Abantu babona izinguquko ezinkulu endleleni aipulasitiki granulatorisebenza namuhla. Ukuthuthukiswa kwakamuva, njengezinzwa ezihlakaniphile namamotho onga amandla, kuyasizai-industrial plastic granulatorabasebenzisi banciphisa izindleko futhi bakhulise umphumela. Abakhiqizi abaningi be-plastic granulator manje bengeza izingxenye ezingagugi, benza ngayinyei-granulator eqinilehlala isikhathi eside ku-aIsistimu yokugaya kabusha.

| Ukuqamba | Ukusebenza Ngempumelelo | Izindleko-Ngempumelelo |

|---|---|---|

| I-Smart Technologies | Ukuqapha kwesikhathi sangempela | Yehlisa isikhathi sokuphumula |

| Ukusebenza Kwamandla | Amandla amancane adingekayo | Yehlisa izindleko zokusebenza |

| Izinto Ezithuthukile | Ukuhlukaniswa okumbalwa | Ilondoloza kokumiselela |

Okuthathwayo Okubalulekile

- Izinzwa ezihlakaniphile kanye ne-automationthuthukisa ukusebenza kwe-plastic granulator ngokunciphisa isikhathi sokuphumula kanye nokuthuthukisa ikhwalithi yomkhiqizo.

- Izinjini ezonga amandlakanye nemiklamo ethuthukisiwe yehlisa ukusetshenziswa kwamandla futhi yehlise izindleko zokusebenza kuyilapho isekela imigomo yemvelo.

- Ama-modular, ama-granulator enziwe ngendlela oyifisayo alingana nezidingo ezahlukene, okwenza ukugaywa kabusha kuphephe, kube lula, futhi kusebenze kahle ezimbonini eziningi.

I-Automation kanye ne-Industry 4.0 ku-Plastic Granulator Technology

Ama-Smart Sensors kanye ne-IoT Integration

Izinzwa ezihlakaniphile ziguqule indlela opharetha abaphatha ngayo i-granulator yepulasitiki. Lezi zinzwa zilandelela imininingwane ebalulekile, njengezinga lokushisa nesivinini sokudla, ukuze kugcinwe imishini isebenza kahle. Ama-opharetha asebenzisa izinzwa zokulawula izinga lokushisa ukuze avimbele izinto ekuncibilikeni. Izinzwa ezizenzakalelayo zokuhlehlisa ummese zisiza ukugwema ukuminyana, ukuze inqubo ingami. Izinzwa eziphakelayo ezihlakaniphile zilungisa ukuthi okubalulekile kungena ngokushesha kangakanani emshinini, kugcine yonke into izinzile.

- Izinzwa zokulawula izinga lokushisa ziqapha izinga lokushisa lokucubungula.

- Izinzwa ezizenzakalelayo zokuhlehlisa ummese zithola ukuminyana futhi zigcine inqubo ihamba.

- Izinzwa eziphakelayo ezihlakaniphile zifanisa isivinini sokufaka nomthamo womshini.

Ukuhlanganiswa kwe-IoT kuletha izinzuzo ezengeziwe. Abasebenzisi bangahlola impilo yomshini noma yikuphi besebenzisa ukuqapha okukude. Ukuxilongwa kwesikhathi sangempela kanye nezinkinga zezindawo zokuhlanganisa ze-PLC kusenesikhathi. Ukunakekela okubikezelwayo kusiza ukuhlela ukulungisa ngaphambi kokuthi kwenzeke ukuwohloka. Lokhu kunciphisa isikhathi sokuphumula futhi konga imali. Izinzwa ziphinde zibheke izinkinga ezifana nokuvala ukufa noma ukugcwala kwemoto. Amapulatifomu asekelwe efwini athumela izikhumbuzi zokunakekelwa, ukuze opharetha bangakhohlwa imisebenzi ebalulekile.

Ithiphu: Izinzwa ezihlakaniphile nezilawuli ze-IoT zisiza opharetha ukubamba izinkinga kusenesikhathi, zigcine imishini isebenza isikhathi eside, futhi zithuthukise ikhwalithi yomkhiqizo.

Ukuthuthukiswa Kwenqubo Eqhutshwa yi-AI

Amasistimu aqhutshwa yi-AI enza imisebenzi ye-plastic granulator ihlakaniphe. Lawa masistimu asebenzisa idatha ukulungisa izilungiselelo ezifana nezinga lokushisa nesivinini sesikulufu. Ama-opharetha abona izinto ezilahliwe ezimbalwa nama-pellets angaguquki. I-AI isiza ukuhlela ukulungiswa ngokubona ukugqokwa kwemishini ngaphambi kokuthi idale inkinga. Lokhu kugcina imishini isebenza futhi kunciphisa ukulungiswa okungalindelekile.

- I-AI ithola amasethingi angcono kakhulu eqeqebana ngalinye, inciphisa izilinganiso zokulahlwa.

- Ukugcinwa kokuqagela kukhulisa isikhathi nokuthembeka kwempahla.

- Ukulawulwa kwekhwalithi eshayelwa yidatha kuthuthukisa ukufana kwe-pellet futhi kukhuphule amanani omkhiqizo webanga lokuqala.

- Imiklamo yokonga amandla kanye nokuthola ukushisa kunganciphisa ukusetshenziswa kwamandla kufika ku-30%.

I-AI iphinde isize opharetha bagweme amaphutha. I-Automation ne-AI isebenza ndawonye ukuze kugcinwe usayizi we-pellet nekhwalithi ingashintshi. Lapho i-AI, i-automation, ne-IoT ijoyina amandla, ukuphuma kukhuphuke futhi imfucuza iyehla. Ezinye izikhungo zisebenzisa ukufunda komshini ukubona izinkinga kanye nezidingo zokubikezela zokulungisa. Lezi zilawuli ezihlakaniphile azikakajwayelekile okwamanje, kodwa izinkampani eziningi zihlela ukuzisebenzisa maduze. Ikusasa lizoletha ukuthuthukiswa kwenqubo yokuzimela kanye nezici eziqagelayo.

Amarobhothi kanye Nokudla Okuzenzakalelayo

Amarobhothi kanye nezinhlelo zokuphakela ezizenzakalelayo zenze izikhungo zepulasitiki ze-granulator zaphepheka futhi zasebenza kahle kakhudlwana. Iziphakeli ezidlidlizayo zisebenzisa izinzwa kanye nempendulo ukuze zilethe okubalulekile ngokunemba. Abasebenzi abasadingi ukuphatha izikhwama ezinzima noma bavule amasaka. Amarobhothi nezinto ezihambisa amamitha zibe izimbudumbudu, ezivimbela ukudlisa ngokweqile noma ukuncelisa kancane. Lokhu kugcina imishini iphephile futhi kunciphisa isikhathi sokungasebenzi.

Izinhlelo zokudla ezizenzakalelayo zinciphisa izidingo zabasebenzi. Abasebenzi bachitha isikhathi esincane benza imisebenzi yezandla futhi babhekana nezingozi ezimbalwa ezivela othulini noma amathuluzi abukhali. Ama-Plastic Auto Loaders agcina impahla igeleza, ngakho imishini ayimi. I-Automation iphinde yehlise izingozi ezixhumene nokuphatha mathupha. Izikhungo zibona imiphumela engcono yokuphepha kanye nesidingo esincane sokungenelela komsebenzisi.

Qaphela: Amarobhothi kanye nezinhlelo zokuphakelayo ezizenzakalelayo zivikela abasebenzi futhi zisize imishini ukuthi isebenze kahle, okwenza imisebenzi ye-plastic granulator iphephe futhi ithembeke kakhudlwana.

Ukusebenza kahle kwamandla kanye nokusimama kuma-Plastiki Granulator

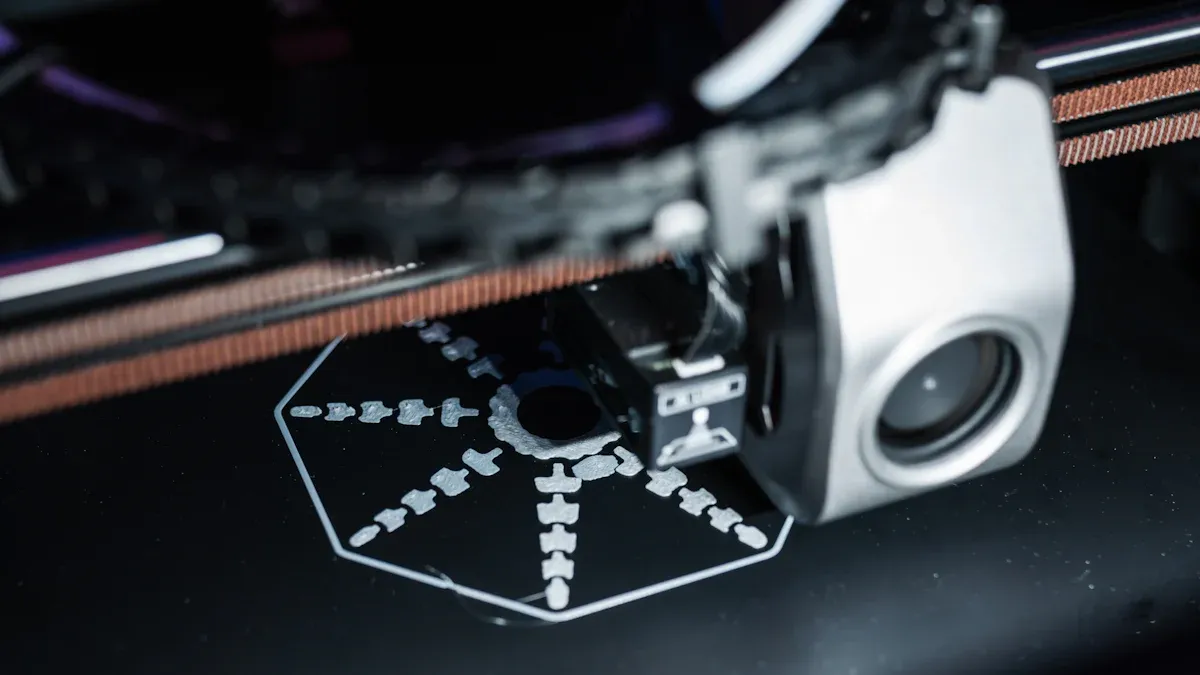

.jpg)

High-Efficiency Motor Systems

Amasistimu ezimoto asebenza kahle kakhulu ashintshe indlela izikhungo ezisebenzisa ngayo amandla ekugayweni kabusha kwepulasitiki. Lezi zinjini zisebenzisa amandla amancane kunawendabuko. Abasebenzisi babona izikweletu eziphansi zikagesi kanye nezinkinga ezimbalwa zokuwulungisa. Ama-crusher epulasitiki esimanje anamamotho asebenza kahle kakhulu nama-variable frequency drives (VFDs) anganciphisa ukusetshenziswa kwamandla ngo-25-30%. Izikhungo eziningi ezishintshela kulawa ma-motor zicubungula inani elifanayo lepulasitiki kodwa zisebenzisa imali encane kakhulu kumandla.

- Izinjini ezisebenza kahle kakhulu zilungisa amandla azo ngokusekelwe emthwalweni. Lokhu kusho ukuthi abawamoshi amandla uma umshini ungagcwele.

- Ama-granulator anesivinini esiphansi onalawa ma-motor ahamba kancane. Zenza ukushisa okuncane futhi ziguge ngokushesha, okonga kokubili amandla kanye nezindleko zokulungisa.

- Izinhlelo zokulawula ezithuthukile zisiza injini ukuthi igijime ngesivinini esingcono kakhulu somsebenzi ngamunye. Lokhu kugcina ukusetshenziswa kwamandla kuphansi nokusebenza kuphezulu.

- Eminye imishini inezinhlelo zokubuyisa amandla. Lezi zinhlelo zithwebula ukushisa okwengeziwe futhi zikuguqule kube ugesi, konga imali eyengeziwe.

Abasebenzisi bathola ukuthi izindleko eziphezulu zangaphambili zalawa ma-motor zikhokha ngokuhamba kwesikhathi. Bachitha imali encane emandleni nasekulungiseni, okwenza yonke le nqubo iqhubekele phambili.

Imiklamo Eyonga Amandla

Abakhiqizi manje bakha ama-granulator epulasitiki anezici ezihlakaniphile ezonga amandla nsuku zonke. Lezi zinguquko zemiklamo zisiza izinkampani ukuhlangabezana nezinhloso zazo eziluhlaza kanye nezindleko eziphansi. Ithebula elingezansi libonisa ezinye izici ezisebenza kahle kakhulu zokonga amandla kanye nezinzuzo zazo:

| Isici sokuklama | Inzuzo Eyonga Amandla |

|---|---|

| Izinjini zokonga amandla aphansi wamahhashi | Yehlisa ukusetshenziswa kwamandla sekukonke |

| Izindlu zokusika ezingenasikrini | Yehlisa isivinini se-rotor futhi yehlise izinhlawulo, ithuthukise ukusebenza kahle kwamandla |

| Isivinini se-rotor esiphansi kakhulu | Yehlisa ukusetshenziswa kwamandla ngenkathi igcina ikhwalithi ye-granule |

| Irotha enamazinyo amaningi enamazinyo aphinde alola | Igcina ukusebenza kahle kokusika, inciphisa ukumosheka kwamandla ngokuhamba kwesikhathi |

| Idizayini ye-torque ephezulu ye-flywheel | Iphatha izinto eziqinile ngendlela efanele, inciphisa ukumosheka kwamandla |

| Umklamo wommese we-Twinshear | Ithuthukisa ukusebenza kahle kokusika, kudla amandla amancane |

| Hlukanisa igumbi | Ivumela ukuhlanza okusheshayo, ukunciphisa isikhathi sokuphumula nokusebenzisa amandla |

| Umbeleko wesikrini esindayo oqinisiwe | Ithuthukisa ukuqina, inciphise ukulahlekelwa amandla ngenxa yokuguga |

Amanye amamodeli amasha, njenge-CMG Granulators' EV Series, asebenzisa umumo wokusika othuthukile nezinhlelo zokushayela ezihlakaniphile. Lezi zinguquko zinganciphisa ukusetshenziswa kwamandla kuze kufike ku-50% uma kuqhathaniswa nemishini emidala. Ukonga amandla amaningi kuvela ekukhetheni usayizi wemoto ofanele kanye nokusebenzisa izilawuli ezonga amandla. Opharetha abasebenzisa le miklamo babona ukwehla okukhulu ezindlekweni zabo zamandla kanye nesikhathi esincane sokulungisa.

Ithiphu: Ukukhetha i-granulator yepulasitiki enezici zokonga amandla kusiza izinkampani zonge imali futhi zivikele imvelo ngesikhathi esifanayo.

Izingxenye Eco-friendly futhi Recyclable

Ukuzinza manje sekuseqhulwini ezinkampanini eziningi. Bafuna imishini ehlala isikhathi eside futhi edala udoti omncane. Izingxenye ze-Eco-friendly nezisebenziseka kabusha kuzimbumbulu zepulasitiki zisiza ukufinyelela le migomo. Lezi zingxenye zisebenzisa izinsiza ezimbalwa futhi zenza ukugaywa kabusha kube lula.

- Izingxenye ze-Eco-friendly zinciphisa udoti wepulasitiki futhi zonga amandla.

- Ubuchwepheshe obuthuthukisiwe, njengokuhlunga okuqhutshwa yi-AI, buthuthukisa ikhwalithi yamapulasitiki agaywe kabusha.

- Imithethonqubo, efana ne-Basel Convention kanye ne-RoHS, icindezela izinkampani ukuthi zisebenzise imishini eluhlaza.

- Izinzuzo zezimali, njengekhefu lentela, zikhuthaza ukutshalwa kwezimali kumishini yokugaywa kabusha elungele imvelo.

- Amayunithi e-modular kanye namaselula okugaywa kabusha anciphisa ukukhishwa futhi enze ukugaywa kabusha kufinyeleleke kakhudlwana.

Abakhiqizi manje bagxile ekuhlangabezaneni namazinga Ezemvelo, Ezenhlalakahle, kanye Nokubusa (ESG). Basebenzisa imiklamo eyonga amandla nezinto eziphephile ukuze bahlangabezane nemithetho eqinile. Lezi zinguquko zisiza izinkampani ukuthi zilandele umthetho futhi zibonise amakhasimende ukuthi ayayikhathalela iplanethi. Ngokusebenzisa i-eco-friendly plastic granulators, izinkampani zisekela umnotho oyindilinga futhi zinciphisa i-carbon footprint yazo.

Ukuphatha Izinto Ezithuthukile Nokwenza Ngokwezifiso KumaGranulator Epulasitiki

Imiklamo ye-Modular ne-Compact

Abakhiqizi manje bakha ama-modular kanye nama-compact granulator angena ezindaweni eziqinile. Le mishini isiza izindawo zokusebenzela ezincane kanye nezimboni ezinkulu zonga indawo yaphansi. Ama-opharetha angabeka ama-compact granulator eduze kwemigqa yokukhiqiza. Lokhu kusetha kubavumela ukuthi bacubungule ngokushesha, okwehlisa izindleko zokuphatha. Imiklamo ye-modular ivumela ukuthuthukiswa okusheshayo lapho ukukhiqiza udinga ukushintsha. Amaqembu angashintshanisa ama-blade noma ama-rotor emahoreni ambalwa nje. Lokhu kuvumelana nezimo kusho isikhathi esincane sokuphumula kanye nokunakekelwa okusheshayo. Amayunithi amaningi ahlanganisa izici zokunciphisa umsindo nezici zokucindezela uthuli, okwenza indawo yokusebenza iphephe futhi ithule. Izinzwa ezihlakaniphile nokuqapha kwesikhathi sangempela kusiza opharetha ukuthi babone izinkinga kusenesikhathi, ngakho ukulungiswa kwenzeka ngaphambi kokuphuka.

Ithiphu: Imiklamo ye-modular nehlangene yenza ukufaka kube lula futhi isekele ukugaywa kabusha kwesayithi, okuthuthukisa ukusebenza kahle futhi kwehlise izinselele zokulungisa.

I-Processing Complex ne-Mixed Plastics

Ukugaywa kabusha kwamapulasitiki axubile kunzima, kodwa ubuchwepheshe obusha bukwenza kube lula. Amasistimu wokuhlela anamandla e-AI asebenzisa amakhamera nezinzwa ukuze ahlukanise izinhlobo ezahlukene zamapulasitiki. Imishini yokuhlunga kazibuthe kanye ne-optical isusa insimbi nokunye ukungcola ngaphambi kwegranulation. Eminye imishini isebenzisa ukugaywa kabusha kwamakhemikhali ukuze iphule amapulasitiki abe izingxenye zawo eziyisisekelo. Lezi zindlela zisiza opharetha ukuthi bathole izinto ezihlanzekile ezigaywe kabusha kanye nokuphuma okuphezulu. Iziphakeli ezidlidlizayo nezikrini zendlala ipulasitiki, ngakho ukuhlunga kusebenza kangcono. Lezi zinyathelo zivikela i-granulator yepulasitiki futhi zithuthukise ikhwalithi yamapellets agaywe kabusha. Abasebenzisi babona izikhathi zokucubungula ngokushesha kanye nezindleko zamandla eziphansi.

- Ukuhlunga okuqhutshwa yi-AI kuthuthukisa ubumsulwa.

- Amasistimu kamagnetic kanye ne-optical asusa ukungcola.

- Ukugaywa kabusha kwamakhemikhali kudala izinto ezisezingeni eliphezulu.

Izixazululo Ezihlanganisiwe Zezidingo Zemboni

Izinkampani zifuna ama-granulator afana nezidingo zabo ezihlukile. Abakhiqizi balalela izicelo zamakhasimende kanye nemishini yokuklama enezici ezikhethekile. Amanye amayunithi anamakhamera okuqapha ngesikhathi sangempela ezindaweni ezibalulekile. Imitshina yensimbi igcina izinto ezingafuneki ngaphandle, okwenza imikhiqizo iphephe. Izilawuli ezihlelekayo zivumela opharetha ukuthi basethe izinga lokushisa, isivinini, nokucindezela. Amasistimu e-vacuum exhaust asusa uthuli nomswakama, agcine okukhiphayo kuhlanzekile. Ukupholisa amanzi kunqanda izinhlayiya ukuthi zingahlangani. Lezi zici zangokwezifiso zisiza izinkampani zonge amandla futhi zihlangabezane nemithetho eqinile yezemvelo. Amaqembu athola ukuqeqeshwa nokusekelwa ngemva kokufakwa, ngakho ayisebenzisa kahle imishini.Izixazululo ngokwezifisosiza izinkampani zikhule futhi zihlale zithembekile.

| Isici Ngokwezifiso | Zuza |

|---|---|

| Ukuqapha kwesikhathi sangempela | Ithuthukisa ukulawulwa kwekhwalithi |

| Ukutholwa kwensimbi | Ithuthukisa ukuphepha |

| Izilawuli ezihlelekayo | Ithuthukisa ukusebenza kahle |

| Vacuum exhaust | Igcina okukhiphayo kuhlanzekile |

| Ukupholisa amanzi | Ivimbela ukunqwabelana |

I-Market Impact kanye Nokwamukelwa Kwezinto Eziqanjiwe Zepulasitiki Yezimbotshana

Ukusheshisa Ukutholwa Kwemboni

Abakhiqizi nabagaya kabusha bahamba ngokushesha ukuze basebenzise ubuchwepheshe obusha be-plastic granulator. Babona izinzuzo ezinkulu ezivela kuzici ezifana nokuqapha okunikwe amandla kwe-IoT kanye nokugcinwa kokuqagela okuqhutshwa yi-AI. Lokhu kuthuthukiswa kusiza ukunciphisa isikhathi sokuphumula kanye nezindleko eziphansi. Imiklamo ye-blade ethuthukisiwe nezinto eziqinile zivumela izinkampani ukuthi zicubungule amapulasitiki axubile anenkinga encane. Imithetho yezemvelo, njenge-EU Circular Economy Action Plan kanye Nomthwalo Wemfanelo Owengeziwe Womkhiqizi, icindezela izinkampani ukuthi zitshale emishinini ethuthukisiwe. Abantu abaningi bakukhathalela ukusimama, ngakho isidingo samagranulator ahlangene, eselula, kanye nawonga amandla silokhu sikhuphuka. Amaqembu asebenzisana ukuze athuthukise futhi aqaliseamamodeli amashaNgokushesha. Izinzuzo zezomnotho, njengezindleko eziphansi zokusebenza nokuthobelana kalula, nakho kuyasheshisa ukutholwa. Ukukhula kuqinile eNyakatho Melika, eYurophu, nase-Asia Pacific ngenxa yesidingo semakethe kanye nengcindezi yokulawula.

- Izici ze-IoT ne-AI zithuthukisa ukusebenza kahle.

- Imiklamo emisha ye-blade ibamba amapulasitiki axubile.

- Imithethonqubo kanye nemigomo yokusimama iqhuba ukutshalwa kwezimali.

- Imishini emincane nehambayo ihlangabezana nezidingo eziguquguqukayo.

- Izinzuzo zomnotho zikhuthaza ukuthuthukiswa.

Amazinga Okulawula Umhlangano kanye Nemvelo

Izinkampani zibhekene nemithetho eqinile yokugaywa kabusha kanye nokuphathwa kwemfucuza. Ukuqamba okusha kubuchwepheshe be-granulator yepulasitiki kuyabasiza ukuthi bahlangabezane nalawa mazinga. I-automation kanye ne-AI yokuhlunga izinto futhi isuse ukungcola ngokunemba okuphezulu. Ukuhlanza okungenamanzi nezindlela zokucubungula okomile zinciphisa ukusetshenziswa kwamanzi futhi zinciphise amanzi angcolile. Amamojula okubuyisela amandla athwebula ukushisa futhi akwenze ugesi, ehlise isidingo samandla. Amasistimu okuqapha edijithali alandelela ukuthobela nokugcinwa ngesikhathi sangempela. Imishini eminingi manje ilandela imithetho ye-RoHS ukukhawulela izinto eziyingozi. Izindinganiso zogesi eziluhlaza zisiza ukunciphisa ukukhishwa kwekhabhoni. Amasistimu okuhlunga athuthukisiwe agcina ukungcola kanye nokungcola kuphansi. Imiklamo ye-modular yenza kube lula ukulungisa imishini yemithetho emisha.

- I-Automation kanye ne-AI kuthuthukisa ukuhlunga nokugcinwa.

- Ukuhlanza okungenamanzi konga izinsiza.

- Ukutholwa kwamandla kwehlisa ukusetshenziswa kwamandla.

- Ukuqapha kwedijithali kuqinisekisa ukuhambisana.

- Imishini ye-modular ivumelana nemithetho eguqukayo.

Ukwandisa Izicelo Nezigaba Zemakethe

Ukuqamba okusha kuma-granulator esindayo kuvula iminyango ezimakethe ezintsha. Izinkampani zisebenzisa le mishini ngaphezu kokwenza kabusha. Ithebula elingezansi libonisa ezinye izingxenye ezikhulayo kanye nokusetshenziswa kwazo okuyinhloko:

| Ingxenye Yemakethe Esafufusa | Izicelo Zokushayela / Abashayeli Bokukhula |

|---|---|

| I-Sustainable Plastic Recycling | Ukucubungula udoti wangemva komthengi ube ama-granules asebenziseka kabusha; isekela umnotho oyindilinga nokusimama. |

| I-Granulation Yezemithi | Ama-granulator omile wezinto ezizwela umswakama; i-high-shear granulation yezidakamizwa eziyinkimbinkimbi; ihlangabezana nemithethonqubo eqinile. |

| Ukucubungula Ukudla | Ukwenza i-granules yesithako esifanayo; ithuthukisa ikhwalithi yomkhiqizo; ihlangabezana nesidingo esikhulayo sokudla okugayiwe. |

| I-Advanced Recycling Technologies | Izixazululo ezisebenzayo ezivela kubadlali ababalulekile; gxila ezindleleni ezingcono ze-granulation nezindlela zokugaywa kabusha. |

| Ukukhula Kwesifunda e-Asia-Pacific | Ukwandiswa eChina, eNdiya naseVietnam; isidingo esinamandla samagranulator ezimbonini eziningi. |

Lokhu kusetshenziswa okusha kusiza izinkampani ukuthi zikhule futhi zifinyelele amakhasimende amaningi. I-granulator yepulasitiki manje idlala indima ebalulekile emikhakheni eminingi, kusukela ekusetshenzisweni kabusha kuya kokudla kanye nemithi.

Izinselele kanye Nekusasa Lokubukeka Kwezimbotshana Zepulasitiki

Izithiyo Zokutholwa Okusabalele

Izinkampani eziningi zifuna ukuthuthukisa izinhlelo zazo zokugaywa kabusha, kodwa izithiyo ezimbalwa ziyazibambezela. Izindleko eziphezulu zangaphambili zenza imishini ethuthukisiwe kube nzima ukuyikhokhela, ikakhulukazi emabhizinisini amancane naphakathi. Isibonelo, ama-shredders e-shaft eyodwa angabiza u-$ 10,000 kuya ku-$ 50,000, kuyilapho amamodeli angama-shaft amane afinyelela ku-$500,000. Izindleko eziqhubekayo zokunakekela nokusebenza zinezela kule nselele. Amanye amabhizinisi akhetha ezinye izindlela ezishibhile, ezikhawulela ukukhula kobuchwepheshe obusha.

Ezinye izithiyo zihlanganisa ubunkimbinkimbi bezobuchwepheshe kanye nesidingo sabasebenzi abanamakhono. Ama-Smart granulators asebenzisa i-IoT ne-AI, kodwa opharetha kufanele bafunde amakhono amasha ukuze bawaqhube kahle. Izinkinga ze-Supply chain kanye nokukhuphuka kwamanani ezinto ezingavuthiwe namandla nakho kwenyusa izindleko. Izinkampani zibhekana nokungaqiniseki ngoba imithethonqubo iyehluka ngokwezindawo. Abakhiqizi bazama ukusiza ngokuklama imishini ebiza kakhulu, ukuthola izingxenye zasendaweni, nokusebenza nabalawuli.

Qaphela: Ukuqeqesha abasebenzi kanye nokwehlisa izindleko kungasiza izinkampani eziningi ukuthi zizitholeleimishini yokugaywa kabusha ethuthukisiwe.

| Umgoqo | Umthelela Ekungenweni |

|---|---|

| Izindleko zokuqala eziphezulu | Ikhawulela ukufinyelela kwamabhizinisi amancane |

| Ubunkimbinkimbi bobuchwepheshe | Idinga opharetha abanamakhono |

| Ukungaqiniseki kokulawula | Yehlisa ukwenza izinqumo |

| Izinkinga ze-Supply chain | Inyusa izindleko zokusebenza |

Intuthuko elindelwe yango-2025 nangaphezulu

Ochwepheshe bezimboni balindele izinguquko ezinkulu eminyakeni embalwa ezayo. Okuzenzakalelayo nezici ezihlakaniphile kuzokwenza imishini isheshe futhi ibe lula ukuyisebenzisa. I-AI ne-IoT izosiza opharetha ukuthi baqaphe izinhlelo, babikezele izinkinga, futhi bonge amandla. Ama-granulator ohlobo lwe-Rotor azothuthukisa ukusika futhi aphathe izinhlobo eziningi zamapulasitiki. Izinkampani zizoklama imishini yokukhipha imfucuza ethile, okwenza ukugaywa kabusha kusebenze kahle kakhulu.

Ukusimama kuzohlala kungumgomo ophezulu. Abakhiqizi bazosebenzisa izinto ezingaphinda zigaywe kabusha kanye nemiklamo ye-modular ukusekela umnotho oyindilinga. Imithetho eqinile yokukhipha umoya nomsindo izoshintsha imikhiqizo emisha. Ukuxhaswa ngezimali kohulumeni nabatshalizimali kuzosheshisa ukusungulwa kobuchwepheshe obuluhlaza. Ukukhula kuzoba namandla e-Asia Pacific, eNyakatho Melika, naseYurophu njengoba izimboni eziningi zidinga izixazululo ezingcono zokugaywa kabusha.

- I-Automation kanye ne-AI kuzothuthukisa ukusebenza kahle.

- Ukuthuthukiswa kwe-modular kuzokwenza imishini ihlale isikhathi eside.

- Izixazululo ezenziwe ngokwezifiso zizolingana nezimboni ezahlukene.

- Imithethonqubo izocindezela ukuthi kutholwe amathuluzi ahlanzekile, athule.

Ithiphu: Izinkampani ezitshala imali emishinini ehlakaniphile, yokonga amandla zizohlala phambili njengoba imakethe ikhula futhi nemithetho ishintsha.

Ukuzenzakalela, ukusebenza kahle kwamandla, kanye nokuphatha izinto ezithuthukisiwe kulolonga ikusasa layo yonke imbudumbudu yepulasitiki. Izinkampani zibona izinzuzo ezifana nezindleko eziphansi, ikhwalithi yomkhiqizo engcono, nokuthobelana kalula.

- Izinzwa ezihlakaniphile kanye ne-automation kuthuthukisa ukukhiqiza.

- Imiklamo yokonga amandla inqamula imfucuza futhi isekela ukusimama.

- Ukwengamela amathrendi amasha kusiza amabhizinisi ukuthi ahlale phambili.

FAQ

Yini eyenza i-granulator yepulasitiki "i-heavy-duty"?

Umsebenzi onzimaipulasitiki granulatorisebenzisa izingxenye eziqinile nezinjini ezinamandla. Ingakwazi ukuphatha izingcezu zepulasitiki eziqinile noma ezinkulu ngaphandle kokubhidliza.

Ingabe izinzwa ezihlakaniphile zisiza kanjani kuma-granulator epulasitiki?

Izinzwa ezihlakaniphile zokubuka impilo nokusebenza komshini. Baxwayisa opharetha ngezinkinga kusenesikhathi. Lokhu kugcina i-granulator isebenza isikhathi eside futhi kunciphisa isikhathi sokuphumula.

Ingabe lezi zimbudumbudu ezintsha zonga amandla?

Yebo! Imiklamo emisha isebenzisa izinjini ezisebenza kahle kakhulu nezilawuli ezihlakaniphile. Lezi zici zisiza izinkampani zehlise izikweletu zamandla futhi zisekele imigomo eluhlaza.

Isikhathi sokuthumela: Aug-13-2025