Mechini ea ho Hlakola Plastikithusa ho sebetsana le bothata bo ntseng bo hola ba litšila tsa polasetiki. Ka 2025, litefiso tsa lefats'e tsa ho sebelisa hape li ntse li le ka tlase ho 10%.

- Ho etsoa lithane tse fetang limilione tse 430 tsa polasetiki e sa tsoakoang selemo le selemo, 'me boholo ba tsona li sebelisoa hanngoe ebe li lahloa.

- Mechini e kang aGranulator, Polasetiki Shredder, kapaPlastiki ea Mochini oa Entee ka fetola litšila hore e be lihlahisoa tse molemo.

- Ho khetha se nepahetsengMochini oa ho Recycle oa Plastikie boloka chelete ebile e thusa polanete.

Lintlha tsa bohlokoa

- Tseba mefuta le boholo ba polasetiki eo u hlokang ho e sebelisa hape ho khetha mechini e lumellanang le litlhoko tsa hau le sekala sa hau.

- Khetha mechine e nang lebokhoni bo nepahetseng, matla a matla, le automation ho boloka chelete le ho ntlafatsa boleng ba ho recycle.

- Nahana ka senatekanyetso, sebaka, tlhokomelo, le melao ea sebaka pele u reka ho netefatsa ts'ebetso e bonolo le katleho ea nako e telele.

Hlalosa Litlhoko tsa Hao tsa ho Recycling ea Plastiki

Mefuta ea Lipolasetiki tse lokelang ho etsoa

Morero o mong le o mong oa ho tsosolosa o qala ka ho tseba hore na ke li-plastiki life tse hlokang ho sebetsa. PET le HDPE li hlaha hangata ka har'a meqomo e sebelisoang hape. Li-plastiki tsena li bonolo ho li sebelisa hape ka mekhoa ea mochini. LDPE, PP, le PS le tsona lia hlaha, empa li tlisa mathata a mangata. Tšebeliso ea lik'hemik'hale e ntse e hola 'me e thusa ka lipolasetiki tse thata joalo ka nylon kapa lintho tse silafetseng.

Keletso: Moralo oametjhini ya ho hlopha, tlhokeho ea 'maraka, le lisebelisoa tsa lehae kaofela li na le sebopeho seo lipolasetiki li ka sebetsanang le tsona.

Mona ke pono e potlakileng ea hore na lipolasetiki tse fapaneng li lumellana joang le sekala sa ho sebelisoa hape:

| Mofuta oa polasetiki | Tekanyo e Nyenyane | Tekanyo e Bohareng | Sekhahla se Seholo |

|---|---|---|---|

| PET | Ee | Ee | Ee |

| HDPE | Ee | Ee | Ee |

| LDPE | Moedi | Ee | Ee |

| PP | Ee | Ee | Ee |

| PS | No | No | Ee |

| Kopantsoeng | No | Moedi | Ee |

Bolumo le Khafetsa ea Litšila tsa Plastiki

Chelete ealitšila tsa polasetikile hore na e fihla hangata hakae e fetola ntho e 'ngoe le e 'ngoe. Lisebelisoa tse fumanang melapo e tsitsitseng ea libotlolo tsa PET kapa lijeke tsa HDPE li hloka mechini e nang le lisebelisoa tse ngata. Mabenkele a manyane a ka hloka feela li-shredders le likhoele tsa ho hlatsoa. Limela tse kholo li sebelisa mela ea ho hlopha liindasteri le li-extruder tse tsoetseng pele.

Tlhokomeliso: Mofuta oa litšila tsa polasetiki o tsamaisa khetho ea Mechini ea ho Recycling ea Plastiki, hammoho le litlhoko tsa sebaka le matla.

Maemo a Tšilafalo le Litlhoko tsa ho Hlopha Pele

Hangata litšila tsa polasetiki li fihla li hloekile. Metsoako e thata e ka ba le lintho tse ka bang 28% tseo e seng tsa polasetiki, lifilimi tse fihlang ho litšila tse 49%, le libopeho tsa 3D hangata li tsoakana le lifilimi.

- Li-separators tsa makenete li ntša tšepe.

- Li-separators tsa hona joale tsa Eddy li nka aluminium.

- Lisebelisoa tsa mahlo li sebelisa li-laser ho bona mebala le libopeho.

- Ho hlopha ka letsoho ho thusa ka taolo ea boleng.

- Lits'oants'o le lihlopha tsa moea li hlopha ka boholo le ho teteana.

Sistimi ea sejoale-joale ea ho hlopha esale pele e kopanya lisebelisoa tsena ho matlafatsa bohloeki le ho fokotsa litšenyehelo. Methapo e hokahaneng ea ho hlopha e nang le lisensara e tšoara lintho tse silafatsang, e etsang hore ho be bonolo ho e sebelisa hape ho bolokehe.

Mechini ea ho Recycling ea Plastiki: Mefuta le Mesebetsi

Li-shredders le li-granulator

Li-shredders leli-granulatorsqala mokhoa oa ho tsosolosa. Li-shredders li pshatla lintho tse kholo tsa polasetiki likotoana tse nyane. Li tšoara likotoana tse ngata, tse teteaneng kapa tse sa tloaelehang habonolo. Lebelo la bona le liehang la rotor le bolela ho fokotseha ho fokolang le ho fokotsa tšebeliso ea matla. Li-granulator li nka nako e tlang. Ba khaola polasetiki e pshatlehileng hore e be li-flakes tse ntle, tse tšoanang. Li-flakes tsena li haufi ka boholo le li-pellets tse ncha tsa polasetiki. Li-granulator li sebetsa hantle ka likotoana tse hloekileng, tse nyane, 'me li hloka phepo e tsitsitseng. Hammoho, li-shredders le li-granulator li theha sistimi ea mekhahlelo e 'meli e matlafatsang ts'ebetso le boleng ba sehlahisoa.

| Sebopeho/Sebopeho | Li-shredders | Li-granulator |

|---|---|---|

| Lebelo la Rotor | Tlase (~100 rpm) | Holimo (~500 rpm) |

| Sephetho sa Karolo ea Boholo | E kholoanyane, e fokolang | E nyane, e ts'oanang |

| Ho Tšoara Lintho | Sekhechana se seholo, se sa tloaelehang | E hloekileng, likotoana tse nyane |

| Tšebeliso ea Matla | Tlase | E phahameng |

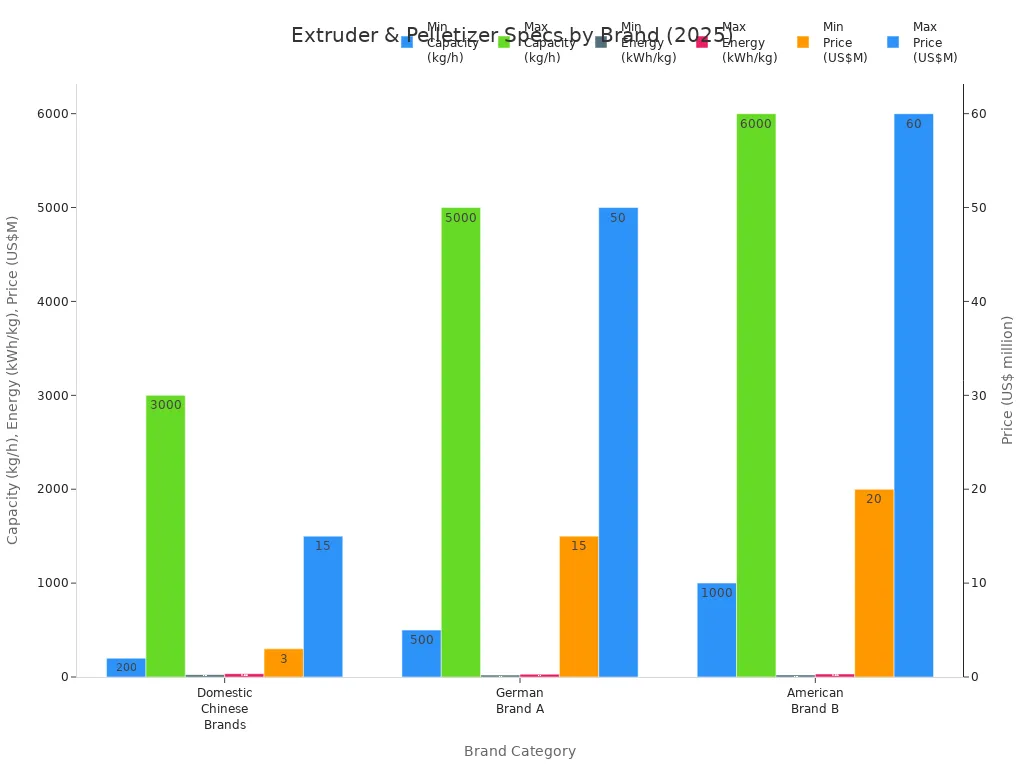

Extruders le Pelletizers

Li-extruders lia qhibiliha ebe li sefa li-flakes tsa polasetiki. Ba tlosa litšila le lintho tse ling tse sa batleheng. Mohato ona o etsa likhoele tsa polasetiki tse boreleli, tse hloekileng. Joale li-pelletizer li khaola likhoele tsena hore li be tse nyane, esita le li-pellets. Li-pellets tsena li fetoha lisebelisoa tse tala bakeng sa lihlahisoa tse ncha. Li-pelletizer tse tsoetseng pele, joalo ka mefuta e ka tlas'a metsi, li etsa li-pellets tse nang le pheletso e benyang le boholo bo phethahetseng. Extruder le pelletizer e nepahetseng e thusa Mechini ea ho Recycling ea Plastiki ho hlahisa li-pellets tsa boleng bo holimo, tse sa fetoheng.

Mekhoa ea ho hlatsoa le ho omisa

Lisebelisoa tsa ho hlatsoa le ho omisa li hloekisa polasetiki pele e qhibiliha. Li-washer tsa lebelo le phahameng li hohla litšila, sekhomaretsi le lileibole. Li-washer tse chesang li sebelisa metsi a futhumetseng kapa soda ea caustic bakeng sa tlhoekiso e tebileng. Ka mor'a ho hlatsoa,liomisatlosa mongobo. Li-dryer tsa sejoale-joale li ka fokotsa metsi ho isa tlase ho 2%. Plastiki e hloekileng, e omeletseng e lebisa ho li-pellets tse ntle le liphoso tse fokolang. Litsamaiso tse ncha li sebelisa matla a fokolang le metsi, e leng se etsang hore ho tsosolosoa ho tšoarelle.

Keletso: Mehato e lokiselitsoeng ea ho hlatsoa le ho omisa e ntlafatsa bohloeki le monko oa lipolasetiki tse tsosolositsoeng, tse thusang ho finyella litekanyetso tse tiileng tsa boleng.

Mehala e Kopantsoeng ea ho Recycling

Methapo e kopantsoeng ea ho tsosolosa e kopanya mehato eohle-ho pshatla, ho hlatsoa, ho omisa, ho ntša le ho penta - ho etsa mokhoa o le mong o boreleli. Methapo ena e sebelisa li-conveyor le li-control tse bohlale ho tsamaisa thepa ho tloha sethaleng se seng ho ea ho se seng. Automation e fokotsa mosebetsi le ho potlakisa tlhahiso. Tlhokomelo ea nako ea 'nete e beha mathata esale pele mme e boloka tsohle li tsamaea hantle. Mehala e kopantsoeng e thusa Mechini ea ho Recycle ea Plastiki ho sebetsa kapele, ho fokotsa litšenyehelo, le ho hlahisa polasetiki ea boleng bo holimo e nchafalitsoeng.

Likarolo tsa Bohlokoa tsa Mechini ea ho Recycling ea Plastiki

Bokhoni ba Ts'ebetso le Ts'ebetso

Bokhoni ba ho sebetsa bo bolela hore na mochini o ka sebetsana le polasetiki e kae hora e 'ngoe le e 'ngoe. Ka 2025, Mechini e mengata ea ho Recycling ea Plastiki e qala ka lik'hilograma tse 300 ka hora. Mefuta e meng ea indasteri, joalo ka JianTai XS-400 le XR-800, e fihla ho lik'hilograma tse 1,500 ka hora. Mofuta ona o pharaletseng o thusa likhoebo ho khetha mechini e lumellanang le litlhoko tsa bona. Lebenkele le lenyenyane le ka 'na la khetha mohlala oa thepa e tlaase, ha fektheri e kholo e hloka ntho e kholoanyane. Ha ba khetha mochine, ba lokela ho nahana ka hore na ho fihla litšila tse kae tsa polasetiki letsatsi ka leng le hore na ba batla ho li sebetsa kapele hakae.

Keletso: Ts'ebetso e phahameng e bolela ho sebelisoa hape ka potlako, empa hape e hloka sebaka se eketsehileng le matla.

Matla a Matla le Tšebeliso ea Matla

Matla a matla a bohlokoa bakeng sa tikoloho le sepache. Mechini e mengata e mecha e sebelisa matla a fokolang hobane e na le lienjineri tse betere le meralo e bohlale. Letoto la S: GRAN le tsoang ho NGR le hlahella ka lebaka la tlhahiso e matla le e tenyetsehang, ha li-pelletizer tsa ACS-H™ li fana ka tlhahiso e phahameng ka tšebeliso e tlase ea matla. Mechini e meng e sebelisa AI le IoT ho hlophisa lipolasetiki ka nepo le ho boloka matla. Tse ling li na le li-blade tse ntlafalitsoeng le lisebelisoa tsa metsi tse koetsoeng tse fokotsang litšila le tšebeliso ea matla.

- Tšebeliso ea matla ke karolo e kholo ea litšenyehelo tsa ts'ebetso.

- Ho ntlafatsa ho dimotlolo tse baballang matla, jwalo ka metjhini ya sekrufuru e habedi, ho theola ditefiso tsa matla.

- Variable frequency drives (VFDs) e fetola lebelo la enjene ho tsamaisana le boima ba mosebetsi.

- Ho hloekisa le ho hlokomela kamehla ho boloka mechine e sebetsa hantle le ho boloka matla.

- Ho tima mechine ha e sa sebelisoe ho qoba ho senya motlakase.

- Ho sebelisa lisebelisoa tse hloekileng tse tala ho thusa mechini hore e sebetse ka potlako le ho sebelisa matla a fokolang.

Litaolo tsa Mosebelisi le Litaolo tsa Mosebelisi

Mechini ea sejoale-joale ea ho Recycling ea Plastiki e sebelisa li-automation tse bohlale ho etsa hore ho be bonolo ho e sebelisa hape ho bolokehe. Ba na le li-programmable logic controllers (PLC) tse laolang lits'ebetso ka nako ea nnete. Human-Machine Interfaces (HMI) e fana ka li-touchscreens bakeng sa taolo e bonolo le ho bonts'a data. Li-sensor li lekola mocheso, khatello le lebelo, ha li-actuator li fetola litekanyetso tsa phepo le phallo ea thepa.

| Automation Feature | Tlhaloso | Mesebetsi ea Bohlokoa |

|---|---|---|

| Programmable Logic Controller (PLC) | Setsi sa taolo se bohareng se phethahatsang litaelo tse hlophisitsoeng ho laola mekhoa ea mochine ka nako ea sebele | Ts'ebetso ea othomathike, ho lekola nako ea nnete, ho lemoha liphoso, taolo ea polokeho |

| Human-Machine Interface (HMI) | Sebopeho sa "touchscreen" bakeng sa tšebelisano ea opareitara le liphetoho tsa paramethara | Bontša data ea nako ea sebele, taolo ea matsoho, ho rengoa ha data ka ts'ebetso |

| Sistimi ea Sensor | Marang-rang a li-sensor tse lekanyang mocheso, khatello, lebelo, sebaka, joalo-joalo. | Lekola mefuta-futa ea ts'ebetso, fana ka maikutlo bakeng sa taolo ea li-loop tse koetsoeng, li-alarm tsa ho qala |

| Li-activators | Lisebelisoa tse fetolang matshwao a taolo hore e be diketso tsa motjhini | Laola litekanyetso tsa ho fepa, lebelo la extrusion, pholiso, lokisa phallo ea thepa, amahanya likarolo tsa mochini |

Basebelisi ba rua molemo holima tlhahlobo ea nako ea nnete le phihlello ea hole. Mekhoa ea ho khetha e ikemetseng e arola lipolasetiki ho ea ka mofuta le mebala, ho fokotsa mosebetsi oa matsoho. Litaolo tse tsamaisoang ke AI li lokisa litlhophiso ho fofa, li boloka tsohle li tsamaea hantle.

Likarolo tsa Tšireletso le Tšireletso ea Basebetsi

Tšireletseho e tla pele setsing sefe kapa sefe sa ho sebelisoa hape. Mechini e hloka likarolo tse matla tsa polokeho ho sireletsa basebetsi kotsing. Litšitiso tsa 'mele li thibela batho ho tloha likarolong tse kotsi. Balebeli ba koaletsoeng ba koala mechine haeba e butsoe. Balebeli ba feto-fetohang le ba itlhophisang ba lekana lisebelisoa tse fapaneng mme ba boloka matsoho a bolokehile.

Kamehla u roale lisebelisoa tsa ho itšireletsa (PPE) joalo ka liatlana, lihelmete, likhalase tsa tšireletso le lieta tse entsoeng ka tšepe.

- Mechini e lokela ho ba le likarolo tsa polokeho tseo ho leng thata ho li tlosa kapa ho li tima.

- Licheke tsa kamehla tsa tlhokomelo li boloka balebeli le li-control li sebetsa.

- Ts'ebetso ea Lockout-tagout e thibela likotsi nakong ea tokiso.

- Likonopo tsa ho emisa ha ts'ohanyetso li tlameha ho ba bonolo ho fihla ho tsona.

- Koetliso ea polokeho e thusa basebetsi ho utloisisa likotsi le ho sebelisa lisebelisoa ka nepo.

- Litlhahlobo tsa polokeho ea kahare li shebana le ts'ireletso ea mochini.

Tlhokomelo le Tšireletseho

Mechini e tšoarellang e nka nako e telele 'me e hloka ho lokisoa ho fokolang. Tlhokomelo ea kamehla, joalo ka ho hloekisa le ho kenya likarolo tse tsofetseng, ho boloka mechini e sebetsa hantle. Lubrication e thibela khohlano le tšenyo. Basebelisi ba lokela ho hlahloba mechini khafetsa le ho lokisa mathata esale pele. Ho sebelisa lisebelisoa le likarolo tsa boleng bo holimo ho thusa mechini hore e eme ka thata. Mechini e meng e na le likarolo tsa ho lokisa tse lemosang basebelisi pele ntho e robeha.

Tlhokomeliso: Mechini e hlokometsoeng hantle e sebelisa matla a fokolang mme e hlahisa polasetiki e nchafalitsoeng hantle.

Likhetho tsa ho Itloaetsa le ho ntlafatsa

Mechini ea ho Recycling ea Plastiki ka 2025 e fana ka mekhoa e mengata ea ho e etsa le ho e ntlafatsa.Li-shredders li se li hlopha ka bohlale haholoanyane, tšebeliso e tlase ea matla, le khokahanyo ea inthanete bakeng sa taolo e hole. Li-granulator li sebelisa li-control tse tsamaisoang ke AI le li-sensor tse bohlale, tse nang le li-rotor tse ntlafalitsoeng le mahare a tšoarellang nako e telele. Lisebelisoa li hatella litšila, li iphepe ka bo eona, 'me li boloke sebaka. Li-extruder li shebana le meralo e bonolo ea tikoloho le ho sebetsana le mefuta e mengata ea polasetiki.

- JianTai e sebetsa le bareki ho roka metjhini ea lipolasetiki tse fapaneng le melao ea lehae.

- Meetso e mecha e boloka matla, e matha butle, 'me e kenelle libakeng tse nyane.

- Lintlafatso li kenyelletsa ho fepa ka boiketsetso, ho kopanya hantle, le bophelo bo bolelele ba blade.

Keletso: Likhetho tse ikhethileng li thusa likhoebo ho fihlela litlhoko tse fetohang tsa ho sebelisoa hape le ho lula ka pele ho melaoana e mecha.

Mehopolo e Sebetsang bakeng sa ho Reka Mechini ea ho Recycling ea Plastiki

Tekanyetso le Kakaretso ea Litšenyehelo tsa Beng

Theko ke ea bohlokoa ha u khetha thepa ea ho tsosolosa. Mechini e meng e bitsa chelete e tlase esale pele empa e hloka ho lokisoa hamorao. Tse ling li bitsa chelete e ngata empa li tšoarella nako e telele ’me li sebelisa matla a fokolang. Bareki ba bohlale ba sheba kakaretso ea litšenyehelo tsa ho ba beng. Sena se bolela ho nahana ka theko, tlhokomelo, likarolo tse ling, le likoloto tsa motlakase. Tafole e bonolo e ka thusa ho bapisa litšenyehelo:

| Litšenyehelo Factor | Mohlala oa Lipotso |

|---|---|

| Theko ea ho Reka | Na e ka har'a budget? |

| Tlhokomelo | E hloka ts'ebeletso hangata hakae? |

| Tšebeliso ea Matla | Na e tla phahamisa likoloto tsa motlakase? |

| Likarolo tsa tlatsetso | Na ho bonolo ho fumana likarolo? |

Keletso: Ho sebelisa chelete e ngata hona joale ho ka boloka chelete ha nako e ntse e ea.

Litlhoko tsa Sebaka le Tlhokahalo

Mochine o mong le o mong o hloka sebaka se lekaneng ho sebetsa ka mokhoa o sireletsehileng. Mechini e meng ea ho Recycling ea Plastiki e kena ka har'a lithupelo tse nyane. Ba bang ba hloka mekato e meholo ea lifeme. Bareki ba lokela ho lekanya sebaka sa bona pele ba reka. Hape ba lokela ho hlahloba hore na fatše ho ka tšoara thepa e boima. Ho rera hantle ho qoba liphetoho tse bitsang chelete e ngata hamorao.

Ka mor'a-Thekiso Tšehetso le Tšebeletso

Tšehetso e tšepahalang e boloka mechine e sebetsa. Bafani ba thepa e ntle ba fana ka koetliso, litokiso tse potlakileng, le phihlello e bonolo ea likarolo tse ling. Ba araba lipotso mme ba thusa ho rarolla mathata. Hona joale lik'hamphani tse ngata li fana ka thuso ea inthaneteng le litataiso tsa livideo.

- Tšehetso e potlakileng e bolela ho fokotsa nako.

- Koetliso e thusa basebetsi ho sebelisa mechine ka mokhoa o sireletsehileng.

Ho latela Melao ea Lehae

Melao ea ho recycle e fetoha ho tloha sebakeng ho ea ho se seng. Bareki ba tlameha ho hlahloba melao ea lehae pele ba reka. Libaka tse ling li hloka li-filters tse khethehileng kapa li-control tsa lerata. Tse ling li hloka licheke tsa polokeho kapa litlaleho tsa ho e sebelisa hape. Ho latela melao ho boloka khoebo e sireletsehile litefisong.

Ela hloko: Kamehla botsa barekisi hore na mechini ea bona e lumellana le maemo a lehae.

Ho khetha mochine o nepahetseng ho qala ka lipakane tse hlakileng tsa ho tsosolosa. Bareki ba lokela ho bapisa litlhoko tsa bona le likarolo tsa mochini. Ba lokela ho nahana ka tekanyetso ea chelete, sebaka le tšehetso. Mohato o bohlale ke ho thathamisa lipheo, likhetho tsa lipatlisiso, le ho bua le barekisi. Sena se ba thusa ho etsa khetho e ntle ka ho fetisisa bakeng sa khoebo ea bona.

LBH

Ke lipolasetiki life tse ka sebelisoang ke mechini e mengata e nchafatsang ka 2025?

Mechini e mengata e sebetsa PET, HDPE, LDPE, le PP. Mefuta e meng e tsoetseng pele e sebetsana le lipolasetiki tse tsoakiloeng kapa tse silafetseng. Kamehla hlahloba lintlha tsa mochini.

Ke hangata hakae basebetsi ba lokelang ho boloka mechini ea polasetiki e sebelisoang hape?

Basebelisi ba lokela ho hlahloba mechini beke le beke. Li hloekisa, li tlotsa le ho tlosa likarolo tse tsofetseng. Mechini e thusang ea ho hlahloba khafetsa e nka nako e telele mme e sebetsa betere.

Na metjhini e hlabollang ya polasetiki e hloka kwetliso e kgethehileng hore e sebetse?

E, basebetsi ba hlokakoetliso. Hangata barekisi ba fana ka litataiso kapa livideo. Koetliso e ntle e boloka basebetsi ba bolokehile hape e thusa mechini hore e sebetse hantle.

Nako ea poso: Aug-18-2025