kuvela ezinhlelweni zokuhlukanisa ezingcono kanye nemiklamo yemishini ehlakaniphile. Ucwaningo lomjikelezo wokuphila lubonisa ukuthi ukusebenzisa amandla avuselelekayo ekugayweni kabusha kunganciphisa imithelela yokufudumala komhlaba nakakhulu. Le ntuthuko isiza ukuhambisa imboni yepulasitiki iye ekusaseni elisimeme.

A Umshini Wokugaywa kabusha wePlastikiisebenzisa ukuqoqwa, ukuhlunga, ukuhlikihla, ukuwasha, ukuhlukanisa, ukukhipha, kanye ne-pelletizing ukuze iguqule imfucuza ibe yimikhiqizo emisha. Intuthuko yakamuva efanaukugaywa kabusha kwamakhemikhalikanye nezinkampani zokuhlunga ezihlakaniphile zisiza izinkampani ukuthi zibuyise amapulasitiki ekhwalithi ephezulu. Lezi zinguquko zenza ukugaywa kabusha kusebenze kahle kakhudlwana futhi kusekela ikusasa elihlanzekile, eliluhlaza kuwo wonke umuntu.

FAQ

Yimaphi amapulasitiki angakwazi inqubo yomshini wokubuyisela kabusha ngo-2025?

Imishini eminingi iphatha i-PET, i-HDPE, i-LDPE, i-PP, ne-PS. Amanye amamodeli athuthukile angakwazi ngisho nokucubungula amapulasitiki axubile noma angcolile esebenzisa ubuchwepheshe obusha bokuhlukanisa.

Qaphela: Njalo hlola imanuwali yomshini ukuze uthole uhlu olugcwele lwamapulasitiki amukelwayo.

Ingabe amasistimu okuhlunga ahlakaniphile asiza kanjani ekugayweni kabusha?

Ukuhlunga okuhlakaniphile kusebenzisa i-AI nezinzwa. Lawa mathuluzi abona amapulasitiki ahlukene ngokushesha. Bathuthukisa ukunemba kokuhlunga futhi banciphise amaphutha. Izinsiza zithola okokusebenza okugaywe kabusha kwekhwalithi ephezulu.

Ingabe imishini yokugaywa kabusha kwepulasitiki iyasebenza manje?

Yebo! Imishini emisha isebenzisa amandla amancane. Banezinjini ezingcono nezilawuli ezihlakaniphile. Izikhungo eziningi manje zilandelela ukusetshenziswa kwamandla ukuze konge imali kanye nokukhishwa kwekhabhoni ephansi.

Isikhathi sokuthumela: Jun-24-2025