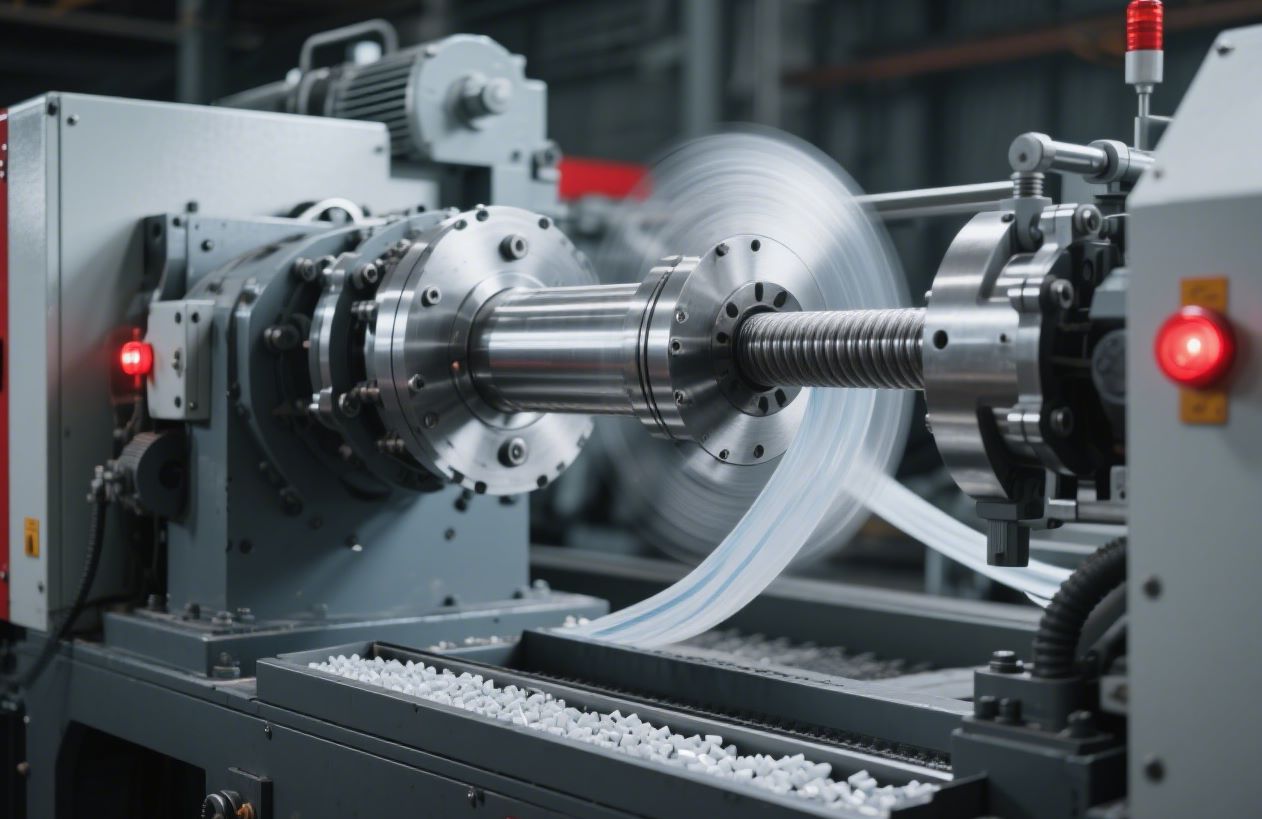

In 2025, the demand for plastic granulators, including plastic grinders and plastic crushers, continues to soar, with global sales projected to reach $1,278.5 million. These machines play a crucial role in recycling processes, helping businesses reduce waste. When choosing a plastic granulator from a reliable plastic granulator supplier, consider factors like performance, energy efficiency, and safety features to find the right fit for your needs.

Key Takeaways

- Consider performance metrics like stability and operational efficiency when choosing a plastic granulator. These factors impact how well the machine will work for your needs.

- Energy efficiency is crucial. Select a granulator that consumes less energy while maintaining high output to save on costs over time.

- Prioritize safety features. Ensure the granulator has mechanisms like safety switches to protect operators during use.

Key Features of Plastic Granulators

When selecting a plastic granulator, understanding its key features is essential. These features can significantly impact performance, efficiency, and safety. Here’s a closer look at what to consider:

Performance Metrics

Performance metrics are vital for evaluating how well a plastic granulator operates. Here are some important metrics to keep in mind:

| Performance Metric | Description |

|---|---|

| Stability | The machine’s ability to run smoothly during each cycle without interruptions. |

| Reliability | The dependability of the granulator’s system software and materials used. |

| Service Life | The longevity of the machine, influenced by key support and wear parts. |

| Operational Efficiency | The effectiveness of the granulator in processing materials with minimal waste. |

| Maintenance Costs | The expenses associated with keeping the granulator in optimal working condition. |

These metrics help users gauge how well a granulator will perform in their specific applications.

Energy Efficiency

Energy efficiency is another crucial feature. A granulator that consumes less energy while maintaining high output can save businesses money in the long run. For instance, the RG-36E model from Rhong Plastic Machinery stands out for its robust cutting system. This model enhances energy efficiency while ensuring high granule quality, making it a top choice for those seeking energy-efficient plastic granulators.

Size and Capacity

The size and capacity of a plastic granulator can greatly affect its operational efficiency. Granulators come in various sizes, with capacities ranging from small units that handle 4 kg/h to larger models capable of processing up to 20,000 kg/h. Here’s a quick overview of typical sizes and capacities:

| Model | Capacity (lbs/hr) | Rotor Diameter (mm) | Rotor Width (mm) | Drive Capacity (kW) | Weight (kg) |

|---|---|---|---|---|---|

| H 35-50 | N/A | 350 | 500 | 22 | 1800 |

| H 50-60 | N/A | 500 | 600 | 55 | 3100 |

| H 50-100 | N/A | 500 | 1000 | 75 | 4200 |

| H 60-80 | N/A | 600 | 800 | 75 | 4500 |

| H 60-160 | N/A | 600 | 1600 | 132 | 6950 |

| H 70-100 | N/A | 700 | 1000 | 132 | 7100 |

Higher capacity granulators are essential for increasing throughput, which is vital for scaling operations and fulfilling production requirements.

Safety Features

Safety should never be overlooked. Top-rated plastic granulators come equipped with several safety features. For example, many models include a safety switch that halts operation if the cutting chamber opens while the motor runs. This feature prevents injury and ensures that operators can safely make adjustments.

Tip: Always ensure the machine is off and power is disconnected before making any adjustments. Using a padlock on the lockout box can prevent accidental re-energization.

Maintenance Requirements

Regular maintenance is crucial for the longevity and efficiency of plastic granulators. Neglecting maintenance can lead to increased wear and tear, resulting in higher operational costs. Here are some recommended maintenance practices:

- Establish a baseline for maintenance intervals, which may vary from every few days for continuous operation to every seven to ten days for lighter use.

- Regularly check and maintain granulator knives to ensure they are sharp, as dull knives increase energy consumption and reduce efficiency.

- Conduct routine inspections to catch minor issues before they escalate into costly repairs.

By following these practices, users can ensure their granulators operate efficiently and effectively over time.

Top Plastic Granulators of 2025

When it comes to choosing the best plastic granulators in 2025, several models stand out for their unique features and capabilities. Here’s a closer look at some of the top contenders:

CMG Granulators EV 92-220

The CMG Granulators EV 92-220 is a powerhouse in the world of plastic granulators. This model boasts several unique selling points that set it apart from competitors:

| Unique Selling Point | Description |

|---|---|

| Advanced Energy Efficiency | Reduces energy utilization by up to 50% compared to conventional granulators. |

| High Throughput | Processing capacities range from hundreds of kilograms to several tons per hour. |

| Ease of Maintenance | Features simplified access to components and self-lubrication systems to minimize downtime. |

| Innovative Design Features | Proprietary cutting chamber design ensures clean, consistent regrind with no micro particles. |

| Heavy-Duty Performance | The EV 92-220 model is designed for extreme operational loads with unmatched output capacity. |

This granulator excels in recycling post-consumer plastics, making it ideal for large-scale operations. Its advanced control integration enhances reliability under extreme operational loads, ensuring consistent performance.

Shini USA Granulators

Shini USA Granulators are known for their innovative features that enhance efficiency and safety. Here’s what makes them stand out:

| Feature | Description |

|---|---|

| Staggered trapezoid cutting design | Enhances cutting efficiency and granulation quality. |

| Gear driven low-speed motor | Provides consistent power and reduces noise during operation. |

| Tilt-back hopper | Facilitates easy loading and maintenance. |

| Safety interlocks | Ensures operator safety during operation. |

| Hardened cutting blades | Increases durability and longevity of the granulator. |

| Obstruction alarm | Alerts users to blockages, preventing damage to the machine. |

| Emergency E-Stop | Allows for immediate shutdown in case of emergencies. |

| Vacuum take-off port | Enhances material handling and reduces waste. |

| Automatic reverse design | Prevents jams and enhances operational efficiency. |

| Caster mounting | Provides mobility for easy repositioning of the granulator. |

For warranty inquiries, users can contact the Service/Parts Department at 440-530-1000. It’s essential to have the model and serial number ready for a smooth process.

Romaco Granulators

Romaco Granulators are recognized for their technological innovations. They deliver consistent and high-quality granules, which improves product performance. Here are some key features:

| Feature | Description |

|---|---|

| Consistency and Quality | Delivers consistent and high-quality granules, improving product performance and reducing variability. |

| Increased Productivity | Faster processing times and higher throughput rates enhance production efficiency and lower costs. |

| Customization and Flexibility | Offers tailored solutions to meet specific customer and product needs, ensuring optimal performance. |

| Cost-Effectiveness | Minimizes waste and maximizes efficiency, reducing production costs and enhancing profitability. |

These features make Romaco Granulators a popular choice among manufacturers looking to optimize their production processes.

MPG Granulators

MPG Granulators are particularly beneficial for small-scale operations. They effectively cut and divide materials with precision, ensuring reliability and minimal downtime. This makes them suitable for various types of plastics, whether for recycling or preparing materials for further processing. Their efficiency and throughput enhance productivity, making them a valuable asset in any plastics manufacturing process.

OneCUT PRO Granulator

The OneCUT PRO Granulator is a preferred choice for precision granulation. It offers several features that enhance its performance:

| Feature | Description |

|---|---|

| Lower speeds | For brittle materials, resulting in lower noise levels and energy consumption. |

| Higher speeds | Suitable for soft materials or when higher capacity is required. |

| Rapid QRR | Quick access to clean or service the granulator in about 30 seconds. |

| Straight cut with offset segments | Maximizes gripping of materials, reducing dust and fine particles during cutting. |

| Turnable knives and hooks | Designed for minimal cost of ownership with double lifetime for main wear parts. |

| PowerTECH execution | For very abrasive materials, enhancing wear resistance. |

| Automatic rotor reversal | Automatically reverses if material blocks the rotor, aiding in material release. |

Additionally, the OneCUT PRO Granulator can save up to 80% of energy consumption by allowing automatic operation based on load. It operates at a reduced speed, which significantly lowers noise and dust generation. This granulator is not just efficient; it’s also environmentally friendly.

Comparison of Plastic Granulator Specifications

When choosing a plastic granulator, comparing specifications helps buyers make informed decisions. Here’s a breakdown of key aspects to consider:

Performance Comparison

Performance varies significantly among different models. For instance, CMG granulators feature the Adaptive Motor Power (AMP) function. This function adjusts power levels based on material characteristics. It optimizes energy use to as low as 20-25 Wh/kg, which is much lower than conventional units.

| Brand/Model | Throughput (kg/h) | Energy Use (Wh/kg) |

|---|---|---|

| CMG | 800 – 5000 | 20 – 25 |

| Conventional | N/A | > 50 |

Efficiency Ratings

Efficiency ratings are crucial for understanding how well a granulator performs. Efficient granulation can lead to reduced energy costs. Proper selection of granulators minimizes energy use and impacts material costs by enabling the reuse of scrap.

Price Points

Price points for plastic granulators can vary widely. Buyers should consider their budget and the features they need. While some high-end models offer advanced features, there are also budget-friendly options that provide solid performance.

User Ratings

User ratings provide insight into real-world performance. Many users appreciate models that combine efficiency with reliability. They often highlight the importance of maintenance and support from manufacturers. Positive feedback can guide potential buyers toward the best options available.

User Testimonials on Plastic Granulators

Positive Experiences

Many users have shared their positive experiences with plastic granulators. Here’s a summary of what they appreciate most:

| Positive Experience | Description |

|---|---|

| User-friendliness | Granulators are designed to be easy to operate, enhancing user experience. |

| Safety | Machines comply with ISO 12100 safety standards, ensuring operator safety during use. |

| Application flexibility | Capable of processing various types of scrap materials, making them versatile for different applications. |

| Improved efficiency | Enhanced performance in recycling processes leads to better material recovery and reduced waste. |

These features contribute to a smoother operation and greater satisfaction among users.

Common Concerns

While many users enjoy their granulators, some common concerns arise. Here are the frequently cited issues:

- Irregular granule size

- Excessive vibration or noise

- Frequent motor tripping

- Material jamming in the cutting chamber

- Poor throughput and output decline

- Blade wear and tear

- Dust accumulation and poor air quality

- Electrical faults and control panel errors

- Increased energy consumption

- Lubrication and maintenance neglect

Addressing these concerns can help improve the overall experience with plastic granulators.

Expert Opinions

Industry experts recommend several factors when selecting a plastic granulator. Here’s a breakdown of their advice:

| Factor | Description |

|---|---|

| Material Type | Choose a granulator that can handle the specific type of plastic you need. |

| Capacity and Throughput | Ensure the granulator meets your production volume requirements. |

| Blade Design | Opt for high-quality blades that offer durability and precision cutting. |

| Energy Efficiency | Look for granulators that consume less energy while maintaining high output. |

Experts also suggest considering the size, shape, and density of the material to be cut, as well as how the regrind will be processed. This guidance helps users make informed decisions tailored to their specific needs.

In summary, the best plastic granulators of 2025, like the CMG Granulators EV 92-220 and OneCUT PRO, offer unique features that cater to various needs. When choosing a granulator, consider factors such as:

- Type of plastic material

- Capacity requirements

- Granule size and shape

- Energy efficiency

- Safety features

Before making a purchase, think about your specific requirements. This ensures you select a granulator that fits your operational needs perfectly. Happy granulating!

Post time: Sep-08-2025