Plastic Recycling Machineskubatsira kugadzirisa dambudziko riri kukura marara epurasitiki. Muna 2025, mazinga epasi rose ekudzokorodza anoramba ari pasi pegumi muzana.

- Anopfuura 430 miriyoni matani epurasitiki mhandara anogadzirwa gore rega rega, akawanda anoshandiswa kamwe chete oraswa.

- Machina akafanana aGranulator, Plastic Shredder, kanaJekiseni Machine Plasticinogona kushandura tsvina kuita zvigadzirwa zvinobatsira.

- Kusarudza zvakanakaPlastic Recycle Machineinochengetedza mari uye inobatsira pasi.

Key Takeaways

- Ziva mhando uye huwandu hwepurasitiki hwaunoda kudzokorodza kuti utore michina inokodzera zvaunoda uye chiyero.

- Sarudza michina inesimba rakakodzera, kushanda nesimba, uye otomatiki kuchengetedza mari uye kunatsiridza kudzokorodza mhando.

- Fungabhajeti, nzvimbo, kuchengetedza, uye mitemo yemunharaunda vasati vatenga kuti vave nechokwadi chekushanda kwakanaka uye kubudirira kwenguva refu.

Ziva Zvido Zvako Zvokutsvagisa Purasitiki

Mhando dzePlastiki Kugadzira

Yese chirongwa chekudzokorora chinotanga nekuziva kuti ndeapi mapurasitiki anoda kugadziriswa. PET neHDPE zvinoonekwa kazhinji mumabhini ekudzokorodza. Aya mapurasitiki ari nyore kudzoreredza nemaitiro emuchina. LDPE, PP, uye PS zvinoonekwawo, asi zvinounza mamwe matambudziko. Kudzokorodza kwemakemikari kuri kukura uye kunobatsira nemapurasitiki akaoma senaironi kana zvinhu zvakasvibiswa.

Zano: Magadzirirwo ekurongedza michina, kudiwa kwemusika, uye zvivakwa zvemuno zvese zvimiro izvo mapurasitiki nzvimbo inogona kubata.

Heano kukurumidza kutarisa kuti akasiyana mapurasitiki anokwana sei nezvikero zvekudzokorodza:

| Plastic Type | Diki Scale | Medium Scale | Yakakura Scale |

|---|---|---|---|

| PET | Ehe | Ehe | Ehe |

| HDPE | Ehe | Ehe | Ehe |

| LDPE | Limited | Ehe | Ehe |

| PP | Ehe | Ehe | Ehe |

| PS | No | No | Ehe |

| Mixed | No | Limited | Ehe |

Kuwanda uye Kuwanda Kwemarara ePlastiki

Huwandu hwemarara epurasitikiuye kuti inosvika kangani inoshandura zvese. Zvishandiso zvinowana nzizi dzakadzikama dzePET mabhodhoro kana HDPE jugs zvinoda michina ine yakakwira throughput. Zvitoro zvidiki zvinogona kungongoda masheredhi ekutanga uye tambo dzekuwachisa. Zvidyarwa zvakakura zvinoshandisa mitsara yekugadzira maindasitiri uye maextruder epamberi.

Ongorora: Mhando yemarara epurasitiki inotyaira sarudzo yePlastiki Recycling Machines, pamwe nenzvimbo uye simba rinodiwa.

Kusvibiswa Matanho uye Pre-Kuronga Zvinodiwa

Marara epurasitiki haawanzosvika akachena. Misanganiswa yakaoma inogona kusvika 28% isiri-plastiki zvinhu, mafirimu anosvika 49% tsvina, uye maumbirwo e3D anowanzo kusanganiswa nemafirimu.

- Magnetic separators anoburitsa simbi.

- Eddy anoparadzanisa anobata aluminium.

- Optical sorters anoshandisa lasers kuona mavara uye maumbirwo.

- Kuronga nemaoko kunobatsira nekutonga kwemhando.

- Masikirini uye emweya classifiers anoronga nehukuru uye density.

Mazuva ano pre-kuronga masisitimu anosanganisa maturusi aya kuwedzera kuchena uye kuderedza mitengo. Mitsetse yekuronga yakabatanidzwa ine masensa inobata tutsvina tudiki, zvichiita kuti kudzokorodza kuve nyore uye kuve nekuchengetedza.

Plastic Recycling Machines: Mhando uye Mabasa

Shredders uye Granulators

Shredders uyegranulatorstanga nzira yekudzokorodza. Mashredders anoputsa zvinhu zvikuru zvepurasitiki kuita zvidimbu zvidiki. Vanobata zvimedu zvakakura, zvakakora, kana zvisina kujairika zviri nyore. Kunonoka kwavo rotor kumhanya kunoreva kusapfeka uye kuderera kwesimba rekushandisa. Granulators inotora inotevera. Vanocheka purasitiki yakatsemurwa kuita maflakes akanaka, mayunifomu. Aya maflakes ari padyo nehukuru kune matsva epurasitiki pellets. Granulator inoshanda zvakanyanya neakachena, zvidimbu zvidiki uye zvinoda kudya kwakadzikama. Pamwe chete, shredders uye granulators vanogadzira maviri-nhanho sisitimu inowedzera kushanda zvakanaka uye kunaka kwechigadzirwa.

| Chimiro/Chimiro | Shredders | Granulators |

|---|---|---|

| Rotor Speed | Yakaderera (~100 rpm) | Pamusoro (~500 rpm) |

| Output Particle Size | Yakakura, yunifomu shoma | Diki, yunifomu |

| Kubata Zvinhu | Zvimedu zvakakura, zvisina kurongeka | Zvakachena, zvimedu zviduku |

| Kushandiswa Kwemagetsi | Lower | Higher |

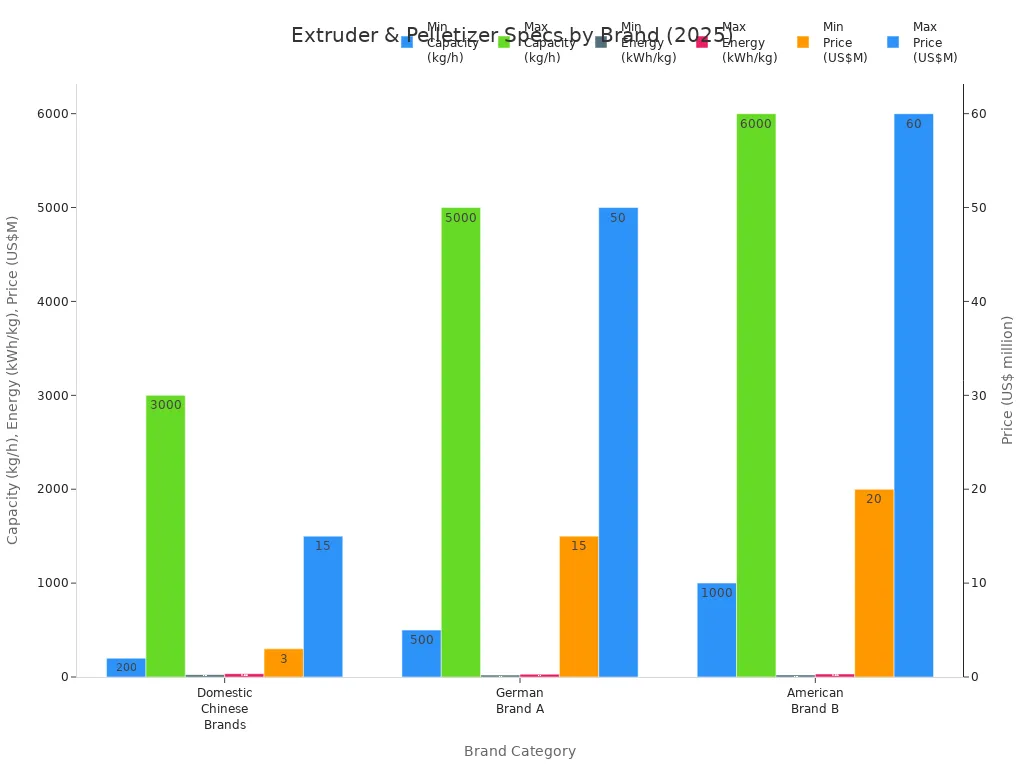

Extruders uye Pelletizers

Extruders inonyunguduka uye kusefa epurasitiki flakes. Vanobvisa tsvina nezvimwe zvinhu zvisingadiwi. Danho iri rinogadzira tambo dzakatsetseka, dzakachena dzepurasitiki. Mapelletizers anobva acheka tambo idzi kuita diki, kunyangwe pellets. Aya ma pellets anove iwo mbichana yezvigadzirwa zvitsva. Yepamberi pelletizers, semhando dzepasi pemvura, gadzira pellets ine inopenya kupera uye saizi yakakwana. Iyo yekurudyi extruder uye pelletizer inobatsira Plastic Recycling Machina kuburitsa emhando yepamusoro, anowirirana pellets.

Washing and Drying Systems

Washing and drying systems dzinochenesa purasitiki isati yanyunguduka. High-speed friction washers inokwesha tsvina, glue, uye mavara. Mawachi anopisa anoshandisa mvura inopisa kana caustic soda pakuchenesa kwakadzika. Mushure mekugeza,dryerbvisa unyoro. Maomese emazuva ano anogona kucheka mvura kusvika pazasi pe2%. Purasitiki yakachena, yakaoma inotungamirira kune mapellets ari nani uye zvishoma zvishoma. Zvishandiso zvitsva zvinoshandisa simba shoma nemvura, zvichiita kuti kudzokororwa kugare kwakasimba.

Zano: Matanho ekugezesa uye kuomeswa akakwenenzverwa anovandudza kuchena uye kunhuhwirira kwemapurasitiki akadzokororwa, ayo anobatsira kusangana akasimba emhando zviyero.

Integrated Recycling Lines

Mitsetse yakabatanidzwa yekudzokorodza inosanganisa nhanho dzese-kuchekerera, kuwacha, kuomeswa, kuburitsa, uye kupuruzira-kuita imwe yakatsetseka. Mitsetse iyi inoshandisa maconveyors uye smart control kufambisa zvinhu kubva pane imwe nhanho kuenda kune inotevera. Automation inoderedza kushanda uye inomhanyisa kugadzirwa. Chaiyo-nguva yekutarisa inoona matambudziko nekukurumidza uye inoita kuti zvese zvifambe mushe. Mitsetse yakabatanidzwa inobatsira Plastic Recycling Machines kushanda nekukurumidza, kuderedza mitengo, uye kugadzira epamusoro-mhando yepurasitiki yakadzokororwa.

Zvinokosha Zvimiro zvePlastiki Recycling Machines

Processing Capacity uye throughput

Kugadzirisa huwandu hunotaurira kuti ipurasitiki yakawanda sei muchina unogona kubata awa yega yega. Muna 2025, Michina yakawanda yePlastic Recycling inotanga pamakirogiramu mazana matatu paawa. Mamwe mamodheru emaindasitiri, seJianTai XS-400 uye XR-800, anosvika 1,500 kilogiramu paawa. Uhwu hwakakura hunobatsira mabhizinesi kutora michina inoenderana nezvavanoda. Chitoro chidiki chinogona kusarudza mhando yemhando yakaderera, nepo fekitori hombe ichida chimwe chinhu chikuru. Pakusarudza muchina, vanofanirwa kufunga nezvekuti ikawanda sei tsvina yepurasitiki inosvika zuva rega rega uye nekukurumidza kwavanoda kuigadzirisa.

Zano: Kupfuura kwepamusoro kunoreva kukurumidza kudzokorodza, asi inodawo imwe nzvimbo nesimba.

Kushanda Kwesimba uye Kushandisa Simba

Kushanda kwesimba kunokosha kune zvese zvakatipoteredza uye chikwama. Michina mitsva mizhinji inoshandisa simba shoma nekuti ine mota dziri nani uye madhizaini akangwara. Iyo S: GRAN nhevedzano kubva kuNGR inomira kunze kune yakasimba shredding uye inoshanduka kubuda, nepo ACS-H ™ pelletizers ichiunza yakakwira kuburitsa nekushomeka kwesimba rekushandisa. Mimwe michina inoshandisa AI neIoT kuronga mapurasitiki nemazvo uye kuchengetedza simba. Vamwe vane mashizha akakwenenzverwa uye masisitimu emvura akavharika anocheka marara uye kushandiswa kwemagetsi.

- Simba rekushandisa chikamu chikuru chemari yekushandisa.

- Kukwidziridza kune mamodhi anobata simba, semichina kaviri screw, inodzikisa mabhiri emagetsi.

- Variable frequency drives (VFDs) gadzirisa mota kumhanya kuti ienderane nebasa.

- Kugara kucheneswa uye kugadzirisa kunoita kuti michina ishande zvakanaka uye kuchengetedza simba.

- Kudzima michina kana isiri kushandiswa kunodzivirira kutambisa magetsi.

- Kushandisa zvinhu zvakachena kunobatsira kuti michina ishande nekukurumidza uye kushandisa simba shoma.

Automation uye Mushandisi-Anoshamwaridzana Zvidzore

Mazuvano Plastic Recycling Machines anoshandisa akangwara otomatiki kuita kuti kudzokorodza kuve nyore uye kwakachengeteka. Ivo vane programmable logic controllers (PLC) inobata maitiro munguva chaiyo. Human-Machine Interfaces (HMI) inopa touchscreens kuti ive nyore kudzora uye data kuratidza. Sensors inoteedzera tembiricha, kudzvanywa, uye kumhanya, nepo actuators inogadzirisa mareti ekudya uye kuyerera kwezvinhu.

| Automation Feature | Tsanangudzo | Mabasa Anokosha |

|---|---|---|

| Programmable Logic Controller (PLC) | Central control unit ichiita yakarongwa mirairo kubata muchina maitiro munguva chaiyo | Maitiro otomatiki, chaiyo-nguva yekutarisa, kuona kukanganisa, kuchengetedza manejimendi |

| Human-Machine Interface (HMI) | Touchscreen interface yekudyidzana kweanoshanda uye parameter kugadzirisa | Ratidza data-chaiyo-nguva, kutonga kwemanyorero, dhizaini rekuita data |

| Sensor Systems | Network yema sensors ekuyera tembiricha, kudzvanywa, kumhanya, kuswedera, nezvimwe. | Monitor maitiro akasiyana, ipa mhinduro kune yakavharwa-loop control, trigger maalarm |

| Actuators | Midziyo inoshandura masaini ekudzora kuita zviito zvemakanika | Kudzora mareti ekudyisa, extrusion kumhanya, kutonhora, gadzirisa kuyerera kwezvinhu, synchronize muchina zvikamu |

Vashandi vanobatsirwa nekutarisa-nguva chaiyo uye kuwana kure. Otomatiki yekuronga masisitimu anopatsanura mapurasitiki nemhando uye ruvara, kuderedza basa remaoko. AI-powered controls inogadzirisa marongero panhunzi, ichichengeta zvese zvichifamba zvakanaka.

Zvekuchengetedza Zvimiro uye Dziviriro Yevashandi

Kuchengetedzeka kunouya pekutanga mune chero nzvimbo yekudzokorodza. Machina anoda akasimba ekuchengetedza maficha kudzivirira vashandi kubva mukukuvadzwa. Zvipingamupinyi zvenyama zvinodzivirira vanhu kubva kune zvikamu zvine ngozi. Varindi vakavharirwa vanovhara michina kana yakavhurwa. Vanogadziriswa uye vanozvigadzirisa varindi vanokwana zvinhu zvakasiyana uye vanochengeta maoko akachengeteka.

Gara uchipfeka zvekuzvidzivirira nazvo (PPE) semagirovhosi, ngowani, magirazi ekuchengetedza, uye bhutsu dzesimbi.

- Machina anofanirwa kuve nekuchengetedza maficha ayo akaoma kubvisa kana kudzima.

- Macheki ekugadzirisa nguva dzose anoita kuti magadhi uye zvidzoro zvishande.

- Lockout-tagout maitiro anodzivirira njodzi panguva yekugadzirisa.

- Emergency stop mabhatani anofanira kunge ari nyore kusvika.

- Kudzidziswa kuchengetedza kunobatsira vashandi kunzwisisa njodzi uye kushandisa midziyo nemazvo.

- Kuongororwa kwekuchengetedzwa kwemukati kunotarisa pakuchengetedza muchina.

Maintenance uye Durability

Michina yakasimba inogara kwenguva refu uye inoda kugadziriswa zvishoma. Kugara uchigadzirisa, sekuchenesa uye kutsiva zvidimbu zvakasakara, zvinoita kuti michina ishande zvakanaka. Lubrication inodzivirira kupokana uye kukuvara. Vashandi vanofanirwa kutarisa michina kazhinji uye kugadzirisa matambudziko nekukurumidza. Kushandisa zvinhu zvemhando yepamusoro uye zvikamu zvinobatsira michina kusimuka kusvika pakushandisa zvinorema. Mimwe michina ine fungidziro yekugadzirisa zvinhu izvo zvinoyambira vashandisi chinhu chisati chapwanyika.

Cherechedza: Michina inochengetedzwa zvakanaka inoshandisa simba shoma uye inogadzira mapurasitiki akadzokororwa zviri nani.

Kugadzirisa uye Kukwidziridza Sarudzo

Plastic Recycling Machines muna 2025 inopa nzira dzakawanda dzekugadzirisa uye kusimudzira.Shredders ikozvino yava nekuronga zvine hungwaru, kuderera kwesimba rekushandisa, uye internet yekubatanidza yeremote control. Granulators anoshandisa AI-driven controls uye smart sensors, ine marotor akagadziridzwa uye mablades anogara kwenguva refu. MaCompactor anodzvanya marara, zvipe otomatiki, uye chengetedza nzvimbo. Extruders inotarisa pane eco-hushamwari dhizaini uye inobata mamwe marudzi epurasitiki.

- JianTai anoshanda nevatengi kugadzira michina yemapurasitiki akasiyana nemitemo yemuno.

- Madhizaini matsva anochengetedza simba, mhanya wakanyarara, uye kupinda munzvimbo diki.

- Makwidziridzo anosanganisira kudya otomatiki, kusanganisa kuri nani, uye hupenyu hurefu hweblade.

Zano: Sarudzo dzechivanhu dzinobatsira mabhizinesi kusangana nekuchinja kudiwa kwekudzokorora uye kuramba ari pamberi pemitemo mitsva.

Mafungiro Anoshanda eKutenga Plastic Recycling Machines

Budget uye Mutengo Wese Wevaridzi

Mutengo unokosha pakusarudza midziyo yekudzokorodza. Mimwe michina inodhura zvishoma kumberi asi inoda imwe gadziriso gare gare. Mamwe anodhura asi anogara kwenguva refu uye anoshandisa simba shoma. Vatengi vakangwara vanotarisa mutengo wakazara wevaridzi. Izvi zvinoreva kufunga nezve mutengo, gadziriso, zvidimbu, uye mabhiri emagetsi. Tafura iri nyore inogona kubatsira kuenzanisa mutengo:

| Cost Factor | Muenzaniso Mibvunzo |

|---|---|

| Purchase Price | Zviri mukati mebhajeti here? |

| Maintenance | Kangani kanoda sevhisi? |

| Kushandisa Simba | Ichakwidza mabhiri emagetsi here? |

| Spare Parts | Zvikamu zviri nyore kuwana here? |

Zano: Kushandisa zvishoma ikozvino kunogona kuchengetedza mari nekufamba kwenguva.

Nzvimbo uye Kuiswa Zvinodiwa

Muchina wega wega unoda nzvimbo yakakwana kuti ushande zvakachengeteka. Mimwe Michina Yekudzokorodza Yepurasitiki inokodzera mumashopu madiki. Zvimwe zvinoda uriri hwefekitari hombe. Vatengi vanofanira kuyera nzvimbo yavo vasati vaodha. Vanofanirawo kutarisa kana pasi ichigona kuchengeta midziyo inorema. Kuronga kwakanaka kunodzivisa kuchinja kunodhura gare gare.

Mushure-Kutengesa Tsigiro uye Sevhisi

Rutsigiro rwakavimbika runoita kuti michina irambe ichishanda. Vatengesi vakanaka vanopa kudzidziswa, kugadzirisa nekukurumidza, uye kuwana nyore kune masipiresi. Vanopindura mibvunzo uye vanobatsira kugadzirisa matambudziko. Makambani mazhinji zvino anopa rubatsiro rwepamhepo uye vhidhiyo madhairekitori.

- Kurumidza kutsigirwa kunoreva kuderera kushoma.

- Kudzidzisa kunobatsira vashandi kushandisa michina zvisina njodzi.

Kutevedza Mitemo Yemunzvimbo

Mitemo yekudzokorora inoshanduka kubva panzvimbo nenzvimbo. Vatengi vanofanira kutarisa mitemo yemunharaunda vasati vatenga. Dzimwe nzvimbo dzinoda masefa akakosha kana zvidzoreso zveruzha. Zvimwe zvinoda kuongororwa kwekuchengetedza kana kudzokorodza mishumo. Kutevedzera mitemo kunochengetedza bhizinesi kubva kumaricho.

Ongorora: Gara uchibvunza vatengesi kana michina yavo ichisangana nezvinodiwa zvemuno.

Kusarudza muchina wakakodzera kunotanga nezvinangwa zvakajeka zvekudzokorora. Vatengi vanofanirwa kufananidza zvavanoda nemaficha emuchina. Vanofanira kufunga nezvebhajeti, nzvimbo, uye rutsigiro. Kufamba kwakangwara ndiko kunyora zvibodzwa, sarudzo dzekutsvagisa, uye kutaura nevanopa. Izvi zvinovabatsira kuita sarudzo yakanaka yebhizinesi ravo.

FAQ

Ndeapi mapurasitiki anogona kushandiswa nemichina yakawanda yekudzokorodza muna 2025?

Michina yakawanda inogadzira PET, HDPE, LDPE, uye PP. Mamwe mamodheru epamusoro anobata mapurasitiki akasanganiswa kana akasvibiswa. Nguva dzose tarisa maitiro emuchina.

Kangani vashandisi vanofanirwa kuchengetedza michina yepurasitiki yekudzokorodza?

Vashandi vanofanirwa kuongorora michina svondo rega rega. Vanochenesa, vanozora mafuta, uye vanotsiva nhengo dzakasakara. Yenguva dzose macheki ekubatsira michina inogara kwenguva refu uye inoshanda zvirinani.

Michina yekudzokorodza epurasitiki inoda kudzidziswa kwakakosha kushanda?

Hongu, vashandisi vanodakudzidzisa. Vatengesi vanowanzopa mazano kana mavhidhiyo. Kudzidziswa kwakanaka kunoita kuti vashandi vachengetedzeke uye kunobatsira kuti michina ifambe zvakanaka.

Nguva yekutumira: Aug-18-2025