Imishini Yokwenza kabusha Ipulasitikiukusiza ukubhekana nenkinga yemfucuza yepulasitiki ekhulayo. Ngo-2025, amazinga omhlaba okusebenzisa kabusha ahlala engaphansi kuka-10%.

- Angaphezu kwezigidi ezingama-430 amathani epulasitiki angasetshenziswa minyaka yonke, kanti iningi lawo lisetshenziswa kanye bese lilahlwa.

- Imishini efana ne-aI-Granulator, I-Plastic Shredder, nomaIpulasitiki Yomshini Wokujovaingaguqula imfucuza ibe yimikhiqizo ewusizo.

- Ukukhetha okulungileUmshini Wokwenza kabusha Wepulasitikiyonga imali futhi isiza iplanethi.

Okuthathwayo Okubalulekile

- Yazi izinhlobo namanani epulasitiki okudingeka uwasebenzise kabusha ukuze ukhethe imishini ehambisana nezidingo zakho nesikali.

- Khetha imishini ngeumthamo ofanele, ukusebenza kahle kwamandla, kanye ne-automation ukonga imali nokuthuthukisa ikhwalithi yokugaywa kabusha.

- Cabangaisabelomali, indawo, ukugcinwa, kanye nemithetho yendawo ngaphambi kokuthenga ukuze kuqinisekiswe ukusebenza kahle nempumelelo yesikhathi eside.

Thola Izidingo Zakho Zokugaywa kabusha kwePlastiki

Izinhlobo zePlastiki ezizocutshungulwa

Yonke iphrojekthi yokuvuselela iqala ngokwazi ukuthi yimaphi amapulasitiki adinga ukucutshungulwa. I-PET ne-HDPE zivela kaningi emigqonyeni yokugaya kabusha. Lawa mapulasitiki kulula ukuwasebenzisa kabusha ngezindlela zemishini. I-LDPE, PP, ne-PS nazo ziyavela, kodwa ziletha izinselele eziningi. Ukugaywa kabusha kwamakhemikhali kuyakhula futhi kusiza ngamapulasitiki aqinile njengenayiloni noma izinto ezingcolile.

Ithiphu: Idizayini yeimishini yokuhlunga, isidingo semakethe, nengqalasizinda yasendaweni konke okungamapulasitiki isikhungo esingasingathwa.

Nakhu ukubuka okusheshayo kokuthi amapulasitiki ahlukene alingana kanjani nezikali zokugaywa kabusha:

| Uhlobo Lwepulasitiki | Isikali Esincane | Isikali Esimaphakathi | Isikali Esikhulu |

|---|---|---|---|

| I-PET | Yebo | Yebo | Yebo |

| I-HDPE | Yebo | Yebo | Yebo |

| I-LDPE | Inomkhawulo | Yebo | Yebo |

| PP | Yebo | Yebo | Yebo |

| PS | No | No | Yebo |

| Kuxutshiwe | No | Inomkhawulo | Yebo |

Ivolumu kanye Nemvamisa Yemfucuza Yepulasitiki

Inani leimfucumfucu yepulasitikinokuthi ifika kaningi kangakanani ishintsha yonke into. Izinsiza ezithola ukugeleza okuqhubekayo kwamabhodlela e-PET noma izimbiza ze-HDPE zidinga imishini enomthamo ophezulu. Izitolo ezincane zingadinga kuphela ama-shredders ayisisekelo nezintambo zokuwasha. Izitshalo ezinkulu zisebenzisa imigqa yokuhlunga yezimboni kanye nama-extruder athuthukile.

Qaphela: Uhlobo lwemfucuza yepulasitiki ishayela ukukhetha kweMishini Yokugaywa Kabusha Kwepulasitiki, kanye nezidingo zesikhala namandla.

Amazinga Okungcola kanye Nezimfuneko Zokuhlunga Ngaphambili

Imfucumfucu yepulasitiki ayivamile ukufika ihlanzekile. Imixube eqinile ingaba nezinto ezingafika ku-28% okungezona ezepulasitiki, amafilimu afinyelela ku-49% wokungcola, futhi umumo we-3D uvame ukuxubana namafilimu.

- Izihlukanisi kazibuthe zikhipha insimbi.

- Izihlukanisi zamanje ze-Eddy zithatha i-aluminium.

- Izihlungi zamehlo zisebenzisa amalaser ukubona imibala nokuma.

- Ukuhlunga mathupha kusiza ngokulawula ikhwalithi.

- Izikrini nezigaba zomoya zihlunga ngosayizi nokuminyana.

Izinhlelo zesimanje zokuhlunga ngaphambilini zihlanganisa la mathuluzi ukuze kukhuliswe ubumsulwa nokunciphisa izindleko. Imigqa yokuhlela ehlanganisiwe enezinzwa ibamba ukungcola okuncane, okwenza ukugaywa kabusha kube bushelelezi futhi kuphephe kakhudlwana.

Imishini Yokugaywa Kabusha Kwepulasitiki: Izinhlobo Nemisebenzi

Ama-shredders nama-Granulators

Shredders kanyeama-granulatorsqala inqubo yokugaywa kabusha. Ama-shredders aphula izinto ezinkulu zepulasitiki zibe izingcezu ezincane. Baphatha izinsalela ezinkulu, eziminyene, noma ezingajwayelekile kalula. Isivinini sabo se-rotor esinensayo sisho ukuguga okuncane nokusebenzisa amandla aphansi. Ama-Granulator athatha ngokulandelayo. Basika ipulasitiki ecwiywe yaba ama-flakes amahle, afanayo. Lawa ma-flakes asondele ngosayizi kuma-pellets amasha epulasitiki. Ama-granulator asebenza kahle kakhulu ngezingcezu ezihlanzekile, ezincane futhi adinga ukuphakelwa njalo. Ngokuhlangene, ama-shredders nama-granulator akha uhlelo olunezigaba ezimbili oluthuthukisa ukusebenza kahle nekhwalithi yomkhiqizo.

| Isici/Isici | Ama-Shredders | Ama-Granulators |

|---|---|---|

| Isivinini se-Rotor | Phansi (~100 rpm) | Phezulu (~500 rpm) |

| Usayizi Wezinhlayiyana Okukhiphayo | Enkulu, iyunifomu encane | Encane, iyunifomu |

| Ukuphatha Izinto | Okukhulu, okungajwayelekile | Hlanza, izingcezu ezincane |

| Ukusetshenziswa kwamandla | Phansi | Phezulu |

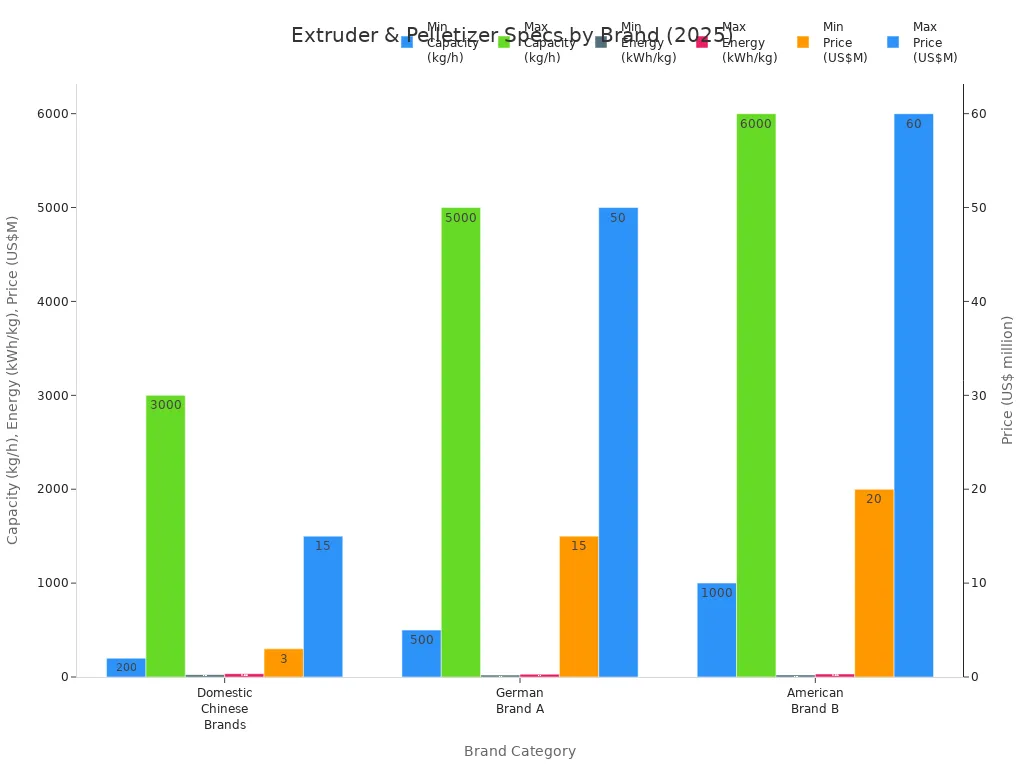

Extruders kanye Pelletizers

Ama-extruders ayancibilika futhi ahlunge ama-flakes epulasitiki. Basusa ukungcola nezinye izinto ezingafuneki. Lesi sinyathelo sidala imicu yepulasitiki ebushelelezi, ehlanzekile. Ama-pelletizer abe esesika le micu ibe mincane, ngisho nama-pellets. Lawa ma-pellets aba izinto ezingavuthiwe zemikhiqizo emisha. Ama-pellets athuthukisiwe, njengezinhlobo ezingaphansi kwamanzi, enza ama-pellets anesiphetho esicwebezelayo nosayizi ophelele. I-extruder elungile ne-pelletizer isiza Imishini Yokugaywa Kabusha Kwepulasitiki ikhiqize amapellets ekhwalithi ephezulu, angashintshi.

Amasistimu wokuwasha nokomisa

Izinhlelo zokuwasha nezomisa zihlanza ipulasitiki ngaphambi kokuncibilika. Amawasha anesivinini esikhulu akhuhla ukungcola, iglue, namalebula. Amawasha ashisayo asebenzisa amanzi ashisayo noma i-caustic soda ekuhlanzeni okujulile. Ngemva kokugeza,okomisisusa umswakama. Imishini yokomisa yesimanje inganciphisa okuqukethwe kwamanzi kube ngaphansi kuka-2%. Ipulasitiki ehlanzekile, eyomile iholela kuma-pellets angcono kanye nokukhubazeka okumbalwa. Amasistimu amasha asebenzisa amandla amancane namanzi, okwenza ukugaywa kabusha kugcineke.

Ithiphu: Izinyathelo zokuwasha nezomisa ezenziwe ngendlela efanele zithuthukisa ubumsulwa nephunga lamapulasitiki agaywe kabusha, okusiza ukuhlangabezana nezindinganiso eziqinile zekhwalithi.

Imigqa Ehlanganisiwe Yokugaywa kabusha

Imigqa yokugaywa kabusha ehlanganisiwe ihlanganisa zonke izinyathelo—ukusika, ukuwasha, ukomiswa, ukukhipha, nokugaywa kwe-pelletizing—kube inqubo eyodwa ebushelelezi. Le migqa isebenzisa amaconveyor kanye nezilawuli ezihlakaniphile ukuhambisa impahla isuka kwesinye isigaba iye kwesinye. I-automation inciphisa umsebenzi futhi isheshise ukukhiqiza. Ukuqapha kwesikhathi sangempela kubeka izinkinga kusenesikhathi futhi kugcina yonke into isebenza kahle. Imigqa ehlanganisiwe isiza Imishini Yokugaywa Kabusha Kwepulasitiki ukuthi isebenze ngokushesha, yehlise izindleko, futhi ikhiqize upulasitiki ogaywe kabusha wekhwalithi ephezulu.

Izici Ezibalulekile Zemishini Yokugaywa Kabusha Kwepulasitiki

Amandla Okucubungula kanye Nokuphumelela

Umthamo wokucubungula utshela ukuthi umshini ungaphatha ipulasitiki engakanani njalo ngehora. Ngo-2025, iningi leMishini Yokugaywa kabusha kwePlastiki iqala cishe kumakhilogremu angama-300 ngehora. Amanye amamodeli ezimboni, njenge-JianTai XS-400 ne-XR-800, afinyelela kumakhilogremu angu-1,500 ngehora. Lolu hlu olubanzi lusiza amabhizinisi ukuthi akhethe imishini efana nezidingo zawo. Isitolo esincane singase sikhethe imodeli yomthamo ophansi, kuyilapho imboni enkulu idinga okuthile okukhulu. Lapho bekhetha umshini, kufanele bacabange ukuthi ingakanani imfucumfucu yepulasitiki efika ngosuku nokuthi bafuna ukuyicubungula ngokushesha kangakanani.

Ithiphu: Ukusetshenziswa okuphezulu kusho ukugaya kabusha okusheshayo, kodwa futhi kudinga isikhala namandla engeziwe.

Ukusebenza kahle kwamandla kanye nokusetshenziswa kwamandla

Ukusebenza kahle kwamandla kubalulekile kukho kokubili imvelo kanye nesikhwama semali. Imishini eminingi emisha isebenzisa amandla amancane ngoba inamamotho angcono kanye nemiklamo ehlakaniphile. Uchungechunge lwe-S:GRAN oluvela ku-NGR lugqama ngokukhipha okuqinile nokuguquguqukayo, kuyilapho ama-pelletizer e-ACS-H™ eletha okukhiphayo okuphezulu ngokusetshenziswa kwamandla okuphansi. Eminye imishini isebenzisa i-AI ne-IoT ukuze ihlele amapulasitiki ngokunembe kakhudlwana futhi yonge amandla. Abanye banezinsimbi ezithuthukisiwe kanye nezinhlelo zamanzi ezivaliwe ezinciphisa udoti kanye nokusetshenziswa kwamandla.

- Ukusetshenziswa kwamandla kuyingxenye enkulu yezindleko zokusebenza.

- Ukuthuthukela kumamodeli awonga amandla, njengemishini yezikulufo ephindwe kabili, kwehlisa izikweletu zamandla.

- Amadrayivu amafrikhwensi aguquguqukayo (ama-VFD) alungisa isivinini semoto ukuze afane nomsebenzi.

- Ukuhlanza nokugcinwa njalo kugcina imishini isebenza kahle futhi yonga amandla.

- Ukucisha imishini uma ingasebenzi kugwema ukumosha ugesi.

- Ukusebenzisa izinto ezingavuthiwe ezihlanzekile kusiza imishini ukuthi isebenze ngokushesha futhi isebenzise amandla amancane.

Okuzenzakalelayo kanye nezilawuli ezilungele umsebenzisi

Imishini Yesimanje Yokugaywa Kabusha Kwepulasitiki isebenzisa ezishintshayo ezihlakaniphile ukwenza ukugaywa kabusha kube lula futhi kuphephe. Banezilawuli ze-logicable logic (PLC) ezilawula izinqubo ngesikhathi sangempela. I-Human-Machine Interfaces (HMI) inikeza izikrini zokuthinta ukuze zilawuleke kalula futhi zibonise idatha. Izinzwa zilandelela izinga lokushisa, ingcindezi, nesivinini, kuyilapho ama-actuator alungisa amazinga okuphakela nokugeleza kwezinto.

| Automation Isici | Incazelo | Imisebenzi Esemqoka |

|---|---|---|

| I-Programmable Logic Controller (PLC) | Iyunithi yokulawula emaphakathi eyenza imiyalelo ehleliwe yokuphatha izinqubo zomshini ngesikhathi sangempela | Inqubo ezenzakalelayo, ukuqapha ngesikhathi sangempela, ukutholwa kwamaphutha, ukuphathwa kokuphepha |

| I-Human-Machine Interface (HMI) | Isikrini sokuthinta esibonakalayo sokusebenzelana kuka-opharetha nokulungiswa kwepharamitha | Bonisa idatha yesikhathi sangempela, ukulawula okwenziwa ngesandla, ukuloga idatha yokusebenza |

| Izinzwa Systems | Inethiwekhi yezinzwa ezikala izinga lokushisa, ingcindezi, isivinini, ukuba seduze, njll. | Gada izinqubo eziguquguqukayo, nikeza impendulo yokulawula iluphu evaliwe, qalisa ama-alamu |

| Ama-Actuator | Amadivayisi aguqula amasiginali okulawula enze izenzo zemishini | Lawula amazinga okuphakela, isivinini se-extrusion, ukupholisa, lungisa ukugeleza kwezinto ezibonakalayo, vumelanisa izingxenye zomshini |

Abasebenzisi bayazuza ngokuqapha kwesikhathi sangempela nokufinyelela kude. Amasistimu okuhlunga azenzakalelayo ahlukanisa amapulasitiki ngohlobo nombala, anciphisa umsebenzi wezandla. Izilawuli ezinikwe amandla yi-AI zilungisa izilungiselelo endizeni, zigcine yonke into isebenza kahle.

Izici Zokuphepha Nokuvikelwa Kwabasebenzi

Ukuphepha kuza kuqala kunoma iyiphi indawo yokugaywa kabusha. Imishini idinga izici eziqinile zokuphepha ukuze ivikele abasebenzi ekulimaleni. Izithiyo ezingokomzimba zigcina abantu bekude nezingxenye eziyingozi. Onogada abaxhumene bavala imishini uma ivuliwe. Onogada abalungisekayo futhi abazilungisayo balingana nezinto ezahlukahlukene futhi bagcina izandla ziphephile.

Gqoka njalo okokuvikela umuntu (i-PPE) njengamagilavu, omakalabha, izibuko zokuphepha, namabhuzu anezinzwane zensimbi.

- Imishini kufanele ibe nezici zokuphepha okunzima ukuzisusa noma ukuzicisha.

- Ukuhlolwa okujwayelekile kokulungisa kugcina onogada nezilawuli zisebenza.

- Izinqubo ze-Lockout-tagout zivimbela izingozi ngesikhathi sokulungiswa.

- Izinkinobho zokumisa izimo eziphuthumayo kufanele kube lula ukuzifinyelela.

- Ukuqeqeshwa kokuphepha kusiza abasebenzi baqonde ubungozi futhi basebenzise amathuluzi ngendlela efanele.

- Ukuhlolwa kokuphepha kwangaphakathi kugxile ekuvikelweni kwemishini.

Isondlo Nokuqina

Imishini ehlala isikhathi eside ihlala isikhathi eside futhi idinga ukulungiswa okumbalwa. Ukunakekelwa njalo, njengokuhlanza nokufaka izingxenye ezigugile, kugcina imishini isebenza kahle. Ukugcoba kuvimbela ukungqubuzana nokulimala. Abasebenzisi kufanele bahlole imishini njalo futhi balungise izinkinga kusenesikhathi. Ukusebenzisa izinto ezisezingeni eliphezulu nezingxenye kusiza imishini ukuthi imelane nokusetshenziswa kanzima. Eminye imishini inezici zokunakekela ezibikezelayo ezixwayisa abaqhubi ngaphambi kokuthi kuphuke okuthile.

Qaphela: Imishini enakekelwa kahle isebenzisa amandla amancane futhi ikhiqiza ipulasitiki esenziwe kabusha kangcono.

Ukwenza ngokwezifiso kanye nezinketho zokuthuthukisa

Imishini Yokugaywa Kabusha Kwepulasitiki ngo-2025 inikela ngezindlela eziningi zokwenza ngokwezifiso kanye nokuthuthukisa.Ama-shredders manje anokuhlunga okuhlakaniphile, ukusetshenziswa kwamandla okuphansi, nokuxhumeka kwe-inthanethi kokulawula okude. Ama-Granulator asebenzisa izilawuli ezishayelwa yi-AI nezinzwa ezihlakaniphile, ezinamarotha athuthukisiwe nama-blade ahlala isikhathi eside. Amakhompiyutha acindezela udoti kakhudlwana, ondle ngokuzenzakalelayo, futhi wonge isikhala. Ama-extruder agxila kumiklamo eco-friendly futhi aphathe izinhlobo eziningi zepulasitiki.

- I-JianTai isebenza namakhasimende ukuthunga imishini yamapulasitiki ahlukene nemithetho yendawo.

- Imiklamo emisha yonga amandla, isebenza kancane, futhi ingena ezindaweni ezincane.

- Ukuthuthukiswa kufaka phakathi ukuphakela okuzenzakalelayo, ukuxuba okungcono, nempilo ende ye-blade.

Ithiphu: Izinketho zangokwezifiso zisiza amabhizinisi ahlangabezane nezidingo ezishintshayo zokugaywa kabusha futhi ahlale ngaphambi kwemithetho emisha.

Ukucatshangelwa Okusebenzayo Kokuthenga Imishini Yokugaywa Kabusha Kwepulasitiki

Isabelomali kanye Nezindleko Ziphelele Zobunikazi

Intengo ibalulekile lapho ukhetha okokusebenza kabusha. Eminye imishini ibiza kancane ekuqaleni kodwa idinga ukulungiswa okwengeziwe ngokuhamba kwesikhathi. Ezinye zibiza kakhulu kodwa zihlala isikhathi eside futhi zisebenzisa amandla amancane. Abathengi abahlakaniphile babheka izindleko eziphelele zobunikazi. Lokhu kusho ukucabanga ngentengo, ukulungiswa, izingxenye ezisele, nezikweletu zamandla. Ithebula elilula lingasiza ukuqhathanisa izindleko:

| I-Cost Factor | Isibonelo semibuzo |

|---|---|

| Thenga Intengo | Ingabe ingaphakathi kwesabelomali? |

| Isondlo | Idinga isevisi kaningi kangakanani? |

| Ukusetshenziswa kwamandla | Ingabe izonyusa izikweletu zamandla? |

| Izingxenye ezisele | Ingabe izingxenye zitholakala kalula? |

Ithiphu: Ukusebenzisa imali ethe xaxa manje kungonga imali ngokuhamba kwesikhathi.

Isikhala kanye Nezidingo Zokufaka

Wonke umshini udinga indawo eyanele ukuze usebenze ngokuphepha. Eminye Imishini Yokugaywa Kabusha Kwepulasitiki ingena ezindaweni zokusebenzela ezincane. Abanye badinga izitezi ezinkulu zefektri. Abathengi kufanele balinganise indawo yabo ngaphambi koku-oda. Kufanele futhi bahlole ukuthi iphansi liyakwazi yini ukubamba izinto ezisindayo. Ukuhlela okuhle kugwema izinguquko ezibizayo kamuva.

Ukusekela Ngemva Kokuthengisa Nesevisi

Ukwesekwa okuthembekile kugcina imishini isebenza. Abahlinzeki abahle banikeza ukuqeqeshwa, ukulungisa ngokushesha, nokufinyelela kalula izingxenye ezisele. Baphendula imibuzo futhi basize ekuxazululeni izinkinga. Izinkampani eziningi manje zinikeza usizo lwe-inthanethi nemihlahlandlela yevidiyo.

- Ukwesekwa okusheshayo kusho ukuphumula okuncane.

- Ukuqeqeshwa kusiza abasebenzi ukuthi basebenzise imishini ngokuphepha.

Ukuhambisana Nemithetho Yendawo

Imithetho yokugaywa kabusha iyashintsha indawo ngezindawo. Abathengi kufanele bahlole imithetho yendawo ngaphambi kokuthenga. Ezinye izindawo zidinga izihlungi ezikhethekile noma izilawuli zomsindo. Ezinye zidinga ukuhlolwa kokuphepha noma imibiko yokugaywa kabusha. Ukulandela imithetho kugcina ibhizinisi liphephile ezinhlawulweni.

Qaphela: Hlala ubuza abahlinzeki ukuthi ingabe imishini yabo iyahlangabezana yini nezindinganiso zendawo.

Ukukhetha umshini ofanele kuqala ngezinjongo ezicacile zokugaywa kabusha. Abathengi kufanele bafanise izidingo zabo nezici zomshini. Kudingeka bacabange ngesabelomali, indawo, nokusekelwa. Umnyakazo okhaliphile uwukubhala imigomo, izinketho zocwaningo, nokukhuluma nabahlinzeki. Lokhu kubasiza ukuthi benze ukukhetha okungcono kakhulu kwebhizinisi labo.

FAQ

Yimaphi amapulasitiki angaphathwa yimishini eminingi yokuvuselela kabusha ngo-2025?

Imishini eminingi icubungula i-PET, i-HDPE, i-LDPE, ne-PP. Amanye amamodeli athuthukile aphatha amapulasitiki axubile noma angcolile. Njalo hlola imininingwane yomshini.

Ngabe opharetha kufanele banakekele kangaki imishini yokugaywa kabusha kwepulasitiki?

Abasebenzi kufanele bahlole imishini masonto onke. Ziyahlanza, zigcobe, futhi zibuyisele izingxenye ezigugile. Ukuhlola okuvamile Imishini yokusiza ihlala isikhathi eside futhi isebenza kangcono.

Ingabe imishini yokuvuselela ipulasitiki idinga ukuqeqeshwa okukhethekile ukuze isebenze?

Yebo, abaqhubi bayadingaukuqeqeshwa. Abahlinzeki bavame ukunikeza imihlahlandlela noma amavidiyo. Ukuqeqeshwa okuhle kugcina abasebenzi bephephile futhi kusiza imishini ukuthi isebenze kahle.

Isikhathi sokuthumela: Aug-18-2025