Anthu amawona kusintha kwakukulu m'njira apulasitiki granulatorzikugwira ntchito lero. Zosintha zaposachedwa, monga masensa anzeru ndi ma mota opulumutsa mphamvu, zimathandizamafakitale pulasitiki granulatorogwiritsa ntchito kuchepetsa mtengo ndi kulimbikitsa zotuluka. Opanga pulasitiki ambiri opanga granulator tsopano akuwonjezera magawo osamva kuvala, kupanga chilichonsegranulator wamphamvukukhala motalika mu aNjira yobwezeretsanso.

| Zatsopano | Kuchita Mwachangu | Mtengo-Kuchita bwino |

|---|---|---|

| Smart Technologies | Kuwunika nthawi yeniyeni | Amachepetsa nthawi yopuma |

| Mphamvu Mwachangu | Mphamvu zochepa zofunika | Amachepetsa ndalama zoyendetsera ntchito |

| Zida Zapamwamba | Zowonongeka zochepa | Zimapulumutsa pazosintha |

Zofunika Kwambiri

- Masensa anzeru ndi automationsinthani magwiridwe antchito a pulasitiki granulator pochepetsa nthawi yopumira komanso kukulitsa mtundu wazinthu.

- Ma motors opulumutsa mphamvundi mapangidwe apamwamba amachepetsa kugwiritsa ntchito mphamvu ndikuchepetsa ndalama zogwirira ntchito kwinaku akuthandizira zolinga zachilengedwe.

- Ma modular, osinthika makonda amakwaniritsa zosowa zosiyanasiyana, kupangitsa kuti zobwezeretsanso zikhale zotetezeka, zosavuta, komanso zogwira mtima pamafakitale ambiri.

Zodzichitira ndi Makampani 4.0 mu Pulasitiki Granulator Technology

Smart Sensors ndi IoT Integration

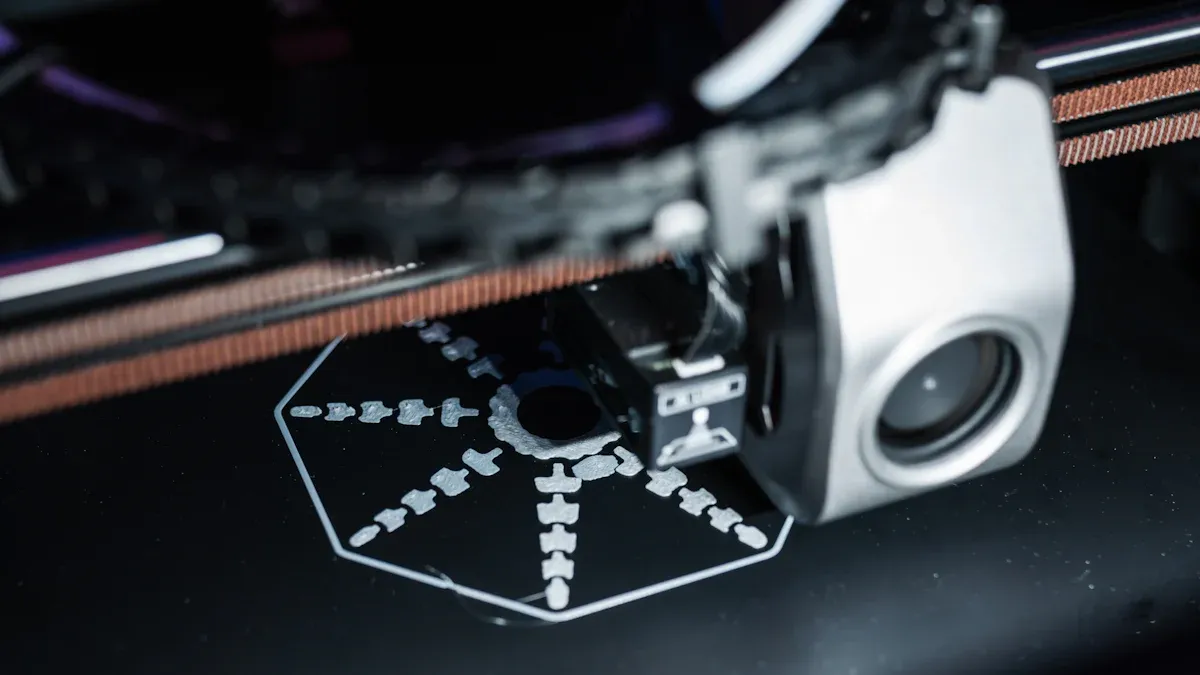

Masensa anzeru asintha momwe ogwira ntchito amayendetsera granulator ya pulasitiki. Masensa awa amatsata zofunikira, monga kutentha ndi kuthamanga kwa chakudya, kuti makina aziyenda bwino. Oyendetsa amagwiritsa ntchito masensa owongolera kutentha kuti aletse zinthu kuti zisasungunuke. Makina osinthira mipeni odzichitira okha amathandizira kupewa kupanikizana, kotero kuti ntchitoyi siyiyime. Masensa a Smart feeding amasintha momwe zinthu zimalowera mwachangu pamakina, ndikupangitsa chilichonse kukhala chokhazikika.

- Kutentha kulamulira masensa kuwunika processing kutentha.

- Makina osinthira mipeni odziwikiratu amazindikira kupanikizana ndikupitilizabe kuyenda.

- Masensa a Smart feeding amafananiza liwiro lolowera ndi kuchuluka kwa makina.

Kuphatikiza kwa IoT kumabweretsa zabwino zambiri. Othandizira amatha kuyang'ana thanzi la makina kulikonse pogwiritsa ntchito kuwunika kwakutali. Kuzindikira zenizeni zenizeni ndi zovuta zophatikizana za PLC koyambirira. Kukonzekera kodziwikiratu kumathandizira kukonza kukonza zisanachitike. Izi zimachepetsa nthawi yopuma ndikusunga ndalama. Masensa amawoneranso zinthu monga kutsekeka kwa kufa kapena kulemetsa kwa injini. Mapulatifomu opangidwa ndi mtambo amatumiza zikumbutso kuti akonzere, kotero ogwira ntchito musaiwale ntchito zofunika.

Langizo: Masensa anzeru ndi maulamuliro a IoT amathandizira ogwiritsa ntchito kuzindikira zovuta, kusunga makina nthawi yayitali, komanso kukonza zinthu zabwino.

Kukhathamiritsa kwa Njira Yoyendetsedwa ndi AI

Makina oyendetsedwa ndi AI amapangitsa kuti ntchito za pulasitiki za granulator zikhale zanzeru. Makinawa amagwiritsa ntchito data kusintha zochunira monga kutentha ndi liwiro la screw. Ogwira ntchito amawona zida zocheperapo komanso ma pellets osakanikirana. AI imathandizira kukonza zokonza powona zida zomwe zidavala zisanadzetse vuto. Izi zimathandizira kuti makina azigwira ntchito ndikuchepetsa kukonza modzidzimutsa.

- AI imapeza makonda abwino kwambiri pa batch iliyonse, kutsitsa mitengo yazachuma.

- Kukonza zolosera kumawonjezera nthawi yokhazikika komanso kudalirika kwazinthu.

- Kuwongolera khalidwe loyendetsedwa ndi deta kumapangitsa kuti pellet ikhale yofanana komanso imakweza mitengo yamtengo wapatali.

- Mapangidwe opulumutsa mphamvu ndi kubwezeretsa kutentha amatha kuchepetsa kugwiritsa ntchito mphamvu mpaka 30%.

AI imathandizanso ogwiritsa ntchito kupewa zolakwika. Automation ndi AI zimagwirira ntchito limodzi kuti ma pellet asamayende bwino komanso kuti azikhala bwino. Pamene AI, automation, ndi IoT zilumikizana, zotuluka zimakwera ndipo zinyalala zimatsika. Malo ena amagwiritsa ntchito kuphunzira pamakina kuti awone zovuta komanso zolosera zokonzekera. Kuwongolera mwanzeru uku sikunali koyenera, koma makampani ambiri akukonzekera kuzigwiritsa ntchito posachedwa. Tsogolo lidzabweretsa kukhathamiritsa kwazinthu zodziyimira pawokha komanso zolosera.

Ma robotiki ndi Kudyetsa Kokha

Ma robotiki ndi njira zodyetserako zokha zapangitsa kuti malo opangira pulasitiki kukhala otetezeka komanso ogwira mtima. Ma vibratory feeders amagwiritsa ntchito masensa ndi mayankho kuti apereke zinthu molondola. Oyendetsa safunikanso kunyamula matumba olemera kapena kudula matumba otsegula. Maloboti ndi ma conveyor mita zinthu kukhala granulator, kupewa kudya mopitirira muyeso kapena kusayamwitsa. Izi zimapangitsa makina kukhala otetezeka komanso kuchepetsa nthawi yopuma.

Njira zodyetserako zokha zimachepetsa zofuna za ogwira ntchito. Ogwira ntchito amathera nthawi yochepa pa ntchito zamanja ndipo amakumana ndi zoopsa zochepa kuchokera ku fumbi kapena zida zakuthwa. Ma Plastic Auto Loaders amapangitsa kuti zinthu ziziyenda bwino, motero makina samayima. Makinawa amachepetsanso ngozi zolumikizidwa ndi kasamalidwe kamanja. Maofesi amawona zotsatira zabwinoko zachitetezo komanso kufunikira kocheperako kwa othandizira.

Zindikirani: Maloboti ndi makina odyetsera okhawo amateteza ogwira ntchito ndikuthandizira makina kuti aziyenda bwino, zomwe zimapangitsa kuti ntchito zamapulasitiki zizikhala zotetezeka komanso zodalirika.

Kuchita Mwachangu ndi Kukhazikika mu Pulasitiki Granulator

.jpg)

Makina Ogwiritsa Ntchito Magalimoto Apamwamba

Makina oyendetsa bwino kwambiri asintha momwe malo amagwiritsira ntchito mphamvu pakubwezeretsanso pulasitiki. Ma injiniwa amagwiritsa ntchito mphamvu zochepa kusiyana ndi akale. Ogwira ntchito amawona mabilu amagetsi otsika komanso zovuta zowongolera. Ma crushers amakono apulasitiki okhala ndi ma mota othamanga kwambiri komanso ma frequency frequency drives (VFDs) amatha kuchepetsa kugwiritsa ntchito mphamvu ndi 25-30%. Malo ambiri omwe amasinthira ku ma motors awa amapanga pulasitiki yofanana koma amawononga mphamvu zochepa.

- Ma motors apamwamba kwambiri amasintha mphamvu zawo potengera katundu. Izi zikutanthauza kuti samawononga mphamvu pamene makina sali odzaza.

- Ma granulator otsika omwe ali ndi ma motor awa amayenda pang'onopang'ono. Amapanga kutentha pang'ono ndikutha msanga, zomwe zimapulumutsa mphamvu zonse ndi kukonza ndalama.

- Machitidwe owongolera apamwamba amathandizira injini kuthamanga pa liwiro labwino kwambiri pantchito iliyonse. Izi zimapangitsa kuti kugwiritsa ntchito mphamvu kukhala kochepa komanso kuti ntchito ikhale yokwera.

- Makina ena amakhala ndi njira zopezera mphamvu. Makinawa amatenga kutentha kwina ndikusandutsa magetsi, kupulumutsa ndalama zambiri.

Othandizira amapeza kuti mtengo wokwera wam'tsogolo wa ma motorswa umalipira pakapita nthawi. Amawononga ndalama zochepa pa mphamvu ndi kukonza, zomwe zimapangitsa kuti ntchito yonseyi ikhale yokhazikika.

Mapangidwe Opulumutsa Mphamvu

Opanga tsopano amamanga ma granulator apulasitiki okhala ndi zinthu zanzeru zomwe zimapulumutsa mphamvu tsiku lililonse. Kusintha kwapangidwe kumeneku kumathandiza makampani kukwaniritsa zolinga zawo zobiriwira komanso kuchepetsa ndalama. Gome ili m'munsili likuwonetsa zina mwazinthu zopulumutsa mphamvu komanso zopindulitsa zake:

| Chojambula Chojambula | Phindu Lopulumutsa Mphamvu |

|---|---|

| Ma motors opulumutsa mphamvu otsika pamahatchi | Amachepetsa kugwiritsa ntchito mphamvu zonse |

| Screenless cutter nyumba | Imachepetsa kuthamanga kwa rotor ndikuchepetsa chindapusa, kupititsa patsogolo mphamvu zamagetsi |

| Kuthamanga kwambiri kwa rotor | Imachepetsa kugwiritsa ntchito mphamvu ndikusunga mtundu wa granule |

| Multi-tooth rotor yokhala ndi mano okuthwanso | Imasunga bwino kudula, kuchepetsa kuwononga mphamvu pakapita nthawi |

| Mapangidwe amtundu wa ma torque apawiri | Imagwira bwino zinthu zolimba, kuchepetsa kutaya mphamvu |

| Mapangidwe a mpeni wa Twinshear | Kupititsa patsogolo kudula, kugwiritsa ntchito mphamvu zochepa |

| Gawani chipinda | Amalola kuyeretsa mwachangu, kuchepetsa nthawi yopumira komanso kugwiritsa ntchito mphamvu |

| Choyika chotchinga chowonjezera cholemetsa | Kumawonjezera kulimba, kuchepetsa kutaya mphamvu chifukwa cha kuvala |

Mitundu ina yatsopano, monga CMG Granulators 'EV Series, imagwiritsa ntchito mawonekedwe odulira apamwamba komanso makina oyendetsa anzeru. Zosinthazi zitha kuchepetsa kugwiritsa ntchito mphamvu mpaka 50% poyerekeza ndi makina akale. Ndalama zambiri zopulumutsa mphamvu zimabwera chifukwa chosankha kukula kwa injini yoyenera ndikugwiritsa ntchito zowongolera zowongola mphamvu. Ogwira ntchito omwe amagwiritsa ntchito mapangidwewa amawona madontho akulu m'mabilu awo amagetsi komanso nthawi yochepa yokonzekera.

Langizo: Kusankha granulator ya pulasitiki yokhala ndi zinthu zopulumutsa mphamvu kumathandiza makampani kusunga ndalama komanso kuteteza chilengedwe nthawi yomweyo.

Zothandiza pa Eco-Friendly ndi Recyclable Components

Kukhazikika tsopano ndichinthu chofunikira kwambiri kwamakampani ambiri. Amafuna makina omwe amakhala nthawi yayitali komanso kupanga zinyalala zochepa. Zida zokomera zachilengedwe komanso zobwezerezedwanso m'magalasi apulasitiki zimathandizira kukwaniritsa zolingazi. Zigawozi zimagwiritsa ntchito zinthu zochepa komanso zimapangitsa kuti zobwezeretsanso zikhale zosavuta.

- Zida zogwiritsira ntchito zachilengedwe zimachepetsa zinyalala za pulasitiki ndikupulumutsa mphamvu.

- Ukadaulo wapamwamba kwambiri, monga kusanja motsogozedwa ndi AI, umakweza mtundu wa mapulasitiki obwezerezedwanso.

- Malamulo, monga Basel Convention ndi RoHS, amakakamiza makampani kugwiritsa ntchito makina obiriwira.

- Zolimbikitsa zachuma, monga nthawi yopuma misonkho, zimalimbikitsa kugulitsa zida zobwezeretsanso zachilengedwe.

- Ma modular ndi ma modular recycling unit amachepetsa mpweya wotulutsa ndikupangitsa kuti zobwezeretsanso zitheke.

Opanga tsopano amayang'ana kwambiri pakukwaniritsa miyezo ya Environmental, Social, and Governance (ESG). Amagwiritsa ntchito mapangidwe opangira mphamvu komanso zinthu zotetezeka kuti akwaniritse malamulo okhwima. Zosinthazi zimathandiza makampani kutsatira malamulo ndikuwonetsa makasitomala kuti amasamala za dziko. Pogwiritsa ntchito ma granulator apulasitiki ochezeka, makampani amathandizira chuma chozungulira ndikuchepetsa kuchuluka kwa mpweya wawo.

Kusamalira Zida Zapamwamba ndi Kusintha Mwamakonda mu Pulasitiki Granulator

Ma Modular ndi Compact Designs

Opanga tsopano amapanga ma modular ndi compact granulator omwe amakwanira mumipata yothina. Makinawa amathandiza malo ogwirira ntchito ang'onoang'ono komanso mafakitale akuluakulu kuti asunge malo pansi. Ogwiritsa ntchito amatha kuyika ma granulator ophatikizika pafupi ndi mizere yopanga. Kukonzekera uku kumawalola kuti azingotaya nthawi yomweyo, zomwe zimachepetsa ndalama zogwirira ntchito. Mapangidwe a modular amalola kukweza mwachangu pamene kupanga kukufunika kusintha. Magulu amatha kusinthana masamba kapena ma rotor m'maola ochepa chabe. Kusinthasintha kumeneku kumatanthauza nthawi yocheperako komanso kukonza mwachangu. Magawo ambiri amaphatikizanso zochepetsera phokoso komanso zoletsa fumbi, zomwe zimapangitsa kuti malo ogwira ntchito azikhala otetezeka komanso opanda phokoso. Masensa anzeru komanso kuyang'anira nthawi yeniyeni amathandizira ogwiritsa ntchito kuwona zovuta msanga, kotero kukonza kumachitika zisanachitike.

Langizo: Mapangidwe amtundu wa modular ndi ophatikizika amapangitsa kukhazikitsa kukhala kosavuta komanso kuthandizira kukonzanso pamalowo, komwe kumathandizira bwino ndikuchepetsa zovuta zokonza.

Processing Complex ndi Mixed Pulasitiki

Kubwezeretsanso mapulasitiki osakanikirana ndizovuta, koma matekinoloje atsopano amachititsa kuti zikhale zosavuta. Makina osankhidwa a AI amagwiritsa ntchito makamera ndi masensa kuti alekanitse mitundu yosiyanasiyana ya mapulasitiki. Zida zosinthira maginito ndi kuwala zimachotsa zitsulo ndi zonyansa zina musanayambe granulation. Makina ena amagwiritsa ntchito mankhwala obwezeretsanso kuti aswe mapulasitiki m'zigawo zawo zoyambira. Njirazi zimathandiza ogwira ntchito kupeza zinthu zoyeretsera zobwezerezedwanso komanso kutulutsa kwapamwamba. Zodyetsa zogwedera ndi zowonera zimayala pulasitiki, kotero kusanja kumagwira ntchito bwino. Izi zimateteza granulator ya pulasitiki ndikuwongolera ma pellets obwezerezedwanso. Othandizira amawona nthawi yofulumira komanso yotsika mtengo yamagetsi.

- Kusankha koyendetsedwa ndi AI kumakulitsa chiyero.

- Magnetic ndi optical systems amachotsa zonyansa.

- Kubwezeretsanso mankhwala kumapanga zida zapamwamba kwambiri.

Tailored Solutions for Industry Zofuna

Makampani amafuna ma granulator omwe amagwirizana ndi zosowa zawo zapadera. Opanga amamvetsera zopempha za makasitomala ndi makina opangira omwe ali ndi mawonekedwe apadera. Mayunitsi ena ali ndi makamera owunikira nthawi yeniyeni pamalo ofunikira. Zowunikira zitsulo zimasunga zinthu zosafunika, zomwe zimapangitsa kuti zinthu zikhale zotetezeka. Zowongolera zomwe zingatheke zimalola ogwiritsa ntchito kukhazikitsa kutentha, liwiro, ndi kuthamanga. Makina otulutsa mpweya amachotsa fumbi ndi chinyezi, ndikusunga zotulukapo zaukhondo. Kuziziritsa kwamadzi kumayimitsa tinthu ting'onoting'ono ting'onoting'ono. Makhalidwewa amathandiza makampani kusunga mphamvu komanso kukwaniritsa malamulo okhwima a chilengedwe. Magulu amaphunzitsidwa ndi kuthandizidwa pambuyo poika, motero amagwiritsa ntchito makinawo bwino.Custom zothetserathandizani makampani kukula ndikukhala odalirika.

| Mwambo Mbali | Pindulani |

|---|---|

| Kuwunika nthawi yeniyeni | Kuwongolera kuwongolera bwino |

| Kuzindikira zitsulo | Kumawonjezera chitetezo |

| Zowongolera zomwe zingatheke | Kumawonjezera mphamvu |

| Vacuum utsi | Imasunga zotulukapo kukhala zoyera |

| Kuziziritsa madzi | Amaletsa kugwa |

Kukhudzika Kwa Msika ndi Kutengera Zopangira Pulasitiki Granulator

Kupititsa patsogolo Kukula kwa Makampani

Opanga ndi obwezeretsanso amayenda mwachangu kutengera umisiri watsopano wa pulasitiki wa granulator. Amawona zopindulitsa zazikulu kuchokera kuzinthu monga kuwunikira kothandizidwa ndi IoT komanso kukonza zolosera zoyendetsedwa ndi AI. Zowonjezera izi zimathandiza kuchepetsa nthawi yopuma komanso kuchepetsa mtengo. Mapangidwe atsamba otsogola ndi zida zamphamvu zimalola makampani kupanga mapulasitiki osakanizika opanda zovuta. Malamulo a zachilengedwe, monga EU Circular Economy Action Plan ndi Extended Producer Responsibility, amakakamiza makampani kuti agwiritse ntchito makina apamwamba. Anthu ambiri amasamala za kukhazikika, kotero kufunikira kwa ma granulator ophatikizika, oyenda m'manja, komanso osagwiritsa ntchito mphamvu kukukulirakulira. Magulu amagwirira ntchito limodzi kupanga ndi kuyambitsazitsanzo zatsopanoMofulumirirako. Zolimbikitsa pazachuma, monga kutsika mtengo kwa magwiridwe antchito komanso kutsata kosavuta, zimafulumizitsanso kulera ana. Kukula kuli kolimba ku North America, Europe, ndi Asia Pacific chifukwa cha kufunikira kwa msika komanso kukakamizidwa kwamalamulo.

- IoT ndi AI zimawonjezera magwiridwe antchito.

- Mapulani atsopano amanyamula mapulasitiki osakanikirana.

- Malamulo ndi zolinga zokhazikika zimayendetsa ndalama.

- Makina apang'ono ndi mafoni amakwaniritsa zosowa zosinthika.

- Phindu lazachuma limalimbikitsa kukweza.

Misonkhano Yoyang'anira ndi Miyezo Yachilengedwe

Makampani amayang'anizana ndi malamulo okhwima obwezeretsanso komanso kasamalidwe ka zinyalala. Zatsopano zaukadaulo wa pulasitiki granulator zimawathandiza kukwaniritsa izi. Makina amtundu wa AI ndikuchotsa zoyipitsidwa molondola kwambiri. Njira zoyeretsera zopanda madzi ndi zowuma zimachepetsa kugwiritsa ntchito madzi ndikuchepetsa madzi onyansa. Ma module obwezeretsa mphamvu amatenga kutentha ndikusandulika kukhala magetsi, kutsitsa kufunikira kwa mphamvu. Makina owunikira a digito amatsata kutsata ndi kukonza munthawi yeniyeni. Makina ambiri tsopano amatsatira malamulo a RoHS kuti achepetse zinthu zowopsa. Miyezo yamagetsi yobiriwira imathandizira kuchepetsa kutulutsa mpweya. Njira zosefera zapamwamba zimapangitsa kuti utsi ndi utsi ukhale wotsika. Mapangidwe a modular amapangitsa kukhala kosavuta kusintha zida zamalamulo atsopano.

- Automation ndi AI zimathandizira kusanja ndi kukonza.

- Kuyeretsa kopanda madzi kumapulumutsa chuma.

- Kubwezeretsa mphamvu kumachepetsa kugwiritsa ntchito mphamvu.

- Kuwunika kwa digito kumatsimikizira kutsata.

- Zida za modular zimagwirizana ndi kusintha kwa malamulo.

Kukulitsa Mapulogalamu ndi Magawo a Msika

Zatsopano zama granulator olemetsa zimatsegula zitseko zamisika yatsopano. Makampani amagwiritsa ntchito makinawa kuposa kungowakonzanso. Gome ili m'munsili likuwonetsa magawo ena omwe akukula komanso ntchito zawo zazikulu:

| Emerging Market Segment | Kuyendetsa Ntchito / Kukula Madalaivala |

|---|---|

| Sustainable Pulasitiki Recycling | Kukonza zinyalala za pambuyo pa ogula kukhala ma granules ogwiritsidwanso ntchito; imathandizira chuma chozungulira komanso kukhazikika. |

| Pharmaceutical Granulation | zowuma granulator zipangizo chinyezi-tcheru; mkulu-kumeta ubweya granulation zovuta mankhwala; amakumana ndi malamulo okhwima. |

| Kukonza Chakudya | Kupanga yunifolomu pophika granules; kumapangitsa kuti zinthu zikhale bwino; imakwaniritsa kukwera kwa kufunikira kwa zakudya zosinthidwa. |

| Advanced Recycling Technologies | Yankho logwira mtima kuchokera kwa osewera ofunika; kuyang'ana kwambiri granulation ndi njira zobwezeretsanso. |

| Kukula Kwachigawo ku Asia-Pacific | Kukula ku China, India, ndi Vietnam; kufunikira kwakukulu kwa granulator m'mafakitale ambiri. |

Ntchito zatsopanozi zimathandiza makampani kukula ndikufikira makasitomala ambiri. Granulator ya pulasitiki tsopano imagwira ntchito yofunika kwambiri m'magawo ambiri, kuyambira pakubwezeretsanso mpaka ku chakudya ndi mankhwala.

Zovuta ndi Tsogolo la Tsogolo la Pulasitiki Granulator

Zolepheretsa Kulera Ana Ambiri

Makampani ambiri akufuna kukweza makina awo obwezeretsanso, koma zopinga zingapo zimawachedwetsa. Mitengo yapamwamba kwambiri imapangitsa makina apamwamba kukhala ovuta kugula, makamaka mabizinesi ang'onoang'ono ndi apakatikati. Mwachitsanzo, ma shaft a single shaft amatha kugula $10,000 mpaka $50,000, pomwe ma shaft anayi amafika mpaka $500,000. Ndalama zimene zimangotsala pang’ono kutha pa ntchito yosamalira ndi kusamalira zinthu zimawonjezera mavuto. Mabizinesi ena amasankha njira zotsika mtengo, zomwe zimalepheretsa kukula kwaukadaulo watsopano.

Zolepheretsa zina ndizovuta zaukadaulo komanso kufunikira kwa ogwira ntchito aluso. Ma granulator anzeru amagwiritsa ntchito IoT ndi AI, koma ogwira ntchito ayenera kuphunzira maluso atsopano kuti aziyendetsa bwino. Mavuto a kagayidwe kazinthu komanso kukwera kwamitengo yazinthu zopangira ndi mphamvu kumawonjezeranso ndalama. Makampani amakumana ndi zokayikitsa chifukwa malamulo amasiyana malinga ndi malo. Opanga amayesetsa kuthandizira popanga makina otsika mtengo, kupeza magawo am'deralo, ndikugwira ntchito ndi owongolera.

Zindikirani: Kuphunzitsa ogwira ntchito ndikutsitsa mtengo kungathandize makampani ambiri kutengerazida zapamwamba zobwezeretsanso.

| Chotchinga | Impact on Adoption |

|---|---|

| Mtengo woyamba | Amaletsa mabizinesi ang'onoang'ono mwayi wopeza |

| Kuvuta kwaukadaulo | Pamafunika akatswiri aluso |

| Kusatsimikizika kwamalamulo | Amachepetsa kupanga zisankho |

| Nkhani za chain chain | Amakweza ndalama zogwirira ntchito |

Zomwe Zikuyembekezeka mu 2025 ndi Kupitilira

Akatswiri amakampani amayembekezera kusintha kwakukulu m'zaka zingapo zikubwerazi. Zochita zokha komanso zanzeru zimapangitsa makinawo kukhala ofulumira komanso osavuta kugwiritsa ntchito. AI ndi IoT zidzathandiza ogwira ntchito kuwunika machitidwe, kulosera zamavuto, ndikupulumutsa mphamvu. Ma granulator amtundu wa rotor athandizira kudula ndikusamalira mitundu yambiri ya mapulasitiki. Makampani apanga makina opangira zinyalala, zomwe zimapangitsa kuti zobwezeretsanso zikhale zogwira mtima.

Kukhazikika kudzakhalabe cholinga chapamwamba. Opanga adzagwiritsa ntchito zida zobwezerezedwanso ndi ma modular mapangidwe kuti athandizire chuma chozungulira. Malamulo okhwima a mpweya ndi phokoso adzasintha zinthu zatsopano. Ndalama zochokera ku maboma ndi osunga ndalama zidzafulumizitsa ukadaulo wobiriwira. Kukula kudzakhala kolimba ku Asia Pacific, North America, ndi Europe popeza mafakitale ambiri amafunikira njira zabwino zobwezeretsanso.

- Automation ndi AI zidzakulitsa luso.

- Kusintha kwa modular kumapangitsa makina kukhala nthawi yayitali.

- Mayankho achikhalidwe angagwirizane ndi mafakitale osiyanasiyana.

- Malamulo adzakankhira zida zoyeretsera, zopanda phokoso.

Langizo: Makampani omwe amaika ndalama m'makina anzeru, opulumutsa mphamvu amakhalabe patsogolo msika ukamakula komanso malamulo akusintha.

Makinawa, kugwiritsa ntchito mphamvu zamagetsi, komanso zida zapamwamba zimapanga tsogolo la granulator iliyonse yapulasitiki. Makampani amawona zopindulitsa monga kutsika mtengo, mtundu wabwino kwambiri wazinthu, komanso kutsata kosavuta.

- Masensa anzeru ndi ma automation amawonjezera zokolola.

- Mapangidwe opulumutsa mphamvu amachepetsa zinyalala ndikuthandizira kukhazikika.

- Kuyang'anira zatsopano kumathandiza mabizinesi kukhala patsogolo.

FAQ

Kodi chimapangitsa granulator ya pulasitiki kukhala "yolemetsa" ndi chiyani?

Ntchito yolemetsapulasitiki granulatoramagwiritsa ntchito mbali zolimba komanso ma mota amphamvu. Imatha kugwira zidutswa zapulasitiki zolimba kapena zazikulu popanda kusweka.

Kodi masensa anzeru amathandiza bwanji mu ma granulator apulasitiki?

Masensa anzeru amawonera thanzi la makina ndi magwiridwe antchito. Amachenjeza ogwira ntchito ku mavuto mwamsanga. Izi zimapangitsa kuti granulator ikhale yayitali komanso imachepetsa nthawi yopuma.

Kodi ma granulator atsopanowa angapulumutse mphamvu?

Inde! Mapangidwe atsopano amagwiritsa ntchito ma motors apamwamba kwambiri komanso zowongolera mwanzeru. Izi zimathandiza makampani kuchepetsa ndalama zamagetsi ndikuthandizira zolinga zobiriwira.

Nthawi yotumiza: Aug-13-2025