Yas Recycling Tshuabpab daws cov teeb meem pov tseg yas loj zuj zus. Nyob rau hauv 2025, lub ntiaj teb no recycling tus nqi tseem qis dua 10%.

- Ntau tshaj 430 lab tonnes ntawm nkauj xwb yas yog tsim txhua xyoo, nrog rau feem ntau siv ib zaug thiab pov tseg.

- Machines zoo li aGranulator, Yas Shredder, los yogTxhaj Tshuab Yastuaj yeem hloov pov tseg rau hauv cov khoom siv tau zoo.

- Xaiv txoj caiYas Recycle Tshuabtxuag nyiaj thiab pab lub ntiaj teb.

Ntsiab Cai

- Paub hom thiab ntau npaum li cas ntawm cov yas uas koj yuav tsum tau rov ua dua los xaiv cov tshuab uas haum koj cov kev xav tau thiab ntsuas.

- Xaiv cov tshuab nrog covtxoj cai muaj peev xwm, zog efficiency, thiab automation kom txuag tau nyiaj thiab txhim kho kev rov ua dua tshiab.

- Xav txogpob nyiaj siv, chaw, tu, thiab cov kev cai hauv zos ua ntej yuav khoom kom ntseeg tau tias kev ua haujlwm zoo thiab ua tiav mus ntev.

Txheeb xyuas koj cov kev xav tau ntawm cov khoom siv yas

Hom Plastics rau txheej txheem

Txhua qhov kev rov ua dua tshiab pib nrog kev paub txog cov yas twg yuav tsum tau ua. PET thiab HDPE feem ntau tshwm sim hauv cov khoom siv rov ua dua tshiab. Cov yas no yooj yim rau rov siv dua nrog cov txheej txheem siv tshuab. LDPE, PP, thiab PS kuj tshwm sim, tab sis lawv coj cov teeb meem ntau dua. Kev siv tshuaj rov ua dua tshiab tau loj hlob thiab pab nrog cov yas tawv zoo li nylon lossis cov khoom tsis huv.

Tswv yim: Tus tsim ntawmsorting tshuab, kev xav tau ntawm kev lag luam, thiab kev tsim kho vaj tse hauv zos tag nrho cov duab uas cov khoom siv yas tuaj yeem ua tau.

Ntawm no yog saib sai npaum li cas cov yas sib txawv haum nrog cov khoom siv rov ua dua:

| Hom yas | Qhov Me Me | Nruab nrab Scale | Loj Loj |

|---|---|---|---|

| PET | Yog lawm | Yog lawm | Yog lawm |

| HDPE | Yog lawm | Yog lawm | Yog lawm |

| LDPE | Txwv tsis pub | Yog lawm | Yog lawm |

| PP | Yog lawm | Yog lawm | Yog lawm |

| PS | No | No | Yog lawm |

| Mixed | No | Txwv tsis pub | Yog lawm |

Ntim thiab zaus ntawm cov khib nyiab yas

Tus nqi ntawmpov tseg yasthiab ntau npaum li cas nws tuaj txog hloov txhua yam. Cov chaw uas tau txais cov dej ntws tsis tu ncua ntawm PET lub raj mis lossis HDPE jugs xav tau cov tshuab nrog ntau dua. Cov khw me yuav tsuas xav tau cov shredders thiab cov kab ntxuav. Cov nroj tsuag loj siv cov kab kev lag luam thiab cov extruders siab heev.

Lus Cim: Hom yas pov tseg tsav cov kev xaiv ntawm Cov Khoom Siv Yas Recycling, nrog rau qhov chaw thiab lub zog xav tau.

Cov qib sib kis thiab cov kev xav tau ua ntej-Sorting

Cov khib nyiab yas tsis tshua tuaj txog huv. Rigid blends tuaj yeem muaj txog 28% cov khoom tsis yog yas, cov yeeb yaj kiab txog li 49% impurities, thiab cov duab 3D feem ntau sib xyaw nrog cov yeeb yaj kiab.

- Sib nqus separators rub tawm hlau.

- Eddy tam sim no separators tuav aluminium.

- Optical sorters siv lasers los pom cov xim thiab cov duab.

- Kev txheeb xyuas phau ntawv pab nrog kev tswj kom zoo.

- Cov ntxaij vab tshaus thiab huab cua classifiers txheeb raws qhov loj thiab qhov ntom.

Niaj hnub nimno pre-sorting systems muab cov cuab yeej no los txhawb purity thiab txiav nqi. Integrated sorting kab nrog sensors ntes cov kab mob me me, ua kom rov ua dua kom zoo dua thiab nyab xeeb dua.

Plastic Recycling Machines: Hom thiab Kev Ua Haujlwm

Granulators thiab Shredders

Shredders thiabgranulatorspib cov txheej txheem rov ua dua. Shredders zom cov khoom yas loj rau hauv cov khoom me me. Lawv tuav cov khoom loj, ntom, lossis tsis sib xws nrog yooj yim. Lawv cov rotor qeeb qeeb txhais tau hais tias hnav tsawg dua thiab siv zog qis dua. Granulators coj mus tom ntej. Lawv txiav cov yas shredded mus rau hauv zoo, uniform flakes. Cov flakes no nyob ze rau qhov loj ntawm cov yas pellets tshiab. Granulators ua haujlwm zoo tshaj plaws nrog cov khoom huv si, me me thiab xav tau kev pub noj tsis tu ncua. Ua ke, shredders thiab granulators tsim ib tug ob-theem system uas boosts efficiency thiab cov khoom zoo.

| Feature/Aspect | Shredders | Granulators |

|---|---|---|

| Rotor Ceev | Tsawg (~ 100 rpm) | Siab (~ 500 rpm) |

| Tso zis Particle Loj | Loj dua, tsis sib xws | Me me, uniform |

| Khoom siv | Loj, irregular seem | Ntxuav, me me |

| Kev siv hluav taws xob | qis | Siab dua |

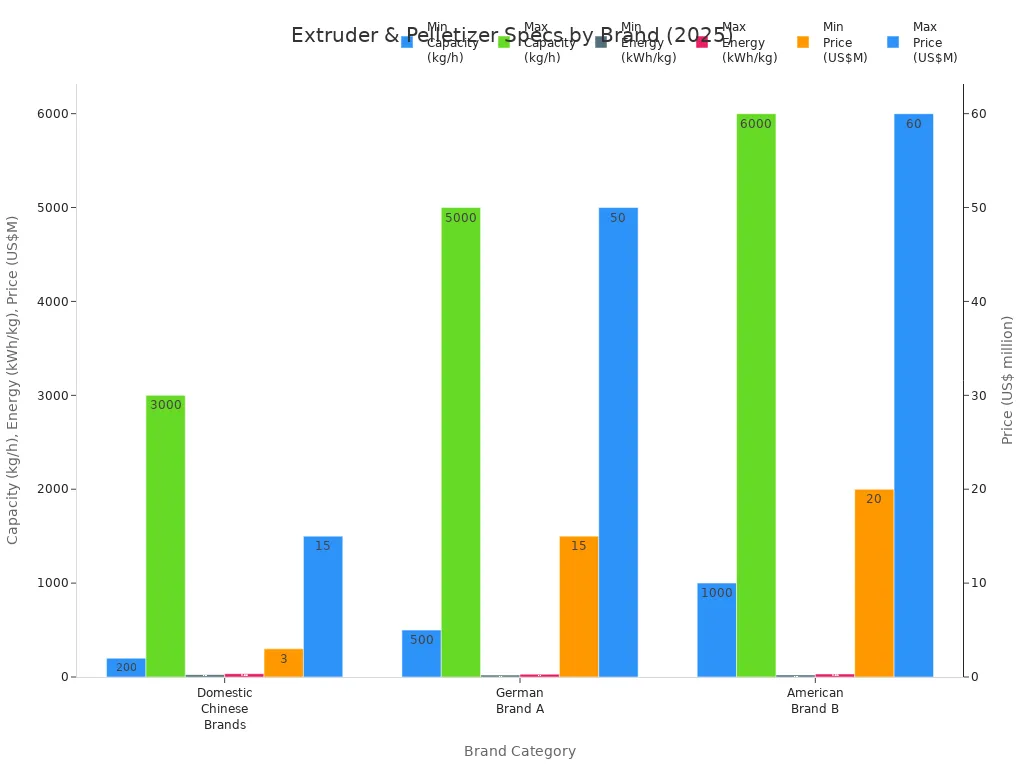

Extruders thiab Pelletizers

Extruders yaj thiab lim cov yas flakes. Lawv tshem tawm cov av thiab lwm yam khoom tsis zoo. Cov kauj ruam no tsim kom du, huv si strands ntawm yas. Pelletizers ces txiav cov strands rau hauv me me, txawm tias pellets. Cov pellets no dhau los ua cov khoom siv raw rau cov khoom tshiab. Advanced pelletizers, zoo li hom underwater, ua pellets nrog lub ci tiav thiab zoo meej loj. Txoj cai extruder thiab pelletizer pab Plastic Recycling Machines tsim cov khoom zoo, zoo ib yam pellets.

Ntxuav thiab ziab Systems

Ntxuav thiab ziab tshuab ntxuav cov yas ua ntej melting. Kev sib txhuam ceev nrawm nrawm tshem tawm cov av, kua nplaum, thiab cov ntawv lo. Cov ntxhua khaub ncaws kub siv cov dej kub los yog cov dej qab zib caustic rau kev ntxuav tob. Tom qab ntxuav,tshuab ziab khaub ncawstshem tawm cov dej noo. Cov tshuab ziab khaub ncaws niaj hnub tuaj yeem txiav cov dej kom qis dua 2%. Cov yas huv, qhuav ua rau cov pellets zoo dua thiab muaj qhov tsis xws luag. Cov tshuab tshiab siv tsawg zog thiab dej, ua kom rov ua dua tshiab dua.

Tswv yim: Cov txheej txheem ntxuav thiab ziab kom qhuav kom huv si thiab tsis hnov tsw ntawm cov yas siv dua tshiab, uas pab ua tau raws li cov qauv nruj.

Integrated Recycling Lines

Integrated recycling kab ua ke tag nrho cov kauj ruam-shredding, ntxuav, ziab, extruding, thiab pelletizing-rau hauv ib tug du txheej txheem. Cov kab no siv conveyors thiab ntse tswj kom txav cov khoom ntawm ib theem mus rau lwm qhov. Automation txo kev ua haujlwm thiab ua kom ntau lawm. Kev saib xyuas lub sijhawm tiag tiag pom cov teeb meem ntxov thiab ua kom txhua yam ua haujlwm zoo. Cov kab sib xyaw ua ke pab Plastic Recycling Machines ua haujlwm sai dua, txiav cov nqi, thiab tsim cov yas zoo dua qub.

Cov yam ntxwv tseem ceeb ntawm cov tshuab siv yas rov siv dua

Processing Peev Xwm thiab Tshaj Tawm

Lub peev xwm ua tau qhia ntau npaum li cas lub tshuab tuaj yeem ua haujlwm txhua teev. Xyoo 2025, feem ntau cov tshuab siv yas rov siv dua pib ntawm li 300 kilograms ib teev. Qee cov qauv kev lag luam, zoo li JianTai XS-400 thiab XR-800, ncav cuag li 1,500 kilograms ib teev. Qhov ntau yam no pab cov lag luam xaiv cov tshuab uas phim lawv cov kev xav tau. Lub khw me yuav xaiv tus qauv qis dua, thaum lub Hoobkas loj xav tau qee yam loj dua. Thaum xaiv lub tshuab, lawv yuav tsum xav txog ntau npaum li cas cov khib nyiab yas tuaj txog txhua hnub thiab lawv xav ua nws sai npaum li cas.

Tswv yim: Kev siv ntau dua txhais tau tias rov ua dua sai dua, tab sis nws kuj xav tau ntau qhov chaw thiab lub zog.

Kev Siv Hluav Taws Xob thiab Kev Siv Hluav Taws Xob

Lub zog efficiency tseem ceeb rau ob qho tib si ib puag ncig thiab lub hnab nyiaj. Ntau lub tshuab tshiab siv lub zog tsawg dua vim tias lawv muaj lub cev muaj zog zoo dua thiab tsim qauv ntse dua. S: GRAN series los ntawm NGR sawv tawm rau qhov muaj zog shredding thiab hloov tau cov zis, thaum ACS-H ™ pelletizers xa tawm siab nrog kev siv hluav taws xob tsawg. Qee lub tshuab siv AI thiab IoT los txheeb cov yas kom raug thiab txuag hluav taws xob. Lwm tus tau ua kom zoo dua cov hniav thiab kaw lub voj kaw dej uas txo cov khib nyiab thiab siv hluav taws xob.

- Kev siv hluav taws xob yog ib feem loj ntawm cov nqi khiav haujlwm.

- Kev kho dua tshiab rau cov qauv siv hluav taws xob, zoo li ob lub tshuab ntsia hlau, txo cov nqi hluav taws xob.

- Variable zaus drives (VFDs) kho lub cev muaj zog kom haum rau kev ua haujlwm.

- Kev tu thiab tu tsis tu ncua ua kom cov tshuab ua haujlwm zoo thiab txuag hluav taws xob.

- Kev tua cov tshuab thaum tsis siv yuav tsum tsis txhob siv hluav taws xob.

- Siv cov ntaub ntawv huv huv pab cov tshuab ua haujlwm sai dua thiab siv zog tsawg.

Automation thiab User-Friendly Controls

Niaj hnub nimno Plastic Recycling Machines siv ntse automation kom rov ua dua yooj yim dua thiab nyab xeeb dua. Lawv muaj programmable logic controllers (PLC) uas tswj cov txheej txheem hauv lub sijhawm. Human-Machine Interfaces (HMI) muab touchscreens rau kev tswj tau yooj yim thiab cov ntaub ntawv tso saib. Sensors taug qab qhov kub thiab txias, siab, thiab ceev, thaum cov actuators kho tus nqi noj thiab cov khoom ntws.

| Automation Feature | Kev piav qhia | Ntsiab Function |

|---|---|---|

| Programmable Logic Controller (PLC) | Lub chaw tswj hwm hauv nruab nrab ua raws li cov lus qhia programmed los tswj cov txheej txheem tshuab hauv lub sijhawm | Cov txheej txheem automation, saib xyuas lub sijhawm tiag tiag, kuaj pom qhov tsis raug, tswj kev nyab xeeb |

| Human-Machine Interface (HMI) | Touchscreen interface rau tus neeg teb xov tooj sib cuam tshuam thiab kev hloov pauv parameter | Tso tawm cov ntaub ntawv hauv lub sijhawm, kev tswj xyuas phau ntawv, kev ua haujlwm cov ntaub ntawv nkag |

| Sensor Systems | Network ntawm sensors ntsuas kub, siab, ceev, sib thooj, thiab lwm yam. | Saib xyuas cov txheej txheem sib txawv, muab kev tawm tswv yim rau kev tswj lub voj kaw, ua rau lub tswb |

| Cov actuators | Devices converting control signals mus rau mechanical actions | Tswj tus nqi pub mis, extrusion ceev, txias, kho cov khoom ntws, synchronize tshuab qhov chaw |

Cov neeg ua haujlwm tau txais txiaj ntsig los ntawm kev saib xyuas lub sijhawm thiab kev nkag mus rau thaj chaw deb. Automated sorting systems cais cov yas los ntawm hom thiab xim, txo cov haujlwm ntawm phau ntawv. AI-powered tswj tau kho qhov chaw ntawm yoov, ua kom txhua yam khiav zoo.

Cov yam ntxwv kev nyab xeeb thiab kev tiv thaiv neeg ua haujlwm

Kev nyab xeeb yog thawj zaug hauv txhua qhov chaw rov ua dua tshiab. Cov tshuab xav tau kev nyab xeeb muaj zog los tiv thaiv cov neeg ua haujlwm los ntawm kev puas tsuaj. Lub cev tiv thaiv kom tib neeg nyob deb ntawm qhov chaw txaus ntshai. Interlocked guards kaw tshuab yog qhib. Adjustable thiab kho tus kheej tiv thaiv haum cov ntaub ntawv sib txawv thiab tuav tes kom zoo.

Ib txwm hnav cov khoom tiv thaiv tus kheej (PPE) xws li hnab looj tes, kaus mom hlau, tsom iav kev nyab xeeb, thiab khau khiab hlau.

- Cov cav tov yuav tsum muaj cov yam ntxwv kev nyab xeeb uas nyuaj rau tshem tawm lossis lov tes taw.

- Kev saib xyuas tsis tu ncua ua kom cov neeg tiv thaiv thiab tswj ua haujlwm.

- Cov txheej txheem kaw-tagout tiv thaiv kev sib tsoo thaum kho.

- Cov khawm nres thaum muaj xwm ceev yuav tsum yooj yim mus cuag.

- Kev cob qhia kev nyab xeeb pab cov neeg ua haujlwm nkag siab txog kev pheej hmoo thiab siv cov cuab yeej raug cai.

- Kev soj ntsuam kev nyab xeeb sab hauv tsom rau kev tiv thaiv lub tshuab.

Kev tu thiab kav ntev

Cov tshuab siv tau ntev ntev thiab xav tau kev kho tsawg dua. Kev saib xyuas tsis tu ncua, zoo li ntxuav thiab hloov cov khoom hnav, ua kom cov tshuab ua haujlwm zoo. Lubrication tiv thaiv kev sib txhuam thiab kev puas tsuaj. Cov neeg ua haujlwm yuav tsum xyuas cov tshuab ntau zaus thiab kho cov teeb meem ntxov. Siv cov ntaub ntawv zoo thiab qhov chaw pab cov cav tov sawv ntsug rau kev siv hnyav. Qee lub tshuab muaj cov yam ntxwv kev saib xyuas uas ceeb toom cov neeg ua haujlwm ua ntej qee yam tawg.

Lus Cim: Cov tshuab ua kom zoo siv lub zog tsawg thiab tsim cov yas zoo dua qub.

Customization thiab Upgrade Options

Plastic Recycling Machines hauv 2025 muaj ntau txoj hauv kev los kho thiab hloov kho.Shredders tam sim no muaj smarter sorting, kev siv hluav taws xob qis dua, thiab kev sib txuas hauv internet rau cov chaw taws teeb tswj. Granulators siv AI-tsav tswj thiab ntse sensors, nrog kev txhim kho rotors thiab cov hniav siv tau ntev. Compactors nias pov tseg nruj dua, pub tau txais, thiab txuag chaw. Extruders tsom mus rau eco-friendly designs thiab lis ntau hom yas.

- JianTai ua haujlwm nrog cov neeg siv khoom los txiav cov tshuab rau cov yas sib txawv thiab cov cai hauv zos.

- Cov qauv tsim tshiab txuag lub zog, khiav ntsiag to, thiab haum rau qhov chaw me me.

- Kev kho dua tshiab suav nrog kev pub mis tsis siv neeg, sib xyaw kom zoo dua, thiab lub neej ntev dua.

Tswv yim: Cov kev xaiv kev cai pab cov lag luam ua tau raws li kev hloov pauv cov kev xav tau thiab nyob ua ntej ntawm cov kev cai tshiab.

Cov tswv yim xav txog kev yuav cov khoom siv yas rov ua dua tshiab

Nyiaj txiag thiab tag nrho cov nqi ntawm cov tswv cuab

Nqe tseem ceeb thaum xaiv cov khoom siv rov ua dua tshiab. Qee lub tshuab raug nqi qis dua ua ntej tab sis xav tau kev kho dua tom qab. Lwm tus raug nqi ntau dua tab sis kav ntev dua thiab siv zog tsawg dua. Cov neeg yuav khoom ntse saib tag nrho cov nqi ntawm cov tswv cuab. Qhov no txhais tau hais tias xav txog tus nqi, kev saib xyuas, cov khoom seem, thiab cov nqi hluav taws xob. Ib lub rooj yooj yim tuaj yeem pab sib piv cov nqi:

| Nqi Factor | Piv txwv cov lus nug |

|---|---|

| Tus nqi yuav khoom | Puas yog nyob rau hauv pob nyiaj siv? |

| Kev tu | Nws xav tau kev pab ntau npaum li cas? |

| Kev siv zog | Nws puas yuav nce nqi hluav taws xob? |

| Khoom seem | Cov khoom puas yooj yim nrhiav tau? |

Tswv yim: Siv me ntsis ntxiv tam sim no tuaj yeem txuag nyiaj dhau sijhawm.

Qhov yuav tsum tau muaj thiab installation

Txhua lub tshuab xav tau chav txaus los ua haujlwm nyab xeeb. Qee lub tshuab siv yas rov siv dua tau haum rau hauv kev cob qhia me me. Lwm tus xav tau lub Hoobkas loj hauv pem teb. Cov neeg yuav khoom yuav tsum ntsuas lawv qhov chaw ua ntej xaj. Lawv kuj yuav tsum xyuas seb lub hauv pem teb puas tuaj yeem tuav cov khoom hnyav. Kev npaj zoo zam tsis txhob raug nqi hloov tom qab.

Kev pab cuam tom qab muag thiab kev pabcuam

Txhim khu kev txhawb nqa kom cov tshuab ua haujlwm. Cov neeg muag khoom zoo muab kev cob qhia, kev kho sai, thiab yooj yim rau cov khoom seem. Lawv teb cov lus nug thiab pab daws teeb meem. Ntau lub tuam txhab tam sim no muab kev pab online thiab cov lus qhia video.

- Kev them nyiaj yug ceev txhais tau tias tsawg dua downtime.

- Kev cob qhia pab cov neeg ua haujlwm siv tshuab kom nyab xeeb.

Ua raws li Cov Cai Hauv Zos

Cov cai rau kev rov ua dua tshiab hloov ntawm qhov chaw mus rau qhov chaw. Cov neeg yuav khoom yuav tsum xyuas cov cai hauv zos ua ntej yuav. Qee qhov chaw xav tau cov ntxaij lim dej tshwj xeeb lossis kev tswj suab nrov. Lwm tus xav tau kev kuaj xyuas kev nyab xeeb lossis cov ntaub ntawv rov ua dua tshiab. Ua raws li cov cai ua kom lub lag luam muaj kev nyab xeeb ntawm kev nplua.

Nco ntsoov: Ib txwm nug cov neeg muag khoom yog tias lawv lub tshuab ua tau raws li cov qauv hauv zos.

Xaiv lub tshuab zoo pib nrog cov hom phiaj kom rov ua dua tshiab. Cov neeg yuav khoom yuav tsum phim lawv cov kev xav tau ntawm lub tshuab nta. Lawv yuav tsum xav txog nyiaj txiag, qhov chaw, thiab kev txhawb nqa. Txoj kev ntse yog sau cov hom phiaj, kev xaiv tshawb fawb, thiab tham nrog cov neeg muag khoom. Qhov no pab lawv xaiv qhov zoo tshaj plaws rau lawv txoj kev lag luam.

FAQ

Dab tsi plastics tuaj yeem siv lub tshuab ua dua tshiab hauv xyoo 2025?

Cov tshuab feem ntau cov txheej txheem PET, HDPE, LDPE, thiab PP. Qee cov qauv ua ntej siv cov khoom sib xyaw lossis cov khoom tsis huv. Nco ntsoov xyuas lub tshuab specs.

Ntau npaum li cas cov neeg ua haujlwm yuav tsum tuav cov tshuab siv yas rov ua dua tshiab?

Cov neeg ua haujlwm yuav tsum tshuaj xyuas cov tshuab txhua lub lim tiam. Lawv ntxuav, lubricate, thiab hloov cov khoom hnav. Kev kuaj xyuas tsis tu ncua pab cov tshuab ua haujlwm ntev dua thiab ua haujlwm zoo dua.

Cov tshuab siv yas puas yuav tsum tau muaj kev cob qhia tshwj xeeb los ua haujlwm?

Yog, cov neeg ua haujlwm xav taukev cob qhia. Cov neeg muag khoom feem ntau muab cov lus qhia lossis cov yeeb yaj kiab. Kev cob qhia zoo ua rau cov neeg ua haujlwm nyab xeeb thiab pab cov tshuab ua haujlwm zoo.

Post lub sij hawm: Aug-18-2025