Nyob rau hauv 2025, lub buzz nyob ib ncig ntawm cov yas recycling tshuab chaw nyob rau hauv advanced automation, txhim kho cov khoom sorting peev xwm, thiab cov txheej txheem tshuaj ubno tshiab. Cov kev tsim kho tshiab no hloov pov tseg rau hauv cov peev txheej muaj txiaj ntsig. Xyoo no yog ib qho tseem ceeb leap hauv efficiency thiab sustainability rau kev lag luam. Cov kws tshaj lij ua haujlwm thoob ntiaj tebyas recycling tshuabkev ua lag luam yuav ncav cuag $ 3.82 billion hauv 2025. Lub khw no cia siab tias yuav muaj kev loj hlob zoo. Ayas crusher tshuabpab zom cov khoom yas loj. Ayas shredderkuj npaj cov ntaub ntawv zoo. Ayas recycle tshuabcov txheej txheem pov tseg rau hauv cov ntaub ntawv rov siv tau. Thaum kawg, ayas ua tshuabtuaj yeem siv cov yas rov ua dua tshiab no.

Ntsiab Cai

- Cov cai tshiab thiab cov cai ua rau xyoo 2025 yog xyoo loj rau kev rov ua dua tshiab. Cov kev cai no thawb cov tuam txhab kom siv cov tshuab zoo dua thiab rov ua dua cov yas ntau dua.

- Plastic recycling tshuab tau ntse dua. Lawv siv AI los txheeb cov yas zoo dua thiab IoT los taug qab cov tshuab ua haujlwm li cas. Qhov no ua rau kev rov ua dua tshiab.

- Mechanical recycling yog txhim kho. Cov tshuab tshiab xaiv cov yas nrog cov neeg siab. Lawv kuj ntxuav thiab shred plastics zoo dua. Qhov no ua rau cov khoom siv zoo dua qub.

- Kev siv tshuaj siv tshuaj rov ua dua tshiab zuj zus. Nws rhuav tshem cov plastics rau hauv qhov chaw yooj yim. Qhov no pab rov ua cov yas uas nyuaj rau kev ua haujlwm. Nws tsim cov khoom tshiab rau cov khoom.

- Cov tshuab ua kom zoo dua qub pab ib puag ncig thiab kev lag luam. Lawv hloov pov tseg rau hauv cov khoom tshiab. Qhov no txuag nyiaj thiab txo cov pa phem.

Lub 2025 Toj roob hauv pes rau yas Recycling Tshuab Innovation

Vim li cas 2025 yog Lub Xyoo Pivotal rau Kev Siv Tshuab Siv Tshuab

Xyoo 2025 yog lub sijhawm tseem ceeb rau kev siv thev naus laus zis tshiab. Cov cai tshiab thiab cov cai tswjfwm tau tsav cov kev hloov pauv tseem ceeb. Extended Producer Responsibility (EPR) cov kev pab cuam, piv txwv li, txhawb cov tuam txhab siv cov yas rov ua dua tshiab. Qhov no ncaj qha nce qhov xav tau ntawm cov khoom siv granulation zoo. Cov kev cai ntawm cov khib nyiab pov tseg thiab cov hom phiaj rov ua dua tshiab tseem thawb cov khoom siv rov ua dua tshiab los txhim kho lawv cov tshuab. Environmental txoj cai tsom rau kev siv hluav taws xob thiab txo qis emissions. Cov kev cai no cuam tshuam li cas cov tuam txhab tsim thiab ua haujlwm cov tshuab granulator, ua rau cov thev naus laus zis ntsuab. Cov koom haum xws li EPA tau teeb tsa cov qauv rau cov khoom siv. Ua raws li cov qauv no ua kom cov tshuab ua tau raws li kev nyab xeeb, ib puag ncig, thiab cov qauv kev ua haujlwm. North American cov kev cai nce ntxiv hais txog kev tswj cov pov tseg kom ruaj khov. Cov tuam txhab lag luam nqis peev hauv cov tshuab ua raws li cov cai no tuaj yeem tau txais kev txhawb nqa los ntawm tsoomfwv thiab zam kev nplua. Qhov no ua rau lawv muaj kev sib tw zoo dua.

Cov Ntsiab Lus Tseem Ceeb hauv Kev Siv Tshuab Siv Lub Tshuab Siv Yas

Ob peb qhov tseem ceeb tiam sis yog shaping txoj kev loj hlob ntawm yas recycling tshuab. AI-powered sorting systems yog ib qho kev nce qib loj. Cov tshuab no tuaj yeem ua tiav 98% purity hauv PET / HDPE kwj. Lawv kuj txo cov kab mob sib kis los ntawm 40%. IoT-enabled saib xyuas tso cai rau lub sijhawm taug qab ntawm lub tshuab ua haujlwm thiab siv lub zog. Qhov no ua rau 25% txo qis hauv lub sijhawm poob. Cov chaw decentralized kuj dhau los ua ntau dua. Cov chav tsev compact no tuaj yeem ua 500-800 kg / h. Lawv pab txo kev thauj mus los thoob ntiaj teb. EU Txoj Cai Ntim thiab Ntim Cov Khoom Pov Tseg (PPWR) yog tus tsav tsheb loj. Nws yuav tsum tau 70% recyclability rau ntim los ntawm 2030. Nws kuj xav tau 10-35% recycled cov ntsiab lus nyob rau hauv plastics. Ua raws li txoj cai no yuav tsum tau siv cov cuab yeej siv tshuab thiab tshuaj lom neeg siv dua tshiab. Txhim kho kev txheeb xyuas thev naus laus zis hloov pauv cov yas rov ua dua tshiab. Automated systems siv cov sensors siab heev, kev txawj ntse txawj ntse, thiab kev kawm tshuab. Lawv tuaj yeem txheeb xyuas thiab cais cov yas raws li lawv cov tshuaj pleev, xim, thiab cov duab. Qhov no txhim kho efficiency thiab purity nyob rau hauv recycling kwj. Qhov kev txhim kho no pab tsim cov yas zoo dua qub.

Advanced Mechanical Plastic Recycling Machine Technologies

Mechanical recycling tseem yog lub hauv paus ntawm kev tswj cov khib nyiab yas. Hauv 2025, kev nce qib tshiab ua rau cov txheej txheem no ua haujlwm tau zoo thiab ua haujlwm tau zoo. Cov tshuab no tam sim no tuav ntau yam ntawm cov yas. Lawv kuj tsim cov khoom siv zoo dua qub.

Next-Gen sorting Systems rau cov tshuab siv yas rov qab

Kev txheeb xyuas yog thawj kauj ruam tseem ceeb hauv kev rov ua dua tshiab. Cov kev txheeb xyuas tshiab siv cov cuab yeej siv siab tshaj plaws, kev txawj ntse (AI), thiab kev kawm tshuab. Cov cuab yeej no zoo heev txhim kho qhov tseeb thiab ceev. Lub khoos phis tawj pom kev siv lub koob yees duab daws teeb meem siab thiab AI algorithms. Lawv txheeb xyuas cov khoom yas hauv lub sijhawm tiag tiag. Cov tshuab no txheeb xyuas qhov sib txawv me me ntawm cov xim, cov duab, thiab kev ntxhib los mos rau kev faib tawm meej. Cov qauv kev kawm tshuab txuas ntxiv txhim kho lawv lub peev xwm lees paub.

Kev kawm tob algorithms txheej txheem cov ntaub ntawv pom kev nyuaj. Lawv txiav txim siab cais thib ob txog cov khoom muaj pes tsawg leeg. Cov algorithms no ua tau zoo ntawm kev paub cov qauv thiab nta tib neeg tsis tuaj yeem pom. Qhov no ua rau kev txheeb xyuas qhov tseeb tshaj 95%. Ze-Infrared (NIR) spectroscopy yog lwm lub tshuab tseem ceeb. Nws siv lub teeb infrared los txheeb xyuas cov molecular muaj pes tsawg leeg. Qhov no tso cai rau kev txheeb xyuas sai thiab raug ntawm ntau hom yas xws li PET, HDPE, thiab PVC. Nws ntsuas lawv qhov tshwj xeeb spectral kos npe.

Hyperspectral imaging siv spectroscopic sorting ntxiv. Nws muab cov duab ib txwm siv nrog spectroscopy. Qhov no ntes cov ntaub ntawv hla ntau pua spectral bands. Nws muab cov ntaub ntawv ntxaws ntxaws heev. Qhov no txheeb xyuas cov kab mob, cov khoom ntxiv, thiab hloov maj mam hloov pauv hauv cov khoom siv yas. Ntse gripper technology kuj pab. Cov grippers tshiab no muaj cov sensors thiab hloov siab tswj. Lawv tuav cov khoom sib txawv ntawm qhov ntau thiab tsawg, cov duab, thiab qhov hnyav yam tsis muaj kev puas tsuaj. Lawv tuaj yeem tshawb pom cov khoom siv los ntawm kev tawm tswv yim tactile. Qhov no txhim khu kev txheeb xyuas qhov tseeb thiab txo cov kab mob.

Cov txheej txheem kho qhov muag tom ntej no siv cov koob yees duab siab, sensors, thiab tshuab kawm algorithms. Lawv nrawm thiab raug txheeb xyuas thiab txheeb xyuas ntau yam khoom pov tseg. Lawv ntiav cov sensors uas ntes cov cim spectral tshwj xeeb rau kev txheeb xyuas cov khoom siv thiab kev sib cais. Qhov no yog qhov tshwj xeeb tshaj yog rau kev txheeb xyuas cov khoom pov tseg tom qab siv. Qhov no suav nrog plastics, iav, ntawv, thiab hlau. Cov tshuab no tuaj yeem txo cov nqi thauj thiab sau nqi tsawg kawg yog 50% thaum ua ke nrog cov tshuab sau cov khib nyiab tsis siv neeg. Lawv siv NIR sensors los txheeb xyuas hom polymer. Lawv cais cov yas raws li xim thiab hom. Cov tshuab no muaj peev xwm ua tau zoo, feem ntau ua ntau pua tons hauv ib hnub. Lawv txo cov kab mob sib kis, ua rau cov khoom siv zoo dua qub. Hyperspectral imaging technology, zoo li Specim FX17 thiab GX17, muab lub sijhawm tiag tiag, txhim khu kev txheeb xyuas. Nws cais PET los ntawm cov kab mob xws li PVC, HDPE, ABS, lwm yam yas, thiab cov khoom siv organic. Hyperspectral koob yees duab muab kev txheeb xyuas kev ntseeg siab thiab ua kom yooj yim. Lawv ntes tag nrho lossis xaiv tau spectral ntau yam. Qhov no tso cai rau reconfiguration thoob plaws lub tshuab lub neej voj voog. Solid-state hyperspectral koob yees duab tsis muaj txij nkawm rau ntau xyoo. Lawv tsis muaj qhov txav mus los uas yuav tsum tau hloov pauv thiab rov ua dua tshiab. Cov tshuab no muab cov duab hyperspectral nrog RGB lub koob yees duab rau kev txhim kho xim thiab duab pom. Lawv siv AI-based neural network qauv ua haujlwm ntawm NVIDIA GPUs muaj zog rau kev txheeb xyuas ntau dua thiab cov ntaub ntawv txheeb xyuas ntxaws. Lawv txawm hais txog kev xaiv cov yas dub siv lub koob yees duab Specim FX50 HSI. Lub koob yees duab no ua haujlwm nyob rau hauv nruab nrab-yoj infrared (MWIR) ntau yam. Nws txheeb xyuas thiab txheeb cov plastics dub raws li lawv cov tshuaj muaj pes tsawg leeg.

Txhim kho kev ntxuav thiab txiav hauv cov tshuab yas rov ua dua tshiab

Tom qab sorting, plastics raug ntxuav thiab shredding. Cov txheej txheem no npaj cov khoom siv rau kev ua haujlwm ntxiv. Niaj hnub nimno ntxhua khaub ncaws thiab shredding tshuab qhia kev txhim kho tseem ceeb hauv kev siv hluav taws xob. Cov tshuab yas rov ua dua tshiab, tshwj xeeb tshaj yog cov neeg siv tshuab servo lub cev muaj zog, txo kev siv hluav taws xob ntau txog 30% piv rau cov qauv qub. Qhov no ua rau kev txuag nqi thiab txiaj ntsig ib puag ncig. Piv txwv li, conical ntxaib ntsia hlau, thaum uas tig mus ntxaib ntsia hlau, thiab compound ntxaib ntsia hlau qauv ua tiav mus txog 30% txo kev siv zog.

Kev tsim kho tshiab hauv shredder hniav cov ntaub ntawv thiab cov qauv tsim kuj txhim kho cov khoom siv thiab txo kev txij nkawm. Ib qho tshiab V rotor tsim, nrog 500 hli txoj kab uas hla thiab mus txog 2,200 hli ntev, ua haujlwm loj pib-up lumps, hollow bins, thiab voluminous qhov chaw. Ib tug meej F rotor nrog milling thiab ib tug tshwj xeeb riam yog zoo tagnrho rau shredding saj zawg zog cov ntaub ntawv xws li fibers thiab films. Nws xyuas kom meej txiav geometry. Adjustable counter blades tuaj yeem hloov kho sai thiab tig los ntawm sab nraud. Qhov no tswj qhov pom qhov sib txawv txawm tias hnav. Nws ua rau muaj kev cuam tshuam loj heev thiab txuas ntxiv kev pab cuam lub neej. Lub ntsej muag tshuaj xyuas dav dav tso cai rau kev saib xyuas yooj yim thiab pom kev nkag mus rau rotor. Qhov no ua kom yooj yim tshem tawm cov khoom txawv teb chaws thiab kev ua haujlwm zoo.

Cov tshuab no siv cov hlau tawv tawv ntawm ob lub rotating shafts. Cov hniav no tuav ob qho tib si mos thiab tawv yas zoo. Qhov qis-ceev, siab-torque tsim kom muaj qhov sib npaug ntawm qhov loj me me. Nws kuj txo cov plua plav thiab suab nrov. Ib qho adjustable txiav chamber tso cai rau cov tswv lag luam los kho qhov ntau thiab tsawg. Industrial-qib Cheebtsam thiab kev tsim kho kom muaj kev ntseeg tau ntev. Lawv txo cov kev xav tau ntawm kev saib xyuas thiab txo qis qis qis. Hnav-resistant Cheebtsam tswj kev ua haujlwm zoo ib yam dhau lub sijhawm ua haujlwm ntev. Lub tshuab hloov hniav nrawm txo qis kev ua haujlwm cuam tshuam.

Extrusion thiab Pelletizing rau Premium Recycled Plastics

Cov kauj ruam kawg hauv kev siv tshuab ua dua tshiab suav nrog extrusion thiab pelletizing. Qhov no transforms shredded thiab ntxuav cov yas flakes rau hauv cov pellets niaj hnub. Cov pellets tom qab ntawd npaj rau kev tsim khoom tshiab. Cov khoom siv yas pelletizing niaj hnub muaj ntau lub peev xwm. Nws feem ntau ua tiav 100-2,500 kg / h. Qhov no haum rau ob qho tib si me thiab loj-kev xav tau ntau lawm. Qee cov qauv, zoo li Wintech WT-150, tsim 500-700 kg / h. Lub Huarui SJ-120 tsim 100-130 kg / h. Cov tshuab loj, xws li PTC185-95, ua tiav 800-1000 kg / h. Ib txoj haujlwm tshiab uas muaj 5G Ob Chav Pom Kev Sib Tsoo Pelletizing Kab muaj peev xwm tso zis ntawm 1100 kg / h. Cov peev txheej siab no qhia txog kev ua haujlwm ntawm cov tshuab pelletizing tam sim no. Lawv ua kom muaj kev ruaj khov ntawm cov khoom siv rov ua dua tshiab rau ntau yam kev lag luam.

Qhov nce ntawm Tshuaj Plastic Recycling Tshuab Txheej Txheem

Kev rov ua dua tshiab tshuaj muaj cov tshuaj muaj zog rau cov yas uas cov txheej txheem siv tsis tau. Cov txheej txheem no rhuav tshem cov yas rau hauv lawv cov khoom siv tshuaj lom neeg qub lossis lwm yam tshuaj muaj txiaj ntsig. Qhov no tsim cov khoom siv tshiab rau kev tsim khoom. Chemical recycling complements mechanical recycling. Nws pab ua kom muaj kev lag luam ntau dua rau cov yas.

Pyrolysis thiab Gasification Plastic Recycling Machine

Pyrolysis thiab gasification yog ob txoj hauv kev siv tshuaj lom neeg. Pyrolysis heats yas pov tseg yam tsis muaj oxygen. Cov txheej txheem no rhuav tshem cov hlua polymer ntev mus rau hauv cov khoom me me. Nws tsim cov roj, roj, thiab char. Gasification siv cov kub kub uas tswj tau cov pa oxygen lossis chav. Qhov no hloov cov yas rau hauv syngas, sib xyaw ntawm hydrogen thiab carbon monoxide. Syngas tuaj yeem dhau los ua roj lossis cov khoom siv tshuaj lom neeg.

Cov tuam txhab xws li ExxonMobil siv cov thev naus laus zis thev naus laus zis. Qhov kev siv tshuab no ua ke cov khib nyiab pov tseg rau hauv coker units. Nws generates hluavtaws crude thiab naphtha. Refineries tuaj yeem ua cov txheej txheem no ntxiv rau hauv petrochemical feedstocks. Xws li polyethylene los yog polystyrene nyob rau hauv coprocessing ho boosts cov kua khoom tawm los. Hauv kev teeb tsa cov kua dej coking, ntxiv cov pov tseg yas kuj nce cov syngas tsim. Lub tshuab microwave-powered pyrolysis siab heev tsim cov roj pyrolysis zoo. Cov roj no ua tau raws li cov qauv kev lag luam. Qhov no qhia tau hais tias muaj peev xwm tsim cov khoom muaj txiaj ntsig.

Cov txheej txheem tshuaj rov ua dua tshiab hloov cov pov tseg yas rau hauv ntau yam txiaj ntsig. Kwv yees li 15-20% ntawm cov pov tseg yas ua propylene thiab ethylene. Cov no yog cov tsev hauv paus rau cov yas tshiab. Qhov seem 80-85% ntawm cov pov tseg yas hloov mus rau hauv cov roj diesel, hydrogen, methane, thiab lwm yam tshuaj. Cov txiaj ntsig no qhia txog ntau yam ntawm pyrolysis thiab gasification.

Depolymerization rau cov yas tshwj xeeb

Depolymerization yog ib txoj kev siv tshuaj ua kom zoo dua qub. Nws rhuav tshem cov yas tshwj xeeb polymers rov qab rau hauv lawv cov qub monomers. Monomers yog cov molecules me me uas txuas ua ke los tsim cov polymers. Cov txheej txheem no tsim cov khoom zoo raw khoom. Cov neeg tsim khoom siv tau cov ntaub ntawv nyoos no los ua cov yas tshiab nrog cov khoom zoo li nkauj xwb.

Depolymerization tsuas yog txwv rau qee hom yas. Cov no yog hu ua condensation polymers. Piv txwv xws li nylon thiab PET (polyethylene terephthalate). PET yog lub hom phiaj tseem ceeb rau kev lag luam depolymerization txheej txheem. Nws qhov tsim nyog thiab kev nplua nuj ua rau nws lub hom phiaj zoo tagnrho. Tom ntej no-tiam depolymerization technologies kuj tsom acrylic pov tseg, tshwj xeeb PMMA (polymethyl methacrylate).

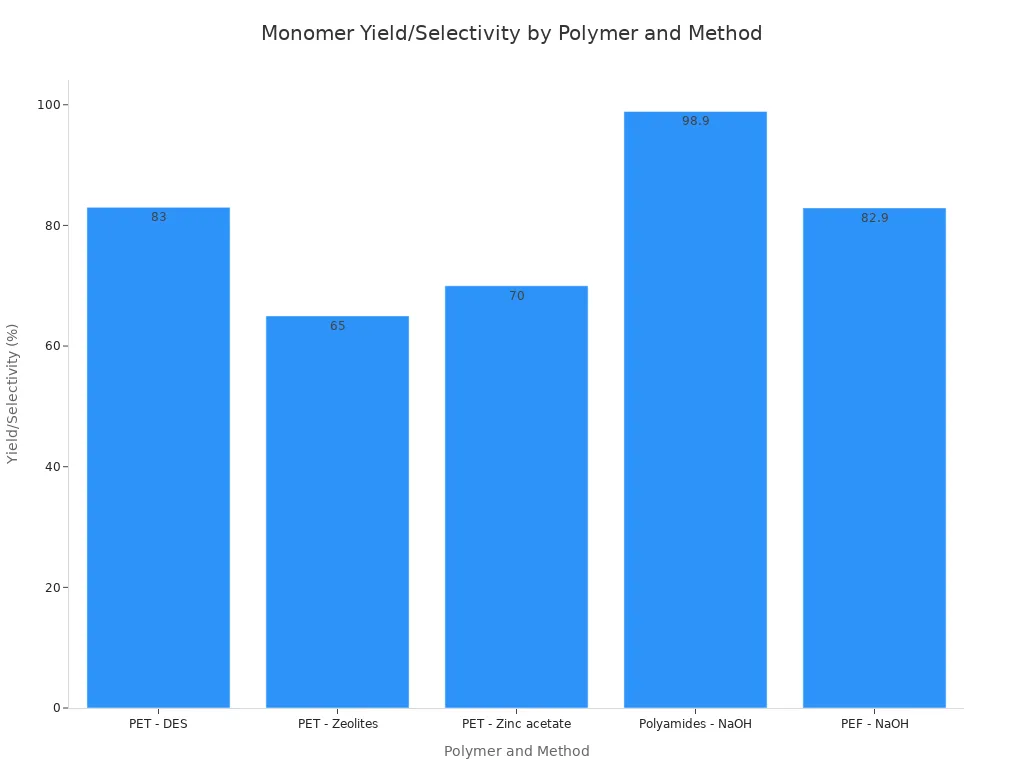

Lub purity ntawm monomers rov qab los ntawm depolymerization yog siab heev. Qhov no ua rau lawv muaj txiaj ntsig rau kev tsim cov yas tshiab. Cov txheej txheem sib txawv thiab cov catalysts ua tiav cov txiaj ntsig sib txawv.

| Polymer | Method/Catalyst | Monomer Yield/Selectivity |

|---|---|---|

| PET | [urea/ZnCl2] DES | 83% kev xaiv rau BHET |

| PET | Zeolites | 65% tawm los ntawm BHET |

| PET | Zinc acetate thiab EG | Txog li 70% tawm los ntawm BHET |

| Polyamides (Kevlar) | Hydrolysis nrog NaOH | 98.9% rau PPD, 95.3% PTA |

| PEB | Hydrolysis nrog NaOH | 82.9% tawm los ntawm 2,5-furandicarboxylic acid |

Dimethylethylamine catalysts txhawb siab depolymerization yields. Lawv ua haujlwm nyob rau hauv cov xwm txheej nruab nrab. Qhov no ua rau muaj kev sib txuam monomer tso zis. Cov txheej txheem qib siab no ua kom muaj kev ntseeg tau ntawm cov ntshiab monomers.

Solvolysis thiab Hydrothermal Plastic Recycling Machine

Solvolysis thiab hydrothermal txheej txheem yog lwm yam tseem ceeb chemical recycling technologies. Solvolysis siv cov kuab tshuaj kom yaj los yog tawg cov yas. Cov txheej txheem no feem ntau ua haujlwm ntawm qhov kub thiab txias. Cov txheej txheem hydrothermal siv cov dej kub, cov dej siab los hloov cov yas. Ob txoj kev muab qhov tshwj xeeb zoo rau ntau hom yas.

Cov xwm txheej ua haujlwm sib txawv rau cov txheej txheem no.

| Hom txheej txheem | Qhov kub thiab txias (°C) | Siab siab (MPa) |

|---|---|---|

| Hydrothermal liquefaction (HTL) | 250–350 : kuv | 10–20 |

Cov txheej txheem Solvolysis kuj tseem ua haujlwm nyob rau hauv cov xwm txheej sib txawv.

| Hom txheej txheem | Qhov kub thiab txias (°C) | Siab siab (MPa) |

|---|---|---|

| Solvolysis (LTP) | <200 | Ambient |

| Solvolysis (HTP) | Mus txog 450 | 0.3 rau 30 |

Cov xwm txheej no tso cai rau kev ua kom haum rau ntau yam khoom pov tseg yas.

Hydrothermal Treatment (HTT) muaj cov txiaj ntsig zoo ib puag ncig. Nws tuaj yeem ua tiav txog li 80% txo qhov kev hloov pauv huab cua emissions. Qhov no yog piv rau incineration, ib hom kev pov tseg rau cov yas uas nyuaj rau rov siv dua. HTT khaws cov khoom hauv qhov system. Qhov no ua rau txo qis kev siv cov khoom siv fossil. Thawj qhov cuam tshuam ib puag ncig ntawm HTT yog kev siv hluav taws xob. Txo qhov no los ntawm kev siv hluav taws xob los yog cov khoom siv hluav taws xob txuas ntxiv tuaj yeem txhim kho nws qhov kev ua tau zoo ib puag ncig. HTT zam kev puas tsuaj los ntawm cov khoom siv xws li dioxins thiab char. Cov txheej txheem tshuaj rov ua dua tshiab, suav nrog HTT, ua haujlwm ntau dua ntawm cov khoom siv uas tsis yog homogeneous tom qab cov neeg siv khoom. Qhov no muab kev daws teeb meem ntawm qhov ntsuas rau kev lag luam ncig. Kev hloov pauv huab cua cuam tshuam ntawm naphtha tsim los ntawm HTT yog piv rau cov txheej txheem fossil chemical feedstock tam sim no. Qhov no muaj cov kev xaiv ncig rau kev tsim khoom yas. Cov txheej txheem txheej txheem yas yas rov siv dua tshiab no yog qhov tseem ceeb rau lub neej yav tom ntej.

Kev Siv Lub Tshuab Siv Hluav Taws Xob Smart Plastic Recycling: AI, IoT, thiab Automation

Niaj hnub nimno yas recycling ua hauj lwm siv advanced technology. Artificial txawj ntse (AI), Internet ntawm Yam (IoT), thiab automation ua cov txheej txheem ntse dua. Cov cuab yeej no txhim kho kev ua tau zoo, txo cov nqi, thiab ua kom zoo ntawm cov khoom siv rov ua dua tshiab.

Predictive Maintenance rau Plastic Recycling Machine

Kev saib xyuas kwv yees ua kom cov yas rov ua dua tshiab ua haujlwm zoo. IoT sensors sau cov ntaub ntawv hauv lub sijhawm los ntawm cov khoom siv. Lawv saib xyuas kev vibrations, kub, thiab kev ua haujlwm ntawm lub cev muaj zog. AI algorithms txheeb xyuas cov ntaub ntawv no. Lawv kwv yees thaum lub tshuab ua haujlwm yuav ua tsis tiav. Qhov no tso cai rau cov chaw ua haujlwm saib xyuas ua ntej muaj kev tawg. Nws tiv thaiv kev poob siab tsis xav txog. Txoj hauv kev no txuag nyiaj thiab nce sijhawm ua haujlwm.

Cov ntaub ntawv Analytics rau Optimized Recycling Processes

Cov ntaub ntawv analytics hloov pauv kev ua haujlwm rov ua dua tshiab. Advanced platforms sau thiab txheeb xyuas ntau hom ntaub ntawv. Lawv taug qab Cov Kev Ntsuas Tseem Ceeb (KPIs) zoo li kev siv hluav taws xob thiab GHG emissions. Lawv kuj sau cov ntaub ntawv muaj pes tsawg leeg, suav nrog cov feem pua ntawm cov khoom siv rov ua dua tshiab. Cov ntaub ntawv ua haujlwm suav nrog kev ua haujlwm ntawm lub tshuab thiab kev ua haujlwm kub. Cov ntaub ntawv ua raws cai ua kom cov chaw ua tau raws li cov cai hauv zos thiab cov ntsiab lus rov siv dua. Kev ntsuas khib nyiab taug qab tus nqi sau, txheeb xyuas qhov tsis raug, thiab kev sib kis. Cov ntaub ntawv Traceability validates thov hais txog cov khoom siv dua tshiab.

AI-powered sorting systems siv ze-infrared (NIR) spectroscopy thiab AI algorithms. Cov tshuab no txo cov kab mob sib kis tau txog li 50 feem pua. Cov kws tshawb fawb tau tsim cov qauv kev kawm tshuab uas txheeb xyuas hom yas nrog txog li 100% raug. Qhov no precision nyob rau hauv sorting txo cov kab mob. Nws ua rau cov khoom siv tau zoo dua qub thiab cov nqi ua haujlwm qis dua. Ntawm AdvanTech Plastics, AI-powered sensors tshuaj xyuas cov khoom pwm hauv lub sijhawm. Qhov no kuaj pom qhov tsis zoo thiab tso cai rau kev hloov kho tam sim. Nws ua rau cov khoom siv tsis zoo, cov khoom seem tsawg dua, thiab siv lub zog qis dua.

Tag Nrho Automated Plastic Recycling Facilities

Cov chaw ua haujlwm puv ntoob hloov pauv qhov chaw rov ua dua tshiab. Cov neeg hlau ua haujlwm ib zaug ua tiav los ntawm tib neeg. Qhov no txo cov nqi zog thiab txhim kho kev nyab xeeb.

| Feature | Cov neeg hlau | Tib neeg Sorter |

|---|---|---|

| Xaiv ib teev | Txog li 4,000 | 500-700 (cov khoom hnyav) |

| Lub sijhawm ua haujlwm | 24/7 | Tsis yog 24/7, yuav tsum tau so |

| Max hnyav tuav | 66 lbs (30 kg) | Tsis ua tau / nyab xeeb rau 66 lbs tsis tu ncua |

Cov neeg hlau tuaj yeem khaws txog 4,000 yam khoom hauv ib teev. Tib neeg sorters lis 500-700 khoom hnyav ib teev. Robots ua haujlwm 24/7 yam tsis muaj kev so. Lawv ruaj ntseg tuav cov khoom hnyav txog li 66 lbs. Lundstams Återvinning AB, ib lub tuam txhab Swedish, txuag txog $22,000 USD ib hlis. Lawv txo cov khib nyiab pov tseg tom qab siv cov neeg hlau. Recycling robots pab txhawb kev txuag mus sij hawm ntev. Lawv txo cov nqi zog thiab txo qhov yuam kev.

Kev cuam tshuam thiab yav tom ntej Outlook ntawm 2025 Yas Recycling Machine

Hais Txog Cov Khoom Siv Uas Nyuaj Rau Cov Plastics Nrog Cov Tshuab Tshiab

Cov tshuab rov ua dua tshiab hauv 2025 tackle plastics yav dhau los suav tias tsis tuaj yeem siv dua. Kev siv tshuaj siv tshuaj ua kom cov khoom pov tseg tsis huv, xws li cov ntim khoom noj lossis lub raj mis roj, mus rau qib molecular. Cov txheej txheem no lim tawm cov kab mob kom zoo. Ntau txheej yas pov tseg, xws li ntim khoom noj yooj yim, kuj tau txais txiaj ntsig los ntawm kev rov ua dua tshiab. Qhov no kov yeej cov teeb meem kev siv tshuab rov ua dua tshiab nrog cov ntaub ntawv no. Cov kev daws teeb meem zoo tshaj plaws tam sim no tsom polystyrene ua npuas ncauj, polyurethane ua npuas ncauj, thiab cov ntaub ntawv mono-cov ntaub ntawv thiab hnab. Lawv kuj hais txog cov hnab ntim ntau, thermoforms / dub rigids, thiab ua npuas ncauj / me rigids. Purification txheej txheem hauv molecular recycling tshem tawm cov kab mob ntawm cov ntaub ntawv nyuaj.

Economic thiab Environmental Benefits ntawm Advanced Recycling

Advanced yas recycling tshuab muab kev lag luam thiab ib puag ncig zoo. Lawv txo cov nqi tswj cov khib nyiab rau hauv nroog thiab cov lag luam. Cov tuam txhab tsim cov nyiaj tau los tshiab los ntawm kev hloov cov khoom pov tseg rau hauv cov khoom muaj txiaj ntsig zoo li cov ntim tshiab lossis cov khoom siv tsim kho. Qhov no tiv thaiv cov peev txheej ntuj los ntawm kev txo qhov xav tau ntawm cov ntaub ntawv nkauj xwb xws li roj av. Ib puag ncig, cov thev naus laus zis no tsim cov khoom yas thiab tshuaj lom neeg nrog txo lub ntiaj teb ua kom sov. Lawv ua tiav qhov no piv rau cov khoom tsim los ntawm cov peev txheej nkauj xwb. Kev rov ua dua tshiab tuaj yeem txo qis CO2 sib npaug emissions ntau dua 100% piv rau cov khoom pov tseg thiab cov txheej txheem pov tseg-rau-zog. Tshaj li 40 txoj haujlwm, sawv cev ntau dua $ 7 nphom hauv kev nqis peev, tuaj yeem hloov pauv kwv yees li 21 billion phaus pov tseg los ntawm qhov chaw pov tseg txhua xyoo.

Cov Kev Sib Tw thiab Lub Sijhawm rau Kev Txais Kev Siv Tshuab Tshiab

Kev siv cov thev naus laus zis tshiab tshiab nthuav tawm ob qho kev sib tw thiab lub sijhawm. Kev nqis peev tseem ceeb tshaj plaws yog feem ntau tsim nyog rau kev siv tshuab thiab kev tsim kho tshiab. Kev koom ua ke cov txheej txheem nyuaj no rau hauv cov chaw uas twb muaj lawm yuav tsum tau ua tib zoo npaj thiab ua haujlwm txawj. Txawm li cas los xij, cov thev naus laus zis no qhib qhov rooj rau kev lag luam tshiab rau cov khoom siv rov ua dua tshiab. Lawv kuj txhawb kev tsim kho tshiab hauv kev tsim khoom lag luam. Kev tsav tsheb mus rau kev lag luam ncig ua rau muaj kev xav tau zoo rau cov khoom siv zoo dua qub. Qhov no muab txoj hauv kev loj hlob zoo rau cov tuam txhab uas tuav cov kev nce qib no.

Kev nce qib hauv cov tshuab siv yas rov siv dua tshiab hauv 2025 sawv cev rau kev hloov pauv tseem ceeb. Kev txawj ntse sorting thiab sophisticated chemical txheej txheem yog transforming kev lag luam. Cov kev tsim kho tshiab no txav peb mus rau kev lag luam ntau dua. Cov khib nyiab yas tau dhau los ua qhov muaj txiaj ntsig zoo. Qhov no ua rau muaj kev vam meej thiab kev loj hlob ntawm kev lag luam rau txhua tus.

FAQ

Dab tsi yog qhov tseem ceeb ntawm cov tshuab yas rov ua dua tshiab hauv xyoo 2025?

Cov tshuab hauv 2025 tsom rau kev ua haujlwm siab tshaj plaws. Lawv kuj muaj peev xwm txheeb xyuas cov ntaub ntawv zoo dua. Cov txheej txheem chemical recycling tshiab yog qhov tseem ceeb. Cov thev naus laus zis no hloov cov khoom pov tseg rau hauv cov peev txheej muaj txiaj ntsig. Lawv ho txhim kho efficiency thiab sustainability. ♻️ ib

Yuav ua li cas tom ntej-gen sorting systems txhim kho kev rov ua dua tshiab?

Tom ntej-gen sorting systems siv AI, kev kawm tshuab, thiab cov sensors siab heev. Lawv txheeb xyuas cov yas los ntawm xim, duab, thiab tshuaj pleev xim. Qhov no txhim kho kev txheeb xyuas qhov tseeb. Nws kuj txo cov kab mob. Qhov no ua rau cov khoom siv zoo dua qub.

Post lub sij hawm: Oct-25-2025