Batho ba bona liphetoho tse kholo ka tsela epolasetiki ea granulatore sebetsa kajeno. Lintlafatso tsa morao-rao, joalo ka lisensara tse bohlale le li-motor tse bolokang matla, lia thusaliindasteri polasetiki granulatorbasebelisi ba fokotsa litšenyehelo le ho eketsa tlhahiso. Baetsi ba li-granulator ba bangata ba polasetiki hona joale ba eketsa likarolo tse sa sebetseng, ho etsa e 'ngoe le e' ngoegranulator e matlatšoarella nako e telele ho aSistimi ea ho sebelisa hape.

| Boqapi | Katleho ea Ts'ebetso | Litšenyehelo-Ka katleho |

|---|---|---|

| Smart Technologies | Tlhokomelo ea nako ea sebele | E fokotsa nako ea ho phomola |

| Matla a Matla | Matla a fokolang a hlokahalang | E fokotsa litšenyehelo tsa ho sebetsa |

| Lisebelisoa tse tsoetseng pele | Likhahla tse fokolang | E boloka linthong tse ling |

Lintlha tsa bohlokoa

- Li-sensor tse bohlale le li-automationntlafatsa ts'ebetso ea granulator ea polasetiki ka ho fokotsa nako le ho matlafatsa boleng ba sehlahisoa.

- Li-motor tse bolokang matlale meralo e tsoetseng pele e theola tšebeliso ea matla le ho fokotsa litšenyehelo tsa ts'ebetso ha e ntse e tšehetsa merero ea tikoloho.

- Li-granulator tse tloaelehileng, tse ka tloahelehang li lekana litlhoko tse fapaneng, li etsa hore ho sebelisoa hape ho bolokehe, ho be bonolo, hape ho sebetse hantle liindastering tse ngata.

Automation le Indasteri 4.0 ho Plastic Granulator Technology

Smart Sensors le IoT Integration

Li-sensor tse bohlale li fetotse tsela eo basebelisi ba tsamaisang granulator ea polasetiki. Li-sensor tsena li latela lintlha tsa bohlokoa, joalo ka mocheso le lebelo la ho fepa, ho boloka mechini e sebetsa hantle. Basebelisi ba sebelisa li-sensor tsa taolo ea mocheso ho thibela thepa hore e se ke ea qhibiliha. Li-sensor tsa ho fetola thipa ka othomathike li thusa ho qoba likhohlano, kahoo ts'ebetso ha e emise. Li-sensor tsa ho fepa tse bohlale li lokisa hore na lisebelisoa li kena kapele hakae mochining, li boloka tsohle li tsitsitse.

- Li-sensor tsa taolo ea mocheso li shebile mocheso oa ho sebetsa.

- Li-sensor tsa ho fetola thipa ka othomathike li lemoha likhohlano 'me li boloka ts'ebetso e ntse e tsamaea.

- Li-sensor tsa ho fepa tse bohlale li tsamaisana le lebelo la ho kenya le matla a mochini.

Khokahano ea IoT e tlisa melemo le ho feta. Basebelisi ba ka hlahloba bophelo bo botle ba mochini ba le kae kapa kae ba sebelisa tlhahlobo e hole. Litlhahlobo tsa nako ea 'nete le mathata a ho kopanya PLC pele ho nako. Tlhokomelo e boletsoeng esale pele e thusa ho rera tokiso pele ho senyeha ho etsahala. Sena se fokotsa nako le ho boloka chelete. Li-sensor li boetse li shebelletse litaba tse kang ho koala ha motlakase kapa ho ba le motlakase o mongata. Li-platform tse thehiloeng marung li romela likhopotso bakeng sa tlhokomelo, kahoo basebetsi ha ba lebale mesebetsi ea bohlokoa.

Keletso: Li-sensor tse bohlale le li-control tsa IoT li thusa basebelisi ho tšoara mathata kapele, ho boloka mechini e sebetsa nako e telele, le ho ntlafatsa boleng ba sehlahisoa.

Ntlafatso ea Ts'ebetso e tsamaisoang ke AI

Sistimi e tsamaisoang ke AI e etsa hore ts'ebetso ea polasetiki ea granulator e be bohlale haholoanyane. Lisebelisoa tsena li sebelisa data ho lokisa litlhophiso joalo ka mocheso le lebelo la screw. Basebelisi ba bona lisebelisoa tse fokolang le li-pellets tse tsitsitseng haholoanyane. AI e thusa ho rera tlhokomelo ka ho bona liaparo tsa thepa pele li baka mathata. Sena se boloka mechine e sebetsa 'me e fokotsa ho lokisoa ka tšohanyetso.

- AI e fumana litlhophiso tse ntle ka ho fetisisa bakeng sa betch e 'ngoe le e' ngoe, e theola litheko tsa sekhechana.

- Tlhokomelo e boletsoeng esale pele e eketsa nako le ts'epo ea thepa.

- Taolo ea boleng e tsamaisoang ke data e ntlafatsa ho tšoana ha pellet le ho phahamisa litefiso tsa sehlahisoa sa pele.

- Meralo e bolokang matla le ho khutlisa mocheso li ka fokotsa tšebeliso ea matla ka 30%.

AI e boetse e thusa basebelisi ho qoba liphoso. Automation le AI li sebetsa 'moho ho boloka boholo ba pellet le boleng bo tsitsitse. Ha AI, automation, le IoT li kopanya matla, phallo e ea holimo mme litšila lia theoha. Mehaho e meng e sebelisa ho ithuta ka mochini ho bona mathata le litlhoko tsa tlhokomelo ea bolepi. Litaolo tsena tse bohlale ha li so tloaelehe, empa lik'hamphani tse ngata li rera ho li sebelisa haufinyane. Bokamoso bo tla tlisa ntlafatso ea ts'ebetso e ikemetseng le likarolo tse boletsoeng esale pele.

Liroboto le Phepelo e Itirisang

Liroboto le litsamaiso tsa ho fepa ka boiketsetso li entse hore lisebelisoa tsa polasetiki tsa granulator li sireletsehe le ho sebetsa hantle haholoanyane. Li-feeders tsa vibratory li sebelisa li-sensor le maikutlo ho fana ka thepa ka nepo. Basebelisi ha ba sa tlameha ho tšoara mekotla e boima kapa ho seha mekotla e bulehileng. Liroboto le thepa ea lipalangoang tsa methara ho li-granulator, ho thibela ho fepa ho feta tekano kapa ho fepa ka tlase. Sena se boloka mechini e bolokehile mme e fokotsa nako ea ho sebetsa.

Mekhoa ea ho fepa ka boiketsetso e fokotsa litlhoko tsa basebetsi. Basebetsi ba qeta nako e nyane ba etsa mesebetsi ea matsoho 'me ba tobana le likotsi tse fokolang tsa lerole kapa lisebelisoa tse bohale. Plastic Auto Loaders e boloka thepa e phalla, kahoo mechini ha e emise. Automation e boetse e fokotsa likotsi tse amanang le ts'ebetso ea matsoho. Lits'ebeletso li bona liphetho tse betere tsa polokeho le tlhoko e nyane ea ho kenella ha opareitara.

Tlhokomeliso: Liroboto le lits'ebetso tsa ho fepa ka boiketsetso li sireletsa basebetsi le ho thusa mechini ho sebetsa hantle, ho etsa hore ts'ebetso ea polasetiki ea granulator e bolokehe le ho tšepahala.

Matla a Matla le Moshoelella ho Li-Granulator tsa Plastiki

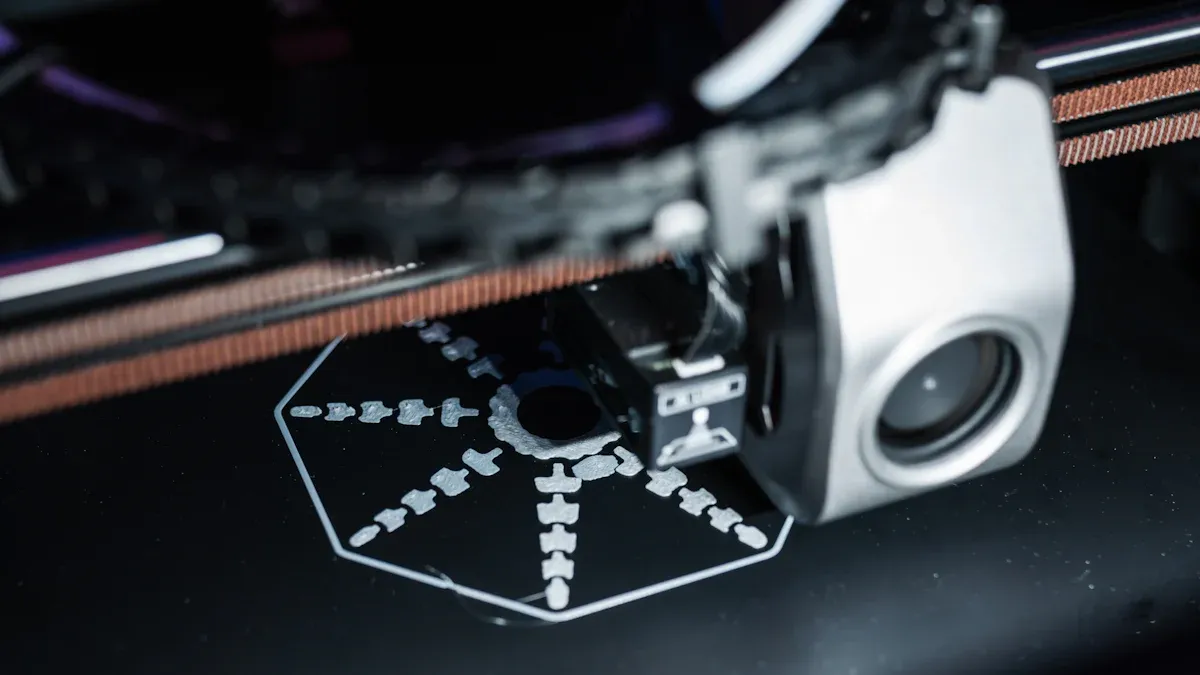

.jpg)

Litsamaiso tsa Likoloi tse Phahameng ka ho Fetisisa

Litsamaiso tsa makoloi tse sebetsang hantle haholo li fetotse tsela eo lits'ebeletso li sebelisang matla ka eona ho nchafatsa polasetiki. Li-motor tsena li sebelisa matla a fokolang ho feta a tloaelehileng. Basebelisi ba bona likoloto tsa motlakase tse tlase le mathata a fokolang a tlhokomelo. Li-crusher tsa sejoale-joale tsa polasetiki tse nang le li-motor tse sebetsang hantle haholo le li-drive frequency drive (VFDs) li ka fokotsa tšebeliso ea matla ka 25-30%. Mehaho e mengata e fetohelang ho li-motors tsena e sebetsa ka bongata bo lekanang ba polasetiki empa e sebelisa matla a fokolang haholo.

- Li-motor tse sebetsang hantle haholo li fetola matla a tsona ho latela mojaro. Sena se bolela hore ha ba senye matla ha mochine o sa tlala.

- Li-granulator tsa lebelo le tlase tse nang le li-motor tsena li tsamaea butle. Li etsa hore mocheso o fokotsehe 'me li khathala ka potlako, e leng ho bolokang matla le litšenyehelo tsa ho lokisa.

- Litsamaiso tse tsoetseng pele tsa taolo li thusa enjene ho matha ka lebelo le nepahetseng bakeng sa mosebetsi ka mong. Sena se boloka tšebeliso ea matla e le tlase le ts'ebetso e phahameng.

- Mechine e meng e bile e na le litsamaiso tsa ho khutlisa matla. Litsamaiso tsena li hapa mocheso o eketsehileng ebe li o fetola motlakase, ho boloka chelete le ho feta.

Basebelisi ba fumana hore litšenyehelo tse holimo tsa li-motor tsena li lefa ha nako e ntse e ea. Ba sebelisa chelete e fokolang ho matla le ho lokisa, ho etsa hore ts'ebetso eohle e tšoarelle.

Meetso ea ho Boloka Matla

Hona joale bahlahisi ba haha li-granulator tsa polasetiki tse nang le likarolo tse bohlale tse bolokang matla letsatsi le leng le le leng. Liphetoho tsena tsa moralo li thusa lik'hamphani ho fihlela lipheo tsa tsona tse tala le litšenyehelo tse tlase. Tafole e ka tlase e bontša tse ling tsa likarolo tse sebetsang ka ho fetesisa tsa ho boloka motlakase le melemo ea tsona:

| Sebopeho sa Moralo | Molemo oa ho Boloka Matla |

|---|---|

| Lienjene tsa ho boloka matla a lipere tse tlase | E fokotsa tšebeliso ea matla ka kakaretso |

| Ntlo e sehang skrineng | E theola lebelo la rotor mme e fokotsa likotlo, e ntlafatsa ts'ebetso ea matla |

| Lebelo la rotor le tlase haholo | E fokotsa tšebeliso ea matla ha u ntse u boloka boleng ba granule |

| Rotor e nang le meno a mangata a nang le meno a khonang ho leotsoa hape | E boloka ts'ebetso ea ho itšeha, e fokotsa tšenyo ea matla ka nako |

| Moralo oa torque e phahameng ea li-flywheel tse peli | E sebetsana ka katleho le thepa e thata, e fokotsa ho senyeha ha matla |

| Moralo oa thipa ea Twinshear | E ntlafatsa ts'ebetso ea ho itšeha, ho sebelisa matla a fokolang |

| Kamore e arohaneng | E lumella ho hloekisa kapele, ho fokotsa nako le tšebeliso ea matla |

| Bereche e matlafalitsoeng ea mosebetsi o boima oa skrine | E matlafatsa nako e telele, e fokotsa tahlehelo ea matla ka lebaka la ho apara |

Mefuta e meng e mecha, joalo ka CMG Granulators 'EV Series, e sebelisa libopeho tse tsoetseng pele tsa ho itšeha le litsamaiso tse bohlale tsa drive. Liphetoho tsena li ka fokotsa tšebeliso ea matla ka 50% ha e bapisoa le mechini ea khale. Bongata ba ho boloka matla ho tsoa ka ho khetha boholo bo nepahetseng ba motlakase le ho sebelisa lisebelisoa tse baballang matla. Basebelisi ba sebelisang meralo ena ba bona marotholi a maholo likolotong tsa bona tsa matla le nako e fokolang ea ho lokisoa.

Keletso: Ho khetha granulator ea polasetiki e nang le likarolo tsa ho boloka matla ho thusa lik'hamphani ho boloka chelete le ho sireletsa tikoloho ka nako e le 'ngoe.

Likarolo tsa Eco-Friendly le Recyclable

Ho boloka botsitso hona joale ke ntho e tlang pele ho lik'hamphani tse ngata. Ba batla mechine e tšoarellang nako e telele le ho baka litšila tse fokolang. Likarolo tse sebetsang hantle ka tikolohong le tse ka sebelisoang hape ka har'a li-granulator tsa polasetiki li thusa ho fihlela lipheo tsena. Likarolo tsena li sebelisa lisebelisoa tse fokolang 'me li etsa hore ho be bonolo ho sebelisa hape.

- Lisebelisoa tsa eco-friendly li fokotsa litšila tsa polasetiki le ho boloka matla.

- Litheknoloji tse tsoetseng pele, joalo ka ho hlopha tse tsamaisoang ke AI, li ntlafatsa boleng ba lipolasetiki tse nchafalitsoeng.

- Melawana, joalo ka Basel Convention le RoHS, e qobella lik'hamphani ho sebelisa mechini e tala.

- Litšusumetso tsa lichelete, joalo ka khefutso ea lekhetho, li khothaletsa matsete ho lisebelisoa tsa ho hlabolla lintho habonolo.

- Lisebelisoa tsa modular le tsa mehala li fokotsa likhase tse tsoang 'me li etsa hore ho sebelisa hape ho fihlellehe haholoanyane.

Hona joale bahlahisi ba shebane le ho finyella litekanyetso tsa Tikoloho, Sechaba, le Puso (ESG). Ba sebelisa meralo e baballang matla le thepa e sireletsehileng ho fihlela melao e thata. Liphetoho tsena li thusa lik'hamphani ho latela molao le ho bontša bareki hore ba tsotella lefatše. Ka ho sebelisa li-granulator tsa polasetiki tse sebetsang hantle ka tikolohong, lik'hamphani li tšehetsa moruo o chitja le ho fokotsa khabone ea tsona.

Ho sebetsana le lisebelisoa tse tsoetseng pele le ho itloaetsa ka li-Granulator tsa polasetiki

Meetso ea Modular le Compact

Hona joale bahlahisi ba theha li-granulator tsa modular le compact tse kenang libakeng tse thata. Mechini ena e thusa lithupelo tse nyane le lifeme tse kholo ho boloka sebaka sa fatše. Basebelisi ba ka beha li-granulator tse kopaneng haufi le mela ea tlhahiso. Setupo sena se ba lumella hore ba sebetse hanghang, e leng ho theolang litšenyehelo tsa ho sebetsana le thepa. Meetso ea modular e lumella lintlafatso tse potlakileng ha litlhoko tsa tlhahiso li fetoha. Lihlopha li ka fetola li-blades kapa li-rotor ka lihora tse 'maloa feela. Ho feto-fetoha ha maemo ho bolela ho fokotsa nako le tlhokomelo e potlakileng. Liyuniti tse ngata li kenyelletsa likarolo tsa ho fokotsa lerata le ho thibela lerōle, ho etsa hore sebaka sa mosebetsi se sireletsehe le ho khutsa. Li-sensor tse bohlale le ho beha leihlo ka nako ea 'nete li thusa basebelisi ho bona mathata esale pele, kahoo ho lokisoa ho etsahala pele ho senyeha.

Keletso: Meralo ea modular le e kopaneng e etsa hore ho be bonolo ho kenya ts'ebetso le ho ts'ehetsa ts'ebetso ea sebaka sa marang-rang, e matlafatsang ts'ebetso le ho fokotsa mathata a tlhokomelo.

Ho sebetsa ho Complex le Metsoako ea Plastiki

Ho tsosolosa li-plastiki tse tsoakiloeng ho thata, empa mahlale a macha a etsa hore ho be bonolo. Sistimi ea ho hlopha e tsamaisoang ke AI e sebelisa lik'hamera le li-sensor ho arola mefuta e fapaneng ea polasetiki. Lisebelisoa tsa ho hlopha tsa makenete le optical li tlosa tšepe le litšila tse ling pele ho granulation. Mechini e meng e sebelisa ho sebelisoa hape ka lik'hemik'hale ho pshatla lipolasetiki likarolong tsa tsona tsa motheo. Mekhoa ena e thusa basebetsi ho fumana lisebelisoa tse hloekileng tse nchafalitsoeng hape le lisebelisoa tse phahameng. Li-feeders tsa vibratory le li-screeners li ala polasetiki, kahoo ho hlophisa ho sebetsa betere. Mehato ena e sireletsa granulator ea polasetiki le ho ntlafatsa boleng ba li-pellets tse nchafalitsoeng. Basebelisi ba bona nako ea ts'ebetso e potlakileng le litšenyehelo tse tlase tsa matla.

- Ho hlophisoa ho tsamaisoang ke AI ho ntlafatsa bohloeki.

- Lisebelisoa tsa Magnetic le Optical li tlosa litšila.

- Ho tsosolosa lik'hemik'hale ho etsa lisebelisoa tsa boleng bo phahameng.

Tailored Tharollo bakeng sa Litlhoko tsa Indasteri

Likhamphani li batla li-granulator tse lumellanang le litlhoko tsa tsona tse ikhethang. Baetsi ba mamela likōpo tsa bareki le mechine ea meralo e nang le likarolo tse khethehileng. Likarolo tse ling li na le lik'hamera bakeng sa tlhahlobo ea nako ea 'nete libakeng tsa bohlokoa. Lisebelisoa tsa tšepe li boloka lintho tse sa batleheng li le ntle, li etsa hore lihlahisoa li sireletsehe haholoanyane. Litaolo tse ka reroang li lumella basebelisi ho beha mocheso, lebelo le khatello. Lisebelisoa tsa vacuum exhaust li tlosa lerōle le mongobo, li boloka tlhahiso e hloekile. Pholiso ea metsi e thibela likaroloana ho bokellana. Likarolo tsena tse tloaelehileng li thusa lik'hamphani ho boloka matla le ho fihlela melao e thata ea tikoloho. Lihlopha li fumana koetliso le tšehetso ka mor'a ho kenya, kahoo li sebelisa mechine hantle.Litharollo tsa tloaelothusa lik'hamphani ho hola le ho lula li tšepahala.

| Custom Feature | Molemo |

|---|---|

| Tlhokomelo ea nako ea sebele | E ntlafatsa taolo ea boleng |

| Ho lemoha ka tšepe | E matlafatsa polokeho |

| Litaolo tse ka reroang | E matlafatsa ts'ebetso |

| Vacuum exhaust | E boloka tlhahiso e hloekile |

| Pholiso ea metsi | E thibela ho bokellana |

Tšusumetso ea 'Maraka le ho Amoheloa ha Lintlafatso tsa Polasetiki ea Granulator

Ho Potlakisa ho Kena ha Indasteri

Baetsi le bahlahisi ba sebetsa ka potlako ho sebelisa mekhoa e mecha ea polasetiki ea granulator. Ba bona melemo e meholo ho tsoa lits'ebetsong tse kang tlhahlobo e nolofalitsoeng ke IoT le tlhokomelo e khannoang ke AI. Lintlafatso tsena li thusa ho fokotsa nako le litšenyehelo tse tlase. Meralo e ntlafalitsoeng ea li-blade le lisebelisoa tse matla li lumella lik'hamphani ho sebetsana le li-plastiki tse tsoakiloeng tse nang le mathata a fokolang. Melao ea tikoloho, joalo ka Leano la Bohato la Moruo oa EU Circular Economy and Extended Producer Responsibility, e qobella lik'hamphani ho tsetela mecheng e tsoetseng pele. Batho ba bangata ba tsotella ho tšoarella, kahoo tlhoko ea li-granulator tse sebetsang hantle, tse tsamaeang, le tse baballang matla e ntse e eketseha. Lihlopha li sebetsa 'moho ho nts'etsapele le ho qalamehlala e mechaKapele. Litšusumetso tsa moruo, joalo ka litšenyehelo tse tlase tsa ts'ebetso le ho latela melao ha bonolo, le tsona li potlakisa ho adoptha. Keketseho e matla Amerika Leboea, Europe le Asia Pacific ka lebaka la tlhoko ea 'maraka le khatello ea taolo.

- Likarolo tsa IoT le AI li eketsa katleho.

- Meetso e mecha ea li-blade e sebetsana le polasetiki e tsoakiloeng.

- Melawana le lipakane tsa moshoelella li khanna matsete.

- Mechini e tšesaane le e tsamaeang e khahlametsa litlhoko tse feto-fetohang.

- Melemo ea moruo e khothaletsa ntlafatso.

Melawana ya Kopano le Maemo a Tikoloho

Lik'hamphani li tobane le melao e thata ea ho tsosolosa le ho laola litšila. Mekhoa e mecha ea theknoloji ea granulator ea polasetiki e ba thusa ho fihlela litekanyetso tsena. Automation le lisebelisoa tsa ho hlophisa AI le ho tlosa litšila ka nepo e phahameng. Mekhoa ea ho hloekisa e se nang metsi le ea ho sebetsa ka mokhoa o omileng e fokotsa tšebeliso ea metsi le ho fokotsa metsi a litšila. Li-module tsa ho khutlisa matla li hapa mocheso ebe li o fetola motlakase, ho theola tlhokahalo ea matla. Sistimi ea ho beha leihlo ea dijithale e latela melao le tlhokomelo ka nako ea nnete. Mechini e mengata joale e latela melao ea RoHS ho fokotsa lintho tse kotsi. Litekanyetso tsa elektronike tse tala li thusa ho fokotsa tlhahiso ea carbon. Sistimi e tsoetseng pele ea ho sefa e boloka mesi le litšila li le tlase. Meetso ea modular e etsa hore ho be bonolo ho fetola lisebelisoa bakeng sa melaoana e mecha.

- Automation le AI li ntlafatsa ho hlophisa le tlhokomelo.

- Ho hloekisa ntle le metsi ho boloka mehloli.

- Ho khutlisa matla ho fokotsa tšebeliso ea matla.

- Tlhokomelo ea dijithale e netefatsa hore ho latela melao.

- Lisebelisoa tsa modular li ikamahanya le melao e fetohang.

Ho Atolosa Likopo le Likarolo tsa Maraka

Litlhahiso tsa li-granulator tsa mosebetsi o boima li bula mamati a limmaraka tse ncha. Likhamphani li sebelisa mechini ena bakeng sa ho feta feela ho e sebelisa hape. Tafole e ka tlase e bonts'a likarolo tse ling tse ntseng li hola le ts'ebeliso ea tsona ea mantlha:

| Karolo ea 'Maraka e Hlahang | Likopo tsa ho khanna / Bakhanni ba Khōlo |

|---|---|

| Tšebeliso e tsitsitseng ea polasetiki | Ho sebetsana le litšila tsa morao-rao ho li-granules tse ka sebelisoang hape; e tšehetsa moruo o chitja le botsitso. |

| Meriana Granulation | Li-granulator tse omileng bakeng sa lisebelisoa tse sa utloeleng mongobo; granulation e phahameng ea ho kuta bakeng sa lithethefatsi tse rarahaneng; e kopana le melao e thata. |

| Phetoho ea Lijo | Ho etsa li-granules tsa motsoako o tšoanang; e ntlafatsa boleng ba sehlahisoa; e kopana le tlhokeho e ntseng e phahama ea lijo tse feliloeng. |

| Mekhoa e tsoetseng pele ea ho Recycling | Litharollo tse sebetsang hantle tse tsoang ho libapali tsa bohlokoa; tsepamisa maikutlo holim'a granulation e betere le mekhoa ea ho e sebelisa hape. |

| Keketseho ea Libaka Asia-Pacific | Katoloso China, India le Vietnam; tlhokahalo e matla ea li-granulator liindasteri tse ngata. |

Lisebelisoa tsena tse ncha li thusa lik'hamphani ho hola le ho fihlela bareki ba bangata. Hona joale granulator ea polasetiki e bapala karolo ea bohlokoa makaleng a mangata, ho tloha ho recycle ho ea ho lijo le meriana.

Mathata le Pono ea Bokamoso bakeng sa Li-Granulator tsa Plastiki

Litšitiso tsa ho Amohela Bana ka Bana

Lik'hamphani tse ngata li batla ho ntlafatsa mekhoa ea tsona ea ho tsosolosa, empa litšitiso tse 'maloa li li fokotsa. Litšenyehelo tse holimo tsa pele li etsa hore ho be thata ho fumana mechini e tsoetseng pele, haholo likhoebong tse nyane le tse mahareng. Ka mohlala, li-shredders tse nang le shaft e le 'ngoe li ka bitsa $10,000 ho ea ho $50,000, ha mefuta e mene ea shaft e fihla ho $500,000. Litšenyehelo tse tsoelang pele tsa ho hlokomela le ho sebetsa li eketsa phephetso. Likhoebo tse ling li khetha mefuta e meng e theko e tlaase, e fokotsang kholo ea theknoloji e ncha.

Litšitiso tse ling li kenyelletsa ho rarahana ha tekheniki le tlhoko ea basebetsi ba nang le boiphihlelo. Li-granulator tse bohlale li sebelisa IoT le AI, empa basebelisi ba tlameha ho ithuta tsebo e ncha ho li tsamaisa hantle. Mathata a phepelo ea thepa le ho phahama ha litheko tsa thepa e tala le matla le tsona li eketsa litšenyehelo. Lik'hamphani li tobana le lipelaelo hobane melaoana e fapana ho ea ka libaka. Baetsi ba leka ho thusa ka ho rala mechini e baballang litšenyehelo, ho fumana likarolo tsa lehae, le ho sebetsa le balaoli.

Tlhokomeliso: Ho koetlisa basebetsi le ho theola litšenyehelo ho ka thusa lik'hamphani tse ngata ho amohelalisebelisoa tse tsoetseng pele tsa ho tsosolosa.

| Tšitiso | Tšusumetso ho Adoption |

|---|---|

| Theko e phahameng ea pele | Meeli ea phihlello ea likhoebo tse nyane |

| Ho rarahana ha tekheniki | E hloka basebetsi ba nang le tsebo |

| Ho hloka bonnete ba taolo | E liehisa ho etsa liqeto |

| Litaba tsa ketane ea phepelo | E phahamisa litšenyehelo tsa ts'ebetso |

Lintlafatso tse Lebeletsoeng tsa 2025 le ho Feta

Litsebi tsa indasteri li lebelletse liphetoho tse kholo lilemong tse 'maloa tse tlang. Boiketsetso le likarolo tse bohlale li tla etsa hore metjhini e potlake hape e be bonolo ho e sebelisa. AI le IoT li tla thusa basebelisi ho lekola litsamaiso, ho bolela esale pele mathata, le ho boloka matla. Li-granulator tsa mofuta oa rotor li tla ntlafatsa ho itšeha le ho sebetsana le mefuta e mengata ea polasetiki. Likhamphani li tla rala metjhini bakeng sa melapo e itseng ea litšila, e leng ho etsang hore ho e sebelisa hape ho atlehe.

Ho tšoarella ho tla lula e le sepheo se holimo. Baetsi ba tla sebelisa thepa e ka sebelisoang hape le meralo ea modular ho tšehetsa moruo oa selikalikoe. Melao e thata bakeng sa mesi le lerata e tla bopa lihlahisoa tse ncha. Lithuso tsa lichelete tse tsoang mebusong le bo-ramatsete li tla potlakisa ntlafatso ea theknoloji e tala. Keketseho e tla ba matla Asia Pacific, Amerika Leboea le Europe kaha liindasteri tse ngata li batla litharollo tse betere tsa ho e sebelisa hape.

- Automation le AI li tla matlafatsa ts'ebetso.

- Lintlafatso tsa modular li tla etsa hore mochini o tšoarelle nako e telele.

- Litharollo tse ikhethileng li tla lumellana le liindasteri tse fapaneng.

- Melao e tla qobella lisebelisoa tse hloekileng, tse khutsitseng.

Keletso: Lik'hamphani tse tsetelang ho mechini e bohlale, e bolokang matla li tla lula li le teng ha 'maraka o ntse o hola le melao e fetoha.

Boiketsetso, ts'ebetso ea matla le lisebelisoa tse tsoetseng pele li theha bokamoso ba granulator e 'ngoe le e 'ngoe ea polasetiki. Likhamphani li bona melemo joalo ka litšenyehelo tse tlase, boleng bo betere ba sehlahisoa, le ho latela melao ha bonolo.

- Li-sensor tse bohlale le li-automation li eketsa tlhahiso.

- Meralo ea ho boloka matla e fokotsa litšila le ho tšehetsa ho tšoarella.

- Ho beha leihlo mekhoa e mecha ho thusa likhoebo ho lula li le pele.

LBH

Ke eng e etsang hore granulator ea polasetiki e be "boima-mosebetsi"?

Mosebetsi o boimapolasetiki ea granulatore sebelisa likarolo tse matla le li-motor tse matla. E khona ho sebetsana le likotoana tsa polasetiki tse thata kapa tse kholo ntle le ho senya.

Li-sensor tse bohlale li thusa joang ho li-granulator tsa polasetiki?

Li-sensor tse bohlale li shebella bophelo bo botle ba mochini le ts'ebetso. Ba hlokomelisa basebetsi ka mathata esale pele. Sena se boloka granulator e sebetsa nako e telele mme e fokotsa nako ea ho theoha.

Na li-granulator tsee tse ncha li ka boloka matla?

Ee! Meetso e mecha e sebelisa lienjenere tse sebetsang hantle haholo le li-control tse bohlale. Likarolo tsena li thusa lik'hamphani ho theola likoloto tsa matla le ho ts'ehetsa lipheo tse tala.

Nako ea poso: Aug-13-2025