Ngo-2025, i-buzz ejikeleze oomatshini bokurisayikilisha beplastiki bamaziko e-automation ephucukileyo, izakhono eziphuculweyo zokuhlela izinto, kunye neenkqubo ezintsha zokuphinda zisetyenziswe iikhemikhali. Olu tshintsho luguqula inkunkuma ibe yimithombo exabisekileyo. Lo nyaka uphawula umtsi obalulekileyo ekusebenzeni kakuhle kunye nozinzo kushishino. Iingcali ziprojekthi yehlabathiumatshini wokurisayikilisha weplastikiimakethi iya kufikelela kwi-USD 3.82 yeebhiliyoni ngo-2025. Le marike ilindele ukukhula olomeleleyo. Aumatshini wokutyumza iplastikiinceda ukwaphula izinto ezinkulu zeplastiki. Aiplastiki shredderkananjalo ulungisa imathiriyeli ngokufanelekileyo. Aumatshini wokuphinda usebenzise iplastikiiinkqubo zenkunkuma zibe ziifom ezinokuphinda zisetyenziswe. Ekugqibeleni, aumatshini wokwenza iplastikibangasebenzisa ezi plastiki zisetyenzisiweyo.

Izinto eziphambili zokuThatha

- Imithetho emitsha kunye nemigaqo-nkqubo yenza i-2025 ibe ngunyaka omkhulu wokurisayikilishwa. Le mithetho inyanzela iinkampani ukuba zisebenzise oomatshini abangcono kwaye ziphinde zisebenzise iplastiki eninzi.

- Oomatshini beplastiki bokurisayikilisha baya besiba krelekrele. Basebenzisa i-AI ukuhlenga iiplastiki ngcono kunye ne-IoT ukulandelela ukuba oomatshini basebenza njani. Oku kwenza ukurisayikilishwa kusebenze ngakumbi.

- Ukurisayikilisha koomatshini kuyaphucuka. Oomatshini abatsha bahlela iiplastiki ngokuchaneka okuphezulu. Bakwahlamba kwaye bakrazule iiplastiki ngcono. Oku kwenza imathiriyeli ehlaziyiweyo ekumgangatho ophezulu.

- Ukurisayikilishwa kweekhemikhali kuyakhula. Iqhekeza iiplastiki zibe ngamalungu asisiseko. Oku kunceda ukuphinda kusetyenziswe iiplastiki ekunzima ukuzilungisa. Yenza izinto ezintsha zeemveliso.

- Oomatshini bokurisayikilisha abakwinqanaba eliphezulu banceda okusingqongileyo kunye noqoqosho. Bajika inkunkuma ibe yimveliso emitsha. Oku konga imali kwaye kunciphisa ungcoliseko.

I-Landscape ka-2025 yePlastiki yokuRisayikilishwa ngokutsha komatshini wokuQala

Kutheni u-2025 enguNyaka oBalulekileyo kwiTekhnoloji yokuRecycling

Unyaka wama-2025 uphawula ixesha elibalulekileyo lokurisayikilisha itekhnoloji. Imigaqo-nkqubo kunye nemimiselo emitsha iqhuba utshintsho olubalulekileyo. Iinkqubo ezongezelelweyo zoXanduva loMvelisi (EPR), umzekelo, zikhuthaza abavelisi ukuba basebenzise iiplastiki ezisetyenzisiweyo. Oku kwandisa ngokuthe ngqo imfuno yezixhobo eziphezulu zegranulation. Imithetho malunga nenkunkuma yokulahla inkunkuma kunye neethagethi zokurisayikilishwa kwakhona zityhala oomatshini bokurisayikilisha ukuba baphucule oomatshini babo. Imigaqo-nkqubo yokusingqongileyo igxile ekusebenziseni amandla kunye nokunciphisa ukukhutshwa kwezinto ezikhutshwayo. Le migaqo-nkqubo inefuthe kwindlela iinkampani eziyila kwaye zisebenza ngayo oomatshini begranulator, ekhokelela kubuchwepheshe obuluhlaza. Ii-arhente ezifana ne-EPA zimisela imigangatho yezixhobo. Ukuthobela le migangatho kuqinisekisa ukuba oomatshini bayahlangabezana nokhuseleko, indalo esingqongileyo, kunye nebenchmarks zokusebenza. Imimiselo yaseMntla Melika iya igxininisa ulawulo lwenkunkuma oluzinzileyo. Iinkampani ezityala imali koomatshini abalandela le migaqo-nkqubo zinokufumana inkuthazo kurhulumente kwaye ziphephe izohlwayo. Oku kubanika inzuzo yokukhuphisana.

IiNdlela eziPhambili kuPhuhliso lwePlastiki yokuRecycling

Iindlela ezininzi eziphambili zokubumba uphuhliso koomatshini bokurisayikilisha beplastiki. Iinkqubo zokuhlela ezinikwe amandla e-AI yinkqubela enkulu. Ezi nkqubo zinokufikelela kwi-98% yokucoceka kwi-PET / HDPE imilambo. Zikwanciphisa ungcoliseko ngama-40%. I-IoT-enabled monitoring ivumela ukulandelwa kwexesha langempela lokusebenza komatshini kunye nokusetyenziswa kwamandla. Oku kukhokelela ekunciphiseni kwe-25% kwixesha lokunciphisa. Izibonelelo ezinatyisiweyo nazo ziya zixhaphaka. Ezi yunithi zincinci ziyakwazi ukucubungula i-500-800 kg / h. Banceda ukunciphisa ukukhutshwa kwezothutho kwihlabathi jikelele. I-EU's Packaging and Packaging Waste Regulation (PPWR) ngumqhubi omkhulu. Ifuna i-70% yokuphinda isetyenziswe ukupakishwa ngo-2030. Ikwafuna i-10-35% yesiqulatho esenziwe ngokutsha kwiiplastiki. Ukudibana nalo mgaqo kufuna ubuchwephesha obuphambili bomatshini kunye neekhemikhali zokurisayikilisha. Itekhnoloji yokuhlela eyomeleziweyo itshintsha ukuphinda kusetyenziswe iplastiki. Iisistim ezizenzekelayo zisebenzisa izinzwa eziphambili, ubukrelekrele bokwenziwa, kunye nokufunda koomatshini. Bayakwazi ukuchonga kunye nokwahlula iiplastiki ngokusekelwe kwimichiza yabo, umbala kunye nokumila. Oku kuphucula ukusebenza kakuhle kunye nokucoceka kwimisinga yokuhlaziya. Olu phuculo lunceda ukuvelisa iiplastiki ezisetyenzisiweyo ezikumgangatho ophezulu.

IiTekhnoloji zoomatshini bePlastiki bokuRecycling obukwinqanaba eliphezulu

Ukurisayikilishwa koomatshini kuhlala kulilitye lembombo lolawulo lwenkunkuma yeplastiki. Ngo-2025, ukuqhubela phambili okutsha kwenza ezi nkqubo zisebenze ngakumbi kwaye zisebenze. Aba matshini ngoku baphatha uluhlu olubanzi lweeplastiki. Bakwavelisa umgangatho ophezulu wezinto ezisetyenzisiweyo.

IiNkqubo zokuHlola ezilandelelweyo zoomatshini bokurisayikilisha bePlastiki

Ukuhlela linyathelo lokuqala elibalulekileyo kuhlaziyo ngoomatshini. Iinkqubo ezintsha zokuhlela zisebenzisa itekhnoloji ye-sensor ephucukileyo, ubukrelekrele bokwenziwa (AI), kunye nokufunda koomatshini. Ezi zixhobo ziphucula kakhulu ukuchaneka kunye nesantya. Iinkqubo zombono weKhompyutha zisebenzisa iikhamera ezinesisombululo esiphezulu kunye ne-AI algorithms. Bahlalutya izinto zeplastiki ngexesha langempela. Ezi nkqubo zichonga iiyantlukwano ezifihlakeleyo zombala, imilo, kunye nokwakheka kwazo ukuze kuhlelwe ngendlela echanekileyo. Iimodeli zokufunda ngoomatshini zihlala ziphucula amandla abo okuqaphela.

Ii-algorithms zokufunda nzulu ziqhuba ulwazi oluntsonkothileyo olubonakalayo. Benza izigqibo zokwahlula-hlula malunga nokwakhiwa kwezinto. Ezi algorithms zigqwesa ekuqondeni iipateni kunye neempawu abantu abangenakuzibona. Oku kukhokelela ekuhleleni ukuchaneka amazinga angaphezu kwama-95%. I-spectroscopy ekufuphi ne-Infrared (NIR) yenye iteknoloji ebalulekileyo. Isebenzisa ukukhanya kwe-infrared ukuhlalutya ukwakheka kweemolekyuli. Oku kuvumela ukuchongwa okukhawulezayo nokuchanekileyo kweentlobo zeplastiki ezahlukeneyo njenge-PET, i-HDPE, kunye ne-PVC. Ilinganisa iisignesha zabo ezizodwa ze-spectral.

I-Hyperspectral imaging ithatha ukuhlelwa kwe-spectroscopic ngakumbi. Idibanisa imifanekiso yemveli kunye ne-spectroscopy. Oku kubamba idatha kumakhulu amabhendi e-spectral. Inika uhlalutyo lwezinto eziphathekayo oluneenkcukacha. Oku kuchonga ungcoliseko, izongezo, kunye nokwahluka okufihlakeleyo ekubunjweni kweplastiki. Itekhnoloji yokubamba iSmart nayo iyanceda. Ezi grippers ezintsha zinezinzwa kunye nolawulo loxinzelelo oluguquguqukayo. Baphatha izinto zobukhulu obahlukeneyo, iimilo, kunye nobunzima ngaphandle komonakalo. Bayakwazi ukubona iimpawu eziphathekayo ngempendulo ye-tactile. Oku kwandisa ukuchaneka kokuhlelwa kwaye kunciphisa ungcoliseko.

Ezi nkqubo zesizukulwana esilandelayo zokuhlela zisebenzisa iisistim zekhamera eziphambili, izinzwa, kunye ne-algorithms yokufunda koomatshini. Bachonga ngokukhawuleza nangokuchanekileyo kwaye bahlele izinto ezahlukeneyo zenkunkuma. Basebenzisa abenzi boluvo abafumanisa iisignitsha ezizodwa zembonakalo yokuchonga izinto ezichanekileyo kunye nokwahlula. Oku kuluncedo ngakumbi ekuhleleni inkunkuma yasemva kwabathengi. Oku kubandakanya iiplastiki, iglasi, iphepha kunye nentsimbi. Ezi nkqubo zinokucutha iindleko zothutho nezokuqokelela ubuncinane ngama-50% xa zidityaniswe neenkqubo zokuqokelelwa kwenkunkuma ezizenzekelayo. Basebenzisa izinzwa ze-NIR ukuchonga iintlobo zepolymer. Bahlula iiplastiki ngokusekelwe kumbala kunye nohlobo. Ezi nkqubo zibonelela ngomthamo ophezulu wokuphuma, zihlala ziqhuba amakhulu eetoni ngosuku. Banciphisa ukungcoliseka, okukhokelela kwimathiriyeli ehlaziyiweyo ekumgangatho ophezulu. I-teknoloji ye-hyperspectral imaging, njenge-Specim FX17 kunye ne-GX17, inikezela ngexesha langempela, ukufumanisa okuthembekileyo. Yahlula i-PET kwizinto ezingcolileyo ezifana ne-PVC, i-HDPE, i-ABS, ezinye iiplastiki, kunye nezinto eziphilayo. Iikhamera ze-Hyperspectral zibonelela ngokuthembeka kokuhlelwa okuphezulu kunye nokuguquguquka. Bathatha uluhlu olupheleleyo okanye olukhethiweyo lwe-spectral. Oku kuvumela uqwalaselo ngokutsha kuwo wonke umjikelo wobomi bomatshini. Iikhamera ze-Solid-state hyperspectral azigcinwanga iminyaka emininzi. Azinamalungu ashukumayo afuna ukutshintshwa rhoqo kunye nohlengahlengiso. Ezi nkqubo zidibanisa i-hyperspectral imaging kunye neekhamera ze-RGB zokuphucula umbala kunye nokuchongwa kwemilo. Basebenzisa iimodeli zenethwekhi ye-neural esekwe kwi-AI esebenza kwii-NVIDIA GPUs ezinamandla ukuze zilungelelaniswe ngokuchanekileyo kunye neerekhodi ezineenkcukacha zamanani. Bade bajongane nokuhlelwa kweplastiki emnyama kusetyenziswa ikhamera yeSpecim FX50 HSI. Le khamera isebenza kuluhlu lwe-infrared ephakathi kwamaza (MWIR). Ichonga kwaye ihlele iiplastiki ezimnyama ngokusekelwe kwimichiza yazo.

Ukuhlamba kunye nokuHletywa okomeleziweyo koomatshini bokurisayikilisha bePlastiki

Emva kokulungiswa, iiplastiki ziyahlanjwa kwaye ziqhekezwe. Ezi nkqubo zilungiselela imathiriyeli ukuqhubekeka phambili. Oomatshini banamhlanje bokuhlamba kunye nokucheba babonisa uphuculo olubonakalayo ekusebenzeni kwamandla. Oomatshini bokurisayikilisha beplastiki abakwinqanaba eliphezulu, ngakumbi abo basebenzisa iteknoloji ye-servo motor, banciphisa ukusetyenziswa kwamandla ukuya kutsho kuma-30% xa kuthelekiswa neemodeli ezindala. Oku kukhokelela kugcino lweendleko kunye neenzuzo zokusingqongileyo. Umzekelo, isikrufu samawele esijije, i-parallel twin screw, kunye nemifuziselo ye-compound twin screw ifezekisa ukuya kuthi ga kwi-30% ecuthiweyo ukusetyenziswa kwamandla.

Ukwenziwa kwezinto ezintsha kwi-shredder blade kunye noyilo kukwaphucula ukusebenza kunye nokunciphisa ukugcinwa. Idizayini entsha ye-rotor ye-V, enobubanzi obuyi-500 mm ukuya kuthi ga kwi-2,200 mm ubude, ibamba amaqhuma okuqalisa amakhulu, imigqomo engenanto, kunye neendawo ezivoluminous. I-rotor ye-F echanekileyo ene-milling kunye nelungiselelo elikhethekileyo lemela lilungele ukukrazula izinto eziguquguqukayo ezifana neefayili kunye neefilimu. Iqinisekisa iijometri zokusika ezichanekileyo. I-counter blades ehlengahlengiswayo inokulungiswa ngokukhawuleza kwaye iguqulwe ukusuka ngaphandle. Oku kugcina i-gap yokusika efanelekileyo nangona ukuguga. Ikhokelela ekusebenzeni okuphezulu kunye nobomi obandisiweyo benkonzo yeemela. I-flap yokuhlola evulekileyo ivumela ukugcinwa okufanelekileyo kunye nokufikelela ngokufanelekileyo kwe-rotor. Oku kwenza kube lula ukususwa kwezinto zangaphandle kunye nomsebenzi wolondolozo olukhululekile.

Aba matshini basebenzisa iincakuba zentsimbi ezomeleleyo kwiishafu ezijikeleza kabini. Ezi blades zibamba zombini iiplastiki ezithambileyo neziqinileyo ngokufanelekileyo. Isantya esisezantsi, idizayini ye-torque ephezulu iqinisekisa ukuncitshiswa kobungakanani be-particle. Ikwanciphisa uthuli nengxolo. Igumbi lokusika elihlengahlengiswayo livumela abaqhubi ukuba benze ngokwezifiso ubungakanani bemveliso. Amacandelo e-Industrial-grade kunye nokwakhiwa okuqinileyo kuqinisekisa ukuthembeka kwexesha elide. Banciphisa iimfuno zokugcina kunye nokunciphisa ixesha lokunciphisa. Amalungu angagugiyo agcina ukusebenza okufanayo kwixesha elongeziweyo lokusebenza. Inkqubo yokubuyisela iblade ekhawulezayo inciphisa ukuphazamiseka kokusebenza.

Extrusion kunye Pelletizing for Premium Recycled Plastics

Inyathelo lokugqibela lokuphinda kusetyenziswe oomatshini libandakanya i-extrusion kunye ne-pelletizing. Oku kuguqula iiflake zeplastiki ezikhutshiweyo nezihlanjiweyo zibe yipellet efanayo. Ezi pellets ke zilungele ukwenza iimveliso ezintsha. Izixhobo zanamhlanje zeplastiki zepelletizing zibonelela ngoluhlu olubanzi lwamandla. Ngokuqhelekileyo iqhuba i-100-2,500 kg / h. Oku kuhambelana neemfuno zemveliso ezincinci nezinkulu. Ezinye iimodeli, ezifana neWintech WT-150, zivelisa i-500-700 kg / h. I-Huarui SJ-120 ivelisa i-100-130 kg / h. Iinkqubo ezinkulu, ezifana ne-PTC185-95, zifikelela kwi-800-1000 kg / h. Iprojekthi entsha ebandakanya i-5G Double Filtration Compacting Pelletizing Line inomthamo wokukhupha i-1100 kg / h. Ezi zakhono ziphakamileyo zibonisa ukusebenza kakuhle kobuchwepheshe bangoku bepelletizing. Baqinisekisa unikezelo oluzinzileyo lweeplastiki ezihlaziyiweyo zeprimiyamu kumashishini ahlukeneyo.

Ukunyuka kweeNkqubo zoomatshini bePlastiki yokuRecycling

Ukuhlaziywa kweekhemikhali kunika isisombululo esinamandla kwiiplastiki iindlela zoomatshini azikwazi ukuphatha. Ezi nkqubo ziqhekeza iiplastiki zibe ziibhloko zazo zokwakha zekhemikhali okanye ezinye iikhemikhali ezixabisekileyo. Oku kudala imathiriyeli entsha yokuvelisa. Ukurisayikilishwa kweekhemikhali kuncedisana nokurisayikilisha koomatshini. Inceda ukufezekisa uqoqosho olusetyhula ngakumbi kwiiplastiki.

I-Pyrolysis kunye neGasification yePlastiki yokuRecycling oomatshini

I-Pyrolysis kunye ne-gasification zimbini iindlela eziphambili zokuphinda zisetyenziswe kwikhemikhali. I-Pyrolysis itshisa inkunkuma yeplastiki ngaphandle kweoksijini. Le nkqubo idiliza imixokelelwane emide yepolymer ibe ziimolekyuli ezincinci. Ivelisa ioli, iigesi, kunye ne-char. I-gasification isebenzisa ubushushu obuphezulu kunye nomthamo olawulwayo we-oksijini okanye umphunga. Oku kuguqula iplastiki ibe yi-syngas, umxube we-hydrogen kunye ne-carbon monoxide. I-Syngas ke inokuba sisibaso okanye isitokhwe sekhemikhali.

Iinkampani ezifana ne-ExxonMobil zisebenzisa itekhnoloji yecoprocessing. Le teknoloji idibanisa inkunkuma yeplastiki kwiiyunithi ze-coker. Ivelisa i-synthetic crude kunye ne-naphtha. Iindawo zokucokisa zingaqhubela phambili ezi zinto zibe yipetrochemical feedstocks. Ukubandakanya i-polyethylene okanye i-polystyrene kwi-coprocessing iphakamisa kakhulu isivuno semveliso yolwelo. Kuseto lwe-coking olumanzi, ukongeza inkunkuma yeplastiki nayo iphakamisa inani le-syngas eveliswayo. Itekhnoloji ye-pyrolysis ye-microwave eqhubela phambili ivelisa i-oyile ye-pyrolysis ekumgangatho ophezulu. Le oli idibana nemigangatho yokucoca. Oku kubonisa amandla okwenza iimveliso ezixabisekileyo.

Iinkqubo zokurisayikilisha iikhemikhali ziguqula inkunkuma yeplastiki ibe yimveliso eyahlukeneyo eluncedo. Malunga ne-15-20% yenkunkuma yeplastiki iba yipropylene kunye ne-ethylene. Ezi ziibhloko ezisisiseko zokwakha iiplastiki ezintsha. I-80-85% eseleyo yenkunkuma yeplastiki iguqula ibe yi-diesel fuel, i-hydrogen, i-methane, kunye nezinye iikhemikhali. Ezi ziphumo zibonisa ukuguquguquka kwe-pyrolysis kunye ne-gasification.

I-Depolymerization kwiintlobo zePlastiki eziKhethekileyo

I-Depolymerization yindlela echanekileyo yokubuyisela ikhemikhali. Iqhekeza iipolima zeplastiki ezithile zibuyela kwiimonomers zazo zangaphambili. Iimolekyuli ziimolekyuli ezincinci ezidibanisa ukwenza iipolymers. Le nkqubo idala izixhobo ezikumgangatho ophezulu. Abavelisi banokusebenzisa ezi zinto zikrwada ukwenza iiplastiki ezintsha ezineempawu ezinjengobuntombi.

I-depolymerization ikhawulelwe kwiintlobo ezithile zeeplastiki. Ezi zaziwa njengeepholima zokujiya. Imizekelo ibandakanya inayiloni kunye ne-PET (i-polyethylene terephthalate). I-PET yeyona nto iphambili ekugxilwe kuyo kwiinkqubo zokurhweba ukuchithwa kwepolymerization. Ukufaneleka kwayo kunye nobuninzi bayo buyenza ibe yinto ekujoliswe kuyo efanelekileyo. Ubuchwephesha besizukulwana esilandelayo se-depolymerization nabo bujolise kwinkunkuma ye-acrylic, ngokukodwa i-PMMA (i-polymethyl methacrylate).

Ukucoceka kwee-monomers ezifunyenwe nge-depolymerization kuphezulu kakhulu. Oku kubenza baxabiseke kwimveliso entsha yeplastiki. Iindlela ezahlukeneyo kunye nee-catalysts zifezekisa izivuno ezahlukeneyo.

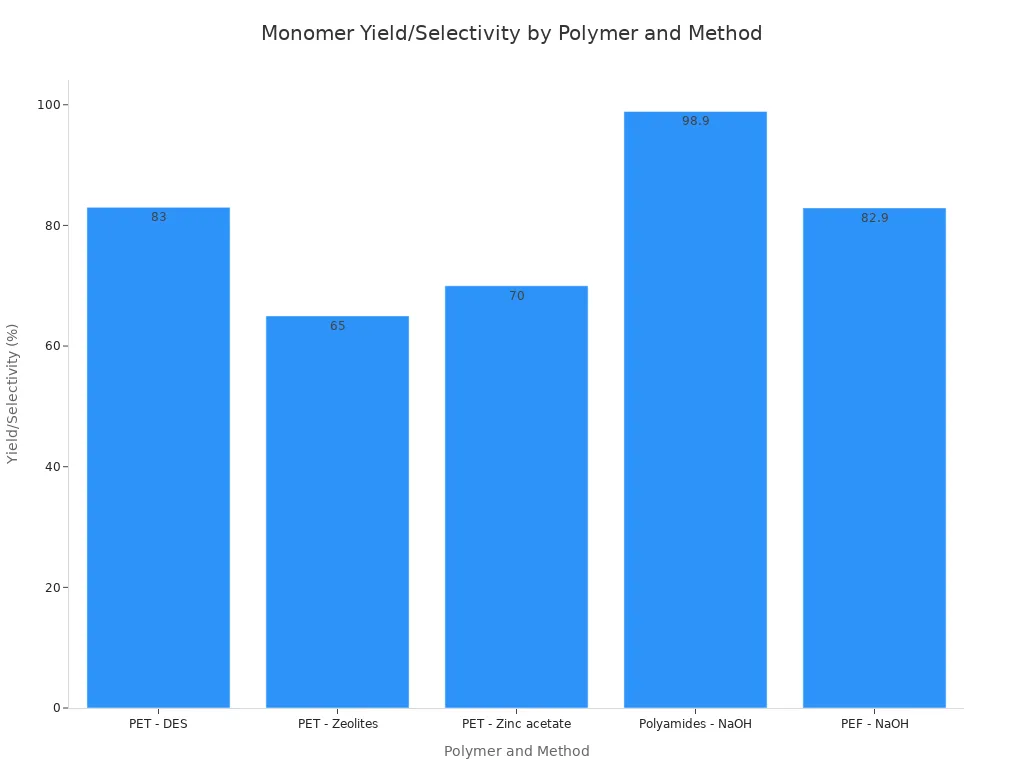

| Ipolymer | Indlela/I-Catalyst | Isivuno se-Monomer / Ukukhetha |

|---|---|---|

| I-PET | [urea/ZnCl2] DES | I-83% yokukhetha kwi-BHET |

| I-PET | AmaZeolites | I-65% isivuno seBHET |

| I-PET | I-Zinc acetate kunye ne-EG | Ukuya kuthi ga kwi-70% isivuno seBHET |

| IiPoliyamide (Kevlar) | I-Hydrolysis kunye ne-NaOH | I-98.9% yePPD, i-95.3% ye-PTA |

| I-PEF | I-Hydrolysis kunye ne-NaOH | I-82.9% isivuno se-2,5-furandicarboxylic acid |

I-Dimethylethylamine catalysts ikhuthaza izivuno eziphezulu ze-depolymerization. Basebenza phantsi kweemeko eziphantsi. Oku kunegalelo kwimveliso ye-monomer engaguqukiyo. Ezi ndlela eziphambili ziqinisekisa unikezelo oluthembekileyo lweemonomers ezicocekileyo.

Oomatshini beSolvolysis kunye ne-Hydrothermal Plastic Recycling

Iinkqubo zeSolvolysis kunye ne-hydrothermal zezinye iitekhnoloji ezibalulekileyo zokusebenzisa kwakhona iikhemikhali. I-Solvolysis isebenzisa izinyibilikisi ukunyibilikisa okanye ukwaphula iiplastiki. Le nkqubo ihlala isebenza kumaqondo obushushu asezantsi. Iinkqubo zeHydrothermal zisebenzisa amanzi ashushu, acinezelekileyo ukuguqula iiplastiki. Zombini iindlela zibonelela ngeenzuzo ezizodwa kwiintlobo ezahlukeneyo zeplastiki.

Iimeko zokusebenza ziyahluka kwezi nkqubo.

| Uhlobo lweNkqubo | Uluhlu lobushushu (°C) | Uluhlu loxinzelelo (MPa) |

|---|---|---|

| I-Hydrothermal Liquefaction (HTL) | 250–350 | 10–20 |

Iinkqubo ze-Solvolysis nazo zisebenza phantsi kweemeko ezahlukeneyo.

| Uhlobo lweNkqubo | Uluhlu lobushushu (°C) | Uluhlu loxinzelelo (MPa) |

|---|---|---|

| I-Solvolysis (LTP) | <200 | I-Ambient |

| I-Solvolysis (HTP) | Ukuya kuthi ga kwi-450 | 0.3 ukuya ku-30 |

Ezi meko zivumela iindlela ezilungelelanisiweyo kwimijelo eyahlukeneyo yenkunkuma yeplastiki.

Unyango lweHydrothermal (HTT) lubonelela ngeenzuzo ezibalulekileyo zokusingqongileyo. Inokufikelela kwi-80% yokunciphisa ukukhutshwa kokutshintsha kwemozulu. Oku kuthelekiswa nokutshisa, indlela eqhelekileyo yokulahla iiplastiki ekunzima ukuzisebenzisa kwakhona. I-HTT igcina imathiriyeli ngaphakathi kwenkqubo. Oku kukhokelela ekuncitshisweni kokusetyenziswa kwemithombo yezinto eziphila phantsi komhlaba. Impembelelo ephambili yokusingqongileyo ye-HTT kukusetyenziswa kombane. Ukunciphisa oku ngokusebenzisa amandla afanelekileyo okanye imithombo yamandla ahlaziyekayo kunokuphucula ngakumbi ukusebenza kwayo kokusingqongileyo. I-HTT inqanda ukutsha okuyingozi kweemveliso ezifana ne-dioxins kunye ne-char. Iinkqubo zokurisayikilishwa kweekhemikhali, kubandakanywa i-HTT, iphatha uluhlu olubanzi lweeplastiki ezingeyo-homogeneous emva komthengi. Oku kunika isisombululo esisebenzayo kwisikali soqoqosho olujikelezayo. Impembelelo yokutshintsha kwemozulu ye-naphtha eveliswe nge-HTT ithelekiseka neenkqubo zangoku zemveliso yeekhemikhali zefosili. Oku kunika iinketho zokujikeleza kwimveliso yeplastiki. Ezi teknoloji zoomatshini bePlastiki beRecycling babalulekile kwikamva elizinzileyo.

I-Smart Plastic yeMisebenzi yokuRisayikilishwa koomatshini: i-AI, i-IoT, kunye ne-Automation

Imisebenzi yale mihla yokuhlaziya iplastiki isebenzisa ubuchwephesha obuphezulu. I-Artificial Intelligence (AI), i-Intanethi yeZinto (IoT), kunye ne-automation yenza iinkqubo zihlakaniphe. Ezi zixhobo ziphucula ukusebenza kakuhle, ukunciphisa iindleko, kunye nokunyusa umgangatho wezinto ezisetyenzisiweyo.

ULondolozo oluqikelelweyo koomatshini bokurisayikilisha bePlastiki

Ugcino oluqikelelweyo lugcina oomatshini bokurisayikilisha beplastiki besebenza kakuhle. Iinzwa ze-IoT ziqokelela idatha yexesha langempela kwizixhobo. Bajonga ukungcangcazela, ubushushu, kunye nokusebenza kwemoto. I-algorithms ye-AI ihlalutya le datha. Baqikelela ukuba inxalenye yomatshini inokusilela nini. Oku kuvumela izibonelelo ukuba zenze ulondolozo phambi kokuba kwenzeke ukuqhawuka. Ithintela ixesha lokuphumla elingalindelekanga. Le ndlela yonga imali kwaye yongeza iiyure zokusebenza.

Uhlalutyo lweDatha yeeNkqubo eziLungisiweyo zokuRisayikilishwa

Uhlalutyo lwedatha luguqula imisebenzi yokurisayikilisha. Amaqonga aphezulu aqokelela kwaye ahlalutye iintlobo ezahlukeneyo zedatha. Balandelela iZalathi zokuSebenza eziPhambili (KPIs) ezifana nokusetyenziswa kwamandla kunye nokukhutshwa kweGHG. Bakwaqokelela idatha yokwakheka kwezinto, kubandakanywa iipesenti ezihlaziyiweyo. Idatha yokusebenza igubungela ukusebenza koomatshini kunye namaqondo obushushu okuqhuba. Idatha yokuthotyelwa iqinisekisa ukuba izibonelelo ziyahlangabezana nezigunyaziso zengingqi kunye neethagethi zomxholo ohlaziyiweyo. Iimetrics zenkunkuma zilandelela amazinga okuqokelelwa, ukuhlela ukungachaneki, kunye nongcoliseko. Idatha yokulandelelwa iqinisekisa amabango malunga neemveliso ezihlaziyiweyo.

Iinkqubo zokuhlela ze-AI zisebenzisa i-Near-infrared (NIR) i-spectroscopy kunye ne-AI algorithms. Ezi nkqubo zinciphisa izinga lokungcoliseka ukuya kutsho kuma-50 ekhulwini. Abaphandi baphuhlise imodeli yokufunda koomatshini echonga iintlobo zeplastiki ukuya kuthi ga kwi-100% ngokuchanekileyo. Oku kuchanekileyo ekuhleleni kunciphisa ungcoliseko. Ikhokelela kumgangatho ophezulu we-resin ehlaziyiweyo kunye neendleko eziphantsi zokusebenza. Kwi-AdvanTech Plastics, i-AI-powered sensors ihlola iindawo ezibunjiweyo ngexesha langempela. Oku kubhaqa ukungafezeki kwaye kuvumele uhlengahlengiso olukhawulezileyo. Ikhokelela kwiimveliso ezimbalwa ezineziphene, i-scrap encinci, kunye nokusetyenziswa kwamandla aphantsi.

IZibonelelo zePlastiki eziziSebenzisa ngokupheleleyo

Izibonelelo ezizisebenzelayo ngokupheleleyo ziyayitshintsha imbonakalo-mhlaba yokurisayikilisha. Iirobhothi zenza imisebenzi eyayikhe yenziwa ngabantu. Oku kunciphisa iindleko zabasebenzi kwaye kuphucula ukhuseleko.

| Uphawu | Iirobhothi | IsiHluli soMntu |

|---|---|---|

| Ukukhetha ngeyure | Ukuya kuthi ga kwi-4,000 | 500-700 (izinto ezinzima) |

| Iiyure zokusebenza | 24/7 | Hayi 24/7, kufuna ikhefu |

| Ubunzima obukhulu buphathwa | 66 lbs (30kg) | Ayinakwenzeka / ikhuselekile kwi-66 lbs ngokuqhubekayo |

Iirobhothi zinokuchola ukuya kutsho kwizinto ezingama-4,000 ngeyure. Abahluli babantu baphatha izinto ezinzima ezingama-500-700 ngeyure. Iirobhothi zisebenza 24/7 ngaphandle kwekhefu. Baphatha ngokukhuselekileyo izinto ezinzima ukuya kuthi ga kwi-66 lbs. I-Lundstams Återvinning AB, inkampani yaseSweden, yonge malunga ne-$22,000 USD ngenyanga. Bayinciphisa inkunkuma etshisiweyo emva kokusebenzisa iirobhothi. Iirobhothi zokurisayikilisha zinegalelo kulondolozo lwexesha elide. Banciphisa iindleko zabasebenzi kwaye banciphise iimpazamo.

Impembelelo kunye nekamva lika-2025 koomatshini bokurisayikilisha bePlastiki

Ukujongana nePlastiki eKunzima uku-Recycled ngoomatshini abaTsha

Oomatshini abatsha bokurisayikilisha ngo-2025 bajongana neeplastiki ebezikade zithathwa njengezingenakuphinda zisetyenziswe. Ukurisayikilisha kweekhemikhali kophula inkunkuma yeplastiki engcolisekileyo, njengokupakishwa kokutya okanye iibhotile zeoyile yemoto, ukuya kwinqanaba lemolekyuli. Le nkqubo ihluza ungcoliseko ngokufanelekileyo. Inkunkuma yeplastiki enamaleko amaninzi, njengokupakishwa kokutya okuguquguqukayo, ikwaxhamla kwi-molecular recycling. Oku koyisa imiceli mngeni ejongene nokurisayikilisha ngoomatshini ngezi mathiriyeli. Izisombululo eziphezulu ngoku zijolise kwi-polystyrene foam, i-polyurethane foam, kunye neefilimu ze-mono-material kunye neengxowa. Bakwajongana neepowutshi ezininzi, i-thermoforms/i-black rigids, kunye ne-foam/i-rigids ezincinci. Iinkqubo zokuhlanjululwa kwi-molecular recycling zisusa ukungcola kwezi zinto ezinzima.

IiNzuzo zezoQoqosho nokusiNgqongileyo zokuRisayikilishwa okuPhezulu

Oomatshini bokurisayikilisha beplastiki abakumgangatho ophezulu babonelela ngeenzuzo ezibalulekileyo zoqoqosho kunye nokusingqongileyo. Banciphisa iindleko zolawulo lwenkunkuma koomasipala kunye namashishini. Iinkampani zenza ingeniso entsha ngokuguqula inkunkuma ibe yimveliso yexabiso efana nokupakishwa okutsha okanye izinto zokwakha. Oku kukhusela ubutyebi bendalo ngokunciphisa imfuno yezinto ezingasetyenziswanga njengepetroleum. Ngokusingqongileyo, obu bugcisa buvelisa iimveliso zeplastiki kunye neekhemikhali ezinokunciphisa ukufudumala kwehlabathi. Bafezekisa oku xa kuthelekiswa neemveliso ezenziwe kwimithombo enyulu. Ukurisayikilisha okukwinqanaba eliphezulu kunokunciphisa ukukhutshwa kwe-CO2 ngokulinganayo ngaphezulu kwe-100% xa kuthelekiswa nokulahla inkunkuma kunye neenkqubo zokulahla amandla. Ngaphezulu kweeprojekthi ezingama-40, ezimele ngaphezulu kwe-7 yeebhiliyoni zeerandi kutyalo-mali, zinokuphambukisa malunga ne-21 yeebhiliyoni zeeponti zenkunkuma kwiindawo zokulahla inkunkuma ngonyaka.

Imiceli mngeni kunye namathuba okwamkela iiTekhnoloji eziNtsha

Ukwamkela ubugcisa obutsha bokurisayikilisha kuzisa imingeni kunye namathuba. Utyalo-mali lwangaphambili olubalulekileyo luhlala luyimfuneko koomatshini abaphambili kunye neziseko zophuhliso. Ukudibanisa ezi nkqubo zintsonkothileyo kwizibonelelo ezikhoyo nako kufuna ukucwangciswa okucokisekileyo kunye nomsebenzi onezakhono. Nangona kunjalo, obu bugcisa buvula iingcango kwiimarike ezintsha zemathiriyeli ehlaziyiweyo. Bakwakhuthaza inguqulelo kwimveliso ezinzileyo. Iphulo elisingise kuqoqosho olusetyhula lidala imfuno emandla yeeplastiki ezisetyenzisiweyo ezikumgangatho ophezulu. Oku kubonelela ngamathuba okukhula okubonakalayo kwiinkampani ezamkela ezi nkqubela phambili.

Ukuqhubela phambili kubuchwepheshe bomatshini bokurisayikilisha beplastiki ngo-2025 kubonisa utshintsho olusisiseko. Ukuhlela ngobuchule kunye neenkqubo zeekhemikhali eziphucukileyo ziguqula ishishini. Ezi zinto zintsha zisiqhubela kuqoqosho olujikelezayo. Inkunkuma yeplastiki iba sisixhobo esixabisekileyo. Oku kuqhuba uzinzo kunye nokukhula koqoqosho kumntu wonke.

FAQ

Yeyiphi eyona nto iphambili ekugxilwe kuyo koomatshini beplastiki bokurisayikilisha ngo-2025?

Oomatshini ngo-2025 bagxile kwi-automation ephezulu. Zikwabonisa izakhono eziphuculweyo zokuhlela izinto. Iinkqubo ezintsha zokurisayikilishwa kweekhemikhali zingundoqo. Ezi teknoloji ziguqula inkunkuma ibe yimithombo exabisekileyo. Baphucula kakhulu ukusebenza kakuhle kunye nokuzinza. ♻️

Ingaba iinkqubo zokuhlela ze-next-gen ziyiphucula njani i-recycling?

Iinkqubo zokuhlela ezilandelayo zisebenzisa i-AI, ukufunda ngomatshini, kunye nezivamvo eziphambili. Bachonga iiplastiki ngokwemibala, imilo, nangemichiza. Oku kuphucula ukuchaneka kokuhlelwa. Kwakhona kunciphisa ungcoliseko. Oku kukhokelela kumgangatho ophezulu wezinto ezisetyenzisiweyo.

Ixesha lokuposa: Oct-25-2025