A Yas Recycling Tshuabnyob rau hauv 2025 nta ob peb yam tseem ceeb, xws li kev sau cov txheej txheem siab heev, sorting units, aGranulator Tshuab, thiab aYas Shredder. Txhua theem hauv cov txheej txheem yog qhov tseem ceeb rau kev hloov cov pov tseg rau hauv cov pellets rov qab siv tau, ua rauYas Recycle Tshuabua tau zoo heev. Raws li cov ntaub ntawv tshaj tawm kev lag luam tshiab,PET cov khoom xa tawm mus txog ze li 251,000 tonnes hauv 2024.

| Qeb | Statistic / Trend Description |

|---|---|

| PET Scrap Ntshuam (2024) | 250,961 tonnes, ze li ntawm 49% ntawm tag nrho cov khoom seem |

Ntsiab Cai

- Plastic recycling tshuabsiv cov txheej txheem ib ntus suav nrog kev sau, txheeb xyuas, txiav, ntxuav, sib cais, extrusion, thiab pelletizing kom cov khoom pov tseg rau hauv cov yas rov siv tau zoo.

- Cov thev naus laus zis zoo li AI-tsav kev txheeb xyuas thiab cov tshuab ntxhua khaub ncaws ua kom zoo dua qub, txo cov khib nyiab, thiab txhawb nqa cov khoom siv rov ua dua tshiab.

- Cov tshuab rov ua dua tshiab txuag lub zog thiab txiav tawm cov pa tawm, ua rau cov txheej txheem rov ua dua tshiab ntawm cov yas siv tau zoo dua qub thiab muaj txiaj ntsig zoo rau yav tom ntej.

Yas Recycling Tshuab Txheej Txheem thiab Cov Khoom Tseem Ceeb

Sau Systems

Kev sau cov tshuab tsim qhov pib rau txhua lub tshuab siv yas rov siv dua. Cov tshuab no sib sau cov khib nyiab yas los ntawm tsev, chaw lag luam, thiab chaw pej xeem. Ntau lub nroog tam sim no siv cov khoom siv ntse thiab kev taug qab digital los txhawb kev sau nqi.Cov cuab yeej digital pab cov neeg ua haujlwm pom cov ntaub ntawv hauv lub sijhawm, uas txhais tau tias lawv tuaj yeem teb sai sai rau tag nrho cov bins lossis tsis tuaj tos.

Tswv yim: Kev cob qhia rau cov neeg khaws khoom pov tseg thiab cov khoom plig muab khoom plig tuaj yeem ua kom muaj txiaj ntsig zoo dua thiab khaws cov pov tseg yas tawm ntawm qhov chaw pov tseg.

Qee yam tseem ceeb uas txhim kho kev sau cov txheej txheem muaj xws li:

- Real-time pov tseg qhia thiab automated cov ntaub ntawv sau.

- Kev saib xyuas kev ua tau zoo siv cov ntsuas tseem ceeb xws li kev hla dhau thiab kev poob qis.

- Kev cob qhia cov neeg ua haujlwm ntawm lub tshuab ua haujlwm thiab kev nyab xeeb.

- Cov tswv yim txuag hluav taws xob, xws li siv cov cuab yeej siv tau zoo thiab kev saib xyuas tsis tu ncua.

Kev cai lij choj kuj ua lub luag haujlwm loj. Tam sim no cov kev cai lij choj xav tau qee cov ntsiab lus ntawm cov khoom siv rov ua dua tshiab, uas thawb cov tuam txhab los sau cov yas ntau dua rau kev rov ua dua tshiab.

Soj ntsuam units

Kev txheeb cais cais cov yas los ntawm hom, xim, thiab zoo. Cov kauj ruam no yog qhov tseem ceeb vim tias cov yas sib txawv xav tau cov txheej txheem rov ua dua tshiab. Niaj hnub nimno sorting units siv lasers thiab AI los soj ntsuam thiab txheeb cov yas ntawm high speeds. Piv txwv li, laser-sorting tshuab ua tauscan txog 860,000 spectra ib ob, ua kom yooj yim rau kev txheeb xyuas txawm tias cov khoom siv tawv dub. FT-NIR detectors tam sim no kav ntev txog 8,000 teev ntawm kev ua txhaum, uas txhais tau hais tias tsawg downtime thiab ntau qhov kev txheeb xyuas.

| Sorting System Combination | Separated Plastic Khib (kg ib tus neeg nyob) |

|---|---|

| Tom qab sib cais xwb | 6.2 |

| Curbside collection nkaus xwb | 5.6 |

| Kev sib xyaw ntawm kev sib cais tom qab + curbside | 7.6-8.0 Nws |

| Curbside collection + nqa qhov chaw | 3.5 |

Lub teb chaws uas siv cov cai tswj kev sib cais, xws li South Kauslim,rov siv dua li 70% ntawm lawv cov pov tseg hauv nroog. Advanced sorting units nrog AI thiab ze-infrared thev naus laus zis tuaj yeem ncav cuag ntau dua 90% qhov tseeb, uas txhawb nqa qhov zoo thiab cov txiaj ntsig ntawm cov khoom siv rov ua dua tshiab.

Granulators thiab Shredders

Shredders thiab granulators zom cov khoom yas loj rau hauv me me. Qhov no ua rau nws yooj yim dua rau lub tshuab siv yas rov ua dua tshiab los ua cov khoom siv hauv cov kauj ruam tom ntej. Cov neeg ua haujlwm yuav tsum khaws cov hniav ntse thiab pub lub tshuab ntawm tus nqi tsis tu ncua kom tsis txhob muaj jams. Kev tshem tawm cov kab mob ua ntej shredding kuj yuav pab lub tshuab kom ntev dua.

Qee qhov kev coj ua zoo tshaj plaws rau shredders thiab granulators suav nrog:

- Kev saib xyuas tsis tu ncua thiab xyuas cov hniav.

- Ua ntej ntxuav cov ntaub ntawv kom txo tau hnav.

- Ua kom tus nqi noj tsis tu ncua.

- Tswj plua plav thiab suab nrov kom muaj kev nyab xeeb.

- Cov neeg ua haujlwm cob qhia kom pom thiab kho cov teeb meem sai sai.

Kev ntsuas kev ua tau zoo xws li tus nqi dhau los, kev siv hluav taws xob, thiab cov khoom siv tau zoo pab cov neeg ua haujlwm kom cov tshuab no ua haujlwm zoo.

Ntxuav Systems

Ntxuav tshuab ntxuav cov yas shredded. Lawv tshem tawm cov av, daim ntawv lo, thiab cov khoom noj khoom haus los yog tshuaj lom. Cov yas huv huv yog yooj yim dua los siv dua thiab ua kom cov khoom zoo dua. Cov kev tshawb fawb qhia tias kev ntxuav nrog dej txias lossis dej kub, qee zaum nrog cov tshuaj ntxuav, tuaj yeem tshem tawm cov kab mob feem ntau. Tom qab ntxuav, ziab ua kom noo noo mus rau 3% lossis tsawg dua, uas yog qhov zoo rau kev ua haujlwm ntxiv.

| Txoj Kev Ntxuav | Kev tshem tawm cov kab mob sib kis | Melt Flow Index (MFI) Variability | Mechanical Properties (Ductility) | Sau ntawv |

|---|---|---|---|---|

| Unwashed (rPPu) | Tsis muaj | Kev hloov pauv siab | Tsawg elongation thaum tawg | Cov kab mob ua rau degradation |

| Kev ntxuav dej txias (rPPcw) | Qhov tseem ceeb | Txo variability | Kev txhim kho me ntsis ductility | Zog txuag hluav taws xob |

| Kev ntxuav dej kub (rPPhw) | Siab | Zoo ib yam li cov dej txias | Kev txhim kho me ntsis ductility | Piv rau kev ntxuav txias |

| Cov dej kub + Tus neeg sawv cev (rPPhwca) | Siab | Zoo ib yam li cov dej txias | Kev txhim kho me ntsis ductility | Piv rau kev ntxuav txias |

Cov tshuab ntxhua khaub ncaws uas sib xyaw ua ke dej thiab cua kom qhuav tuaj yeem txhim kho qhov zoo thiab ua tiav ntawm cov khoom siv rov ua dua tshiab.

Kev sib cais tshuab

Kev sib cais thev naus laus zis ua kom cov kwj yas txuas ntxiv. Cov tshuab no siv txoj hauv kev zoo li ze-infrared sorting, flotation, thiab txawm tias cov txheej txheem tshuaj lom neeg los cais cov yas los ntawm qhov ntom ntom lossis tshuaj pleev xim.Cov tuam txhab xws li Dow thiab SABIC siv kev txheeb xyuas qib siabthiab compatibilizer additives kom rov siv tau cov yas zoo. AI-tsav sorting thiab hnyav-raws li purification kuj pab tshem tawm cov khoom tsis xav tau.

| Hom siv | Kev piav qhia | Pab txhawb rau kev ntseeg |

|---|---|---|

| Cov ntawv tshawb fawb | Kev tshawb fawb ntawm flotation, huab cua kev faib tawm, thiab kev sib cais ceev | Muab cov ntaub ntawv sim rau kev sib cais |

| Patents | Proprietary txheej txheem rau kev sib cais yas | Ua kom muaj kev ua kom huv huv zoo |

| Conference Proceedings | Advances nyob rau hauv melt filtration thiab automated sorting | Txhim kho kev txheeb xyuas qhov tseeb thiab zoo |

| Spectral Identification Methods | Ze-infrared thiab laser-induced emission | Pab kom ceev, txhim khu kev qha sorting |

| Kev Tshaj Tawm Txog Kev Lag Luam | Cov ntaub ntawv pov thawj ntawm cov txheej txheem optimization | Txhawb kev thov hauv ntiaj teb tiag |

Cov thev naus laus zis no ua kom paub tseeb tias tsuas yog hom yas txav mus rau cov kauj ruam tom ntej, uas yog qhov tseem ceeb rau kev ua cov khoom lag luam zoo.

Extrusion Units

Extrusion units yaj thiab hloov cov yas huv si rau hauv daim ntawv tshiab. Plastic Recycling Machine siv cov cua sov thiab lub zog los thawb cov yas los ntawm cov pwm, tsim cov hlua ntev los yog cov nplooj ntawv. Cov extruders tshiab muaj txiaj ntsig ntau dua li cov qauv qub. Piv txwv li, cov tshuab tshiab tuaj yeem ua tauboost productivity ntau dua 36%thiab siv hluav taws xob qis dua, uas txuag nyiaj thiab lub zog.

| Metric | Qub Extruders | Tshiab Extruders | Kev txhim kho (%) |

|---|---|---|---|

| Productivity (tons / hnub) | 11 | 15 | 36.4 ib |

| Kev faib tawm Margin (units) | 6 126.9 | 6 881.3 | +754.4 |

Advanced extrusion technology ua kom cov yas muaj zog, txawm tias tom qab ob peb lub voj voog rov ua dua. Qhov no txhais tau hais tias cov khoom siv rov ua dua tuaj yeem kav ntev npaum li cov khoom tsim los ntawm cov yas tshiab.

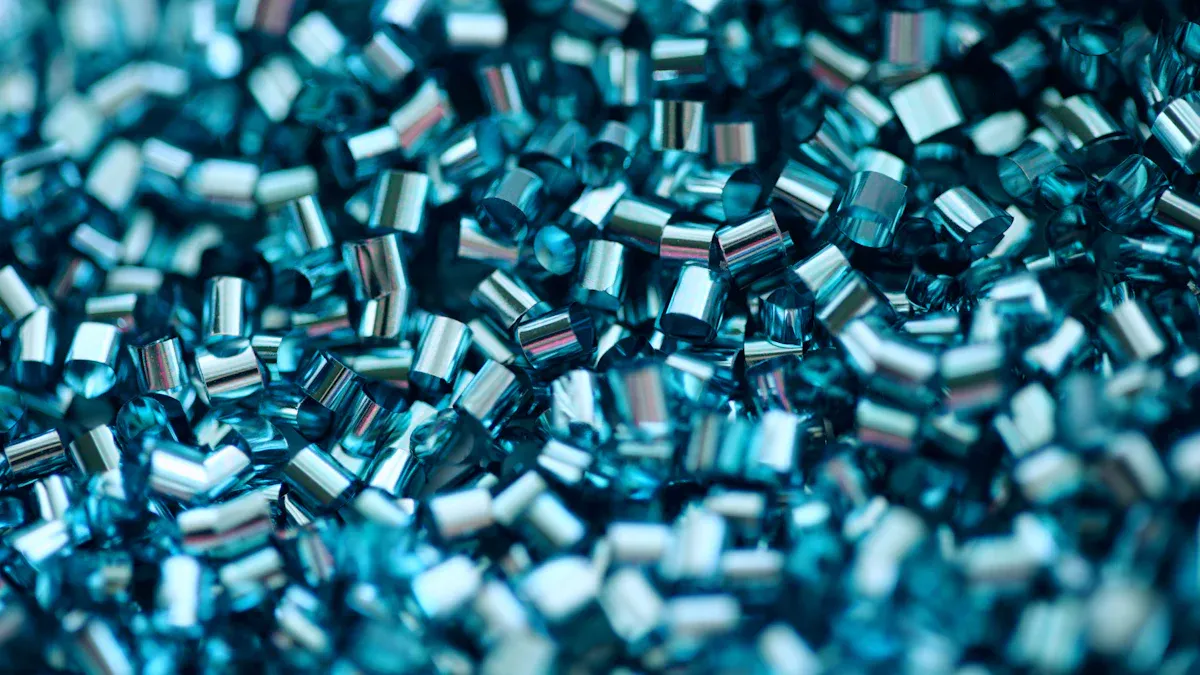

Pelletizing units

Pelletizing units txiav cov yas extruded rau hauv me me, zoo li pellets. Cov pellets no yooj yim thauj thiab siv los ua cov khoom tshiab.Pelletizing efficiency feem ntau nce mus txog 90%thaum cov neeg ua haujlwm tswj cov dej noo thiab tshuab ceev.

| Pub Qauv | Cov ntsiab lus noo noo | Tuag txoj kab uas hla | Tshuab ceev (rpm) | Pelletizing Efficiency |

|---|---|---|---|---|

| X1 | 7% | 3 hli | 75 | 94.0% |

| X2 | 7% | 3 hli | 75 | 93.2% |

| X3 | 7% | 3 hli | 75 | 92.1% |

Cov neeg ua haujlwm tuaj yeem kho qhov chaw xws li tus nqi ntau lawm thiab riam nrugkom tau qhov zoo tshaj plaws pellet zoo. Kev ua haujlwm siab pelletizing txhais tau tias tsawg dua pov tseg thiab siv tau ntau dua rau cov khoom tshiab.

Kev tsim kho tshiab hauv cov tshuab yas rov ua dua tshiab rau xyoo 2025

Smart Sorting thiab AI Integration

Kev txheeb xyuas ntse tau hloov pauv cov khoom siv rov ua haujlwm li cas. Ntau lub tuam txhab tam sim no sivlub computer tsis pom kev, kev kawm tob, thiab hyperspectral imagingnyob rau hauv lawv sorting systems. Cov cuab yeej no pab cov neeg hlau pom cov khoom siv rov ua dua tshiab, npaj lawv cov kev txav mus los, thiab txheeb cov yas nrog qhov raug siab. Cov qauv kev kawm tob tuaj yeem kwv yees hom khib nyiab thiab pab nrog kev npaj.

- Robotic caj npab siv hyperspectral imaging los kho lawv tuav, ua sorting ntau meej.

- Neural tes hauj lwm thiab kev kawm tshuab pab kwv yees cov khoom pov tseg, yog li cov chaw muaj peev xwm npaj tau zoo dua.

- Algorithms zoo li random hav zoov thiab txhawb vector tshuab txhim kho kev txheeb xyuas, txawm tias muaj cov ntaub ntawv me me.

Cov piv txwv tiag tiag hauv ntiaj teb qhia qhov cuam tshuam. HERA hauv tebchaws Ltalis tau ua haujlwm nrog IBM ntxiv AI rau lawv cov txheej txheem txheeb xyuas. Qhov no ua rau cov nqi rov ua dua tshiab dua thiab ua haujlwm tsawg dua. Hauv Nyij Pooj thiab Asmeskas, AI-powered robots txheeb cov khib nyiab siv cov sensors thiab cov koob yees duab. Cov neeg hlau no raug nqi nruab nrab ntawm$250,000 thiab $500,000txhua, tab sis cov chaw loj feem ntau pom cov nyiaj rov qab hauv 5 mus rau 10 xyoo vim tias kev txuag nyiaj thiab kev txheeb xyuas zoo dua. Smart bins thiab sensors kuj pab los ntawm kev txo qis npaum li cas cov tsheb thauj khoom yuav tsum tau khaws cov khib nyiab, txuag nyiaj thiab sijhawm.

Advanced Washing and Separation Technologies

Ntxuav thiab cais tshuabtau ua ntse dua thiab txhim khu kev qha. Cov tshuab ntxhua khaub ncaws niaj hnub sivsensors thiab automationtswj kev ntxuav thiab ziab. Qhov no khaws cov khib nyiab pov tseg kom huv thiab npaj rau cov kauj ruam tom ntej. Kev saib xyuas lub sijhawm tiag tiag pab cov neeg ua haujlwm pom cov teeb meem ntxov thiab ua kom cov txheej txheem ua haujlwm zoo.

- Ze-infrared spectroscopyxaiv cov yas zoo li HDPE nrog siab purity.

- Compatibilizers txhim kho qhov zoo ntawm cov yas rov ua dua tshiab.

- Solvent-based purification tshem tawm cov kab mob thiab cov ntxhiab tsw.

- Kev siv tshuaj lom neeg, xws li pyrolysis, pab daws cov khoom sib xyaw lossis cov khoom qias neeg.

Txoj kev sib cais lub ntiajteb txawj nqus, zoo li lub dab dej-float thiab hydrocycloning, cais cov yas los ntawm qhov ntom ntom. Cov tswv yim tshiab, xws li microwave irradiation, ua rau cov hau kev no zoo dua. Optical sensors thiab AI daim duab lees paub txhawb kev txheeb xyuas qhov tseeb, pab cov chaw ncav cuagmus txog 95% puritynyob rau hauv recycled polymers.

Zog Efficiency thiab Sustainability

Kev siv hluav taws xob tam sim no yog lub hom phiaj saum toj kawg nkaus rau txhua lub tshuab siv yas rov siv dua. Kev tshawb fawb los ntawm National Renewable Energy Laboratory qhia tau hais tias cov txheej txheem rov ua dua tshiab siv lub zog tsawg dua thiab tsim cov pa roj carbon tsawg dua. Lawv Cov Khoom Siv Los Ntawm Kev Lag Luam Cov cuab yeej pab cov tuam txhab taug qab kev siv hluav taws xob thiab emissions, ua kom yooj yim nrhiav txoj hauv kev txuag hluav taws xob.

Integrated recycling txheej txheem tam sim no ncav lub zog efficiency ntawm75%. Cov kev txhim kho no yog los ntawm kev sib cais zoo dua qub thiab cov qauv siv tshuab ntse dua. Cov kev tshawb fawb txog lub neej qhia tau hais tias kev siv lub zog tauj dua tshiab hauv kev rov ua dua tshiab tuaj yeem txo qhov cuam tshuam rau lub ntiaj teb sov sov ntau dua. Cov kev nce qib no pab txhawb kev lag luam plastics mus rau lub neej yav tom ntej.

A Yas Recycling Tshuabsiv cov khoom sib dhos, sib cais, txiav, txiav, ntxuav, sib cais, extrusion, thiab pelletizing tig pov tseg rau hauv cov khoom tshiab. Tsis ntev los no kev nce qib zoo lichemical recyclingthiab ntse sorting pab cov tuam txhab lag luam rov qab cov yas zoo. Cov kev hloov pauv no ua rau kev rov ua dua tshiab dua thiab txhawb nqa kev huv, ntsuab rau yav tom ntej rau txhua tus.

FAQ

Dab tsi plastics tuaj yeem siv lub tshuab rov ua dua tshiab hauv 2025?

Cov tshuab feem ntau siv PET, HDPE, LDPE, PP, thiab PS. Qee cov qauv zoo tshaj tuaj yeem ua cov khoom sib xyaw lossis cov khoom qias neeg siv cov cuab yeej sib cais tshiab.

Nco tseg: Nco ntsoov xyuas lub tshuab phau ntawv qhia kom pom tag nrho cov npe ntawm cov khoom siv tau txais.

Yuav ua li cas ntse sorting systems pab rov ua dua?

Kev txheeb xyuas ntse siv AI thiab sensors. Cov cuab yeej no pom cov yas sib txawv sai sai. Lawv txhawb kev txheeb xyuas qhov tseeb thiab txo qhov yuam kev. Cov khoom siv tau huv dua, cov khoom siv zoo dua qub.

Puas yog cov khoom siv yas rov ua dua tshiab tam sim no?

Yog lawm! Cov tshuab tshiab siv lub zog tsawg dua. Lawv muaj cov motors zoo dua thiab ntse tswj. Ntau qhov chaw tam sim no taug qab siv lub zog kom txuag tau nyiaj thiab txo qis emissions.

Post lub sij hawm: Jun-24-2025