Muna 2025, ruzha rwakatenderedza mapurasitiki ekudzokorodza machina anogara pane epamberi otomatiki, akagadziridzwa ekugadzirisa zvinhu, uye hunyanzvi hwekudzokorodza kemikari. Zvitsva izvi zvinoshandura marara kuita zviwanikwa zvakakosha. Gore rino rinoratidza kusvetuka kwakakosha mukubudirira uye kusimba kweindasitiri. Nyanzvi dzinoronga pasi roseepurasitiki recycling muchinamusika uchasvika USD 3.82 bhiriyoni muna 2025. Musika uyu unotarisira kukura kwakasimba. Aplastiki crusher muchinainobatsira kuputsa zvinhu zvakakura zvepurasitiki. Aplastiki shredderinogadzirawo zvinhu zvakanaka. Aepurasitiki recycle muchinainogadzirisa tsvina kuita mafomu anogona kushandiswa zvakare. Pakupedzisira, aplastiki kugadzira muchinaanogona kushandisa mapurasitiki akadzokororwa aya.

Key Takeaways

- Mitemo mitsva nemitemo inoita kuti 2025 rive gore guru rekudzokorodza zvakare. Mitemo iyi inosundidzira makambani kushandisa michina iri nani uye kudzoreredza mamwe mapurasitiki.

- Michina yekudzokorodza yepurasitiki iri kuwedzera kungwara. Ivo vanoshandisa AI kuronga mapurasitiki zvirinani uye IoT kuteedzera kuti michina inoshanda sei. Izvi zvinoita kuti kushandiswa patsva kushande.

- Mechanical recycling iri kuvandudzika. Michina mitsva inoronga mapurasitiki nehupamhi hwepamusoro. Vanowachawo nekutsemura mapurasitiki zviri nani. Izvi zvinogadzira zvigadzirwa zvemhando yepamusoro zvakadzokororwa.

- Kugadziriswa kwemakemikari kuri kukura. Inoputsa mapurasitiki kuita zvikamu zvakakosha. Izvi zvinobatsira kudzoreredza mapurasitiki akaoma kugadzirisa. Inogadzira zvinhu zvitsva zvezvigadzirwa.

- Michina yekudzokorodza yepamusoro inobatsira nharaunda nehupfumi. Vanoshandura marara kuita zvigadzirwa zvitsva. Izvi zvinochengetedza mari uye zvinoderedza kusvibiswa.

Iyo 2025 Landscape yePlastiki Recycling Machine Innovation

Nei 2025 iGore Rakakosha reKudzokorodza Tekinoroji

Gore ra2025 rinoratidza nguva yakakosha yekudzokorodza tekinoroji. Mitemo mitsva nemirau zviri kufambisa shanduko huru. Zvirongwa Zvakawedzerwa Mugadzirisi Webasa (EPR), semuenzaniso, zvinokurudzira vanogadzira kushandisa mapurasitiki akadzokororwa. Izvi zvinowedzera zvakananga kudiwa kwemhando yepamusoro granulation michina. Mitemo pamarara emarara uye zvinangwa zvekudzokorodza zvakare zvinosundidzira marecyclers kuvandudza michina yavo. Mitemo yezvakatipoteredza inotarisa kushandiswa kwesimba uye kuderedza kubudiswa. Aya marongero anopesvedzera magadzirirwo nemashandiro emakambani michina yegranulator, zvichitungamira kune akasvibira matekinoroji. Masangano akaita seEPA anoisa zviyero zvemidziyo. Kutevedzera zviyero izvi kunoita kuti michina ikwane kuchengetedzeka, zvakatipoteredza, uye mabhenji ekushanda. Mitemo yeNorth America inowedzera kusimbisa kuchengetedzwa kwemarara. Makambani anodyara mari mumakina anotevera marongero aya anogona kuwana kurudziro yehurumende uye kudzivirira zvirango. Izvi zvinovapa mukana wekukwikwidza.

Makiyi Mafambiro ePlastiki Recycling Machine Development

Mafambiro akati wandei ari kuumba kuvandudzwa kwemichina yekudzokorodza epurasitiki. AI-powered kurongedza masisitimu ibudiriro huru. Aya masisitimu anogona kuwana 98% kuchena muPET/HDPE hova. Vanoderedzawo kusvibiswa ne40%. IoT-inogonesa yekutarisa inobvumira chaiyo-nguva yekutevera yemashini kuita uye kushandiswa kwesimba. Izvi zvinotungamira kune 25% kuderedzwa kwekuderera. Decentralized zvivakwa zviri kuwedzera kuwanda. Aya ma compact units anogona kugadzira 500–800 kg/h. Vanobatsira kuderedza kubudiswa kwezvifambiso pasi rose. EU's Packaging and Packaging Waste Regulation (PPWR) mutyairi mukuru. Zvinoda 70% kudzokorodza kurongedza panosvika 2030. Inodawo 10-35% yezvinyorwa zvakadzokororwa mumapurasitiki. Kusangana nemutemo uyu kunoda advanced mechanic and chemical recycling technologies. Tekinoroji dzekurongedza dzakavandudzwa dziri kushandura kudzokorodza kwepurasitiki. Automated system inoshandisa masensa epamberi, hungwaru hwekugadzira, uye kudzidza muchina. Vanogona kuona uye kuparadzanisa mapurasitiki zvichienderana nemakemikari avo, ruvara, uye chimiro. Izvi zvinovandudza kushanda uye kuchena mukudzokorodza hova. Kuvandudza uku kunobatsira kugadzira mapurasitiki akadzokororwa emhando yepamusoro.

Yepamberi Mechanical Plastic Recycling Machine Technologies

Mechanical recycling inoramba iri dombo repakona rekutonga kwemarara epurasitiki. Muna 2025, kufambira mberi kutsva kunoita kuti maitiro aya ashande uye anoshanda. Michina iyi ikozvino inobata huwandu hwakawanda hwemapurasitiki. Ivo zvakare vanogadzira zvemhando yepamusoro zvekushandisa zvakare.

Inotevera-Gen Kuronga Masisitimu ePlastiki Recycling Machina

Kuronga ndiro danho rekutanga rakakosha mukudzokorodza michina. Mitsva yekuronga masisitimu anoshandisa advanced sensor tekinoroji, artificial intelligence (AI), uye muchina kudzidza. Zvishandiso izvi zvakanyanya kunatsiridza huchokwadi uye nekukurumidza. Makomputa ekuona masisitimu anoshandisa yakakwirira-resolution makamera uye AI algorithms. Vanoongorora zvinhu zvepurasitiki munguva chaiyo. Aya masisitimu anozivisa misiyano isingaoneki muruvara, maumbirwo, uye magadzirirwo emhando chaiyo. Mamodheru ekudzidza emuchina anoramba achivandudza kugona kwavo kuzivikanwa.

Kudzidza kwakadzama algorithms gadzira ruzivo rwakaoma rwekuona. Ivo vanoita sarudzo dzekuparadzanisa-yechipiri nezve kuumbwa kwezvinhu. Aya maalgorithms anokunda pakuziva mapatani uye maficha asingaonekwe nevanhu. Izvi zvinotungamira pakuronga kurongeka kwemitengo inopfuura 95%. Near-Infrared (NIR) spectroscopy imwe tekinoroji yakakosha. Inoshandisa infrared mwenje kuongorora mamorekuru. Izvi zvinobvumira kukurumidza uye kwakaringana kuzivikanwa kwemhando dzakasiyana dzepurasitiki sePET, HDPE, uye PVC. Iyo inoyera yavo yakasarudzika spectral siginecha.

Hyperspectral imaging inotora spectroscopic kuronga mberi. Inobatanidza kufungidzira kwechinyakare ne spectroscopy. Izvi zvinotora data mumazana emabhendi e spectral. Inopa kuongorora kwakadzama kwezvinhu. Izvi zvinozivisa zvinosvibisa, zvinowedzera, uye zvisizvo zvakasiyana-siyana mukuumbwa kwepurasitiki. Smart gripper tekinoroji inobatsirawo. Aya magadzirirwo emagetsi ane masensa uye anogadzirisa kudzvinyirira kutonga. Vanobata zvinhu zvehukuru hwakasiyana, maumbirwo, uye huremu pasina kukuvara. Ivo vanogona zvakare kuona zvinhu zvemukati kuburikidza netactile mhinduro. Izvi zvinowedzera kurongeka kwechokwadi uye kunoderedza kusvibiswa.

Aya anotevera-chizvarwa optical kurongedza masisitimu anoshandisa epamberi kamera masisitimu, masensa, uye muchina kudzidza algorithms. Vanoona nekukasira uye nemazvo nekurongedza zvinhu zvakasiyana siyana zvemarara. Ivo vanoshandisa masensa anoona akasarudzika masiginecha ekunyatso kuzivikanwa kwezvinhu uye kupatsanura. Izvi zvinonyanya kubatsira pakuronga marara emutengi. Izvi zvinosanganisira mapurasitiki, girazi, bepa, uye simbi. Aya masisitimu anogona kuderedza mari yekufambisa nekuunganidza neinosvika 50% kana yasanganiswa neautomated tsvina yekuunganidza masisitimu. Ivo vanoshandisa NIR sensors kuona marudzi epolymer. Vanoparadzanisa mapurasitiki anobva pane ruvara uye rudzi. Aya masisitimu anopa huwandu hwepamusoro, kazhinji kugadzirisa mazana ematani pazuva. Vanoderedza kusvibiswa, zvichitungamira kune zvemhando yepamusoro zvakadzokororwa zvinhu. Hyperspectral imaging tekinoroji, seSpecim FX17 uye GX17, inopa chaiyo-nguva, yakavimbika yekuona. Inoparadzanisa PET kubva kune zvinosvibisa zvakaita sePVC, HDPE, ABS, mamwe mapurasitiki, uye organic zvinhu. Makamera eHyperspectral anopa kuvimbika kwekuronga uye kuchinjika. Ivo vanotora yakazara kana yakasarudzika spectral siyana. Izvi zvinobvumira kugadzirisazve mukati mehupenyu hwemuchina. Solid-state hyperspectral makamera haana kugadzirisa-yemahara kwemakore mazhinji. Izvo hazvina zvikamu zvinofamba zvinoda kudzokororwa nguva dzose uye kudzokorora. Aya masisitimu anosanganisa hyperspectral imaging neRGB makamera ekuwedzera ruvara uye kuonekwa kwechimiro. Ivo vanoshandisa AI-yakavakirwa neural network modhi inomhanya pane ane simba NVIDIA GPUs kuti anyatso kurongeka uye akadzama manhamba marekodhi. Vanotogadzirisa kurongedza kwepurasitiki nhema vachishandisa Specim FX50 HSI kamera. Iyi kamera inoshanda mukati me-wave infrared (MWIR) renji. Inozivisa uye kuronga mapurasitiki matema zvichienderana nemakemikari awo.

Kuwedzeredzwa Kuwacha uye Kuchekeresa muPlastiki Recycling Machines

Mushure mekugadzirisa, mapurasitiki anowachwa uye kuputika. Aya maitiro anogadzirira zvinyorwa kuti zviwedzere kugadziriswa. Michina yemazuva ano yekuwachisa uye yekuchekeresa inoratidza kuvandudzwa kwakanyanya mukuita kwesimba. Michina yepamberi yekudzokorodza mapurasitiki, kunyanya ayo anoshandisa servo mota tekinoroji, inoderedza mashandisiro emagetsi anosvika makumi matatu muzana zvichienzaniswa nemhando dzekare. Izvi zvinotungamirira kukuchengetedza mari uye zvikomborero zvakatipoteredza. Semuyenzaniso, conical twin screw, parallel twin screw, uye makomboni twin screw modhi zvinokwanisa kusvika 30% kuderedza kushandiswa kwesimba.

Kuvandudzwa mune shredder blade zvinhu uye magadzirirwo zvakare anovandudza kubuda uye kuderedza kugadzirisa. Dhizaini yeV rotor, ine dhayamita mazana mashanu uye kureba kusvika 2,200 mm, inobata mapundu makuru ekutanga, mabhini asina maburi, uye zvikamu zvinopenya. Iyo chaiyo F rotor ine milling uye yakasarudzika banga gadziriro yakanakira kucheka zvinhu zvinochinjika senge fiber nemafirimu. Inovimbisa chaiyo yekucheka geometries. Adjustable counter blades anogona kukurumidza kugadziriswa uye kutendeuka kubva kunze. Izvi zvinochengetedza rakakwana rekucheka gaka kunyangwe nekupfeka. Inotungamira kune inogara yakakwira throughput uye yakawedzerwa hupenyu hwesevhisi yebanga. Iyo ine rupo yekutarisa flap inobvumira kugadzirisa kwakaringana uye kwakaringana rotor kuwana. Izvi zvinoita kuti zvive nyore kubviswa kwezvinhu zvekunze uye basa rekugadzirisa rakasununguka.

Michina iyi inoshandisa mashizha akaomeswa esimbi pane maviri anotenderera shafts. Aya mashizha anobata mapurasitiki akapfava uye akaomarara zvakanaka. Iyo yakaderera-kumhanya, yakakwira-torque dhizaini inovimbisa kuenderana kuderera kwechikamu chekukura. Inoderedzawo huruva uye ruzha. Iyo inogadziriswa yekucheka kamuri inobvumira vashandisi kugadzirisa saizi yekubuda. Maindasitiri-giredhi zvikamu uye kuvaka kwakasimba kunovimbisa kuvimbika kwenguva refu. Vanoderedza zvinodiwa zvekuchengetedza uye kuderedza nguva yekuderera. Zvipfeko zvinodzivirira zvipfeko zvinochengetedza kushanda kwakafanana pamusoro penguva yakareba yekushanda. A quick blade replacement system inoderedza kukanganisa kushanda.

Extrusion uye Pelletizing for Premium Recycled Plastics

Nhanho yekupedzisira mukudzokorodza michina inosanganisira extrusion uye pelletizing. Izvi zvinoshandura maflakisi epurasitiki akachekwa uye akagezwa kuita mayunifomu pellets. Aya ma pellets anobva agadzirira kugadzira zvigadzirwa zvitsva. Yemazuva ano epurasitiki pelletizing midziyo inopa huwandu hwakawanda hwekugona. Iyo inowanzoita 100-2,500 kg / h. Izvi zvinogadzirisa zvese zvidiki uye zvakakura-zvido zvekugadzira. Mamwe mamodheru, seWintech WT-150, anoburitsa 500-700 kg/h. Iyo Huarui SJ-120 inoburitsa 100-130 kg/h. Mahombe masisitimu, akadai sePTC185-95, anowana 800-1000 kg/h. Chirongwa chitsva chinosanganisira 5G Double Filtration Compacting Pelletizing Line ine simba rekubuda rinosvika 1100 kg/h. Aya masimba epamusoro anoratidza kugona kweazvino pelletizing matekinoroji. Ivo vanova nechokwadi chekupihwa kwakasimba kwemapurasitiki akadzokororwa zvakare kumaindasitiri akasiyana.

Kusimuka kweChemical Plastic Recycling Machine Matanho

Kemikari kudzokorodza zvakare inopa mhinduro ine simba yemapurasitiki ayo ma mechanika nzira haagone kubata. Aya maitiro anopwanya mapurasitiki kuita mabhuroko avo ekutanga emakemikari ekuvaka kana mamwe makemikari anokosha. Izvi zvinogadzira zvinhu zvitsva zvekugadzira. Kudzokorodza kwekemikari kunozadzisa mechanical recycling. Inobatsira kuwana hupfumi hwakatenderedza hwemapurasitiki.

Pyrolysis uye Gasification Plastic Recycling Machines

Pyrolysis uye gasification nzira mbiri dzakakosha dzekugadzirisa makemikari. Pyrolysis inopisa marara epurasitiki pasina oxygen. Iyi nzira inopwanya macheni akareba epolymer kuita mamorekuru madiki. Inogadzira mafuta, magasi, uye char. Gasification inoshandisa tembiricha yepamusoro ine huwandu hunodzorwa hweokisijeni kana chiutsi. Izvi zvinoshandura plastiki kuita syngas, musanganiswa wehydrogen necarbon monoxide. Syngas inogona kuzoita mafuta kana makemikari feedstocks.

Makambani akaita seExxonMobil anoshandisa coprocessing tekinoroji. Iyi tekinoroji inobatanidza marara epurasitiki muzvikamu zvecoker. Inogadzira synthetic crude uye naphtha. Refineries inogona kuenderera mberi kugadzirisa izvi kuita petrochemical feedstocks. Kusanganisira polyethylene kana polystyrene mukubatanidzwa kunosimudzira zvakanyanya goho rechigadzirwa chemvura. Mune fluidized coking setup, kuwedzera marara epurasitiki zvakare kunokwidza huwandu hwema syngas anogadzirwa. Iyo yepamusoro microwave-powered pyrolysis tekinoroji inoburitsa emhando yepamusoro pyrolysis oiri. Oiri iyi inosangana nezviyero zvekunatsa. Izvi zvinoratidza mukana wekugadzira zvigadzirwa zvakakosha.

Makemikari ekudzokorodza maitiro anoshandura marara epurasitiki kuita akasiyana anobatsira anobuda. Inenge 15-20% yemarara epurasitiki inova propylene uye ethylene. Aya ndiwo matombo ekuvakisa epurasitiki matsva. Iyo yasara 80-85% yemarara epurasitiki inoshandura kuita dhiziri mafuta, haidrojeni, methane, nemamwe makemikari. Izvi zvinobuda zvinoratidzira kuwanda kwe pyrolysis uye gasification.

Depolymerization yeChaiyo Plastic Types

Depolymerization inzira chaiyo yekudzokorodza kemikari. Iyo inopwanya chaiwo mapolymer epurasitiki kumashure mumamonomers avo ekutanga. Monomers ndiwo mamorekuru madiki anobatana kuti aumbe mapolymers. Iyi nzira inogadzira zvemhando yepamusoro zvinhu. Vagadziri vanogona kushandisa mbichana idzi kugadzira mapurasitiki matsva ane virgin-like properties.

Depolymerization inogumira kune chaiwo marudzi emapurasitiki. Aya anozivikanwa secondensation polymers. Mienzaniso inosanganisira nylon uye PET (polyethylene terephthalate). PET ndiyo inonyanya kutariswa yekutengeserana depolymerization maitiro. Kukodzera kwayo uye kuwanda kunoita kuti ive chinangwa chakakodzera. Inotevera-chizvarwa depolymerization tekinoroji zvakare inotarisa acrylic tsvina, kunyanya PMMA (polymethyl methacrylate).

Kuchena kwemamonomers akadzorerwa kuburikidza ne depolymerization yakanyanya kukwirira. Izvi zvinoita kuti zvive zvakakosha pakugadzirwa kwepurasitiki itsva. Nzira dzakasiyana uye catalysts dzinowana zvibereko zvakasiyana.

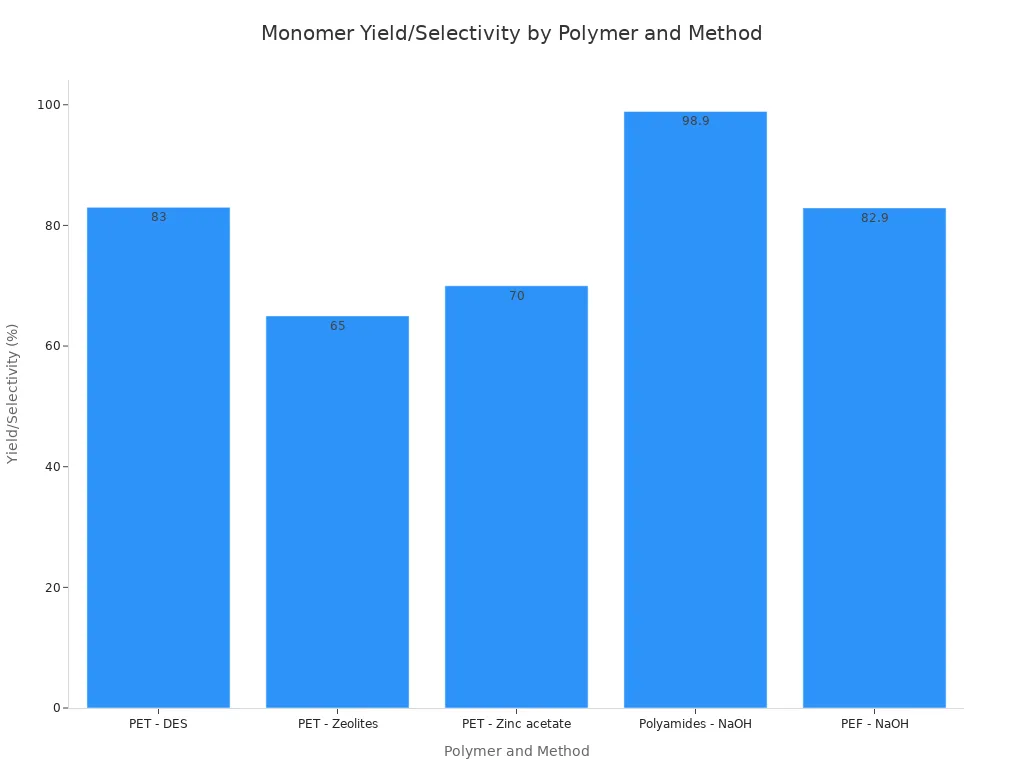

| Polymer | Nzira/Catalyst | Monomer Kubereka / Kusarudzwa |

|---|---|---|

| PET | [urea/ZnCl2] DES | 83% kusarudza kuBHET |

| PET | Zeolites | 65% goho reBHET |

| PET | Zinc acetate uye EG | Kusvikira ku70% goho reBHET |

| Polyamides (Kevlar) | Hydrolysis neNaOH | 98.9% yePPD, 95.3% yePTA |

| PEF | Hydrolysis neNaOH | 82.9% goho re2,5-furandicarboxylic acid |

Dimethylethylamine catalysts inosimudzira goho rakakwira depolymerization. Vanoshanda pasi pemamiriro epakati. Izvi zvinobatsira mukuenderana kwemonomeri kubuda. Idzi nzira dzepamusoro dzinovimbisa kuwanikwa kwakavimbika kwemamonomers akachena.

Solvolysis uye Hydrothermal Plastic Recycling Machines

Solvolysis uye hydrothermal maitiro mamwe akakosha makemikari ekudzoreredza tekinoroji. Solvolysis inoshandisa zvinonyungudutsa kunyungudutsa kana kuputsa mapurasitiki. Iyi nzira inowanzoshanda kune tembiricha yakaderera. Maitiro eHydrothermal anoshandisa mvura inopisa, yakamanikidzwa kushandura mapurasitiki. Nzira mbiri idzi dzinopa mabhenefiti akasiyana emhando dzakasiyana dzepurasitiki.

Mamiriro ekushanda anosiyana kune aya maitiro.

| Process Type | Tembiricha Range (°C) | Pressure Range (MPa) |

|---|---|---|

| Hydrothermal Liquefaction (HTL) | 250–350 | 10–20 |

Solvolysis maitiro anoshandawo pasi pemamiriro akasiyana.

| Process Type | Tembiricha Range (°C) | Pressure Range (MPa) |

|---|---|---|

| Solvolysis (LTP) | <200 | Ambient |

| Solvolysis (HTP) | Kusvika ku450 | 0.3 kusvika ku30 |

Aya mamiriro anobvumira nzira dzakagadzirirwa kune dzakasiyana siyana dzepurasitiki tsvina.

Hydrothermal Treatment (HTT) inopa zvakakosha zvakatipoteredza. Inogona kuwana kusvika ku80% kudzikiswa kwehutsi hwekushanduka kwemamiriro ekunze. Izvi zvinofananidzwa nekupisa, nzira yakajairika yekurasa mapurasitiki akaoma-kudzokorodza. HTT inochengetedza zvinhu mukati mehurongwa. Izvi zvinoita kuti kuderedzwa kwekushandiswa kwefossil-based resources. Iko kukonzeresa kwezvakatipoteredza kweHTT kushandisa magetsi. Kudzikisira izvi kuburikidza nekushanda kwesimba kana kudzokororwazve simba masosi kunogona kuwedzera kuvandudza kushanda kwayo kwezvakatipoteredza. HTT inodzivirira kupisa kunokuvadza ne-zvigadzirwa senge dioxin uye char. Kemikari kudzokorodza maitiro, kusanganisira HTT, inobata huwandu hwakakura hweasiri-homogeneous post-vatengi mapurasitiki. Izvi zvinopa mhinduro inoshanda pachiyero chehupfumi hwedenderedzwa. Kuchinja kwemamiriro ekunze kwenaphtha inogadzirwa kuburikidza neHTT inofananidzwa neazvino fossil kemikari feedstock kugadzira maitiro. Izvi zvinopa circularity sarudzo dzekugadzira mapurasitiki. Aya makemikari epamberi ePlastiki Recycling Machine matekinoroji akakosha kune remangwana rakagadzikana.

Smart Plastic Recycling Machine Operations: AI, IoT, uye otomatiki

Mazuva ano mapurasitiki ekudzokorodza mabasa anoshandisa tekinoroji yepamusoro. Artificial intelligence (AI), iyo Internet yeZvinhu (IoT), uye otomatiki inoita kuti maitiro ave nehungwaru. Zvishandiso izvi zvinovandudza kushanda zvakanaka, kuderedza mitengo, uye kuwedzera kunaka kwezvinhu zvakadzokororwa.

Predictive Maintenance for Plastic Recycling Machines

Predictive maintenance inochengeta mapurasitiki ekudzokorodza machina achishanda zvakanaka. IoT sensors inounganidza chaiyo-nguva data kubva kumidziyo. Ivo vanotarisa vibrations, tembiricha, uye mota kuita. AI algorithms inoongorora iyi data. Vanofanotaura apo chikamu chemuchina chingakundikana. Izvi zvinobvumira zvivako kuita kugadzirisa kusati kwaitika. Inodzivirira kunonoka kusingatarisirwi. Iyi nzira inochengetedza mari uye inowedzera maawa ekushanda.

Data Analytics yeOptimized Recycling Matanho

Data analytics inoshandura mashandiro ekudzokorodza. Mapuratifomu epamberi anounganidza uye anoongorora akasiyana marudzi e data. Vanoteedzera Key Performance Indicators (KPIs) sekushandiswa kwesimba uye kuburitswa kweGHG. Ivo zvakare vanounganidza data yekuumbwa kwezvinhu, kusanganisira yakadzokororwa mapeji ekuisa. Operational data inovhara mashandiro emuchina uye kupisa tembiricha. Dhata rekuteerera rinoita kuti zvivakwa zvinosangana nezvinotemerwa zvemuno uye zvakadzokororwa zvemukati zvinangwa. Waste metrics inoteedzera mitengo yekuunganidza, kuronga zvisirizvo, uye kusvibiswa. Traceability data inosimbisa zvichemo nezvezvakagadzirwazve.

AI-powered kurongedza masisitimu anoshandisa Near-infrared (NIR) spectroscopy uye AI algorithms. Aya masisitimu anoderedza kusvibiswa kwehuwandu nezvikamu makumi mashanu kubva muzana. Vatsvagiri vakagadzira mamodhi ekudzidza emuchina anoona marudzi epurasitiki anosvika zana muzana. Kurongeka uku kunoderedza kusvibiswa. Inotungamira kune yepamusoro-mhando yakadzokororwa resin uye yakaderera mutengo wekushandisa. PaAdvanTech Plastics, AI-powered sensors inoongorora zvikamu zvakaumbwa munguva chaiyo. Izvi zvinoona kusakwana uye zvinobvumira kugadzirisa pakarepo. Zvinokonzera zvigadzirwa zvishoma zvakakanganisika, zvimedu zvishoma, uye kuderera kwesimba rekushandisa.

Fully Automated Plastic Recycling Facilities

Fully automated zvivakwa zviri kushandura recycling landscape. Marobhoti anoita mabasa akamboitwa nevanhu. Izvi zvinoderedza mari yevashandi uye zvinovandudza kuchengetedzwa.

| Feature | Robhoti | Murongi Wevanhu |

|---|---|---|

| Picks paawa | Kusvika ku4,000 | 500-700 (zvinorema zvinhu) |

| Maawa ekushanda | 24/7 | Kwete 24/7, inoda kuzorora |

| Max huremu yakabatwa | 66 lbs (30 kg) | Hazvigoneke / zvakachengeteka kune 66 lbs nguva dzose |

Marobhoti anogona kutora zvinhu zvinosvika 4,000 paawa. Marori evanhu anobata 500-700 zvinhu zvinorema paawa. Robhoti inoshanda 24/7 pasina kuzorora. Ivo vanobata zvakachengeteka zvinhu zvinorema kusvika ku66 lbs. Lundstams Återvinning AB, kambani yekuSweden, yakachengeta mari inosvika $22,000 USD pamwedzi. Vakaderedza marara akapiswa mushure mekushandisa marobhoti. Marobhoti anogadziridza zvakare anobatsira pakuchengetedza kwenguva refu. Vanoderedza mari yevashandi uye kuderedza zvikanganiso.

Impact uye Remangwana Maonero e2025 Plastic Recycling Machines

Kugadzirisa Zvakaoma-ku-Recycle Plastics neMichina Mitsva

Michina mitsva yekudzokorodza muna 2025 inobata mapurasitiki aimboonekwa seasingashandiswe zvakare. Kudzokorodza kemikari kunoputsa tsvina yepurasitiki yakasvibiswa, sepakurongedzerwa kwechikafu kana mabhodhoro emafuta emota, kusvika padanho remamorekuru. Iyi nzira inosefa zvinosvibisa zvinobudirira. Multi-layer marara epurasitiki, akadai seanochinja-chinja chikafu kurongedza, zvakare inobatsira kubva mukugadzirisa mamorekuru. Izvi zvinokunda zvipingamupinyi zvinotarisana nemichina yekudzokorodza zviso nezvinhu izvi. Mhinduro dzepamberi zvino dzinonanga polystyrene foam, polyurethane foam, uye mono-material mafirimu nemabhegi. Ivo zvakare vanogadzirisa multilayer pouches, thermoforms / dema rigids, uye furo / diki rigids. Maitiro ekunatsa mukudzokorodza mamorekuru anobvisa zvinosvibisa kubva kune izvi zvakaoma zvinhu.

Mabhenefiti eEconomic and Environmental of Advanced Recycling

Michina yepamberi yekudzokorodza epurasitiki inopa zvakakosha zvehupfumi uye zvakatipoteredza zvakanakira. Vanodzikisira mari yekudzora marara kumanisipala nemabhizinesi. Makambani anounza mari nyowani nekushandura marara kuita zvigadzirwa zvakakosha senge mapeji matsva kana zvekuvaka. Izvi zvinodzivirira zviwanikwa nekuderedza kudiwa kwezviwanikwa zvemhandara zvakaita sepetroleum. Nezvakatipoteredza, matekinoroji aya anogadzira zvigadzirwa zvepurasitiki nemakemikari zvine kuderedzwa kwepasirese kudziya. Vanozadzisa izvi zvichienzaniswa nezvigadzirwa zvakagadzirwa kubva kumhandara zviwanikwa. Kudzokorodza kwepamusoro kunogona kuderedza CO2 yakaenzana kubudiswa nepamusoro pe100% zvichienzaniswa nemarara uye marara-ku-simba maitiro. Anopfuura mapurojekiti makumi mana, anomiririra anopfuura mabhiriyoni manomwe emadhora mukudyara, anogona kutsausa anosvika mabhiriyoni makumi maviri nerimwe emapaunzi emarara kubva mumarara gore negore.

Matambudziko uye Mikana Yekutora New Technologies

Kutora matekinoroji matsva ekudzokorodza zvakare kunopa zvese matambudziko nemikana. Yakakosha kumberi kwekudyara kazhinji inodiwa kumichina yepamberi uye zvivakwa. Kubatanidza aya masisitimu akaomarara muzvivakwa zviripo zvinodawo kuronga kwekungwarira uye basa rine hunyanzvi. Nekudaro, matekinoroji aya anovhura mikova kumisika mitsva yezvinhu zvakadzokororwa. Ivo zvakare vanokurudzira hunyanzvi mukugadzirwa kwakasimba. Kutyaira kwakanangana nehupfumi hwakatenderedzwa kunogadzira kudiwa kwakasimba kwemapurasitiki akadzokororwa emhando yepamusoro. Izvi zvinopa mikana yakakura yekukura kune makambani anogashira izvi kufambira mberi.

Iko kufambira mberi mumakina epurasitiki ekudzoreredza matekinoroji muna 2025 inomiririra shanduko yakakosha. Kuronga zvine hungwaru uye kwakaoma makemikari maitiro ari kushandura indasitiri. Mabhindauko aya anotiendesa kune hupfumi hwakatenderedza. Purasitiki tsvina iri kuita chinhu chakakosha. Izvi zvinofambisa kusimba uye kukura kwehupfumi kune wese munhu.

FAQ

Chii chinonyanya kutariswa chemapurasitiki ekudzokorodza michina muna 2025?

Machina muna 2025 anotarisa pane yepamusoro otomatiki. Iwo zvakare anoratidza akakwidziridzwa ekugadzirisa zvinhu. Innovative makemikari recycling maitiro akakosha. Tekinoroji idzi dzinoshandura marara kuita zviwanikwa zvakakosha. Vanonyanya kuvandudza kushanda uye kuchengetedza. ♻️

Masisitimu ekurongedza anotevera anovandudza sei kudzokorodza?

Inotevera-gen yekuronga masisitimu anoshandisa AI, kudzidza muchina, uye masensa epamberi. Vanoziva mapurasitiki neruvara, chimiro, uye makemikoro. Izvi zvinovandudza kurongeka chaiko. Inoderedzawo kusvibiswa. Izvi zvinotungamira kune zvemhando yepamusoro zvakadzokororwa zvinhu.

Nguva yekutumira: Oct-25-2025