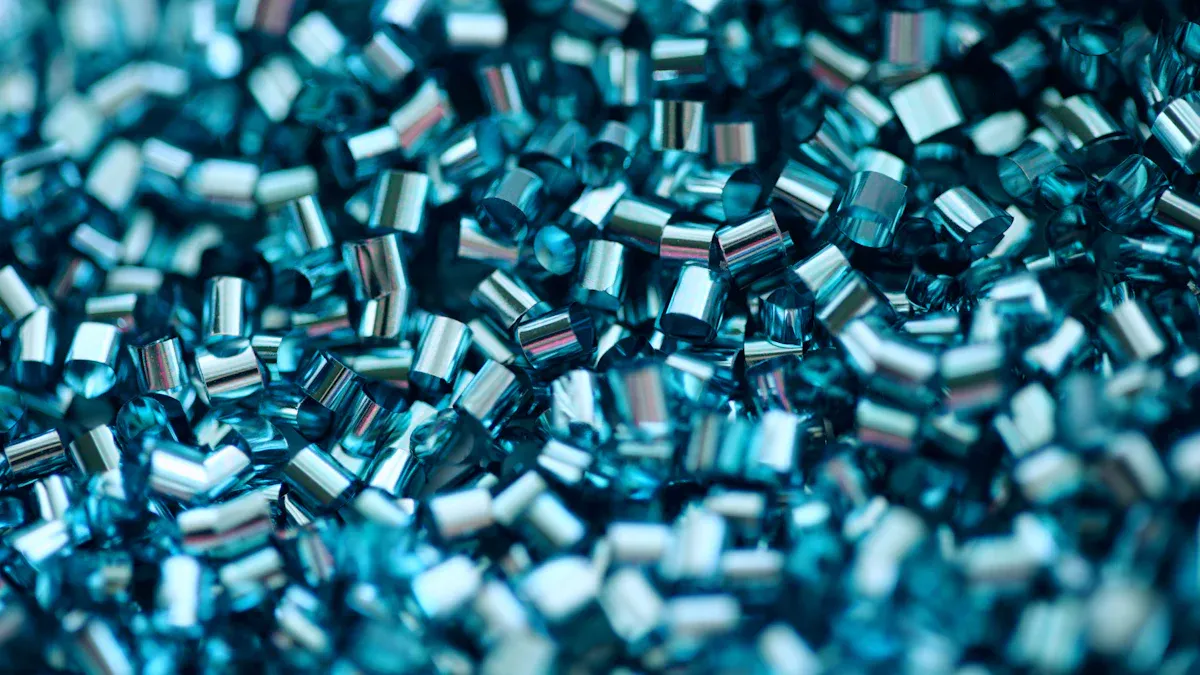

A Mochini oa ho Recycling ea Plastikika 2025 e na le likarolo tse 'maloa tsa bohlokoa, joalo ka litsamaiso tse tsoetseng pele tsa pokello, likarolo tsa ho hlopha, aMochini oa Granulator, le aPolasetiki Shredder. Mothati o mong le o mong ts'ebetsong o bohlokoa bakeng sa ho fetola litšila hore e be li-pellets tse ka sebelisoang hape, ho etsa horeMochini oa ho Recycle oa Plastikie sebetsang hantle haholo. Ho latela lintlha tsa morao-rao tsa 'maraka,Lihlahisoa tsa PET tse tsoang kantle ho naha li fihlile lithane tse ka bang 251,000 ka 2024.

| Sehlopha | Lipalopalo / Tlhaloso ea Mokhoa |

|---|---|

| PET Scrap Imports (2024) | 250,961 tonnes, hoo e ka bang 49% ea kakaretso ea lihlahisoa tse tsoang kantle ho naha |

Lintlha tsa bohlokoa

- Mechini e sebelisoang hape ea polasetikisebelisa mokhoa oa mohato ka mohato ho kenyeletsa ho bokella, ho hlophisa, ho senya, ho hlatsoa, ho arohana, extrusion, le pelletizing ho fetola litšila ho li-pellets tsa polasetiki tse sebelisoang hape ka katleho.

- Litheknoloji tse bohlale tse kang ho hlopha tse tsamaisoang ke AI le litsamaiso tsa ho hlatsoa tse tsoetseng pele li ntlafatsa ho nepahala ha ho sebelisoa hape, ho fokotsa litšila, le ho matlafatsa boleng ba lipolasetiki tse rekolotsoeng.

- Mechini e mecha ea ho recycle e boloka matla le ho fokotsa likhase, e leng ho etsang hore mokhoa oa ho sebelisa polasetiki e be oa moshoelella le ho boloka chelete e ngata nakong e tlang.

Ts'ebetso ea Mochini oa ho Recycling ea Plastiki le Likarolo tse Ka sehloohong

Litsamaiso tsa Pokello

Sistimi ea pokello e theha sebaka sa ho qala mochini ofe kapa ofe oa ho Recycling ea Plastiki. Litsamaiso tsena li bokella litšila tsa polasetiki malapeng, likhoebong le libakeng tsa sechaba. Litoropo tse ngata joale li sebelisa meqomo e bohlale le tracking ea dijithale ho phahamisa litefiso tsa pokello.Lisebelisoa tsa dijithale li thusa basebelisi ho bona data ea nako ea nnete, ho bolelang hore ba ka arabela ka potlako ho meqomo e felletseng kapa li-pickup tse fetiloeng.

Keletso: Koetliso bakeng sa ba bokellang litšila le mananeo a meputso e ka etsa hore pokello e atlehe haholoanyane le ho thibela litšila tsa polasetiki hore li se ke tsa qhaloa.

Lintlha tse ling tsa bohlokoa tse ntlafatsang katleho ea sistimi ea pokello li kenyelletsa:

- Tlaleho ea tšenyo ea nako ea 'nete le pokello ea data e ikemetseng.

- Tlhokomelo ea ts'ebetso ka ho sebelisa matšoao a bohlokoa joalo ka nako ea ho feta le ho theoha.

- Koetliso ea basebetsi mabapi le ts'ebetso ea mochini le polokeho.

- Mekhoa ea ho boloka matla, joalo ka ho sebelisa lisebelisoa tse sebetsang hantle le tlhokomelo ea kamehla.

Melao le eona e na le karolo e kholo. Hona joale melao e hloka palo e itseng ea lintho tse sebelisoang hape lihlahisoa, e leng se qobellang lik'hamphani ho bokella polasetiki e ngata bakeng sa ho e sebelisa hape.

Lihlopha tsa ho hlopha

Likarolo tsa ho hlopha li arola lipolasetiki ho ea ka mofuta, mebala le boleng. Mohato ona o bohlokoa hobane lipolasetiki tse fapaneng li hloka mekhoa e fapaneng ea ho e sebelisa hape. Litsi tsa sejoale-joale tsa ho hlopha li sebelisa li-laser le AI ho skena le ho hlophisa lipolasetiki ka lebelo le holimo. Ka mohlala, lisebelisoa tsa laser-sorting li kascan ho fihlela ho 860,000 spectra ka motsotsoana, ho etsa hore ho be bonolo ho hlophisa esita le lipolasetiki tse ntšo tse qhekellang. Li-detectors tsa FT-NIR joale li nka lihora tse ka bang 8,000 pakeng tsa liphoso, ho bolelang hore ho na le nako e fokolang le ho hlopha ka nepo.

| Motsoako oa Sistimi ea ho hlopha | Litšila tsa Plastiki tse Arohaneng (kg ho moahi ka mong) |

|---|---|

| Karohano ea poso feela | 6.2 |

| Pokello ea curbside feela | 5.6 |

| Motsoako oa karohano ea poso + curbside | 7.6 - 8.0 |

| Pokello ea Curbside + tlisa libaka | 3.5 |

Linaha tse sebelisang maano a thata a karohano ea mehloli, joalo ka Korea Boroa,botjha botjha ho fihla ho 70% ya matlakala a masepala a bona. Likarolo tsa ho hlopha tse tsoetseng pele tse nang le AI le theknoloji e haufi le infrared li ka fihlela ho nepahala ho fetang 90%, e leng se matlafatsang boleng le chai ea lipolasetiki tse tsosolositsoeng.

Li-shredders le li-granulator

Li-shredders le li-granulator li pshatla lintho tse kholo tsa polasetiki likotoana tse nyane. Sena se nolofalletsa Mochini oa ho Recycling oa Plastiki ho sebetsana le lisebelisoa ka mehato ea morao-rao. Basebelisi ba tlameha ho boloka li-blade li le nchocho 'me ba fe mochine ka lebelo le tsitsitseng ho qoba jeme. Ho tlosa litšila pele ho shredding ho boetse ho thusa mochine ho tšoarella nako e telele.

Mekhoa e meng e metle bakeng sa li-shredders le granulator e kenyelletsa:

- Tlhokomelo ea kamehla le ho hlahloba lehare.

- Lisebelisoa tsa ho hlatsoa pele ho fokotsa ho khathala.

- Ho boloka sekhahla sa phepelo se tsitsitseng.

- Ho laola lerole le lerata bakeng sa polokeho.

- Koetlisa basebetsi ho bona le ho lokisa mathata kapele.

Lintlha tsa ts'ebetso joalo ka sekhahla sa ho sebetsa, tšebeliso ea matla, le boleng ba tlhahiso li thusa basebelisi ho boloka mechini ena e sebetsa hantle.

Mekhoa ea ho hlatsoa

Lisebelisoa tsa ho hlatsoa li hloekisa polasetiki e pshatlehileng. Ba tlosa litšila, lileibole le lijo tse setseng kapa lik'hemik'hale. Plastiki e hloekileng e bonolo ho e sebelisa hape ebile e etsa lihlahisoa tse betere. Liphuputso li bontša hore ho hlatsoa ka metsi a batang kapa a chesang, ka linako tse ling ka lisebelisoa tsa ho hloekisa, ho ka tlosa litšila tse ngata. Ka mor'a ho hlatsoa, ho omisa ho tlisa mongobo ho ea ho 3% kapa ka tlase, e leng se loketseng bakeng sa ts'ebetso e tsoelang pele.

| Mokhoa oa ho hlatsoa | Matla a ho Tlosa Tšilafalo | Melt Flow Index (MFI) Ho fapana | Mechanical Properties (Ductility) | Lintlha |

|---|---|---|---|---|

| E sa hlatsuoang (rPPu) | Ha ho letho | Phapang e phahameng | Nako e telele nakong ea khefu | Lintho tse silafatsang li baka ho senyeha |

| Hlatsoa ka Metsi a Batang (rPPcw) | Bohlokoa | Phapang e fokotsehileng | Ntlafatso e nyane ea ductility | E baballang matla |

| Hlatsoa ka Metsi a Chesang (rPPhw) | Phahameng | Ho tšoana le ho hlatsoa ha serame | Ntlafatso e nyane ea ductility | E bapisoa le ho hlatsoa ha serame |

| Metsi a Chesang + Liemeli (rPPhwca) | Phahameng | Ho tšoana le ho hlatsoa ha serame | Ntlafatso e nyane ea ductility | E bapisoa le ho hlatsoa ha serame |

Lisebelisoa tsa ho hlatsoa tse kopanyang ho omisa metsi le moea li ka ntlafatsa boleng le ts'ebetso ea lipolasetiki tse tsosolositsoeng.

Karohano Technologies

Theknoloji ea karohano e ntlafatsa phallo ea polasetiki le ho feta. Sistimi ena e sebelisa mekhoa e joalo ka ho hlopha haufi le infrared, flotation, esita le lits'ebetso tsa lik'hemik'hale ho arola lipolasetiki ka bongata kapa litlolo tsa lik'hemik'hale.Likhamphani tse kang Dow le SABIC li sebelisa mokhoa o tsoetseng pele oa ho hlophale li-compatibilizer additives ho boloka boleng ba polasetiki bo tsosolositsoeng bo le holimo. Ho hlophisoa ho tsamaisoang ke AI le tlhoekiso e thehiloeng ho solvent le hona ho thusa ho tlosa thepa e sa batleheng.

| Mofuta oa Litšupiso | Tlhaloso | Tlatsetso ho Tšepahala |

|---|---|---|

| Lihlooho tsa Lipatlisiso | Lithuto mabapi le ho phaphamala, ho arola moea, le karohano ea bongata | Fana ka lintlha tsa liteko bakeng sa mekhoa ea karohano |

| Patents | Mekhoa ea thepa bakeng sa karohano ea polasetiki | Netefatsa tlhoekiso e sebetsang |

| Litsamaiso tsa Seboka | Tsoelo-pele ea ho qhibiliha ha qhibiliha le ho hlopha ka boiketsetso | Ntlafatsa ho nepahala le boleng ba ho hlopha |

| Mekhoa ea Boitsebiso ba Spectral | Khau ea infrared le laser-induced emission | Lumella ho hlopha ka potlako, le ho ts'epahala |

| Litlaleho tsa Indasteri | Bopaki bo sebetsang ba ts'ebetso ea ts'ebetso | Ts'ehetsa ts'ebeliso ea lefats'e la nnete |

Litheknoloji tsena li etsa bonnete ba hore mofuta o nepahetseng oa polasetiki o fetela mohatong o latelang, e leng senotlolo sa ho etsa lihlahisoa tsa boleng bo holimo.

Lihlopha tsa Extrusion

Li-extrusion units lia qhibiliha ebe li fetola polasetiki e hloekisitsoeng hore e be sebopeho se secha. Mochini oa ho Recycling oa Plastiki o sebelisa mocheso le khatello ho sutumelletsa polasetiki ka har'a hlobo, ho etsa likhoele tse telele kapa maqephe. Li-extruder tse ncha li sebetsa hantle haholo ho feta mefuta ea khale. Ka mohlala, mechine e mecha e kaeketsa tlhahiso ka ho feta 36%le tšebeliso e tlaase ea motlakase, e bolokang chelete le matla.

| Metric | Li-Extruders tsa Khale | Li-Extruders tse Ncha | Ntlafatso (%) |

|---|---|---|---|

| Tlhahiso (lithane/letsatsi) | 11 | 15 | 36.4 |

| Moeli oa Monehelo (liyuniti) | 6126.9 | 6881.3 | +754,4 |

Theknoloji e tsoetseng pele ea extrusion e boloka polasetiki e le matla, esita le ka mor'a lipotoloho tse 'maloa tsa ho tsosolosa. Sena se bolela hore lihlahisoa tse nchafalitsoeng li ka tšoarella halelele joalo ka tse entsoeng ka polasetiki e ncha.

Lihlopha tsa Pelletizing

Li-pelletizing units li khaola polasetiki e ntšitsoeng ka har'a li-pellets tse nyane, tse tšoanang. Li-pellets tsena li bonolo ho li tsamaisa le ho li sebelisa ha ho etsoa lihlahisoa tse ncha.Hangata katleho ea pelletizing e fihla ho feta 90%ha basebetsi ba laola mongobo le lebelo la mochine.

| Fepa Mohlala | Mongobo | Die Diameter | Lebelo la Mochini (rpm) | Pelletizing Katleho |

|---|---|---|---|---|

| X1 | 7% | 3 limilimithara | 75 | 94.0% |

| X2 | 7% | 3 limilimithara | 75 | 93.2% |

| X3 | 7% | 3 limilimithara | 75 | 92.1% |

Basebelisi ba ka fetola litlhophiso joalo ka sekhahla sa tlhahiso le sebaka sa thipaho fumana boleng bo botle ba pellet. Bokhoni bo phahameng ba pelletizing bo bolela litšila tse fokolang le lisebelisoa tse ka sebelisoang bakeng sa lihlahisoa tse ncha.

Litlhahiso tsa Mechini ea ho Recycle ea Plastiki bakeng sa 2025

Ho hlopha ka bohlale le ho kopanya AI

Ho hlopha ka bohlale ho fetotse tsela eo lisebelisuoa tsa ho tsosolosa li sebetsang ka eona. Lik'hamphani tse ngata li sebetsa hona joalepono ea k'homphieutha, ho ithuta ka botebo, le litšoantšo tsa hyperspectralmekhoeng ea bona ea ho hlopha. Lisebelisoa tsena li thusa liroboto ho bona lintho tse ka sebelisoang hape, ho rera metsamao ea tsona, le ho hlophisa lipolasetiki ka nepo e phahameng. Mehlala ea ho ithuta e tebileng e ka bolela esale pele mefuta ea litšila le ho thusa ka moralo.

- Matsoho a liroboto a sebelisa litšoantšo tsa hyperspectral ho fetola tsela eo a tšoarang ka eona, ho etsa hore ho hlopha ho be bonolo haholoanyane.

- Marang-rang a Neural le ho ithuta ka mochini li thusa ho lepa tlhahiso ea litšila, kahoo lits'ebeletso li ka rera hantle.

- Li-algorithms tse kang moru o sa reroang le mechini ea li-vector tse tšehetsang li ntlafatsa ho hlopha, leha ho na le lintlha tse nyane.

Mehlala ea sebele ea lefatše e bontša phello. HERA ea Italy e sebelitse le IBM ho kenya AI tšebetsong ea bona ea ho hlopha. Sena se ile sa etsa hore ho be le litefiso tse phahameng tsa ho sebelisoa hape le ho fokotseha ha mosebetsi oa matsoho. Japane le US, liroboto tse tsamaisoang ke AI li hlophisa litšila li sebelisa lisensara le lik'hamera. Liroboto tsena li bitsa chelete e pakeng tsa$250,000 le $500,000e 'ngoe le e 'ngoe, empa meaho e meholo e atisa ho bona puseletso ka lilemo tse 5 ho isa ho tse 10 ka lebaka la ho boloka chelete ea basebetsi le ho hlopha hamolemo. Meqomo le lisensara tse bohlale li boetse li thusa ka ho fokotsa hore na literaka li hloka hangata hakae ho bokella litšila, ho boloka chelete le nako.

Mekhoa e tsoetseng pele ea ho Hlatsoa le ho Arola

Mekhoa ea ho hlatsoa le ea ho arohanae se e le bohlale le ho tšepahala haholoanyane. Mechini ea sejoale-joale e hlatsoang e sebelisoali-sensor le li-automationho laola ho hloekisa le ho omisa. Sena se boloka litšila tsa polasetiki li hloekile 'me li loketse mohato o latelang. Ho beha leihlo ka nako ea 'nete ho thusa basebelisi ho bona mathata esale pele le ho boloka ts'ebetso e sebetsa hantle.

- Haufi le infrared spectroscopye khetha li-plastiki tse kang HDPE ka bohloeki bo phahameng.

- Li-Compatibilizer li ntlafatsa boleng ba lipolasetiki tse nchafalitsoeng.

- Tlhoekiso e thehiloeng ho solvent e tlosa litšila tse thata le menko.

- Ho tsosolosa lik'hemik'hale, tse kang pyrolysis, ho thusa ho sebetsana le lipolasetiki tse tsoakiloeng kapa tse litšila.

Mekhoa ea karohano ea matla a khoheli, joalo ka sink-float le hydrocycloning, e arola lipolasetiki ka ho teteana. Mekhoa e mecha, joalo ka microwave irradiation, e etsa hore mekhoa ena e be betere le ho feta. Li-sensor tsa Optical le tlhokomeliso ea setšoantšo sa AI li matlafatsa ho hlopha ho nepahala, ho thusa lits'ebeletso ho fihlaho fihlela ho 95% bohloekika lipolima tse recycled.

Matla a Matla le Moshoelella

Ho sebetsa hantle ha matla hona joale ke sepheo se kaholimo bakeng sa Mochini o mong le o mong oa ho Recycling oa Plastiki. Lipatlisiso tse tsoang ho National Renewable Energy Laboratory li bontša hore mekhoa e mecha ea ho tsosolosa e sebelisa matla a fokolang le ho etsa hore ho be le likhase tse fokolang tsa mocheso. Lisebelisoa tsa bona li Phalla ka Sesebelisoa sa Indasteri se thusa lik'hamphani ho lekola tšebeliso ea matla le mesi, ho etsa hore ho be bonolo ho fumana mekhoa ea ho boloka matla.

Mekhoa e kopantsoeng ea ho tsosolosa hona joale e fihlella litekanyetso tsa ho boloka matla a75%. Lintlafatso tsena li tsoa lits'ebetsong tse betere tsa karohano le meralo e bohlale ea mochini. Lithuto tsa potoloho ea bophelo li bonts'a hore ho sebelisa matla a ka nchafatsoang ho sebelisoa hape ho ka fokotsa litlamorao tsa ho futhumala ha lefatše le ho feta. Likhatelo-pele tsena li thusa ho tsamaisa indasteri ea polasetiki ho isa bokamosong bo tsitsitseng.

A Mochini oa ho Recycling ea Plastikie sebelisa pokello, ho hlopha, ho pshatla, ho hlatsoa, ho arola, extrusion, le pelletizing ho fetola litšila lihlahisoa tse ncha. Lintlafatso tsa morao-rao joalo kaho sebelisoa hape ka lik'hemik'halele ho hlopha ka bohlale ho thusa lik'hamphani ho fumana lipolasetiki tsa boleng bo holimo. Liphetoho tsena li etsa hore recycle e sebetse hantle le ho ts'ehetsa bokamoso bo hloekileng, bo botala bakeng sa bohle.

LBH

Ke lipolasetiki life tse ka sebelisoang mochining o ka sebelisoang hape ka 2025?

Mechini e mengata e sebetsana le PET, HDPE, LDPE, PP, le PS. Mefuta e meng e tsoetseng pele e ka sebetsa le li-plastiki tse tsoakiloeng kapa tse litšila li sebelisa mahlale a macha a karohano.

Tlhokomeliso: Kamehla hlahloba bukana ea mochini bakeng sa lethathamo le felletseng la lipolasetiki tse amoheloang.

Litsamaiso tse bohlale tsa ho hlopha li thusa joang ho recycle?

Ho hlopha ka bohlale ho sebelisa AI le lisensara. Lisebelisoa tsena li bona lipolasetiki tse fapaneng kapele. Ba matlafatsa ho hlopha ho nepahala le ho fokotsa liphoso. Lisebelisoa li fumana lisebelisoa tsa boleng bo holimo tse hloekisitsoeng.

Na metjhini e hlabollang ya polasetiki e sebetsa hantle jwale?

Ee! Mechini e mecha e sebelisa matla a fokolang. Ba na le li-motor tse betere le li-control tse bohlale. Mehaho e mengata hona joale e latela tšebeliso ea matla ho boloka chelete le ho fokotsa likhase.

Nako ea poso: Jun-24-2025