A Makina Ogwiritsa Ntchito Pulasitikimu 2025 imakhala ndi zigawo zingapo zofunika, monga makina otsogola apamwamba, masanjidwe a magawo, aMakina a Granulator,ndi aPulasitiki Shredder. Gawo lirilonse pakuchitapo kanthu ndilofunika kwambiri posintha zinyalala kukhala ma pellets osinthika, kupangaPulasitiki Recycle Machineyothandiza kwambiri. Malinga ndi zomwe zachitika posachedwa pamsika,Zogulitsa kunja kwa PET zidafika pafupifupi matani 251,000 mu 2024.

| Gulu | Mawerengedwe / Mafotokozedwe Amakono |

|---|---|

| PET Scrap Imports (2024) | Matani 250,961, pafupifupi 49% ya zinthu zonse zomwe zidachokera kunja |

Zofunika Kwambiri

- Makina obwezeretsanso pulasitikigwiritsani ntchito ndondomeko yapang'onopang'ono kuphatikizapo kusonkhanitsa, kusanja, kupukuta, kutsuka, kupatukana, kutulutsa, ndi ma pellets kuti asandutse zinyalala kukhala mapepala apulasitiki ogwiritsidwanso ntchito bwino.

- Ukadaulo wanzeru monga kusanja koyendetsedwa ndi AI ndi makina ochapira apamwamba amawongolera kukonzanso zobwezeretsanso, kuchepetsa zinyalala, komanso kukulitsa mtundu wa mapulasitiki obwezerezedwanso.

- Makina atsopano obwezeretsanso amapulumutsa mphamvu ndikuchepetsa mpweya, zomwe zimapangitsa kuti ntchito yobwezeretsanso pulasitiki ikhale yokhazikika komanso yotsika mtengo mtsogolo.

Njira Yamakina Obwezeretsanso Pulasitiki ndi Zida Zazikulu

Zosonkhanitsa Systems

Makina osonkhanitsira amapanga poyambira Makina aliwonse Obwezeretsanso Pulasitiki. Makinawa amasonkhanitsa zinyalala zapulasitiki kuchokera m'nyumba, mabizinesi, ndi malo omwe anthu onse amakhala. Mizinda yambiri tsopano imagwiritsa ntchito nkhokwe zanzeru komanso kutsatira digito kuti akweze mitengo yotolera.Zida zama digito zimathandizira ogwiritsa ntchito kuwona zenizeni zenizeni, zomwe zikutanthauza kuti amatha kuyankha mwachangu ku nkhokwe zodzaza kapena zojambulidwa zomwe zaphonya.

Langizo: Kuphunzitsa otolera zinyalala ndi mapulogalamu a mphotho kungapangitse kusonkhanitsa kukhala kothandiza komanso kuti zinyalala za pulasitiki zisatayike.

Zina mwazinthu zazikulu zomwe zimapangitsa kuti ntchito yotolera ikhale yabwino ndi izi:

- Kupereka malipoti owononga nthawi yeniyeni komanso kusonkhanitsa deta pawokha.

- Kuyang'anira magwiridwe antchito pogwiritsa ntchito zizindikiro zazikulu monga kupitilira ndi nthawi yotsika.

- Maphunziro a ogwira ntchito pamakina ndi chitetezo.

- Njira zopulumutsira mphamvu, monga kugwiritsa ntchito zida zoyenera komanso kukonza nthawi zonse.

Malamulo amakhalanso ndi gawo lalikulu. Malamulo tsopano amafuna kuchuluka kwa zinthu zobwezerezedwanso muzinthu, zomwe zimakankhira makampani kuti atole pulasitiki yochulukirapo kuti abwezeretsenso.

Kusanja Mayunitsi

Magawo osankhira amalekanitsa mapulasitiki ndi mtundu, mtundu, ndi mtundu. Izi ndizofunikira chifukwa mapulasitiki osiyanasiyana amafunikira njira zosiyanasiyana zobwezeretsanso. Magawo amakono osankha amagwiritsa ntchito ma lasers ndi AI kusanthula ndikusintha mapulasitiki pa liwiro lalikulu. Mwachitsanzo, makina opangira laser amathajambulani mpaka mawonedwe 860,000 pamphindikati, kupangitsa kuti zikhale zosavuta kusankha ngakhale mapulasitiki akuda achinyengo. Zowunikira za FT-NIR tsopano zimatha mpaka maola 8,000 pakati pa zolakwika, zomwe zikutanthauza kuti nthawi yocheperako komanso kusanja kolondola.

| Kusanja System Combination | Zinyalala Zapulasitiki Zolekanitsidwa (kg pa munthu aliyense) |

|---|---|

| Tumizani kulekana kokha | 6.2 |

| Zotolera m'mbali mwa m'mphepete mwa nyanja zokha | 5.6 |

| Kuphatikiza kwa kupatukana kwa positi + curbside | 7.6 - 8.0 |

| Kusonkhanitsa kwa Curbside + kubweretsa malo | 3.5 |

Maiko omwe amagwiritsa ntchito malamulo okhwima olekanitsa magwero, monga South Korea,kukonzanso mpaka 70% ya zinyalala zamatauni awo. Magawo osankhika otsogola okhala ndi AI komanso ukadaulo wapafupi ndi infrared amatha kulondola kupitilira 90%, zomwe zimakulitsa mtundu ndi zokolola zamapulasitiki obwezerezedwanso.

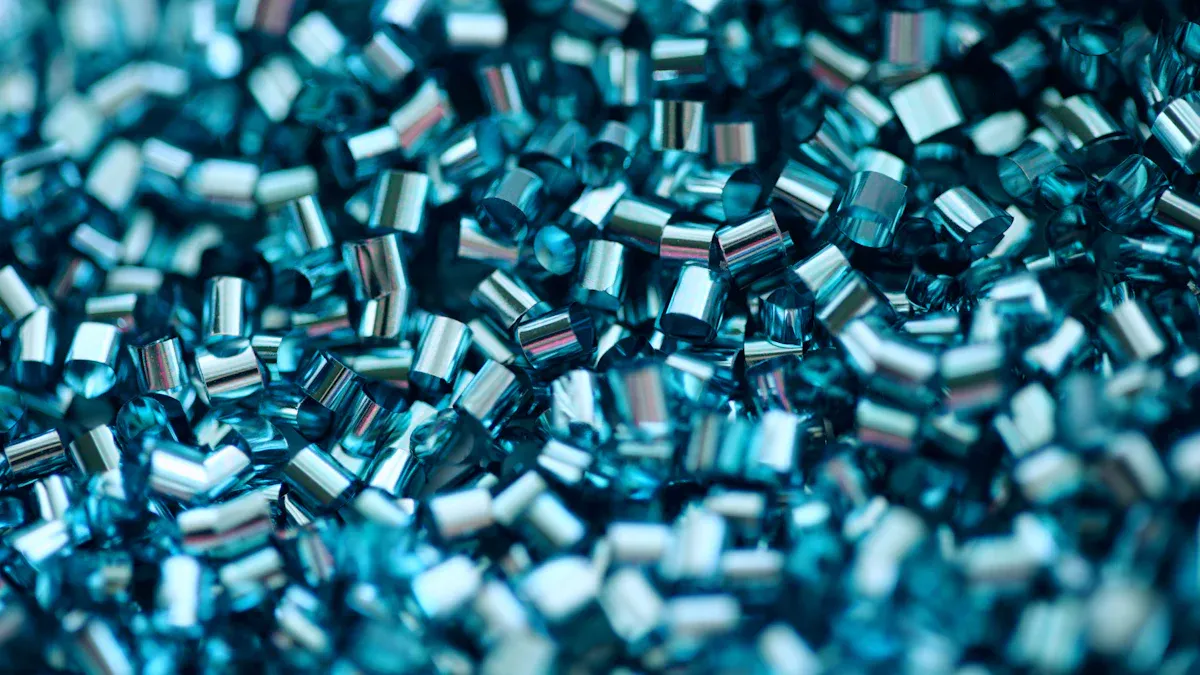

Shredders ndi Granulators

Zopangira matabwa ndi ma granulator amathyola zinthu zazikulu zapulasitiki kukhala tizidutswa tating'ono. Izi zimapangitsa kukhala kosavuta kuti Makina Obwezeretsanso Pulasitiki azitha kukonza zinthuzo pambuyo pake. Ogwiritsa ntchito ayenera kusunga masamba akuthwa ndikudyetsa makinawo pafupipafupi kuti apewe kupanikizana. Kuchotsa zodetsa musanamete kumathandizanso makinawo kukhala nthawi yayitali.

Zina zabwino kwambiri zopangira shredders ndi granulator ndi:

- Kusamalira nthawi zonse ndikuwunika masamba.

- Zida zotsukiratu kuti muchepetse kuvala.

- Kusunga chakudya chokhazikika.

- Kusamalira fumbi ndi phokoso pofuna chitetezo.

- Kuphunzitsa ogwira ntchito kuti awone ndikukonza zovuta mwachangu.

Miyezo ya kagwiridwe ka ntchito monga kuchuluka kwa kutulutsa, kugwiritsa ntchito mphamvu, ndi mtundu wa zotulutsa zimathandiza ogwiritsa ntchito kuti makinawa aziyenda bwino.

Makina Ochapira

Makina ochapira amatsuka pulasitiki wong'ambika. Amachotsa litsiro, zolemba, ndi zakudya zotsalira kapena mankhwala. Pulasitiki yoyera ndiyosavuta kuyibwezeretsanso ndikupanga zinthu zabwinoko. Kafukufuku amasonyeza kuti kusamba ndi madzi ozizira kapena otentha, nthawi zina pogwiritsa ntchito zoyeretsera, kumatha kuchotsa zonyansa zambiri. Mukatha kutsuka, kuyanika kumabweretsa chinyezi mpaka 3% kapena kuchepera, komwe kuli koyenera kukonzanso.

| Njira Yochapira | Kuchotsa Zowonongeka Mwachangu | Kusiyanasiyana kwa Melt Flow Index (MFI) | Katundu Wamakina (Ductility) | Zolemba |

|---|---|---|---|---|

| Zosasamba (rPPu) | Palibe | Kusinthasintha kwakukulu | Kutalika kochepa panthawi yopuma | Zowonongeka zimayambitsa kuwonongeka |

| Kusamba kwa Madzi Ozizira (rPPcw) | Zofunika | Kusintha kwachepetsedwa | Kusintha pang'ono kwa ductility | Zopanda mphamvu |

| Kusamba kwamadzi otentha (rPPhw) | Wapamwamba | Zofanana ndi kusamba kozizira | Kusintha pang'ono kwa ductility | Zofanana ndi kuchapa ozizira |

| Madzi otentha + Agents (rPPhwca) | Wapamwamba | Zofanana ndi kusamba kozizira | Kusintha pang'ono kwa ductility | Zofanana ndi kuchapa ozizira |

Makina ochapira omwe amaphatikiza kuyanika kwamadzi ndi mpweya amatha kuwongolera bwino komanso kusinthika kwa mapulasitiki opangidwanso.

Kupatukana Technologies

Matekinoloje olekanitsa amawongolera mayendedwe apulasitiki kwambiri. Makinawa amagwiritsa ntchito njira monga kusanja pafupi ndi infrared, kuyandama, komanso ngakhale njira zama mankhwala kuti alekanitse mapulasitiki ndi kachulukidwe kapena makemikolo.Makampani monga Dow ndi SABIC amagwiritsa ntchito kusanja kwapamwambandi zowonjezera zowonjezera kuti zisungidwe pulasitiki zobwezerezedwanso zapamwamba. Kusankha koyendetsedwa ndi AI ndi kuyeretsa kochokera ku zosungunulira kumathandizanso kuchotsa zinthu zosafunikira.

| Mtundu Wolozera | Kufotokozera | Kuthandizira Kudalirika |

|---|---|---|

| Nkhani Zofufuza | Maphunziro okhudza kuyandama, gulu la mpweya, ndi kulekanitsa kachulukidwe | Perekani deta yoyesera ya njira zolekanitsira |

| Ma Patent | Njira zaumwini zolekanitsa pulasitiki | Onetsetsani kuyeretsa kogwira mtima |

| Zokambirana pa Msonkhano | Kutsogola pakusefera kwa sungunuka ndi kusanja pawokha | Limbikitsani kusanja molondola ndi khalidwe |

| Njira Zozindikiritsira Ma Spectral | Near-infrared and laser-induced emission | Yambitsani kusanja mwachangu, kodalirika |

| Malipoti a Makampani | Umboni wothandiza wa kukhathamiritsa kwa njira | Thandizani ntchito zenizeni padziko lapansi |

Matekinolojewa amaonetsetsa kuti pulasitiki yamtundu wokhayo ikupita ku sitepe yotsatira, yomwe ndi yofunika kwambiri popanga zinthu zapamwamba zobwezerezedwanso.

Extrusion Units

Magawo owonjezera amasungunuka ndikusinthanso pulasitiki yoyeretsedwayo kukhala mawonekedwe atsopano. Makina Obwezeretsanso Pulasitiki amagwiritsa ntchito kutentha ndi kukakamiza kukankhira pulasitiki kudzera mu nkhungu, kupanga zingwe zazitali kapena mapepala. Ma extruder atsopano ndi othandiza kwambiri kuposa zitsanzo zakale. Mwachitsanzo, makina atsopano akhozaonjezerani zokolola ndi 36%ndi kuchepetsa kugwiritsa ntchito magetsi, zomwe zimapulumutsa ndalama ndi mphamvu.

| Metric | Old Extruders | New Extruders | Kupititsa patsogolo (%) |

|---|---|---|---|

| Kuchuluka (matani/tsiku) | 11 | 15 | 36.4 |

| Mbali Yopereka (mayunitsi) | 6126.9 | 6881.3 | + 754.4 |

MwaukadauloZida extrusion luso amasunga pulasitiki wamphamvu, ngakhale pambuyo pa maulendo angapo obwezeretsanso. Izi zikutanthauza kuti zinthu zobwezerezedwanso zimatha kukhalapo ngati zomwe zimapangidwa kuchokera ku pulasitiki yatsopano.

Pelletizing Units

Pelletizing mayunitsi amadula pulasitiki extruded kukhala ang'onoang'ono, yunifolomu pellets. Ma pellets awa ndi osavuta kunyamula ndikugwiritsa ntchito popanga zinthu zatsopano.Kuchita bwino kwa pelletizing nthawi zambiri kumafika pa 90%pamene ogwira ntchito akuwongolera chinyezi ndi liwiro la makina.

| Feed Chitsanzo | Chinyezi | Die Diameter | Liwiro la Makina (rpm) | Kuchita bwino kwa Pelletizing |

|---|---|---|---|---|

| X1 | 7% | 3 mm | 75 | 94.0% |

| X2 | 7% | 3 mm | 75 | 93.2% |

| X3 | 7% | 3 mm | 75 | 92.1% |

Othandizira amatha kusintha makonda monga kuchuluka kwa kupanga ndi mtunda wa mpenikuti mupeze mtundu wabwino kwambiri wa pellet. Kuchita bwino kwa ma pelletizing kumatanthauza kuti zinyalala zocheperako komanso zinthu zomwe zingagwiritsidwe ntchito pazinthu zatsopano.

Zatsopano Pamakina Obwezeretsanso Pulasitiki a 2025

Kusankha Mwanzeru ndi Kuphatikiza kwa AI

Kusankha mwanzeru kwasintha momwe malo obwezeretsanso amagwirira ntchito. Makampani ambiri tsopano amagwiritsa ntchitomasomphenya apakompyuta, kuphunzira mozama, ndi kujambula kwa hyperspectralmu machitidwe awo osankhidwa. Zida zimenezi zimathandiza maloboti kuona zinthu zomwe zingagwiritsidwenso ntchito, kukonza mayendedwe awo, ndi kusankha mapulasitiki molondola kwambiri. Mitundu yophunzirira mozama imatha kulosera mitundu ya zinyalala ndikuthandizira pokonzekera.

- Mikono ya robotiki imagwiritsa ntchito kujambula kwa hyperspectral kuti isinthe kugwira kwawo, kupangitsa kusanja kukhala kolondola.

- Maukonde a Neural ndi kuphunzira pamakina amathandizira kulosera za zinyalala, kuti malo amatha kukonzekera bwino.

- Ma algorithms ngati nkhalango mwachisawawa komanso makina othandizira ma vector amawongolera kusanja, ngakhale ndi data yaying'ono.

Zitsanzo zenizeni zikuwonetsa zotsatira zake. HERA ku Italy adagwira ntchito ndi IBM kuti awonjezere AI pakusintha kwawo. Izi zinapangitsa kuti achulukitse mitengo yobwezeretsanso ntchito komanso kuchepa kwa ntchito yamanja. Ku Japan ndi ku US, maloboti oyendetsedwa ndi AI amasankha zinyalala pogwiritsa ntchito masensa ndi makamera. Maloboti awa amadula pakati$250,000 ndi $500,000chilichonse, koma malo akuluakulu nthawi zambiri amawona kubweza m'zaka 5 mpaka 10 chifukwa cha ndalama zogwirira ntchito komanso kusanja bwino. Ma bin anzeru ndi masensa amathandizanso pochepetsa kuchuluka kwa magalimoto omwe amafunikira kutolera zinyalala, kusunga ndalama ndi nthawi.

Advanced Kuchapira ndi Kupatukana Technologies

Kuchapira ndi kulekanitsa machitidweakhala anzeru ndi odalirika. Makina ochapira amakono amagwiritsa ntchitomasensa ndi automationkuwongolera kuyeretsa ndi kuyanika. Izi zimapangitsa kuti zinyalala zapulasitiki zikhale zaukhondo komanso zokonzekera sitepe yotsatira. Kuyang'anira munthawi yeniyeni kumathandizira ogwira ntchito kuwona zovuta msanga ndikupangitsa kuti ntchitoyo ikuyenda bwino.

- Near-infrared spectroscopyamasankha mapulasitiki ngati HDPE ndi chiyero chapamwamba.

- Ma comptibilizer amapangitsa kuti mapulasitiki obwezerezedwanso akhale abwino.

- Kuyeretsa kochokera ku zosungunulira kumachotsa zonyansa zolimba ndi fungo.

- Kubwezeretsanso mankhwala, monga pyrolysis, kumathandiza kugwira mapulasitiki osakanikirana kapena onyansa.

Njira zolekanitsa mphamvu yokoka, monga sink-float ndi hydrocycloning, zimasiyanitsa mapulasitiki ndi kachulukidwe. Njira zatsopano, monga microwave irradiation, zimapangitsa njirazi kukhala zabwinoko. Ma sensor a Optical ndi kuzindikira kwa zithunzi za AI kumakulitsa kulondola kwa kusanja, kuthandiza malo kufikampaka 95% chiyeromu ma polima obwezerezedwanso.

Kugwiritsa Ntchito Mphamvu ndi Kukhazikika

Kugwiritsa ntchito mphamvu kwamphamvu tsopano ndicho cholinga chachikulu pa Makina aliwonse Obwezeretsanso Pulasitiki. Kafukufuku wochokera ku National Renewable Energy Laboratory akuwonetsa kuti njira zatsopano zobwezeretsanso zimagwiritsa ntchito mphamvu zochepa ndikupanga mpweya wowonjezera kutentha. Zida Zawo Zimayenda Kupyolera mu Chida Chamakampani zimathandiza makampani kuyang'anira momwe mphamvu zimagwiritsidwira ntchito ndi mpweya, zomwe zimapangitsa kuti zikhale zosavuta kupeza njira zopulumutsira mphamvu.

Integrated zobwezerezedwanso ndondomeko tsopano kufika pa mphamvu mphamvu75%. Zosinthazi zimachokera ku machitidwe abwino olekanitsa komanso makina anzeru. Kafukufuku wozungulira moyo akuwonetsa kuti kugwiritsa ntchito mphamvu zongowonjezedwanso pakubwezeretsanso kumatha kuchepetsa kutentha kwa dziko kwambiri. Kupita patsogolo kumeneku kumathandizira kusuntha makampani apulasitiki kupita ku tsogolo lokhazikika.

A Makina Ogwiritsa Ntchito Pulasitikiamagwiritsa ntchito kutolera, kusanja, kung'amba, kuchapa, kupatukana, kutulutsa, ndi ma pelletizing kuti asinthe zinyalala kukhala zatsopano. Zowonjezereka zaposachedwa ngatimankhwala yobwezeretsansokomanso makampani osankha mwanzeru amathandizira kuti apezenso mapulasitiki apamwamba kwambiri. Zosinthazi zimapangitsa kuti zobwezeretsanso zigwire ntchito bwino komanso zimathandizira tsogolo laukhondo, lobiriwira kwa aliyense.

FAQ

Ndi mapulasitiki ati omwe angapange makina obwezeretsanso mu 2025?

Makina ambiri amagwira PET, HDPE, LDPE, PP, ndi PS. Zitsanzo zina zapamwamba zimatha kupanga mapulasitiki osakanikirana kapena onyansa pogwiritsa ntchito matekinoloje atsopano olekanitsa.

Chidziwitso: Nthawi zonse fufuzani bukhu la makina kuti muwone mndandanda wathunthu wa mapulasitiki ovomerezeka.

Kodi makina osankhidwa mwanzeru amathandiza bwanji kubwezereranso?

Kusankha mwanzeru kumagwiritsa ntchito AI ndi masensa. Zida izi zimawona mapulasitiki osiyanasiyana mwachangu. Amathandizira kusanja molondola komanso kuchepetsa zolakwika. Malo amapeza zinthu zaukhondo, zobwezerezedwanso zapamwamba.

Kodi makina obwezereranso pulasitiki ndi opatsa mphamvu tsopano?

Inde! Makina atsopano amagwiritsa ntchito mphamvu zochepa. Iwo ali ndi injini zabwinoko ndi zowongolera mwanzeru. Malo ambiri tsopano amatsata momwe magetsi amagwiritsidwira ntchito kuti asunge ndalama komanso kuchepetsa mpweya.

Nthawi yotumiza: Jun-24-2025