Vanhu vanoona shanduko huru munzira aplastiki granulatorinoshanda nhasi. Zvichangobva kukwidziridzwa, senge ma sensor akangwara uye ekuchengetedza simba mota, rubatsiromaindasitiri epurasitiki granulatorvashandisi vanocheka mitengo uye kuwedzera kuburitsa. Vazhinji vagadziri vepurasitiki granulator ikozvino vanowedzera kusapfeka-resistant zvikamu, zvichiita imwe neimwegranulator yakasimbakugara kwenguva refu muna aRecycling system.

| Innovation | Kubudirira Kwekushanda | Mutengo-Kubudirira |

|---|---|---|

| Smart Technologies | Real-time monitoring | Inoderedza nguva |

| Kushanda Kwesimba | Simba shoma rinodiwa | Inoderedza mari yekushandisa |

| Advanced Materials | Kuputsika kushoma | Inochengetedza pane zvinotsiva |

Key Takeaways

- Smart sensors uye otomatikikunatsiridza kuita kwepurasitiki granulator nekudzikisa nguva uye kuwedzera kunaka kwechigadzirwa.

- Magetsi anochengetedza magetsiuye dhizaini yepamberi yakadzikira simba rekushandisa uye kucheka mari yekushandisa uchitsigira zvinangwa zvezvakatipoteredza.

- Modular, customizable granulators inokodzera zvakasiyana zvinodiwa, zvichiita kuti kudzokorodza kuve kwakachengeteka, kuri nyore, uye kwakanyanya kushanda kune akawanda maindasitiri.

Automation uye Indasitiri 4.0 muPlastiki Granulator Technology

Smart Sensors uye IoT Kubatanidzwa

Masensa akangwara akachinja mabatiro evashandisi epurasitiki granulator. Aya masensa anoteedzera zvakakosha, senge tembiricha uye kumhanya kwekudya, kuchengetedza michina ichimhanya zvakanaka. Vashandi vanoshandisa masensa ekudzora tembiricha kudzivirira zvinhu kubva pakunyungudika. Otomatiki banga reversal sensors inobatsira kudzivirira jam, saka maitiro haamire. Smart feeding sensors inogadzirisa kuti inokurumidza sei zvinhu kupinda muchina, kuchengetedza zvese zvakatsiga.

- Temperature control sensors inotarisisa tembiricha yekugadzirisa.

- Otomatiki banga reversal sensors inoona jamu uye chengetedza maitiro achifamba.

- Smart feeding sensors inoenderana nekumhanya kwekuisa nehukuru hwemuchina.

Kubatanidzwa kweIoT kunounza zvakatowanda zvikomborero. Vashandi vanogona kutarisa hutano hwemuchina kubva chero kupi vachishandisa kure kure kutarisa. Real-time diagnostics uye PLC yekubatanidza nzvimbo matambudziko kutanga. Kufanotaura kugadzirisa kunobatsira kuronga kugadzirisa kusati kwaitika. Izvi zvinoderedza kuderera uye kuchengetedza mari. Sensors zvakare inotarisa kune nyaya dzakaita sekufa clogging kana mota kuwandisa. Cloud-based platforms inotumira zviyeuchidzo zvekugadzirisa, saka vashandi usakanganwa mabasa anokosha.

Zano: maSmart sensors uye maIoT anotonga anobatsira vashandisi kubata matambudziko nekukurumidza, kuchengetedza michina ichimhanya kwenguva yakareba, uye kugadzirisa mhando yechigadzirwa.

AI-Inofambiswa Maitiro Ekugadzirisa

AI-inotyairwa masisitimu anoita epurasitiki granulator mashandiro akangwara. Aya masisitimu anoshandisa data kugadzirisa marongero senge tembiricha uye screw speed. Vashandi vanoona zvimedu zvishoma uye mamwe mapellets anowirirana. AI inobatsira kuronga kugadzirisa nekuona kupfeka kwemidziyo isati yakonzera dambudziko. Izvi zvinoita kuti michina irambe ichishanda uye inoderedza kugadzirisa kunoshamisa.

- AI inowana zvigadziriso zvakanakisa zvebatch yega yega, ichidzikisa zvirahwe mitengo.

- Predictive maintenance inowedzera uptime uye asset kuvimbika.

- Dhata-inofambiswa nemhando yekudzora inovandudza pellet kufanana uye inosimudza yekutanga-giredhi chigadzirwa mitengo.

- Madhizaini ekuchengetedza magetsi uye kudzoreredza kupisa kunogona kuderedza kushandiswa kwesimba kusvika ku30%.

AI inobatsirawo vashandisi kudzivirira kukanganisa. Automation uye AI inoshanda pamwe chete kuchengetedza saizi yepellet uye mhando dzakatsiga. Kana AI, otomatiki, uye IoT ikabatana nemauto, kubuda kunokwira uye tsvina inodzika. Zvimwe zvivakwa zvinoshandisa muchina kudzidza kuona matambudziko uye kufanotaura kwekugadzirisa zvinodiwa. Aya akangwara ekudzora haasati akajairika, asi mamwe makambani anoronga kuashandisa munguva pfupi. Ramangwana richaunza mamwe ekuzvimiririra maitiro optimization uye ekufungidzira maficha.

Robotics uye Automated Kudyisa

Marobhoti uye otomatiki ekudyisa masisitimu akaita kuti zvivakwa zvepurasitiki zvichengetedzeke uye zvishande. Vibratory feeder vanoshandisa masensa uye mhinduro kuendesa zvinhu nemazvo. Vashandi havachadi kubata mabhegi anorema kana kucheka masaga akavhura zvakare. Marobhoti uye anotakura mita zvinhu kuita granulator, kudzivirira kudyisa kana kudyisa. Izvi zvinochengeta michina yakachengeteka uye inoderedza nguva yekudzikira.

Automated feeding masisitimu anoderedza zvinodiwa zvevashandi. Vashandi vanopedza nguva shoma pamabasa emaoko uye vanotarisana nenjodzi shoma kubva kuguruva kana maturusi akapinza. Plastic Auto Loaders inochengeta zvinhu zvichiyerera, saka michina haimire. Automation zvakare inoderedza tsaona dzine chekuita nekubata nemaoko. Zvivako zvinoona zvirinani kuchengetedzwa uye kushomeka kudiki kwekupindira kwevashandisi.

Ongorora: Marobhoti uye otomatiki ekudyisa masisitimu anodzivirira vashandi uye anobatsira michina kuti ifambe zvakanaka, zvichiita kuti mashandiro epurasitiki egranulator ave akachengeteka uye akavimbika.

Kushanda Kwesimba uye Kusimba muPlastiki Granulator

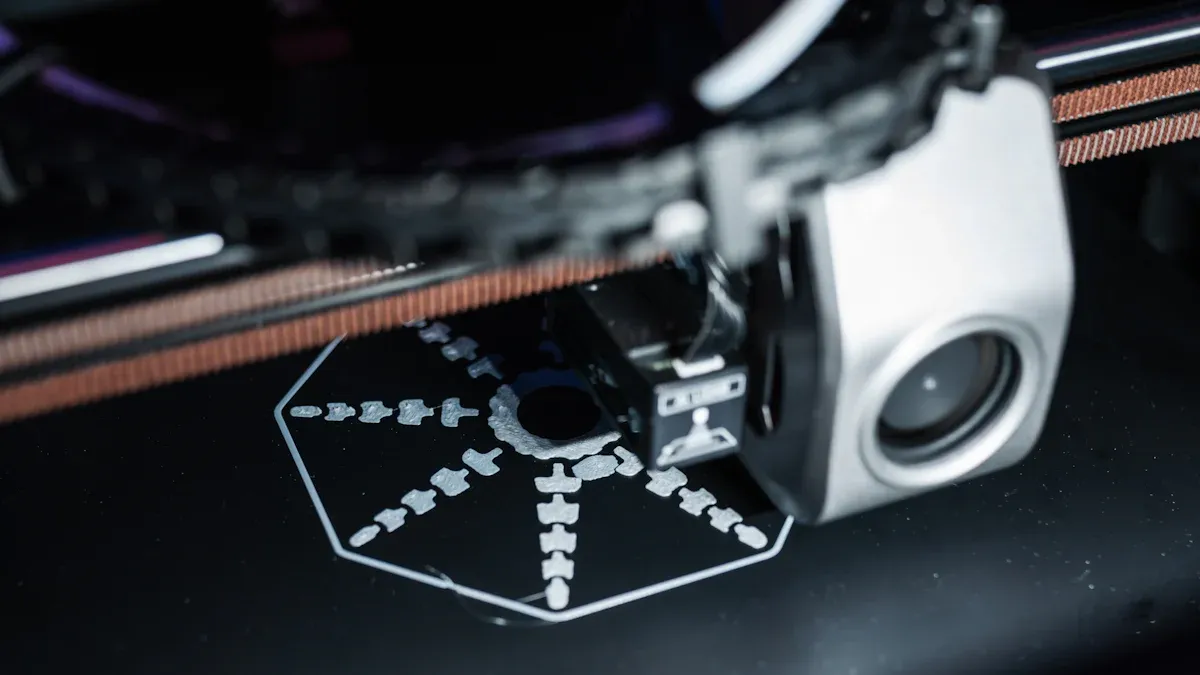

.jpg)

High-Efficiency Motor Systems

Yepamusoro-inoshanda mota masisitimu akachinja mashandisiro anoita zvivakwa simba mukudzoreredza epurasitiki. Idzi mota dzinoshandisa simba shoma pane dzechinyakare. Vashandi vanoona mabhiri emagetsi mashoma uye matambudziko mashoma ekugadzirisa. Mapuranga emazuva ano anopwanya ane mota dzemhando yepamusoro uye akasiyana madhiraivha (VFDs) anogona kucheka kushandiswa kwesimba ne25-30%. Zvivakwa zvakawanda zvinochinja kune aya mota dzinogadzira huwandu hwakafanana hwepurasitiki asi dzinoshandisa shoma pane simba.

- High-effective motors inogadzirisa simba ravo zvichienderana nemutoro. Izvi zvinoreva kuti havasi kutambisa simba kana muchina wacho usina kuzara.

- Low-speed granulators ane mamotor aya anomhanya zvishoma. Vanoita kupisa kushoma uye kupera zvishoma nekukurumidza, izvo zvinochengetedza zvese simba nekugadzirisa mari.

- Yepamberi kudzora masisitimu anobatsira mota kumhanya zvakanyanya kumhanyisa pabasa rega rega. Izvi zvinoita kuti kushandiswa kwesimba kurambe kwakadzikira uye kushanda kwakakwirira.

- Mimwe michina inotova nehurongwa hwekudzoreredza simba. Aya masisitimu anotora kupisa kwakawedzera uye oita magetsi, achichengetedza mari yakawanda.

Vashandi vanoona kuti mutengo wepamusoro wemota idzi unobhadhara nekufamba kwenguva. Vanopedza zvishoma pane simba nekugadzirisa, zvichiita kuti hurongwa hwose huve hwakasimba.

Magadzirirwo Anochengetedza Simba

Vagadziri ikozvino vanovaka mapurasitiki granulator ane smart maficha anochengetedza simba mazuva ese. Idzi shanduko dzekugadzira dzinobatsira makambani kusangana nezvinangwa zvawo zvakasvibirira uye mitengo yakaderera. Tafura iri pazasi inoratidza mamwe anonyanya kushanda ekuchengetedza magetsi uye mabhenefiti awo:

| Dhizaini Feature | Kubatsira Kwekuchengetedza Simba |

|---|---|

| Simba rekuchengetedza yakaderera bhiza mota | Inoderedza kushandiswa kwesimba rose |

| Screenless cutter dzimba | Inodzikisa kumhanya kwerotor uye inoderedza faindi, inovandudza kushanda kwesimba |

| Ultra-yakaderera rotor kumhanya | Inoderedza kushandiswa kwesimba uku uchichengetedza granule mhando |

| Multi-tooth rotor ine mazino anopinza zvakare | Inochengetedza kucheka kushanda zvakanaka, kuderedza kutambisa simba nekufamba kwenguva |

| Dual flywheel yakakwira torque dhizaini | Inobata zvinhu zvakaoma zvinobudirira, kuderedza kupera kwesimba |

| Twinshear banga kugadzira | Inovandudza kucheka kushanda, kushandisa simba shoma |

| Split chamber | Inobvumira kukurumidza kucheneswa, kuderedza nguva uye kushandisa simba |

| Yakasimbiswa heavy duty screen cradle | Inowedzera kusimba, kuderedza kurasikirwa kwesimba nekuda kwekupfeka |

Mamwe mamodheru matsva, senge CMG Granulators 'EV Series, shandisa epamberi ekucheka maumbirwo uye smart drive masisitimu. Shanduko idzi dzinogona kucheka kushandiswa kwesimba kusvika pa50% zvichienzaniswa nemichina yechikuru. Mazhinji ekuchengetedza simba anobva pakunhonga saizi chaiyo yemota uye kushandisa zvidzori zvinoshandisa simba. Vashandi vanoshandisa madhizaini aya vanoona madonhwe makuru mumabhiri emagetsi avo uye nguva shoma yekugadzirisa.

Zano: Kusarudza epurasitiki granulator ine simba rekuchengetedza zvinhu zvinobatsira makambani kuchengetedza mari uye kuchengetedza zvakatipoteredza panguva imwe chete.

Eco-Hushamwari uye Recyclable Zvikamu

Sustainability ikozvino ndiyo inonyanya kukosha kumakambani mazhinji. Vanoda michina inogara kwenguva yakareba uye inogadzira tsvina shoma. Eco-inoshamwaridzika uye inodzokororwa zvikamu mumapurasitiki granulator zvinobatsira kuzadzisa izvi zvinangwa. Zvikamu izvi zvinoshandisa zviwanikwa zvishoma uye zvinoita kuti kudzokorora kuve nyore.

- Eco-hushamwari zvikamu zvinoderedza marara epurasitiki uye kuchengetedza simba.

- Tekinoroji dzepamberi, senge AI-inotyairwa kuronga, inovandudza mhando yemapurasitiki akadzokororwa.

- Mitemo, yakadai seBasel Convention neRoHS, inosundidzira makambani kushandisa michina yakasvibira.

- Kukurudzira kwemari, sekuzorora kwemutero, kunokurudzira kudyara mune eco-inoshamwaridzika yekudzokorodza michina.

- Modular uye mobile recycling units inoderedza kuburitsa uye kuita kuti kudzokorodza kusvike nyore.

Vagadziri zvino vanotarisa kusangana neEnvironment, Social, uye Governance (ESG) zviyero. Vanoshandisa magadzirirwo emagetsi uye zvinhu zvakachengeteka kusangana nemitemo yakasimba. Shanduko idzi dzinobatsira makambani kutevedzera mutemo uye kuratidza vatengi vane hanya nepasi. Nekushandisa eco-hushamwari epurasitiki granulator, makambani anotsigira hupfumi hwedenderedzwa uye kuderedza kabhoni tsoka.

Yepamberi Zvishandiso Kubata uye Kugadzirisa muPlastiki Granulator

Modular uye Compact Dhizaini

Vagadziri ikozvino vanovaka modular uye compact granulator inokodzera munzvimbo dzakasimba. Michina iyi inobatsira mashopu madiki uye mafekitori makuru kuchengetedza nzvimbo yepasi. Vashandi vanogona kuisa compact granulator padyo nemitsetse yekugadzira. Kuseta uku kunoita kuti vagadzirise zvimedu nekukasira, izvo zvinodzikisira mari yekubata zvinhu. Modular dhizaini inobvumira kukurumidza kukwidziridzwa kana kugadzirwa kunoda shanduko. Matimu anogona kuchinjanisa mablades kana rotor mumaawa mashoma. Uku kushanduka kunoreva kushomeka nguva uye nekukurumidza kugadzirisa. Mazhinji mayuniti anosanganisirawo kuderedza ruzha uye maficha ekudzvinyirira guruva, zvichiita kuti nzvimbo yebasa ive yakachengeteka uye ine runyararo. Smart sensors uye chaiyo-nguva yekutarisa inobatsira vashandisi kuona matambudziko nekukurumidza, saka kugadzirisa kunoitika kusati kwaparara.

Zano: Modular uye compact dhizaini inoita kuti kuisirwa kuve nyore uye kutsigira pa-saiti kudzokorodza, izvo zvinowedzera kushanda nesimba uye kudzikisira matambudziko ekugadzirisa.

Kugadzirisa Complex uye Yakasanganiswa Plastics

Kudzoreredza mapurasitiki akasanganiswa kwakaoma, asi matekinoroji matsva anoita kuti zvive nyore. AI-powered kurongedza masisitimu anoshandisa makamera nemasensor kuparadzanisa marudzi akasiyana emapurasitiki. Magnetic uye optical yekuronga michina inobvisa simbi nezvimwe zvinosvibisa pamberi pegranulation. Mimwe michina inoshandisa makemikari kudzokorodza kuputsa mapurasitiki pasi muzvikamu zvawo zvakakosha. Idzi nzira dzinobatsira vashandisi kuwana zvinhu zvakacheneswa zvakadzokororwa uye nepamusoro pekupinda. Vibratory feeders uye screeners anoparadzira purasitiki, saka kuronga kunoshanda zvirinani. Aya nhanho anodzivirira epurasitiki granulator uye anovandudza mhando yemapellets akadzokororwa. Vashandi vanoona kukurumidza kugadzirisa nguva uye kuderera kwesimba mari.

- Kurongeka kunofambiswa neAI kunovandudza kuchena.

- Magnetic uye optical systems inobvisa tsvina.

- Kudzokorodza kwemakemikari kunogadzira zvinhu zvemhando yepamusoro.

Tailored Solutions for Industry Needs

Makambani anoda granulators inoenderana nezvavanoda zvakasiyana. Vagadziri vanoteerera zvikumbiro zvevatengi uye michina yekugadzira ine akakosha maficha. Mamwe mayunitsi ane makamera ekutarisisa-nguva chaiyo panzvimbo dzakakosha. Metal detectors inochengeta zvinhu zvisingadiwe kunze, zvichiita kuti zvigadzirwa zvive zvakachengeteka. Zvigadziriso zvinorongwa zvinorega vashandisi kuseta tembiricha, kumhanya, uye kumanikidza. Vacuum exhaust masisitimu anobvisa huruva uye unyoro, kuchengetedza zvinobuda zvakachena. Kutonhodzwa kwemvura kunomisa zvidimbu kubva pakugwamba. Aya maitiro echivanhu anobatsira makambani kuchengetedza simba uye kusangana nemitemo yakasimba yezvakatipoteredza. Zvikwata zvinowana kudzidziswa uye kutsigirwa mushure mekuiswa, saka vanoshandisa michina nemazvo.Tsika mhindurobatsira makambani kukura uye kuramba akavimbika.

| Custom Feature | Benefit |

|---|---|

| Real-time monitoring | Inovandudza hutano hwehutano |

| Kuonekwa kwesimbi | Kunowedzera kuchengeteka |

| Programmable controls | Inowedzera kushanda zvakanaka |

| Vacuum exhaust | Inochengeta zvinobuda zvakachena |

| Kutonhora kwemvura | Inodzivirira kugwamba |

Musika Impact uye Kutorwa kwePlastiki Granulator Innovations

Kuwedzera Indasitiri Uptake

Vagadziri nevagadziri vanofamba nekukurumidza kutora tekinoroji nyowani yepurasitiki yegranulator. Ivo vanoona mabhenefiti makuru kubva kuzvinhu zvakaita seIoT-inogonesa yekutarisa uye AI-inotyairwa kufungidzira kugadzirisa. Aya ekusimudzira anobatsira kuderedza nguva yekudzikira uye kuderera kwemitengo. Yakanatsiridzwa blade dhizaini uye yakasimba zvinhu zvinoita kuti makambani agadzirise mapurasitiki akasanganiswa ane dambudziko shoma. Mitemo yezvakatipoteredza, yakadai seEU Circular Economy Action Plan uye Extended Producer Responsibility, inosundidzira makambani kuisa mari mumichina yepamusoro. Vanhu vazhinji vane hanya nekugadzikana, saka kudiwa kwema compact, nhare, uye simba-rinoshanda granulator kunoramba kuchikwira. Zvikwata zvinoshanda pamwechete kugadzira uye kutangamhando itsvafaster. Zvinokurudzira zvehupfumi, semitengo yakaderera yekushandisa uye kuteedzera kuri nyore, zvakare kukurumidzisa kugamuchirwa. Kukura kwakasimba muNorth America, Europe, uye Asia Pacific nekuda kwekuda kwemusika uye kumanikidza kwekudzora.

- IoT uye AI inoratidzira inowedzera kushanda zvakanaka.

- Zvigadzirwa zvitsva zveblade zvinobata mapurasitiki akasanganiswa.

- Mitemo uye zvinangwa zvekusimudzira zvinofambisa mari.

- Compact uye mobile michina inosangana nezvinodiwa zvinochinjika.

- Mabhenefiti ehupfumi anokurudzira kuvandudzwa.

Meeting Regulatory and Environmental Standards

Makambani anotarisana nemitemo yakasimba yekudzokorodza uye kutonga kwemarara. Hutsva muhunyanzvi hwekugadzira granulator yepurasitiki inovabatsira kuzadzisa zviyero izvi. Otomatiki uye AI rongedza zvinhu uye bvisa zvinosvibisa nehupamhi hwechokwadi. Kuchenesa kusina mvura uye nzira dzakaoma-kugadzirisa dzinocheka kushandiswa kwemvura uye kuderedza mvura yetsvina. Energy recovery modules inotora kupisa uye kuishandura kuita magetsi, ichidzikisa kudiwa kwesimba. Digital yekutarisa masisitimu inoteedzera kutevedzera uye kugadzirisa munguva chaiyo. Michina mizhinji ikozvino inotevera mitemo yeRoHS kudzikamisa zvinhu zvine njodzi. Green electronics zviyero zvinobatsira kuderedza kabhoni emissions. Advanced filtration systems inoita kuti utsi netsvina dzive shoma. Modular dhizaini inoita kuti zvive nyore kugadzirisa michina yemitemo mitsva.

- Automation uye AI inovandudza kuronga uye kugadzirisa.

- Kuchenesa kusina mvura kunochengetedza zviwanikwa.

- Kudzosa simba kunoderedza kushandiswa kwesimba.

- Digital monitoring inovimbisa kutevedza.

- Modular midziyo inoenderana nekuchinja mitemo.

Kuwedzera Zvishandiso uye Zvikamu Zvikamu

Kuvandudzwa mune inorema-basa granulator inovhura mikova kumisika mitsva. Makambani anoshandisa michina iyi kwete kungodzokorora zvakare. Tafura iri pazasi inoratidza zvimwe zvinokura zvikamu uye mashandisiro azvo makuru:

| Emerging Market Segment | Kutyaira Zvishandiso / Kukura Vatyairi |

|---|---|

| Sustainable Plastic Recycling | Kugadzira tsvina yemashure evatengi kuita magranules anogona kushandiswazve; inotsigira hupfumi hwedenderedzwa uye kusimba. |

| Pharmaceutical Granulation | Dry granulators for mwando-sensitive materials; high-shear granulation yemishonga yakaoma; inosangana nemitemo yakasimba. |

| Food Processing | Kugadzira yunifomu ingredient granules; inovandudza kunaka kwechigadzirwa; inosangana nekudiwa kuri kuwedzera kwezvekudya zvakagayiwa. |

| Advanced Recycling Technologies | Mhinduro dzinoshanda kubva kuvatambi vanokosha; tarisa pane zviri nani granulation uye nzira dzekudzokorora. |

| Kukura Kwedunhu muAsia-Pacific | Kuwedzera muChina, India, neVietnam; kudiwa kwakasimba kwemagranulator mumaindasitiri mazhinji. |

Aya mashandisirwo matsva anobatsira makambani kukura uye kusvika kune vatengi vakawanda. Iyo granulator yepurasitiki ikozvino inoita basa rakakosha muzvikamu zvakawanda, kubva pakudzokorodza kusvika kuchikafu nemishonga.

Matambudziko uye Ramangwana Maonero ePlastiki Granulator

Zvipingamupinyi Pakurerwa Kwevana Kwakawanda

Makambani mazhinji anoda kukwidziridza masisitimu avo ekudzokorodza, asi zvipingamupinyi zvakati wandei zvinovanonotsa. Mitengo yepamusoro yepamberi inoita kuti michina yepamberi iome kutenga, kunyanya kumabhizinesi madiki nepakati. Semuenzaniso, single-shaft shredders inogona kuita $10,000 kusvika $50,000, nepo mana-shaft modhi inosvika $500,000. Mari inoshandiswa pakugadzirisa uye kushanda kwayo inowedzera dambudziko racho. Mamwe mabhizinesi anosarudza dzimwe nzira dzakachipa, izvo zvinotadzisa kukura kwehunyanzvi hutsva.

Zvimwe zvipingamupinyi zvinosanganisira kuoma kwehunyanzvi uye kudiwa kwevashandi vane hunyanzvi. Smart granulators vanoshandisa IoT neAI, asi vashandisi vanofanirwa kudzidza hunyanzvi hutsva kuti vamhanye nemazvo. Supply cheni matambudziko uye kukwira mitengo yezvinhu mbishi uye simba anowedzerawo mari. Makambani anotarisana nekusava nechokwadi nekuti mitemo inosiyana munzvimbo nenzvimbo. Vagadziri vanoedza kubatsira nekugadzira michina isingadhuri, kutsvaga zvikamu munharaunda, uye kushanda nevanodzora.

Cherechedza: Kudzidzisa vashandi uye kuderedza mitengo kunogona kubatsira mamwe makambani kutoraadvanced recycling midziyo.

| Barrier | Impact pane Adoption |

|---|---|

| Mutengo wekutanga wakakwira | Inoganhurira kuwana mabhizimisi madiki |

| Technical yakaoma | Inoda vashandi vane hunyanzvi |

| Regulatory kusava nechokwadi | Inononoka kuita sarudzo |

| Supply chain issues | Inokwidza mari yekushandisa |

Zvinotarisirwa Kubudirira kwe2025 uye Kupfuura

Nyanzvi dzemaindasitiri dzinotarisira shanduko huru mumakore mashoma anotevera. Automation uye akangwara maficha achaita kuti michina ikurumidze uye nyore kushandisa. AI neIoT ichabatsira vashandisi kutarisa masisitimu, kufanotaura matambudziko, uye kuchengetedza simba. Rotor-mhando granulator inovandudza kucheka uye kubata mamwe marudzi emapurasitiki. Makambani achagadzira michina yeaya chaiwo hova dzemarara, zvichiita kuti kudzokorodza kushande.

Sustainability icharamba iri chinangwa chepamusoro. Vagadziri vachashandisa zvinhu zvinodzokororwa uye modular dhizaini kutsigira hupfumi hwedenderedzwa. Mitemo yakaoma yekuburitsa uye ruzha ichagadzira zvigadzirwa zvitsva. Mari kubva kuhurumende uye vanoisa mari ichakurumidza kuvandudza tekinoroji. Kukura kuchave kwakasimba muAsia Pacific, North America, uye Europe sezvo mamwe maindasitiri arikuda mhinduro dziri nani dzekudzokorora.

- Automation uye AI ichawedzera kushanda zvakanaka.

- Modular upgrades ichaita kuti michina igare kwenguva refu.

- Tsika mhinduro dzichakodzera maindasitiri akasiyana.

- Regulations inosundira kune yakachena, yakanyarara michina.

Zano: Makambani anoisa mari mumakina akangwara, anochengetedza simba acharamba ari mberi sezvo musika uchikura uye mitemo ichichinja.

Otomatiki, kugona kwesimba, uye zvepamberi zvinhu zvinogadzirisa zvinogadzirisa ramangwana rega rega epurasitiki granulator. Makambani anoona mabhenefiti akaita semitengo yakaderera, mhando yezvigadzirwa zviri nani, uye kuteedzera kuri nyore.

- Smart sensors uye otomatiki inowedzera kugadzirwa.

- Magadzirirwo ekuchengetedza magetsi anocheka marara uye anotsigira kusimudzira.

- Kuongorora mafambiro matsva kunobatsira mabhizinesi kuramba ari mberi.

FAQ

Chii chinoita kuti plastiki granulator "inorema-basa"?

A heavy-dutyplastiki granulatorinoshandisa zvikamu zvakasimba uye injini dzine simba. Inogona kubata yakaoma kana yakakura zvidimbu zvepurasitiki pasina kuputsa.

Masensa akangwara anobatsira sei mumapurasitiki granulator?

Smart sensors tarisa hutano hwemuchina uye kuita. Vanozivisa vashandisi nezvematambudziko nekukurumidza. Izvi zvinoita kuti granulator ishande kwenguva yakareba uye inoderedza nguva yekudzikira.

Aya magranulator matsva anogona kuchengetedza simba here?

Ehe! Zvigadzirwa zvitsva zvinoshandisa mota dzepamusoro-soro uye akangwara kudzora. Aya maficha anobatsira makambani kudzikisa mabhiri emagetsi uye kutsigira girinhi zvinangwa.

Nguva yekutumira: Aug-13-2025