A Plastic Recycling Machinemuna 2025 inoratidzira akati wandei akakosha zvinhu, senge advanced kuunganidza masisitimu, kurongedza zvikamu, aGranulator Machine,uye aPlastic Shredder. Imwe neimwe nhanho mukuita iyi yakakosha pakushandura marara kuita reusable pellets, kugadzira iyoPlastic Recycle Machineinoshanda zvakanyanya. Zvinoenderana neazvino musika data,PET zvimedu zvekupinza kunze kwenyika zvakasvika 251,000 matani muna 2024.

| Category | Statistics / Trend Tsananguro |

|---|---|

| PET Zvimedu Zvinotengeswa (2024) | 250,961 tonnes, ingangoita 49% yezvirasika zvekunze |

Key Takeaways

- Plastic recycling machinesshandisa nhanho-ne-nhanho maitiro anosanganisira kuunganidza, kurongedza, kucheka, kugeza, kupatsanura, extrusion, uye pelletizing kushandura tsvina kuita reusable epurasitiki pellets zvinobudirira.

- Smart matekinoroji senge AI-inotyairwa kurongedza uye epamberi ekugeza masisitimu anovandudza kudzokorodza kurongeka, kuderedza marara, uye kuwedzera kunaka kwemapurasitiki akadzokororwa.

- Michina mitsva yekudzokorodza inochengetedza simba uye kucheka zvinobuda, zvichiita kuti mapurasitiki adzokorore maitiro arambe akamira uye anodhura-inoshanda kune ramangwana.

Plastic Recycling Machine Maitirwo uye Zvikuru Zvikamu

Kuunganidza Systems

Kuunganidza masisitimu anoumba nzvimbo yekutanga kune chero Plastic Recycling Machine. Aya masisitimu anounganidza marara epurasitiki kubva mudzimba, mabhizinesi, nenzvimbo dzeveruzhinji. Maguta mazhinji zvino anoshandisa akangwara mabhini uye yekutevera yedhijitari kuwedzera mitengo yekuunganidza.Zvishandiso zvedhijitari zvinobatsira vashandisi kuona chaiyo-nguva data, zvinoreva kuti vanogona kupindura nekukurumidza kumabhini akazara kana mapikicha akapotsa.

Zano: Kudzidzira vanonhonga marara uye zvirongwa zvemubairo zvinogona kuita kuti kuunganidza kushande uye kuchengetedza marara epurasitiki kubva mumarara.

Zvimwe zvinhu zvakakosha zvinovandudza kuunganidza system kushanda zvakanaka zvinosanganisira:

- Real-time waste reporting uye otomatiki kuunganidza data.

- Performance monitoring uchishandisa akakosha zviratidzo senge throughput uye downtime.

- Kudzidziswa kwevashandi pamusoro pekushanda kwemichina uye kuchengeteka.

- Nzira dzekuchengetedza magetsi, dzakadai sekushandisa midziyo inoshanda uye kugadzirisa nguva dzose.

Mitemo inewo basa guru. Mitemo ikozvino inoda humwe huwandu hwezvakagadzirwazve muzvigadzirwa, izvo zvinosundidzira makambani kuunganidza mamwe mapurasitiki ekudzokorodza.

Kuronga Units

Kuronga zvikamu zvinopatsanura mapurasitiki nemhando, ruvara, uye mhando. Danho iri rakakosha nekuti mapurasitiki akasiyana anoda maitiro akasiyana ekudzokorodza. Zvikamu zvemazuva ano zvekuronga zvinoshandisa lasers uye AI kuongorora uye kuronga mapurasitiki nekumhanya kwakanyanya. Semuenzaniso, laser-sorting masisitimu anogonatarisa kusvika ku860,000 spectra pasekondi, zvichiita kuti zvive nyore kuronga kunyange mapurasitiki matema anonyengera. FT-NIR ma detectors ikozvino anogara kusvika kumaawa e8,000 pakati pezvikanganiso, zvinoreva nguva shoma yekuderedza uye kunyatsogadzirisa.

| Kuronga System Combination | Yakaparadzana Plastic Waste (kg pavagari vemo) |

|---|---|

| Post kuparadzana chete | 6.2 |

| Curbside collection chete | 5.6 |

| Musanganiswa wekuparadzaniswa kwemashure + curbside | 7.6 - 8.0 |

| Curbside collection + inounza nzvimbo | 3.5 |

Nyika dzinoshandisa mitemo yakasimba yekuparadzanisa, seSouth Korea,kudzokorodza kusvika 70% yemarara ekanzuru yavo. Yepamberi yekuronga mayuniti neAI uye pedyo-infrared tekinoroji inogona kusvika pamusoro pe90% kunyatsoita, iyo inowedzera kunaka uye goho remapurasitiki akadzokororwa.

Shredders uye Granulators

Shredders uye granulators inoputsa zvinhu zvikuru zvepurasitiki kuita zvidimbu zvidiki. Izvi zvinoita kuti zvive nyore kune Plastic Recycling Machine kugadzirisa zvinhu mumatanho anotevera. Vashandi vanofanira kuchengetedza mashizha akapinza uye kudyisa muchina wacho zvishoma nezvishoma kudzivirira jam. Kubvisa zvinosvibisa usati watsemura zvakare kunobatsira kuti muchina ugare kwenguva refu.

Mamwe akanakisa maitiro e shredders uye granulator anosanganisira:

- Nguva dzose kugadzirisa uye blade checks.

- Pre-washing zvinhu kuderedza kupera.

- Kuchengeta chiyero chekudya chakafanana.

- Kugadzirisa guruva uye ruzha rwekuchengetedza.

- Kudzidzisa vashandisi kuona uye kugadzirisa matambudziko nekukurumidza.

Metrics ekuita senge chiyero chekupfuura, kushandiswa kwesimba, uye kubuda kwemhando inobatsira vashandisi kuchengetedza michina iyi ichishanda zvakanaka.

Washing Systems

Washing systems dzinochenesa mapurasitiki akachekwa. Vanobvisa tsvina, mavara, uye zvokudya zvakasara kana makemikari. Purasitiki yakachena iri nyore kudzokorora uye inoita zvigadzirwa zviri nani. Zvidzidzo zvinoratidza kuti kugeza nemvura inotonhora kana inopisa, dzimwe nguva nemishonga yekuchenesa, inogona kubvisa tsvina yakawanda. Mushure mekugeza, kuomeswa kunounza hunyoro pasi kusvika ku3% kana pasi, iyo yakanaka kune imwezve kugadzirisa.

| Washing Method | Kunosvibisa Kubvisa Kubudirira | Melt Flow Index (MFI) Kusiyana | Mechanical Properties (Ductility) | Notes |

|---|---|---|---|---|

| Kusagezwa (rPPu) | Hapana | Kusiyanisa kwepamusoro | Kureba kwakaderera panguva yekuzorora | Kusvibisa kunokonzera kuora |

| Kugeza Mvura Inotonhora (rPPcw) | Chinokosha | Yakaderedzwa musiyano | Kuvandudza zvishoma ductility | Simba-inoshanda |

| Kugeza Mvura Inopisa (rPPhw) | High | Zvakafanana nechando chekugeza | Kuvandudza zvishoma ductility | Kufananidzwa nechando chekugeza |

| Mvura Inopisa + Agents (rPPhwca) | High | Zvakafanana nechando chekugeza | Kuvandudza zvishoma ductility | Kufananidzwa nechando chekugeza |

Washing masisitimu anosanganisa mvura uye kuomeswa kwemhepo anogona kuvandudza kunaka uye processability yemapurasitiki akadzokororwa.

Separation Technologies

Kuparadzanisa matekinoroji anonatsiridza rwizi rwepurasitiki zvakanyanya. Aya masisitimu anoshandisa nzira dzakaita sepedyo-infrared kurongedza, flotation, uye kunyange makemikari maitiro kuparadzanisa mapurasitiki nekuwanda kana kemikari makeup.Makambani akaita seDow neSABIC anoshandisa kuseta kwepamberiuye comptibilizer additives kuchengeta yakadzokororwa epurasitiki mhando yakakwirira. AI-inotyairwa kurongedza uye solvent-based kucheneswa kunobatsirawo kubvisa zvisingadiwe.

| Reference Type | Tsanangudzo | Kubatsira Kuvimbika |

|---|---|---|

| Zvinyorwa zvekutsvakurudza | Zvidzidzo zve flotation, air classification, uye density kupatsanurwa | Ipa ruzivo rwekuedza nzira dzekuparadzanisa |

| Patents | Proprietary maitiro ekuparadzanisa kwepurasitiki | Iva nechokwadi chekuchenesa kunoshanda |

| Conference Proceedings | Kufambira mberi mukunyunguduka kwesefa uye otomatiki kuronga | Kuvandudza kurongeka uye kunaka |

| Spectral Identification Nzira | Pedyo-infrared uye laser-induced emission | Ita kuti kurongeka kwakakurumidza, kwakavimbika |

| Industry Reports | Humbowo hunoshanda hwe process optimization | Tsigira real-world application |

Aya matekinoroji anoita shuwa chete mhando chaiyo yepurasitiki inoenda kune inotevera nhanho, inova yakakosha pakugadzira zvemhando yepamusoro zvigadzirwa zvakadzokororwa.

Extrusion Units

Extrusion units inonyunguduka uye inogadzirisa zvakare purasitiki yakacheneswa kuita fomu nyowani. Iyo Plastic Recycling Machine inoshandisa kupisa uye kumanikidza kusundira purasitiki kuburikidza neforoma, kugadzira tambo refu kana mashizha. New extruder inoshanda zvakanyanya kupfuura yekare mhando. Semuenzaniso, michina mitsva inogonakuwedzera kugadzirwa nepamusoro pe36%uye kuderedza kushandiswa kwemagetsi, izvo zvinochengetedza mari nesimba.

| Metric | Old Extruders | New Extruders | Kuvandudza (%) |

|---|---|---|---|

| Kubudirira (matani / zuva) | 11 | 15 | 36.4 |

| Mupiro Margin (zvikamu) | 6126.9 | 6881.3 | +754.4 |

Advanced extrusion tekinoroji inochengeta purasitiki yakasimba, kunyangwe mushure mekutenderera kwakati wandei. Izvi zvinoreva kuti zvigadzirwa zvakadzokororwa zvinogona kugara sekureba sekunge izvo zvakagadzirwa kubva mupurasitiki nyowani.

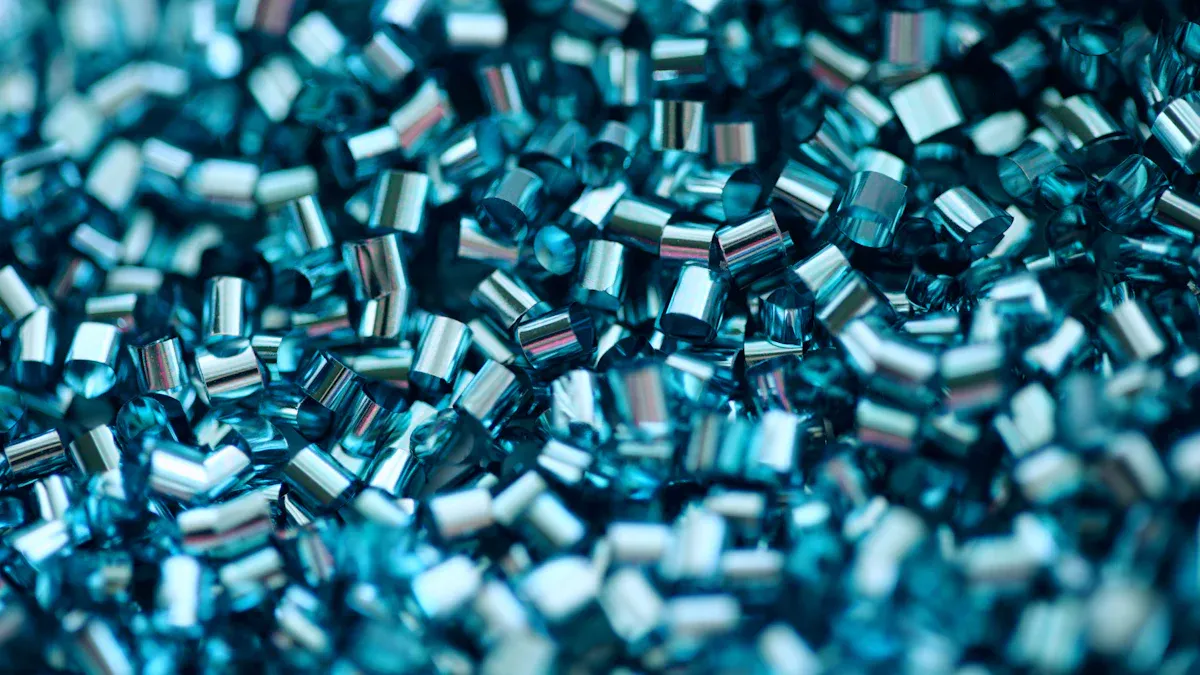

Pelletizing Units

Pelletizing units anocheka epurasitiki yakawedzera kuita madiki, mayunifomu pellets. Aya ma pellets ari nyore kutakura uye kushandisa mukugadzira zvigadzirwa zvitsva.Kushanda kwepelletizing kazhinji kunosvika pamusoro pe90%apo vashandi vanodzora unyoro uye kumhanya kwechina.

| Feed Sample | Unyoro Content | Die Diameter | Kumhanya kwemuchina (rpm) | Pelletizing Kubudirira |

|---|---|---|---|---|

| X1 | 7% | 3 mm | 75 | 94.0% |

| X2 | 7% | 3 mm | 75 | 93.2% |

| X3 | 7% | 3 mm | 75 | 92.1% |

Vashandisi vanogona kugadzirisa marongero senge chiyero chekugadzira uye kureba kwebangakuti uwane yakanakisa pellet mhando. Kushanda kwepamusoro pelletizing kunoreva kusarasa kushoma uye zvimwe zvinoshandisika zvezvigadzirwa zvitsva.

Zvitsva muPlastiki Recycling Machines ye2025

Smart Sorting uye AI Kubatanidzwa

Kuronga zvine hungwaru kwachinja mashandiro anoita zvivakwa zvekudzokorodza. Makambani mazhinji zvino anoshandisakuona komputa, kudzidza kwakadzama, uye hyperspectral imagingmuhurongwa hwavo hwekuronga. Maturusi aya anobatsira marobhoti kuona zvinodzokororwa, kuronga mafambiro awo, uye kuronga mapurasitiki nemazvo. Mienzaniso yekudzidza yakadzama inogona kutofanotaura marudzi emarara uye kubatsira pakuronga.

- Maoko eRobhoti anoshandisa hyperspectral imaging kugadzirisa kubata kwavo, zvichiita kuti kurongeka kuve kwakajeka.

- Neural network uye muchina kudzidza kunobatsira kufanotaura kugadzirwa kwemarara, saka zvivakwa zvinogona kuronga zvirinani.

- Algorithms senge yakasarudzika sango uye inotsigira vector michina inovandudza kurongedza, kunyangwe neashoma data.

Mienzaniso yenyika chaiyo inoratidza kukanganisa. HERA yekuItaly yakashanda neIBM kuwedzera AI kuhurongwa hwavo hwekuronga. Izvi zvakaita kuti pave nemitengo yakakwira yekudzokorodza uye kushomeka kwemabasa emawoko. MuJapan neUS, marobhoti ane simba reAI anoronga tsvina achishandisa masensa nemakamera. marobhoti aya mari pakati$250,000 uye $500,000chimwe nechimwe, asi zvivako zvakakura zvinowanzoona kubhadhara mumakore mashanu kusvika gumi nekuda kwekuchengetedza kwevashandi uye kuronga zviri nani. Smart mabhini nemasensa anobatsirawo nekudzikisa kangani marori anoda kunhonga tsvina, kuchengetedza mari nenguva.

Yepamusoro Washing uye Separation Technologies

Washing uye kupatsanura zvirongwavave vakangwara uye vakavimbika. Michina yekuwachisa yemazuva ano inoshandisasensors uye otomatikikudzora kuchenesa nekuomesa. Izvi zvinochengeta tsvina yepurasitiki yakachena uye yakagadzirira danho rinotevera. Real-time yekutarisa inobatsira vashandisi kuona matambudziko nekukurumidza uye kuchengetedza maitiro achifamba zvakanaka.

- Pedyo-infrared spectroscopyinogadzira mapurasitiki akaita seHDPE nekuchena kwepamusoro.

- Macompatibilizers anovandudza kunaka kwemapurasitiki akadzokororwa.

- Solvent-based purification inobvisa tsvina yakaoma uye hwema.

- Kemikari recycling, senge pyrolysis, inobatsira kubata mapurasitiki akasanganiswa kana akasviba.

Nzira dzekuparadzanisa giravhiti, senge sink-float uye hydrocycloning, inoparadzanisa mapurasitiki nekuwanda. Maitiro matsva, akadai semicrowave irradiation, anoita kuti nzira idzi dzive nani. Optical sensors uye AI kucherechedzwa kwemufananidzo kunowedzera kurongeka, kubatsira zvivakwa kusvikakusvika ku95% kuchenamuma polymers akadzokororwa.

Kushanda Kwesimba uye Kugadzikana

Kushanda kwesimba ikozvino chinangwa chepamusoro kune yega yega Plastic Recycling Machine. Tsvagiridzo kubva kuNational Renewable Energy Laboratory inoratidza kuti nzira nyowani dzekudzokorodza dzinoshandisa simba shoma uye kugadzira mashoma egreenhouse magasi. Zvishandiso Zvavo Zvinoyerera kuburikidza neIndasitiri chishandiso chinobatsira makambani kuteedzera mashandisiro esimba uye kubuda, zvichiita kuti zvive nyore kutsvaga nzira dzekuchengetedza simba.

Maitirwo akabatanidzwa ekudzokorodza zvino asvika kusimba rekushandisa kwesimba re75%. Idzi gadziriso dzinouya kubva kune ari nani ekuparadzanisa masisitimu uye akangwara emuchina dhizaini. Zvidzidzo zvekutenderera kwehupenyu zvinoratidza kuti kushandisa simba rinodzokororwa mukudzokorodza kunogona kuderedza kudziya kwepasirese zvakanyanya. Kufambira mberi uku kunobatsira kufambisa indasitiri yepurasitiki kune ramangwana rakagadzikana.

A Plastic Recycling Machineinoshandisa kuunganidza, kuronga, kucheka, kugeza, kupatsanura, extrusion, uye pelletizing kushandura tsvina kuita zvigadzirwa zvitsva. Recent advances likemakemikari patsvauye kurongedza kwakangwara kunobatsira makambani kudzoreredza emhando yepamusoro mapurasitiki. Shanduko idzi dzinoita kuti kudzokorodza kushande uye kunotsigira rakachena, remangwana rakasvibira remunhu wese.

FAQ

Ndeapi mapurasitiki anogona kudzokorodza muchina maitiro muna 2025?

Michina yakawanda inobata PET, HDPE, LDPE, PP, uye PS. Mamwe mamodheru epamusoro anogona kutogadzira mapurasitiki akasanganiswa kana akasviba vachishandisa tekinoroji nyowani dzekuparadzanisa.

Cherechedza: Gara uchitarisa bhuku remuchina kuti uwane runyoro ruzere rwemapurasitiki anogamuchirwa.

Masisitimu ekuronga akangwara anobatsira sei kudzokorora?

Kuronga kwakangwara kunoshandisa AI uye masensa. Zvishandiso izvi zvinoona mapurasitiki akasiyana nekukurumidza. Vanowedzera kurongeka kwechokwadi uye kuderedza zvikanganiso. Zvivako zvinowana zvakachena, zvemhando yepamusoro zvakadzokororwazve.

Michina yekudzokorodza epurasitiki inoshanda nesimba iko zvino?

Ehe! Michina mitsva inoshandisa simba shoma. Ivo vane mota dziri nani uye smart control. Zvivakwa zvakawanda zvino zvinoteedzera kushandiswa kwesimba kuchengetedza mari uye kuderera kwehutsi.

Nguva yekutumira: Jun-24-2025