Plastic Recycling Machines help tackle the growing plastic waste problem. In 2025, global recycling rates remain below 10%.

- Over 430 million tonnes of virgin plastic are made each year, with most used once and thrown away.

- Machines like a Granulator, Plastic Shredder, or Injection Machine Plastic can turn waste into useful products.

- Choosing the right Plastic Recycle Machine saves money and helps the planet.

Key Takeaways

- Know the types and amounts of plastic you need to recycle to pick machines that fit your needs and scale.

- Choose machines with the right capacity, energy efficiency, and automation to save money and improve recycling quality.

- Consider budget, space, maintenance, and local rules before buying to ensure smooth operation and long-term success.

Identify Your Plastic Recycling Needs

Types of Plastics to Process

Every recycling project starts with knowing which plastics need processing. PET and HDPE show up most often in recycling bins. These plastics are easy to recycle with mechanical methods. LDPE, PP, and PS also appear, but they bring more challenges. Chemical recycling is growing and helps with tough plastics like nylon or contaminated items.

Tip: The design of sorting machines, market demand, and local infrastructure all shape which plastics a facility can handle.

Here’s a quick look at how different plastics fit with recycling scales:

| Plastic Type | Small Scale | Medium Scale | Large Scale |

|---|---|---|---|

| PET | Yes | Yes | Yes |

| HDPE | Yes | Yes | Yes |

| LDPE | Limited | Yes | Yes |

| PP | Yes | Yes | Yes |

| PS | No | No | Yes |

| Mixed | No | Limited | Yes |

Volume and Frequency of Plastic Waste

The amount of plastic waste and how often it arrives changes everything. Facilities that get steady streams of PET bottles or HDPE jugs need machines with higher throughput. Small shops might only need basic shredders and washing lines. Large plants use industrial sorting lines and advanced extruders.

Note: The type of plastic waste drives the choice of Plastic Recycling Machines, along with space and energy needs.

Contamination Levels and Pre-Sorting Requirements

Plastic waste rarely arrives clean. Rigid blends can have up to 28% non-plastic stuff, films up to 49% impurities, and 3D shapes often mix with films.

- Magnetic separators pull out steel.

- Eddy current separators grab aluminum.

- Optical sorters use lasers to spot colors and shapes.

- Manual sorting helps with quality control.

- Screens and air classifiers sort by size and density.

Modern pre-sorting systems combine these tools to boost purity and cut costs. Integrated sorting lines with sensors catch tiny contaminants, making recycling smoother and safer.

Plastic Recycling Machines: Types and Functions

Shredders and Granulators

Shredders and granulators start the recycling process. Shredders break down large plastic items into smaller pieces. They handle bulky, dense, or irregular scrap with ease. Their slow rotor speed means less wear and lower energy use. Granulators take over next. They cut the shredded plastic into fine, uniform flakes. These flakes are close in size to new plastic pellets. Granulators work best with clean, small pieces and need steady feeding. Together, shredders and granulators form a two-stage system that boosts efficiency and product quality.

| Feature/Aspect | Shredders | Granulators |

|---|---|---|

| Rotor Speed | Low (~100 rpm) | High (~500 rpm) |

| Output Particle Size | Larger, less uniform | Small, uniform |

| Material Handling | Large, irregular scrap | Clean, small pieces |

| Energy Consumption | Lower | Higher |

Extruders and Pelletizers

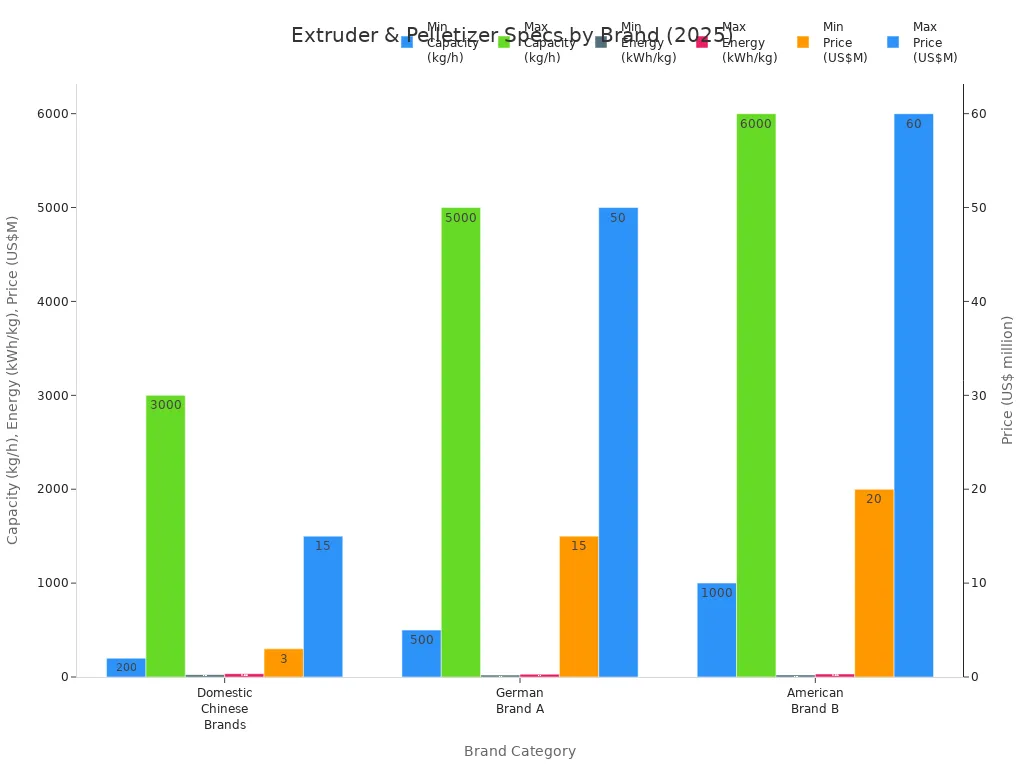

Extruders melt and filter the plastic flakes. They remove dirt and other unwanted materials. This step creates smooth, clean strands of plastic. Pelletizers then cut these strands into small, even pellets. These pellets become the raw material for new products. Advanced pelletizers, like underwater types, make pellets with a shiny finish and perfect size. The right extruder and pelletizer help Plastic Recycling Machines produce high-quality, consistent pellets.

Washing and Drying Systems

Washing and drying systems clean the plastic before melting. High-speed friction washers scrub away dirt, glue, and labels. Hot washers use heated water or caustic soda for deep cleaning. After washing, dryers remove moisture. Modern dryers can cut water content to below 2%. Clean, dry plastic leads to better pellets and fewer defects. New systems use less energy and water, making recycling more sustainable.

Tip: Tailored washing and drying steps improve the purity and smell of recycled plastics, which helps meet strict quality standards.

Integrated Recycling Lines

Integrated recycling lines combine all steps—shredding, washing, drying, extruding, and pelletizing—into one smooth process. These lines use conveyors and smart controls to move material from one stage to the next. Automation reduces labor and speeds up production. Real-time monitoring spots problems early and keeps everything running smoothly. Integrated lines help Plastic Recycling Machines work faster, cut costs, and produce higher-quality recycled plastic.

Essential Features of Plastic Recycling Machines

Processing Capacity and Throughput

Processing capacity tells how much plastic a machine can handle every hour. In 2025, most Plastic Recycling Machines start at about 300 kilograms per hour. Some industrial models, like the JianTai XS-400 and XR-800, reach up to 1,500 kilograms per hour. This wide range helps businesses pick machines that match their needs. A small shop might choose a lower-capacity model, while a large factory needs something bigger. When choosing a machine, they should think about how much plastic waste arrives each day and how quickly they want to process it.

Tip: Higher throughput means faster recycling, but it also needs more space and power.

Energy Efficiency and Power Consumption

Energy efficiency matters for both the environment and the wallet. Many new machines use less power because they have better motors and smarter designs. The S:GRAN series from NGR stands out for strong shredding and flexible output, while the ACS-H™ pelletizers deliver high output with low energy use. Some machines use AI and IoT to sort plastics more accurately and save energy. Others have optimized blades and closed-loop water systems that cut down on waste and power use.

- Power consumption is a big part of operating costs.

- Upgrading to energy-efficient models, like double screw machines, lowers energy bills.

- Variable frequency drives (VFDs) adjust motor speed to match the workload.

- Regular cleaning and maintenance keep machines running smoothly and save power.

- Turning off machines when not in use avoids wasting electricity.

- Using clean raw materials helps machines work faster and use less energy.

Automation and User-Friendly Controls

Modern Plastic Recycling Machines use smart automation to make recycling easier and safer. They have programmable logic controllers (PLC) that manage processes in real time. Human-Machine Interfaces (HMI) offer touchscreens for easy control and data display. Sensors track temperature, pressure, and speed, while actuators adjust feeding rates and material flow.

| Automation Feature | Description | Key Functions |

|---|---|---|

| Programmable Logic Controller (PLC) | Central control unit executing programmed instructions to manage machine processes in real time | Process automation, real-time monitoring, fault detection, safety management |

| Human-Machine Interface (HMI) | Touchscreen interface for operator interaction and parameter adjustments | Display real-time data, manual control, operational data logging |

| Sensor Systems | Network of sensors measuring temperature, pressure, speed, proximity, etc. | Monitor process variables, provide feedback for closed-loop control, trigger alarms |

| Actuators | Devices converting control signals into mechanical actions | Control feeding rates, extrusion speed, cooling, adjust material flow, synchronize machine parts |

Operators benefit from real-time monitoring and remote access. Automated sorting systems separate plastics by type and color, reducing manual work. AI-powered controls adjust settings on the fly, keeping everything running smoothly.

Safety Features and Worker Protection

Safety comes first in any recycling facility. Machines need strong safety features to protect workers from harm. Physical barriers keep people away from dangerous parts. Interlocked guards shut down machines if opened. Adjustable and self-adjusting guards fit different materials and keep hands safe.

Always wear personal protective equipment (PPE) like gloves, helmets, safety glasses, and steel-toed boots.

- Machines should have safety features that are hard to remove or disable.

- Regular maintenance checks keep guards and controls working.

- Lockout-tagout procedures prevent accidents during repairs.

- Emergency stop buttons must be easy to reach.

- Safety training helps workers understand risks and use equipment correctly.

- Internal safety inspections focus on machine safeguards.

Maintenance and Durability

Durable machines last longer and need fewer repairs. Regular maintenance, like cleaning and replacing worn parts, keeps machines running well. Lubrication prevents friction and damage. Operators should check machines often and fix problems early. Using high-quality materials and parts helps machines stand up to heavy use. Some machines have predictive maintenance features that warn operators before something breaks.

Note: Well-maintained machines use less energy and produce better recycled plastic.

Customization and Upgrade Options

Plastic Recycling Machines in 2025 offer many ways to customize and upgrade. Shredders now have smarter sorting, lower energy use, and internet connectivity for remote control. Granulators use AI-driven controls and smart sensors, with improved rotors and longer-lasting blades. Compactors press waste tighter, feed automatically, and save space. Extruders focus on eco-friendly designs and handle more types of plastic.

- JianTai works with customers to tailor machines for different plastics and local rules.

- New designs save energy, run quieter, and fit into small spaces.

- Upgrades include automated feeding, better mixing, and longer blade life.

Tip: Custom options help businesses meet changing recycling needs and stay ahead of new regulations.

Practical Considerations for Buying Plastic Recycling Machines

Budget and Total Cost of Ownership

Price matters when choosing recycling equipment. Some machines cost less upfront but need more repairs later. Others cost more but last longer and use less energy. Smart buyers look at the total cost of ownership. This means thinking about the price, maintenance, spare parts, and energy bills. A simple table can help compare costs:

| Cost Factor | Example Questions |

|---|---|

| Purchase Price | Is it within the budget? |

| Maintenance | How often does it need service? |

| Energy Use | Will it raise power bills? |

| Spare Parts | Are parts easy to find? |

Tip: Spending a bit more now can save money over time.

Space and Installation Requirements

Every machine needs enough room to work safely. Some Plastic Recycling Machines fit in small workshops. Others need big factory floors. Buyers should measure their space before ordering. They should also check if the floor can hold heavy equipment. Good planning avoids costly changes later.

After-Sales Support and Service

Reliable support keeps machines running. Good suppliers offer training, fast repairs, and easy access to spare parts. They answer questions and help solve problems. Many companies now provide online help and video guides.

- Quick support means less downtime.

- Training helps workers use machines safely.

Compliance with Local Regulations

Rules for recycling change from place to place. Buyers must check local laws before buying. Some areas need special filters or noise controls. Others require safety checks or recycling reports. Following the rules keeps the business safe from fines.

Note: Always ask suppliers if their machines meet local standards.

Choosing the right machine starts with clear recycling goals. Buyers should match their needs to machine features. They need to think about budget, space, and support. A smart move is to list goals, research options, and talk with suppliers. This helps them make the best choice for their business.

FAQ

What plastics can most recycling machines handle in 2025?

Most machines process PET, HDPE, LDPE, and PP. Some advanced models handle mixed or contaminated plastics. Always check the machine specs.

How often should operators maintain plastic recycling machines?

Operators should inspect machines weekly. They clean, lubricate, and replace worn parts. Regular checks help machines last longer and work better.

Do plastic recycling machines need special training to operate?

Yes, operators need training. Suppliers often provide guides or videos. Good training keeps workers safe and helps machines run smoothly.

Post time: Aug-18-2025